technical specification non-destructive testing of welding on rails of ...

technical specification non-destructive testing of welding on rails of ...

technical specification non-destructive testing of welding on rails of ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELDOCUMENT NO.3. TECHNICAL SPECIFICATIONS

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELTABLE OF CONTENTS OF THE DETAILED DESIGNDOCUMENT NO. 1- DETAILED DESIGN REPORT AND ANNEXESDOCUMENT NO. 1- DETAILED DESIGN REPORT AND ANNEXESDOCUMENT NO. 3- TECHNICAL SPECIFICATIONSDETAILED DESIGN REPORTANNEXE 20TESTING AND COMMISIONING1 GENERAL REQUIREMENTS, SPECIFICATIONS AND STANDARSANNEXE 1.PROJECT BACKGROUNDANNEXE 21HEALTH&SAFETY ASPECTS2 WORK DESCRIPTIONANNEXE 2.PHOTOGRAPHIC REPORT3 CONSTRUCTION TASKSANNEXE 3.CARTOGRAPHY & TOPOGRAPHYDOCUMENT NO. 2- DRAWINGSANNEXE 4.STACKE OUT & PEGGING SYSTEMTRTABLE OF CONTENTSANNEXE 5.TRACK LAYOUTTRSITUATIONANNEXE 6.SUPERSTRUCTURE MATERIALSTRLAYOUTANNEXE 7.STRUCTURE-TRACK INTERACTIONTRSKETCH OF LINEANNEXE 8.SUPPLY LOGISTICSTRTYPICAL SECTIONSANNEXE 9.TRACK ASSEMBLY METHODTRSUPESTRUCTURE MATERIALSANNEXE 10.TREATMENTS IN THE EXISTING INFRASTRUCTURETRACCESSES TO THE WORK SITE & TREATMENTS IN THE EXISTING INFRASTRUCTUREANNEXE 11.WORK BASEWBWORK BASEANNEXE 12.FIXED COMMUNICATIONFCFIXED COMMUNICATIONANNEXE 13MOBILE COMMUNICATIONSGSIGNALLINGANNEXE 14SIGNALLINGSGDETECTORSANNEXE 15DETECTORSEVENVIRONMENTANNEXE 16TUNNEL SYSTEMS INTEGRATIONANNEXE 17ELECTRIFICATIONANNEXE 18ENVIRONMENTAL REPORTANNEXE 19COMPLEMENTARY WORKS

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELTECHNICAL SPECIFICATIONS

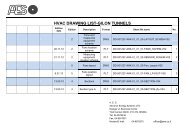

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELTABLE OF CONTENTS1.8 ELECTRIFICATION STANDARDS (ONLY FOR THE AKKO‐CARMIEL AND HERZELYA‐KEFAR SABA LINES)61.8.2 EN ................................................................................................................................ 61 GENERAL REQUIREMENTS, SPECIFICATIONS AND STANDARDS ...................................................... 11.1 INTRODUCTION ........................................................................................................................ 11.2 TRACK STANDARDS................................................................................................................... 11.2.1 ISRAELI STANDARDS .................................................................................................... 11.2.2 INTERNATIONAL STANDARDS‐UIC LEAFLETS AND REPORTS ....................................... 11.2.3 EUROPEAN STANDARDS .............................................................................................. 21.3 FIXED COMMUNICATION STANDARDS ..................................................................................... 21.3.1 CELENEC STANDARDS .................................................................................................. 21.3.2 TELECOMMUNICATION STANDARISATION SECTOR, ITU‐T RECOMMENDATIONS.TRANSMISSION SYSTEMS AND MEDIA, DIGITAL SYSTEMS AND NETWORKS .............. 31.4 MOBILE COMMUNICATION STANDARDS ................................................................................. 31.4.1 RAILWAY STANDARDS ................................................................................................. 31.4.2 EUROPEAN COMMITTEE FOR ELECTROTECHNICAL STANDARDIZATION (CENELEC)STANDARDS ................................................................................................................. 31.4.3 STANDARDS AND TECHNICAL REGULATIONS FOR ENERGY SUPPLY INSTALLATIONS . 41.4.4 CIVIL WORKS AND EDIFICATION .................................................................................. 41.4.5 VARIOUS ...................................................................................................................... 41.4.6 ISRAELI STANDARD FOR RAIL TUNNELS (FIRE SAFETY REQUIREMENT) ...................... 41.4.7 VHF STANDARD............................................................................................................ 41.5 SIGNALLING .............................................................................................................................. 41.5.1 EUROPEAN STANDARDS .............................................................................................. 41.5.2 OTHER GENERAL RULES AND TECHNICAL SPECIFICATIONS ........................................ 51.6 DETECTION SYSTEMS STANDARDS ........................................................................................... 51.6.1 EUROPEAN AND INTERNATIONAL STANDARDS .......................................................... 51.6.2 OTHER GENERAL RULES AND TECHNICAL SPECIFICATIONS ........................................ 51.7 TUNNEL SYSTEMS STANDARDS ................................................................................................ 