Whyalla Presentation 23 May 2007 - OneSteel

Whyalla Presentation 23 May 2007 - OneSteel

Whyalla Presentation 23 May 2007 - OneSteel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

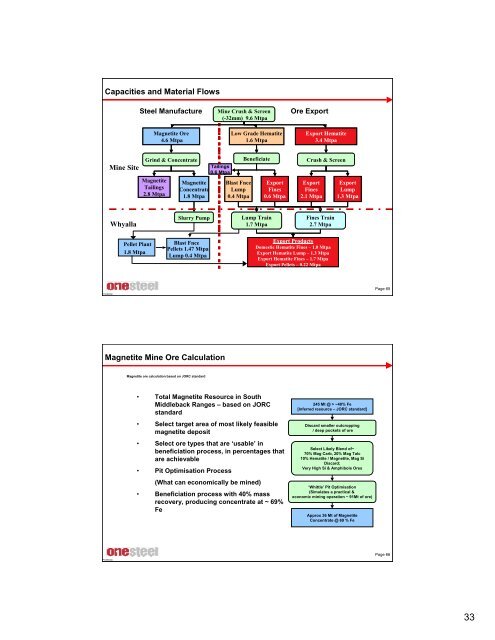

Capacities and Material FlowsSteel ManufactureMagnetite Ore4.5Mtpa 4.6 Mine Crush & Screen(-32mm) 9.5 9.6 MtpaLow Grade Hematite1.6 MtpaOre ExportExport Hematite3.4 MtpaGrind & Concentrate Beneficiate Crush & ScreenMine SiteTailings0.6 MtpaMagnetiteMagnetiteBlast FnceExportExportExportTailingsConcentrateLumpFinesFinesLump2.7 2.8 Mtpa1.8 Mtpa0.4 Mtpa0.6 Mtpa 2.4 2.1 Mtpa 1.0 1.3 Mtpa<strong>Whyalla</strong>Slurry PumpLump Train1.4 1.7 MtpaFines Train3.0 2.7 MtpaPellet Plant1.8 MtpaBlast FncePellets 1.47 MtpaLump 0.4 MtpaExport ProductsDomestic Hematite Fines – 1.0 MtpaExport Hematite Lump – 1.0 1.3 MtpaExport Hematite Fines – 2.0 1.7 MtpaExport Pellets – 0.32 0.22 MtpaPage 65(P729B324)Magnetite Mine Ore CalculationMagnetite ore calculation based on JORC standard• Total Magnetite Resource in SouthMiddleback Ranges – based on JORCstandard• Select target area of most likely feasiblemagnetite deposit• Select ore types that are ‘usable’ inbeneficiation process, in percentages thatare achievable• Pit Optimisation Process(What can economically be mined)• Beneficiation process with 40% massrecovery, producing concentrate at ~ 69%Fe245 Mt @ > ~40% Fe[Inferred resource – JORC standard]Discard smaller outcropping/ deep pockets of oreSelect Likely Blend of~70% Mag Carb, 20% Mag Talc10% Hematite / Magnetite, Mag SiDiscard;Very High Si & Amphibole Ores‘Whittle’ Pit Optimisation(Simulates a practical &economic mining operation ~ 91Mt of ore)Approx 36 Mt of MagnetiteConcentrate @ 69 % FePage 66(P729B324)33