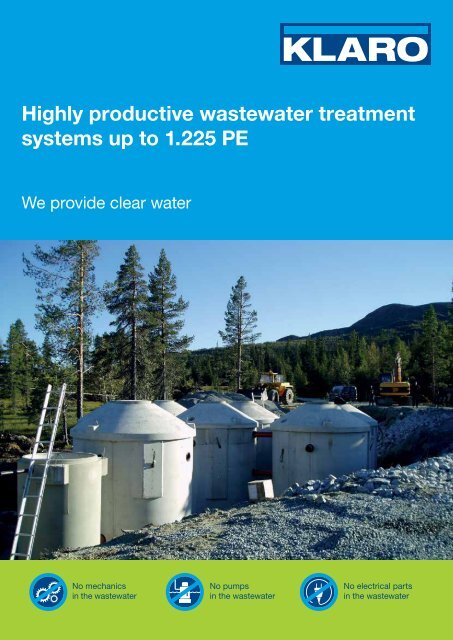

Highly productive wastewater treatment systems up ... - KLARO GmbH

Highly productive wastewater treatment systems up ... - KLARO GmbH

Highly productive wastewater treatment systems up ... - KLARO GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Holiday homes / Hotel4 PE to 200 PEWalchensee and Hotel Post major projectBy the Walchensee lake lies the villageof Walchensee with approximately600 inhabitants. For years, there werediscussions over which opportunityof <strong>wastewater</strong> <strong>treatment</strong> was thebest. The decentralised solution wasultimately chosen - a contributing factorwas <strong>KLARO</strong>‘s clear cost structure,whereby everyone knew from the outsetwhat costs they would incur.In addition, the Hotel Post locatedthere needed to be „retrofitted“. Limitedspace, heavily fluctuating <strong>wastewater</strong>incidence due to seasonal factorsand high <strong>treatment</strong> requirementswere only some of the challenges posedto the system.The solution: a two-line system, eachwith an output of 100 PE. Additionaldispensing technology for P precipitationand a UV module were installedwith the machine technology in aneasily accessible manner in a cellarroom of the hotel.Project dataLocation: Walchensee, GermanyNumber of plants: ca. 150Sizes: 4 PE - 200 PEConstruction: 2010Extra: with phosphate precipitationand partly disinfectionDrawing:200 PE Hotel Post, two-line plant4

Restaurant andindustry 80 PEWinery in Serraux, Lake GenevaProject dataLocation: Serraux, SwitzerlandSize: 80 PEConstruction: 2008Extra: for industrial <strong>wastewater</strong>with heavy fluctuations<strong>KLARO</strong> s<strong>up</strong>plied a <strong>wastewater</strong> <strong>treatment</strong>system for a winery at LakeGeneva.Three plastic tanks with pre-assembledtechnology were placed behind anexisting concrete tank.Three different types of <strong>wastewater</strong>arise from the wine press house, publicroom and house that need to betreated. In addition, the grape harvestand the infrequent events (includingwine tasting) lead to strong fluctuationsin <strong>wastewater</strong> quantity and load.In its first year of operation, the plantwas scientifically monitored as part ofa pilot project. It was established thatthe strict effluent values demandedare always safely complied with by<strong>KLARO</strong>, even at busy times.Drawing:80 PE Winery in Serraux, one-line plant5

VillageGumpersdorf 100 PEGumpersdorfThe village of Gumpersdorf lies nearthe drinking water fountains of theUpper Franconian town of Kulmbach.The heightened requirements of thedegree of cleanness of the <strong>wastewater</strong>could no longer be fulfilled withthe outdated facilities. The monetaryand labour outlay for a central solutionwas somewhat higher than theconstruction of a <strong>KLARO</strong> <strong>wastewater</strong><strong>treatment</strong> system.The specially constructed buildingfor technical purposes also housesthe machine technology and the UVmodule with sampling facilities. Monitoringand maintenance work can beperformed easily in all weather.In addition, the plant is connected tothe <strong>KLARO</strong> WebMonitor®.Project dataLocation: Gumpersdorf, GermanySize: 100 PEConstruction: 2013Extra: with disinfection and remotemonitoringDrawing:100 PE Village Gumpersdorf, one-line plant6

Shipyard1.000 PEShipyardProject dataLocation: Stord, NorwaySize: 1.000 PEConstruction: 2009Extra: Phosphate precipitation,two-lineA <strong>KLARO</strong> 1,000 PE plant works forAker Kværner, Norway‘s largest shipyard,in Stord. The largest oil platformsin the world were constructedand equipped here.The plant, which is located right at thebank of the fjord, treats all the <strong>wastewater</strong>for offices, canteens and theworker flats.The septic tank was manufacturedin a rectangular shape from cast-inplaceconcrete, with approximatelyhalf of it rising out of the ground. Thebiological level is divided onto twobasins, which can be driven independentlyof each other.Drawing:1.000 PE Stord, rectangular concrete tank7