51.8.3 TSI ................................................................................................................................ 61.8.4 CEI IEC .......................................................................................................................... 61.8.5 UIC ............................................................................................................................... 61.9 ENVIRONMENTAL STANDARDS ................................................................................................ 71.9.1 APPLICABLE ISRAELI REGULATIONS ............................................................................ 71.9.2 ENVIRONMENTAL PLANNING REGULATIONS ............................................................. 71.9.3 NATURE, BIODIVERSITY AND LANDSCAPE REGULATIONS .......................................... 71.9.4 WATER REGULATIONS ................................................................................................. 71.9.5 SOILS REGULATIONS .................................................................................................... 71.9.6 RECYCLING AND WASTE REGULATIONS ...................................................................... 71.9.7 HAZARDOUS SUBSTANCES REGULATIONS .................................................................. 81.9.8 AIR QUALITY REGULATIONS ........................................................................................ 81.9.9 NOISE REGULATIONS ................................................................................................... 81.9.10 CULTURAL HERITAGE REGULATIONS .......................................................................... 81.9.11 OTHER REGULATIONS ................................................................................................. 82 WORK DESCRIPTION ........................................................................................................................ 92.1.1 TRACK LAYOUT ............................................................................................................ 92.1.2 WORKBASE .................................................................................................................. 112.1.3 SUPPLY LOGISTICS ....................................................................................................... 112.1.4 TRACK ASSEMBLY METHOD ........................................................................................ 112.1.5 FIXED COMMUNICATION ............................................................................................ 122.1.6 MOBILE COMMUNICATION ......................................................................................... 122.1.7 SIGNALLING ................................................................................................................. 122.1.8 TUNNEL SYSTEMS ........................................................................................................ 123 CONSTRUCTIONS TASKS .................................................................................................................. 143.1 BALLASTED TRACK .................................................................................................................... 153.1.1 ISR 11001 MILESTONE FOR MAIN STAKEOUT NETWORK ........................................... 15

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL3.1.2 ISR11002 MILESTONE FOR SECONDARY STAKEOUT NETWORK .................................. 173.1.3 ISR11003 STAKEOUT AND PEGGING............................................................................ 173.1.4 ISR11004 SUPPLY AND TRANSPORTATION OF 60E2 RAILS IN 18 M BARS, 260HB ...... 173.2.8 ISR 11013 STRESS NEUTRALIZATION ........................................................................... 503.2.9 ISR12026 UNDER SLEEPER PADS (USP) ....................................................................... 503.2.10 ISR13008 CONCRETING IN TUNNEL WITH FILLING CONCRETE (MEDIUM QUALITY) .. 523.1.5 ISR11005 SUPPLY AND TRANSPORTATION OF 60E2 RAILS IN 18 M BARS, 350HB ...... 183.1.6 ISR11007 SUPPLY AND TRANSPORTATION OF B70 SLEEPERS ..................................... 183.1.7 ISR 11008 LAYING OF BALLAST BED INCLUDING SUPPLY AND TRANSPORTATIONOF BALLAST .................................................................................................................. 263.1.8 ISR11009 ASSEMBLY, TRANSPORTATION AND LAYING ON TRACK ............................. 323.1.9 ISR11010 FLASH‐BUTT WELDING ................................................................................ 353.1.10 ISR11011 ALUMINOTHERMIC WELDING ..................................................................... 353.1.11 ISR11012 EXECUTION OF 1ST TAMPING INCLUDING SUPPLY ANDTRANSPORTATION OF BALLAST ................................................................................... 