SIIT Commemorative Publication (10 Years of International ...

SIIT Commemorative Publication (10 Years of International ...

SIIT Commemorative Publication (10 Years of International ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

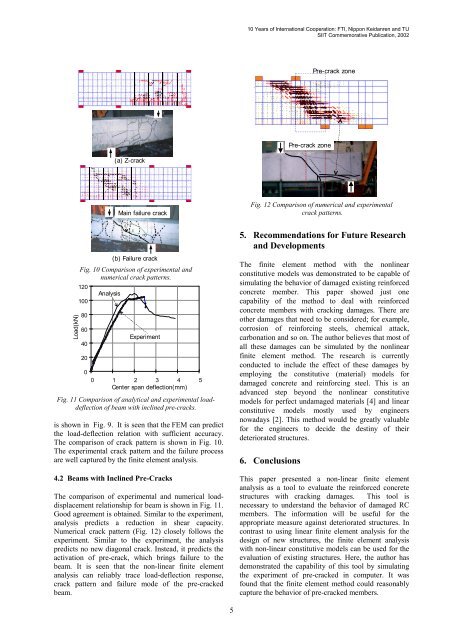

<strong>10</strong> <strong>Years</strong> <strong>of</strong> <strong>International</strong> Cooperation: FTI, Nippon Keidanren and TU<strong>SIIT</strong> <strong>Commemorative</strong> <strong>Publication</strong>, 2002Pre-crack zonePre-crack zone(a) Z-crackMain failure crackFig. 12 Comparison <strong>of</strong> numerical and experimentalcrack patterns.Load(kN)(b) Failure crackFig. <strong>10</strong> Comparison <strong>of</strong> experimental andnumerical crack patterns.120<strong>10</strong>0806040200AnalysisExperiment0 1 2 3 4 5Center span deflection(mm)Fig. 11 Comparison <strong>of</strong> analytical and experimental loaddeflection<strong>of</strong> beam with inclined pre-cracks.is shown in Fig. 9. It is seen that the FEM can predictthe load-deflection relation with sufficient accuracy.The comparison <strong>of</strong> crack pattern is shown in Fig. <strong>10</strong>.The experimental crack pattern and the failure processare well captured by the finite element analysis.4.2 Beams with Inclined Pre-CracksThe comparison <strong>of</strong> experimental and numerical loaddisplacementrelationship for beam is shown in Fig. 11.Good agreement is obtained. Similar to the experiment,analysis predicts a reduction in shear capacity.Numerical crack pattern (Fig. 12) closely follows theexperiment. Similar to the experiment, the analysispredicts no new diagonal crack. Instead, it predicts theactivation <strong>of</strong> pre-crack, which brings failure to thebeam. It is seen that the non-linear finite elementanalysis can reliably trace load-deflection response,crack pattern and failure mode <strong>of</strong> the pre-crackedbeam.5. Recommendations for Future Researchand DevelopmentsThe finite element method with the nonlinearconstitutive models was demonstrated to be capable <strong>of</strong>simulating the behavior <strong>of</strong> damaged existing reinforcedconcrete member. This paper showed just onecapability <strong>of</strong> the method to deal with reinforcedconcrete members with cracking damages. There areother damages that need to be considered; for example,corrosion <strong>of</strong> reinforcing steels, chemical attack,carbonation and so on. The author believes that most <strong>of</strong>all these damages can be simulated by the nonlinearfinite element method. The research is currentlyconducted to include the effect <strong>of</strong> these damages byemploying the constitutive (material) models fordamaged concrete and reinforcing steel. This is anadvanced step beyond the nonlinear constitutivemodels for perfect undamaged materials [4] and linearconstitutive models mostly used by engineersnowadays [2]. This method would be greatly valuablefor the engineers to decide the destiny <strong>of</strong> theirdeteriorated structures.6. ConclusionsThis paper presented a non-linear finite elementanalysis as a tool to evaluate the reinforced concretestructures with cracking damages. This tool isnecessary to understand the behavior <strong>of</strong> damaged RCmembers. The information will be useful for theappropriate measure against deteriorated structures. Incontrast to using linear finite element analysis for thedesign <strong>of</strong> new structures, the finite element analysiswith non-linear constitutive models can be used for theevaluation <strong>of</strong> existing structures. Here, the author hasdemonstrated the capability <strong>of</strong> this tool by simulatingthe experiment <strong>of</strong> pre-cracked in computer. It wasfound that the finite element method could reasonablycapture the behavior <strong>of</strong> pre-cracked members.5