IQWrench2 Opta Key Features Product Overview - Crane Electronics

IQWrench2 Opta Key Features Product Overview - Crane Electronics

IQWrench2 Opta Key Features Product Overview - Crane Electronics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

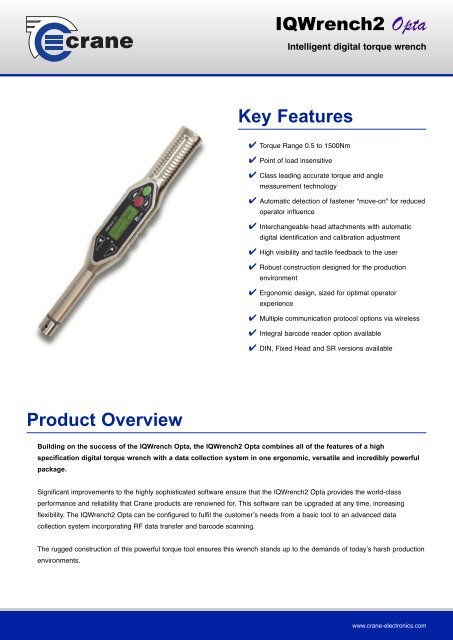

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrench<strong>Key</strong> <strong>Features</strong>4 Torque Range 0.5 to 1500Nm4 Point of load insensitive4 Class leading accurate torque and anglemeasurement technology4 Automatic detection of fastener "move-on" for reducedoperator influence4 Interchangeable head attachments with automaticdigital identification and calibration adjustment4 High visibility and tactile feedback to the user4 Robust construction designed for the productionenvironment4 Ergonomic design, sized for optimal operatorexperience4 Multiple communication protocol options via wireless4 Integral barcode reader option available4 DIN, Fixed Head and SR versions available<strong>Product</strong> <strong>Overview</strong>Building on the success of the IQWrench <strong>Opta</strong>, the <strong>IQWrench2</strong> <strong>Opta</strong> combines all of the features of a highspecification digital torque wrench with a data collection system in one ergonomic, versatile and incredibly powerfulpackage.Significant improvements to the highly sophisticated software ensure that the <strong>IQWrench2</strong> <strong>Opta</strong> provides the world-classperformance and reliability that <strong>Crane</strong> products are renowned for. This software can be upgraded at any time, increasingflexibility. The <strong>IQWrench2</strong> <strong>Opta</strong> can be configured to fulfil the customer’s needs from a basic tool to an advanced datacollection system incorporating RF data transfer and barcode scanning.The rugged construction of this powerful torque tool ensures this wrench stands up to the demands of today’s harsh productionenvironments.www.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrench4 Based on the proven success of the IQWrench <strong>Opta</strong>4 An integral part of the <strong>Crane</strong> family of products4 Easy read icon based display4 Visual, physical and audible alarms4 Battery life of the <strong>IQWrench2</strong> <strong>Opta</strong> in typical usage is 16hours4 Compatible with most standard interchangeable heads4 Vibrating handle - gives clear indication of fastener status4 Easy recording and storage of critical data:4 User4 Time4 Results4 ProcessID HeadsNot only is the selection of quick release interchangeableheads simple and convenient with the <strong>IQWrench2</strong> <strong>Opta</strong>, itis also robust and accurate. The use of availableautomatic digital ID heads, to adjust the calibration andcompensate for changes in length, ensures a highlyaccurate reading every time. ID heads can also be usedfor automatic Job selection which minimises the inputrequired by the operator. The <strong>Crane</strong> auto ID system canbe fitted to standard DIN heads and offers up to 999unique IDs.www.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrenchRFRF on board the <strong>IQWrench2</strong> <strong>Opta</strong> operates at a userprogrammable frequency of 868/915MHz according tothe country of installation. The system has a workingrange of up to 10m and features a fully internal antennafor maximum durability. The robust wireless protocolallows for up to 5 wrenches to communicatesimultaneously with a single base station receiver.The RF function can be used in a number ofconfigurations to allow:4 Simple data transfer from the wrench to PC/PLC4 Integration into the OMS system to collect productiondata against multiple Jobs4 Remote selection of Jobs4 Integration into 3rd party systems4 Transfer of a Job to the wrenchBarcode ScanningThe <strong>IQWrench2</strong> <strong>Opta</strong> features an optional barcodereader which is capable of scanning all major 1D barcodeformats. The barcode reader is conveniently located onthe underside of the wrench to allow best access forscanning. Ideal for a production environment.As a fully integrated function of the software, barcodescan be utilised in a number of ways:4 Scan product/part identifiers to select thecorresponding Job or Round4 Select user details to log in and store against torqueand angle data4 Enter comments and references to store torque andangle datawww.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrench<strong>IQWrench2</strong> <strong>Opta</strong> Technical SpecificationPhysical measurements Bi-directional torque (clockwise calibration unless otherwise requested), auto sense or right andleft hand torque (and angle value)Measurement unitsNm, Ncm, kgfcm, kgfm, ozin, lbin, lbft (depends on span)Measurement modes Track, Peak (Auto-reset), Angle, Yield, Audit, MoveOnMeasurement parameters Torque & angle threshold (can be as low as 1% of rating); Upper/Lower Specification Limits(USL can be up to 100% of nominal rating); Additional Upper/Lower Control LimitsCycle status indication Bar graph giving real time visual representation of torque or angleArrow icon in display, tri-colour LED (front & back of unit) and acoustic buzzer indicating torquestatus - HI/OK/LOData storage200 reading memory of both parameter values with time and date stamp (in Quick Store)User selectable autostore/store promptUp to 50,000 readings in job store modeUp to 50 graphsPrint modesVia communication softwareSingle reading or page mode with header, including serial number and recalibration date viaRS232 to serial printer or RS232 terminal emulatorsPrinter compatibility Via RS232 output: 40/80 columnsPC compatibilityVia communication softwareOperating languages English, Deutsch, Français, Espanol, Italiano, Svenska, Czech, Portugues, TurkceCalibration reminder Visible indication of wrench calibration due dateConstructionShaft material: SteelHousing: AluminiumOverload capacity: 125% rated torqueSquare drives fitted with pin and spring socket retainerDIN sockets with quick release functionDisplayBacklit graphic LCD display with backlight auto off to save power<strong>Key</strong>padEasy clean membrane keypad with 6 function keysAuto zeroAuto zero on entering measurement mode. Display indication of excessive zero offsetPower/batteryLi polymer battery – High capacity with 16 hours typical usage from 4 hours chargePower management User selectable Auto Power Off: 1, 2, 5, 10, 20, 30, 40 minutes; 1, 2, 4, 8 hours; neverBattery charge status barInput/output portsOptional wireless communication (RF)Battery charge: Via charging/programming cradleZero stability< ± 0.1% FSD/°CStatic accuracy± 0.5% FSDOperating environment Temperature: +5˚C to +40˚CIngress Protection rating: IP40. Can be used outdoorsAngle measurement +/- 1%Warranty12 months parts and labour against faulty workmanship or materialswww.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrench<strong>IQWrench2</strong> <strong>Opta</strong> Comparison Chartwww.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrenchWeights and DimensionsAccessories List4 <strong>IQWrench2</strong> <strong>Opta</strong> Charging Cradle IQW2S-0000-CRCCXX4 <strong>IQWrench2</strong> <strong>Opta</strong> Programming Cradle (USB) IQW2S-0000-CRCPUX4 <strong>IQWrench2</strong> <strong>Opta</strong> Power Supply IQW2S-0000-CRPXXX4 USB Cable 0902604 RS232 Cable 0901844 Replacement Li Polymer 3.7V Battery 0801594 External Desk Top Battery Charger 0801614 RF Receiver – 2 volt free relay outputs (UK/EUR version) IQRX4-0000-NET4 RF Receiver – 2 volt free relay outputs (US version) IQRX5-0000-NET4 RF Receiver – 10 volt free relay outputs (UK/EUR version) IQRX6-0000-NET4 RF Receiver – 10 volt free relay outputs (US version) IQRX7-0000-NET4 Carry case and foams (Suitable to carry 10, 25 and 75Nm only) IQW2S-0000-CRCFXXShipping List4 Cradle with charger & mains lead (Charging cradle with Basic and <strong>Product</strong>ion, Programming cradle withAdvanced)4 Calibration certificate4 User manual & quickstart guide4 USB cable4 Communications softwarewww.crane-electronics.com