353.1.12 ISR11013 STRESS NEUTRALIZATION ............................................................................ 363.1.13 ISR11014 EXECUTION OF 2 ND TAMPING INCLUDING SUPPLY ANDTRANSPORTATION OF BALLAST ................................................................................... 383.1.14 ISR11015 CLEARANCE POINTS ..................................................................................... 393.1.15 ISR11016 MILESTONES TYPE 1 (EVERY KM) ................................................................. 393.1.16 ISR11017 MILESTONES TYPE 2 (EVERY 200 M) ............................................................ 393.1.17 ASPHALTIC TREATMENT .............................................................................................. 39APPENDIX 1. GUIDELINES FOR LAYING DOWN AND MAINTENANCE OF WELDED RAILSAPPENDIX 2. TECHNICAL SPECIFICATIONS FOR THE FLASH BUTT WELDING OF RAILS BY MOBILE WELDINGMACHINEAPPENDIX 3. TECHNICAL SPECIFICATION NON‐DESTRUCTIVE TESTING OF WELDING ON RAILS OF TYPES UIC 54,U50, AND UIC 60APPENDIX 4. TECHNICAL SPECIFICATION WELDING RAILWAY LINES BY AN ALUMINO‐THERMAL METHODAPPENDIX 5. RAILWAY BUFFER STOPS PLANNING GUIDELINESAPPENDIX 6. TEMPORARY COMMUNICATION DUCTSAPPENDIX 7. ISR MILESTONESAPPENDIX 8. SAFETY FENCE IN STATIONSAPPENDIX 9. GENERAL REQUIREMENTS FOR THE PRELIMINARY PLANNING OF A SLAB TRACKAPPENDIX 10. SLAB TRACK REQUIREMENTS FOR SIGNALLINGAPPENDIX 11. TUNNEL SYSTEM SPECIFICATIONS3.1.18 ISR11020 SUPPLY AND ASSEMBLY OF SWITCHES ........................................................ 413.1.19 ISR11021 CONCRETE BUFFER ...................................................................................... 433.1.20 ISR84001 SAFETY FENCE BETWEEN PLATFORMS ........................................................ 433.2 SLAB TRACK .............................................................................................................................. 433.2.1 SLAB TRACK‐GENERAL SPECIFICATIONS ...................................................................... 443.2.2 ISR13001 MILESTONE FOR SECORDARY STAKEOUT NETWORK IN TUNNEL ............... 483.2.3 ISR13002 LABELS FOR LEVELLING THE TRACK EVERY 5 M ........................................... 483.2.4 ISR11003 STAKEOUT AND PEGGING............................................................................ 483.2.5 ISR12004 SUPPLY AND ASSEMBLY OF SLAB TRACK ..................................................... 483.2.6 ISR 11004 SUPPLY AND TRANSPORTATION OF 60 E2 RAILS IN 18 M BARS, 260 HB ... 503.2.7 ISR11010 FLASH‐BUTT WELDING ................................................................................ 50

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL1 GENERAL REQUIREMENTS, SPECIFICATIONS AND STANDARDS1.1 INTRODUCTIONThis article is intended to give a list <str<strong>on</strong>g>of</str<strong>on</strong>g> standards to be applied <strong>on</strong> the design <str<strong>on</strong>g>of</str<strong>on</strong>g> the new railway lines Akko‐Carmiel and Haifa‐Bet Shean.1.2 TRACK STANDARDS1.2.1 ISRAELI STANDARDSTracks Design Guidelines. Israel Railways Ltd. March 2008Tracks Design Guidelines for Speeds <str<strong>on</strong>g>of</str<strong>on</strong>g> up to 230 km/h. Israel Railways Ltd. March 2012Specificati<strong>on</strong> for producti<strong>on</strong> and supply <str<strong>on</strong>g>of</str<strong>on</strong>g> gravel ballast for railway tracks E‐01‐0013 Versi<strong>on</strong> 1.1 <str<strong>on</strong>g>of</str<strong>on</strong>g> Israelrailways infrastructures divisi<strong>on</strong> track and envir<strong>on</strong>ment department.Railway buffer stops planning guidelinesTechnical <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> E‐06‐0001. Welding railway lines by an alumino‐thermal method.Technical <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> for <str<strong>on</strong>g>n<strong>on</strong></str<strong>on</strong>g>‐<str<strong>on</strong>g>destructive</str<strong>on</strong>g> <str<strong>on</strong>g>testing</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>welding</str<strong>on</strong>g> <strong>on</strong> <strong>rails</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> types UIC‐54, U50, and UIC 60.Guidelines for laying down and maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> welded <strong>rails</strong>.Technical Specificati<strong>on</strong> for Producti<strong>on</strong> and Supply Prestressed M<strong>on</strong>oblock C<strong>on</strong>crete Sleeper.SI 466‐ C<strong>on</strong>crete CodeSI 4466‐ Steel for Reinforcement <str<strong>on</strong>g>of</str<strong>on</strong>g> C<strong>on</strong>creteSI 413‐ Israel Seismic Code1.2.2 INTERNATIONAL STANDARDS‐UIC LEAFLETS AND REPORTSSUB‐SECTION 70 GENERAL