Operating Manual - KLARO GmbH

Operating Manual - KLARO GmbH

Operating Manual - KLARO GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

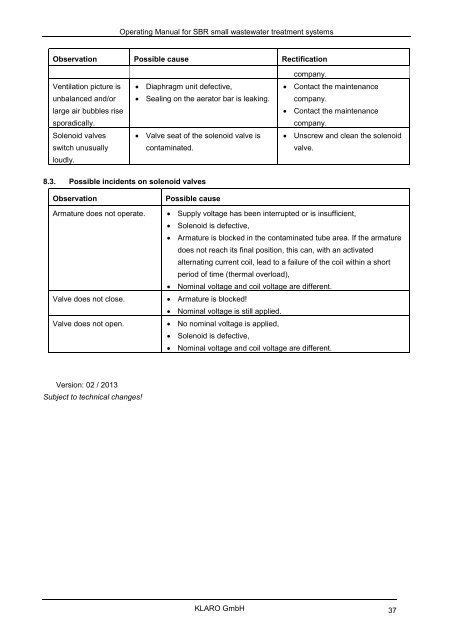

<strong>Operating</strong> <strong>Manual</strong> for SBR small wastewater treatment systemsObservation Possible cause RectificationVentilation picture isunbalanced and/orlarge air bubbles risesporadically.Solenoid valvesswitch unusuallyloudly.• Diaphragm unit defective,• Sealing on the aerator bar is leaking.• Valve seat of the solenoid valve iscontaminated.company.• Contact the maintenancecompany.• Contact the maintenancecompany.• Unscrew and clean the solenoidvalve.8.3. Possible incidents on solenoid valvesObservationPossible causeArmature does not operate. • Supply voltage has been interrupted or is insufficient,• Solenoid is defective,• Armature is blocked in the contaminated tube area. If the armaturedoes not reach its final position, this can, with an activatedalternating current coil, lead to a failure of the coil within a shortperiod of time (thermal overload),• Nominal voltage and coil voltage are different.Valve does not close. • Armature is blocked!• Nominal voltage is still applied.Valve does not open. • No nominal voltage is applied,• Solenoid is defective,• Nominal voltage and coil voltage are different.Version: 02 / 2013Subject to technical changes!<strong>KLARO</strong> <strong>GmbH</strong> 37