<strong>IQWrench2</strong> <strong>Opta</strong>Intelligent digital torque wrench<strong>IQWrench2</strong> <strong>Opta</strong> <strong>Product</strong> CodesThe <strong>IQWrench2</strong> <strong>Opta</strong> is available with the following specifications:Software Basic SoftwareAdvanced Software Refer to comparison chart for details<strong>Product</strong>ion SoftwareSize10Nm, 25Nm, 75Nm, 180Nm, 340Nm, 600Nm, 750Nm and 1500NmHead Type Fixed Head - 10Nm, 750Nm and 1500Nm onlyDin and SR Style Head - 10Nm, 25Nm, 75Nm, 180Nm, 340Nm and 600NmAngleWith angle measurement capability or no angleWireless Integrated RF wireless communication or no RFScanner Integrated barcode reader or no barcode<strong>IQWrench2</strong> <strong>Opta</strong> <strong>Product</strong> Code CreatorFollow the product code creator to build the perfect <strong>IQWrench2</strong> <strong>Opta</strong> for your needs.Just fill in the blanks to create the code.www.crane-electronics.com

OMS4 Single database tostore torqueinformation from alldepartments4 All data completelytraceable and securetJRS <strong>Opta</strong>4 A joint simulatorusing a threadedfastener and nut4 Fully automatic quickrelease of fastener<strong>IQWrench2</strong> <strong>Opta</strong>4 Point of loadinsensitive4 Interchangeablehead attachmentswith auto ID andcalibrationTorqueStar <strong>Opta</strong>4 Torque or forceindicator and datacollector4 Simple readout tocomprehensive audittoolCheckStar4 In line transducerwith optional anglemeasurement4 Accuracy +/– 0.25%of full scaleService Centres4 Centres throughoutthe world4 Fully traceablecalibration and repairservice<strong>Crane</strong> <strong>Electronics</strong> LtdWatling DriveSketchley MeadowsHinckley LE10 3EYUnited Kingdom+44 (0)1455 25 14 88+44 (0)1455 61 47 17sales@crane-electronics.comwww.crane-electronics.comThe force in torque management<strong>Crane</strong> <strong>Electronics</strong> Inc1260 11 th Street WestMilanIllinois 61264USA+1 309-787-1263+1 309-787-2099salesusa@crane-electronics.comwww.crane-electronics.comIQW2/UK/12/02www.crane-electronics.com