CHARACTERISTICS OF LINES700 Classificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> lines ‐ Resulting load limits for wag<strong>on</strong>s702 Static loading diagrams to be taken into c<strong>on</strong>siderati<strong>on</strong> for the design <str<strong>on</strong>g>of</str<strong>on</strong>g> rail carrying structures <strong>on</strong> linesused by internati<strong>on</strong>al services703 Layout characteristics for lines used by fast passenger trains705 Infrastructure for tilting trainsSUB‐SECTION 71 LAYING AND MAINTENANCE OF TRACK710 Minimum track gauge in curves711 Geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> points and crossings with UIC <strong>rails</strong> permitting R speeds <str<strong>on</strong>g>of</str<strong>on</strong>g> 100 km/h or more <strong>on</strong> thediverging track712 Rail defects713 Design <str<strong>on</strong>g>of</str<strong>on</strong>g> m<strong>on</strong>oblock c<strong>on</strong>crete sleepers714 Classificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> lines for the purpose <str<strong>on</strong>g>of</str<strong>on</strong>g> track maintenance715 Factors affecting track maintenance costs ‐ Their relative importance715‐1 Applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> digital track geometry analysis to the planning <str<strong>on</strong>g>of</str<strong>on</strong>g> tamping and lining/levelling work715‐2 Recommendati<strong>on</strong>s for management <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>rails</strong>716 Maximum permissible wear pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles for switches717 Recommendati<strong>on</strong>s for the design <str<strong>on</strong>g>of</str<strong>on</strong>g> bridges to satisfy track requirements and reduce noise dimensi<strong>on</strong>s717‐3 Steel bridges ‐ Laying <str<strong>on</strong>g>of</str<strong>on</strong>g> track <strong>on</strong> steel without ballast – Direct laying718‐1 Criteria to be taken into c<strong>on</strong>siderati<strong>on</strong> when approving mechanical track maintenance equipment718‐2 Criteria to be taken into c<strong>on</strong>siderati<strong>on</strong> when approving tamping and lining machines for plain track718‐3 Criteria to be taken into c<strong>on</strong>siderati<strong>on</strong> when approving tamping lining machines for points andcrossings718‐4 Guidelines for the measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> noise emitted by track machines719 Earthworks and track bed c<strong>on</strong>structi<strong>on</strong> for railway linesSUB‐SECTION 72 LAYING AND MAINTENANCE OF TRACK (CONTINUATION)720 Laying and Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> CWR Track721 Recommendati<strong>on</strong>s for the use <str<strong>on</strong>g>of</str<strong>on</strong>g> rail steel grades722 Methods <str<strong>on</strong>g>of</str<strong>on</strong>g> improving the track formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> existing lines723 Vegetati<strong>on</strong> c<strong>on</strong>trol ‐ Technical and management aspects724 Track equipment for 25 t<strong>on</strong>s (250 kN) axle loads <strong>on</strong> ballasted track725 Treatment <str<strong>on</strong>g>of</str<strong>on</strong>g> rail defects728 Absolute coordinates for tack engineering work ‐ A Railway Geodesy approachSUB‐SECTION 73 SIGNALLING AND INTERLOCKINGDocument No.3. Technical Specificati<strong>on</strong>s ‐1‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL730‐3 Automatic warning <str<strong>on</strong>g>of</str<strong>on</strong>g> track maintenance gangs731 Inspecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> signalling installati<strong>on</strong>s732 Principles for signalling trains routes using wayside signals734 Adaptati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> safety installati<strong>on</strong>s to high‐speed requirements736 Signalling relays737‐1 Combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> track circuits and treadles737‐2 Measures to be taken to improve track circuits shunting sensitivity737‐3 Applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> thyristors in railway technology ‐ Measures for the preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> functi<strong>on</strong>al disturbancein signaling installati<strong>on</strong>s737‐4 Measures for limiting the disturbance <str<strong>on</strong>g>of</str<strong>on</strong>g> light current installati<strong>on</strong>s by electric tracti<strong>on</strong> (in particularthyristor apparatus)738 Processing and transmissi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> safety informati<strong>on</strong>739 Slip limits bey<strong>on</strong>d signalsSUB‐SECTION 74 BUILDINGS741 Passenger stati<strong>on</strong>s ‐ Height <str<strong>on</strong>g>of</str<strong>on</strong>g> platforms – Regulati<strong>on</strong>s governing the positi<strong>on</strong>ing <str<strong>on</strong>g>of</str<strong>on</strong>g> platform edges inrelati<strong>on</strong> to the trackSUB‐SECTION 76 LEVEL CROSSINGS760 Level crossings ‐ Road signs and signals761 Guidance <strong>on</strong> the automatic operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> level crossings762 Safety measures to be taken at level crossings <strong>on</strong> lines operated from 120 to 200 km/h776‐4 Computer‐aid calculati<strong>on</strong> for bridges and other civil engineering structuresOTHER774‐3 Track‐bridge interacti<strong>on</strong>. Recommendati<strong>on</strong>s for calculati<strong>on</strong>s779‐9 Safety in railway tunnels779‐10 Management and maintenance principles for existing tunnels779‐11 Determinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> railway tunnel cross‐secti<strong>on</strong>al areas <strong>on</strong> the basis <str<strong>on</strong>g>of</str<strong>on</strong>g> aerodynamic c<strong>on</strong>siderati<strong>on</strong>s1.2.3 EUROPEAN STANDARDSEN 13803‐1:2011EN 13450EN 13674‐1EN 13230‐2EN 13232Railway applicati<strong>on</strong>s ‐ Track ‐ Track alignment design parameters ‐ Track gauges1435 mm and wider ‐ Part 1: Plain lineAggregates for railway ballastRailway applicati<strong>on</strong>s‐Track‐Rail‐Part 1: Vignole railways 46 kg/m and aboveRailway applicati<strong>on</strong>s‐Track‐C<strong>on</strong>crete sleepers and bearers‐Prestressed m<strong>on</strong>oblocksleepersRailway applicati<strong>on</strong>s‐Track‐Switches and crossingsBesides,if there is nothing stated in the “Ir<strong>on</strong> Tracks Design Guidelines (Israel Railways Ltd, March 2008), aNAV Standard (Spanish Standard for railways) could be taken as reference for the following tasks or trackcomp<strong>on</strong>ents as well as Internati<strong>on</strong>al Standards prior to NI approval:EarthworksRailSleepersFasteningsTurnouts and crossingsBallast and subballastSuperstructure in bridgesLevel crossingsTrack assembly1.3 FIXED COMMUNICATION STANDARDS1.3.1 CELENEC STANDARDSEN 50121‐1EN 50121‐4EN 50122‐1Railway applicati<strong>on</strong>s. Electromagnetic compatibility. GeneralRailway applicati<strong>on</strong>s. Electromagnetic compatibility. Emissi<strong>on</strong> and immunity <str<strong>on</strong>g>of</str<strong>on</strong>g> thesignalling and telecommunicati<strong>on</strong>s apparatusRailway applicati<strong>on</strong>s – Fixed installati<strong>on</strong>s – Electrical safety, earthing and the returncircuit Part 1: Protective provisi<strong>on</strong>s against electric shockDocument No.3. Technical Specificati<strong>on</strong>s ‐2‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELEN 50124‐1Railway applicati<strong>on</strong>s. Insulati<strong>on</strong> coordinati<strong>on</strong>. Basic requirements. Clearances andcreepage distances for all electrical and electr<strong>on</strong>ic equipmentITU‐T G.709Synchr<strong>on</strong>ous multiplexing structureEN 50125‐3Railway applicati<strong>on</strong>s ‐ Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s for equipment ‐ Part 3: Equipmentfor signalling and telecommunicati<strong>on</strong>s1.4 MOBILE COMMUNICATION STANDARDSEN 50126‐1EN 50128EN 50129Railway applicati<strong>on</strong>s ‐ The <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> and dem<strong>on</strong>strati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Reliability, Availability,Maintainability and Safety (RAMS) ‐ Part 2: Guide to the applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> EN 50126‐1for safetyRailway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>, signalling and processing systems ‐ S<str<strong>on</strong>g>of</str<strong>on</strong>g>twarefor railway c<strong>on</strong>trol and protecti<strong>on</strong> systemsRailway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. Safetyrelated electr<strong>on</strong>ic systems for signallingEN 50159‐1 Railway applicati<strong>on</strong>s — Communicati<strong>on</strong>, signalling and processing systems — Part 1:Safety‐related communicati<strong>on</strong> in closed transmissi<strong>on</strong> systemsEN 50159‐2 Railway applicati<strong>on</strong>s — Communicati<strong>on</strong>, signalling and processing systems — Part 2:Safety related communicati<strong>on</strong> in open transmissi<strong>on</strong> systemsEN 50261EN 55011EN 55022EN 60439EN 60947EN 60529EN 60793‐2‐50Railway Applicati<strong>on</strong>s ‐ Mounting <str<strong>on</strong>g>of</str<strong>on</strong>g> Electr<strong>on</strong>ic EquipmentIndustrial, scientific and medical (ISM) radio‐frequency equipment ‐ Electromagneticdisturbance characteristics ‐ Limits and