Guest house51 PESillberghausThe Sillberghaus Almbad & Lodge liesat a height of 1,100 m in the middle ofthe Bavarian Alps and serves numerousguests as a place of relaxation orfor events in a special ambience.For the 51 PE <strong>wastewater</strong> <strong>treatment</strong>system, plastic tanks were opted for,which facilitated transportation andinstallation.The technology in the tanks was alsocompletely pre-assembled.Particularly heavy peak loads at weekendsand on public holidays can behandled with an additional buffer. Inthe event of low load, this buffer disassemblesitself.Project dataLocation: Bayrischzell, GermanySize: 51 PEConstruction: 2009Extra: with additional bufferDrawing:51 PE Sillberghaus8

Mountain village200 PEAvers im Kanton GraubündenAvers im Kanton GraubündenProject dataLocation: Avers, SwitzerlandSize: 200 PEConstruction: 2011Extra: Onsite concrete tankThe Die municipality Gemeinde of Avers Avers im in schweizer the Swisscanton Kanton of Graubünden liegt lies at auf a height einerof Höhe 2,126 von m 2.126 and is m thus und ist the somit highest diesettlement höchstgelegene in Europe gänzjährig that is bewohnte inhabitedall Siedlung year round. Europas.Due Aufgrund to the location, der schwer which zugänglichen is difficultto Lage access, wurde the der concrete notwendige tank Betonbe-requiredhälter for the für 200 die PE 200 plant EW was Anlage cast vor on Ort site.gegossen. This approach shows that we find aDieses customised Vorgehen and zeigt, suitable dass wir solution selbst forfür the schwierig tank even zu for erreichende places that Orte are eine difficultto access. passende Lösung für denindividuellTank finden.ProjektdOrt: AversGröße: 20Bau: 2011Extra: BeProjektskizze:Drawing:200 200 EW PE Betonbehälter, Concrete tank, Avers, Avers, Kanton Kanton Graubünden© und Foto-Urh9

Safe technology in a switch cabinetor a machine cabin!Safe keeping of the machine technologyinside the switch cabinet or the machine cabine<strong>KLARO</strong> Indoor switchcabinet A-4••Suitable for compressor LA 60,LA 80, LA 120, LAM 200, DT 4.4,DT 4.6, DT 4.8••Metal••Size: 114 x 120 x 75 cm (b x h x t)••Empty weight: 142 kg<strong>KLARO</strong> Outdoor switchcabinet A-4••Suitable for compressor DT 4.25,DTN41, KDT 3.60, 3.80••Metal••Size: 120 x 111 x 80 cm (b x h x t)••Empty weight: 140 kg<strong>KLARO</strong> Outdoor switchcabinet concrete••Suitable for compressor KDT3.100, 3.140••Concrete••Size: 206 x 110 x 90 cm (b x h x t)••Empty weight: 800 kg<strong>KLARO</strong> Machine cabinThe alternative to the conventionalswitch cabinet offers sufficient spacefor possibly required additionalcomponents.Inside a machine cabin with UV-module10

Machine cabin of a 100 PE plantFurther information in thebrochure „<strong>KLARO</strong> WebMonitor ® “Components for your plantStandard componentsThe following components arestandard that every <strong>KLARO</strong> plantconsists of:••air compressor••magnetic distributor••cooling fan••micro-processor control••main switch••management planAdditional componentsDue to our modular applied <strong>wastewater</strong>technology various additionalcomponents can be installed:••metering technology (e.g. forphosphate precipitation)••telecontrol (modem or LAN)••warning lights••acoustic hood for air compressorRemote monitoringFor use, wherever the highest degree ofoperational safety is required. The plantcan be monitored remotely by a maintenancecompany thanks to a remotediagnosis system. Intervention in thecase of faults is possible immediately.®UV-ModuleDosierpumpe<strong>KLARO</strong> WebMonitor••Increased efficiency and operationalsafety••Optimized service intervals••Increased customer benefitthanks to monitoring services••Low-priced remote diagnosis inthe event of a fault11

<strong>KLARO</strong> <strong>GmbH</strong>Spitzwegstraße 6395447 BayreuthTelephone: +49 (0) 921 16279-0Fax: +49 (0) 921 16279-100E-Mail: info@klaro.e<strong>up</strong>art of the GRAF gro<strong>up</strong>More information atwww.klaro.euTechnical hotline+49 (0) 921 16279-330Photo Copyright: <strong>KLARO</strong> <strong>GmbH</strong>; Fotolia.com: © Mearicon © <strong>KLARO</strong> <strong>GmbH</strong> Bayreuth 2014 / Art.-Nr. KKA 0106