methods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurementInformati<strong>on</strong> technology equipment ‐ Radio disturbance characteristics ‐ Limits andmethods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurementLow‐voltage switchgear and c<strong>on</strong>trolgear assemblies ‐ Part 1: Type‐tested andpartially type‐tested assembliesLow‐voltage switchgear and c<strong>on</strong>trolgear ‐ Part 7‐1: Ancillary equipment ‐ Terminalblocks for copper c<strong>on</strong>ductorsDegrees <str<strong>on</strong>g>of</str<strong>on</strong>g> protecti<strong>on</strong> provided by enclosures (IP Code)Optical fibres ‐ Part 2‐50: Product <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s ‐ Secti<strong>on</strong>al <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> for class Bsingle‐mode fibres1.3.2 TELECOMMUNICATION STANDARISATION SECTOR, ITU‐T RECOMMENDATIONS. TRANSMISSIONSYSTEMS AND MEDIA, DIGITAL SYSTEMS AND NETWORKSITU‐T G.652ITU‐T G.707Characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> a single‐mode optical fibre and cableSynchr<strong>on</strong>ous multiplexing structure1.4.1 RAILWAY STANDARDSEN50126‐1EN 50128EN 50129Railway applicati<strong>on</strong>s ‐ The <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> and dem<strong>on</strong>strati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Reliability, Availability,Maintainability and Safety (RAMS). Part 1: Basic requirements and generic process.Railway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>s, signalling and processing systems ‐ S<str<strong>on</strong>g>of</str<strong>on</strong>g>twarefor railway c<strong>on</strong>trol and protecti<strong>on</strong> systemsRailway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>, signalling and processing systems ‐ Safetyrelated electr<strong>on</strong>ic systems for signaling1.4.2 EUROPEAN COMMITTEE FOR ELECTROTECHNICAL STANDARDIZATION (CENELEC) STANDARDSEN 50121‐1EN 50121‐2EN 50121‐4EN 50122‐1Railway applicati<strong>on</strong>s ‐ Electromagnetic compatibility ‐‐ Part 1: General.Railway applicati<strong>on</strong>s ‐ Electromagnetic compatibility ‐‐ Part 2: Emissi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the wholerailway system to the outside world.Railway applicati<strong>on</strong>s ‐ Electromagnetic compatibility ‐‐ Part 4: Emissi<strong>on</strong> andimmunity <str<strong>on</strong>g>of</str<strong>on</strong>g> the signalling and telecommunicati<strong>on</strong>s apparatus.Railway applicati<strong>on</strong>s ‐ Fixed installati<strong>on</strong>s ‐‐ Part 1: Protective provisi<strong>on</strong>s relating toelectrical safety and earthingEN 50124‐1 Railway applicati<strong>on</strong>s ‐ Insulati<strong>on</strong> coordinati<strong>on</strong> ‐‐ Part 1: Basic requirements ‐Clearances and creepage distances for all electrical and electr<strong>on</strong>ic equipment.EN 50125‐3EN 50126‐1EN 50128EN 50129EN 50155Railway applicati<strong>on</strong>s ‐ Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s for equipment ‐‐ Part 3: Equipmentfor signalling and telecommunicati<strong>on</strong>s.Railway applicati<strong>on</strong>s‐ The <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> and dem<strong>on</strong>strati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Reliability, Availability,Maintainability and Safety (RAMS). Part 1: Basic requirements and generic proces.Railway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>s, signalling and processing systems ‐ S<str<strong>on</strong>g>of</str<strong>on</strong>g>twarefor railway c<strong>on</strong>trol and protecti<strong>on</strong> systems.Railway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>, signalling and processing systems ‐ Safetyrelated electr<strong>on</strong>ic systems for signalling.Railway applicati<strong>on</strong>s ‐ Electr<strong>on</strong>ic equipment used <strong>on</strong> rolling stock.Document No.3. Technical Specificati<strong>on</strong>s ‐3‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELEN 50159‐1 Railway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>, signalling and processing systems ‐‐ Part 1:Safety‐related communicati<strong>on</strong> in closed transmissi<strong>on</strong> systems.EN 50159‐2 Railway applicati<strong>on</strong>s ‐ Communicati<strong>on</strong>, signalling and processing systems ‐‐ Part 2:Safety related communicati<strong>on</strong> in open transmissi<strong>on</strong> systems.1.4.3 STANDARDS AND TECHNICAL REGULATIONS FOR ENERGY SUPPLY INSTALLATIONSEN 61000‐6‐2EN 61000‐6‐3EN 55011EN 55022EN 60950DIN 7990DIN 4131Electromagnetic compatibility (EMC) ‐‐ Part 6‐2: Generic standards ‐ Immunity forindustrial envir<strong>on</strong>ments.Electromagnetic compatibility (EMC) ‐‐ Part 6‐3: Generic standards ‐ Emissi<strong>on</strong>standard for residential, commercial and light‐industrial envir<strong>on</strong>ments.Industrial, scientific and medical (ISM) radio‐frequency equipment ‐ Electromagneticdisturbance characteristics ‐ Limits and methods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement.Informati<strong>on</strong> technology equipment ‐ Radio disturbance characteristics ‐ Limits andmethods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement da.Informati<strong>on</strong> technology equipment ‐ Safety.Hexag<strong>on</strong> head bolts with hexag<strong>on</strong> nut for steel structuresWind acti<strong>on</strong>s <strong>on</strong> square lattice masts1.4.5 VARIOUSENV 50141ENV 50204EN 55011EN 55022EN 60439‐1Electromagnetic compatibility. Basic immunity standard. C<strong>on</strong>ducted disturbancesinduced by radio‐frequency fields. Immunity test.Radiated electromagnetic field from digital radio teleph<strong>on</strong>es. Immunity test.Industrial, scientific and medical (ISM) radio‐frequency equipment ‐ Electromagneticdisturbance characteristics ‐ Limits and methods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement.Informati<strong>on</strong> technology equipment ‐ Radio disturbance characteristics ‐ Limits andmethods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement.Low‐voltage switchgear and c<strong>on</strong>trolgear assemblies ‐‐ Part 1: Type‐tested andpartially type‐tested assembliesEN 60439‐2 Low‐voltage switchgear and c<strong>on</strong>trolgear assemblies ‐‐ Part 2: Particularrequirements for busbar trunking systems (busways)EN 60439‐3EN 60439‐4Low‐voltage switchgear and c<strong>on</strong>trolgear assemblies. Part 3: particular requirementsfor low‐voltage switchgear and c<strong>on</strong>trolgear assemblies intended to be installed inplaces where unskilled pers<strong>on</strong>s have access for their use. Distributi<strong>on</strong> boardsLow‐voltage switchgear and c<strong>on</strong>trolgear assemblies. Part 4: Particular requirementsfor assemblies for c<strong>on</strong>structi<strong>on</strong> sites (ACS)DIN 267DIN 555Fasteners; <str<strong>on</strong>g>technical</str<strong>on</strong>g> delivery c<strong>on</strong>diti<strong>on</strong>s; design and dimensi<strong>on</strong>al accuracyHexag<strong>on</strong> nutsEN 60439‐5Low‐voltage switchgear and c<strong>on</strong>trolgear assemblies. Part 5: Particular requirementsfor assemblies for power distributi<strong>on</strong> in public networksDIN 7989Washers for steel structures1.4.6 ISRAELI STANDARD FOR RAIL TUNNELS (FIRE SAFETY REQUIREMENT)1.4.4 CIVIL WORKS AND EDIFICATIONIS 5435EN 10025Hot rolled products <str<strong>on</strong>g>of</str<strong>on</strong>g> structural steels1.4.7 VHF STANDARDEN ISO 5817Welding ‐ Fusi<strong>on</strong>‐welded joints in steel, nickel, titanium and their alloys (beam<str<strong>on</strong>g>welding</str<strong>on</strong>g> excluded) ‐ Quality levels for imperfecti<strong>on</strong>s .ETS 300 384Radio broadcasting systems; Very High Frequency (VHF), frequency modulated,sound broadcasting transmittersEN ISO 1461EN 353‐1Hot dip galvanized coatings <strong>on</strong> fabricated ir<strong>on</strong> and steel articles ‐ Specificati<strong>on</strong>s andtest methods”.Pers<strong>on</strong>al protective equipment against falls from a height ‐ Part 1: Guided type fallarresters including a rigid anchor line1.5 SIGNALLING1.5.1 EUROPEAN STANDARDSEN 50121‐1Electromagnetic compatibility. Part 1: general.EN 10025‐2Hot rolled products <str<strong>on</strong>g>of</str<strong>on</strong>g> structural steels ‐ Part 2: Technical delivery c<strong>on</strong>diti<strong>on</strong>s for<str<strong>on</strong>g>n<strong>on</strong></str<strong>on</strong>g>‐alloy structural steels.EN 50121‐4Electromagnetic compatibility. Part 4: emissi<strong>on</strong> and immunity <str<strong>on</strong>g>of</str<strong>on</strong>g> the signalling andtelecommunicati<strong>on</strong>s apparatus.Document No.3. Technical Specificati<strong>on</strong>s ‐4‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELEN 50122‐1EN 50124‐1EN 50125‐3Railway applicati<strong>on</strong>s. Fixed installati<strong>on</strong>s. Electrical safety, earthing and the returncircuit. Part 1: protective provisi<strong>on</strong>s against electric shock.Railway applicati<strong>on</strong>s. Insulati<strong>on</strong> coordinati<strong>on</strong>. Part 1: basic requirements. Clearanceand creepage distances for all electrical and electr<strong>on</strong>ic equipment.Railway applicati<strong>on</strong>s. Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s for equipments. Part 3: equipmentfor signalling and telecommunicati<strong>on</strong>s.Supply <str<strong>on</strong>g>of</str<strong>on</strong>g> alphanumeric signals.Supply cables signalling facilities.Provisi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> cable distributor boxes.Supply <str<strong>on</strong>g>of</str<strong>on</strong>g> axle counter.Supply <str<strong>on</strong>g>of</str<strong>on</strong>g> point machine and associated equipments.EN 50126‐1Railway applicati<strong>on</strong>s. The <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> and dem<strong>on</strong>strati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> reliability, availability,maintainability and safety (RAMS). Part 1: basic requirements and generic process.Operati<strong>on</strong>al functi<strong>on</strong>ality <str<strong>on</strong>g>of</str<strong>on</strong>g> electr<strong>on</strong>ic interlocking.Operati<strong>on</strong>al functi<strong>on</strong>ality <str<strong>on</strong>g>of</str<strong>on</strong>g> line blocks.EN 50128Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. S<str<strong>on</strong>g>of</str<strong>on</strong>g>twarefor railway c<strong>on</strong>trol and protecti<strong>on</strong>s systems.Technical recommendati<strong>on</strong> for delivery <str<strong>on</strong>g>of</str<strong>on</strong>g> drawings and <str<strong>on</strong>g>technical</str<strong>on</strong>g> documentati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> securityinstallati<strong>on</strong>s.EN 50129Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. Safetyrelated electr<strong>on</strong>ic systems for signalling.EN 50159‐1 Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. Part 1:safety related communicati<strong>on</strong> in closed transmissi<strong>on</strong> systems.EN 50159‐2 Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. Part 2:safety related communicati<strong>on</strong> in open transmissi<strong>on</strong> systems.EN 50261EN 55011EN 55022EN 60439EN 60947Railway applicati<strong>on</strong>s. Mounting <str<strong>on</strong>g>of</str<strong>on</strong>g> electr<strong>on</strong>ic equipment.Limits and methods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> radio disturbance characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g>industrial, scientific and medical (ISM) radio‐frequency equipment.Informati<strong>on</strong> technology equipment. Radio disturbance characteristics. Limits andmethods <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement.Low‐voltage switchgear and c<strong>on</strong>trolgear assemblies (BT panels).Low‐voltage switchgear and c<strong>on</strong>trolgear1.6 DETECTION SYSTEMS STANDARDS1.6.1 EUROPEAN AND INTERNATIONAL STANDARDSEN 50125‐3EN 50126‐1EN 50128EN 50129EN 60529IEC 60439Railway applicati<strong>on</strong>s. Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s for equipments. Part 3: equipmentfor signalling and telecommunicati<strong>on</strong>s.Railway applicati<strong>on</strong>s. The <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> and dem<strong>on</strong>strati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> reliability, availability,maintainability and safety (RAMS). Part 1: basic requirements and generic process.Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. S<str<strong>on</strong>g>of</str<strong>on</strong>g>twarefor railway c<strong>on</strong>trol and protecti<strong>on</strong>s systems.Railway applicati<strong>on</strong>s. Communicati<strong>on</strong>, signalling and processing systems. Safetyrelated electr<strong>on</strong>ic systems for signalling.Degrees <str<strong>on</strong>g>of</str<strong>on</strong>g> protecti<strong>on</strong> provided by enclosures (IP Code)Low‐voltage switchgear and c<strong>on</strong>trol gear assembliesEN 60529Specificati<strong>on</strong> for degrees <str<strong>on</strong>g>of</str<strong>on</strong>g> protecti<strong>on</strong>s provided by enclosures (IP code).1.6.2 OTHER GENERAL RULES AND TECHNICAL SPECIFICATIONS1.5.2 OTHER GENERAL RULES AND TECHNICAL SPECIFICATIONSBesides other nati<strong>on</strong>al regulati<strong>on</strong>s and <str<strong>on</strong>g>technical</str<strong>on</strong>g> <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s will be c<strong>on</strong>sidered:Apart from the European Standards, the Authority ruling the railway network could also define the followingStandards:General regulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> circulati<strong>on</strong>General <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s regarding installati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> sideway equipmentGeneral regulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> circulati<strong>on</strong>.1.7 TUNNEL SYSTEMS STANDARDSTechnical instructi<strong>on</strong>. Gauge <str<strong>on</strong>g>of</str<strong>on</strong>g> the network.EN 50121CENELEC Electromagnetic CompatibilitySupply <str<strong>on</strong>g>of</str<strong>on</strong>g> light signals.NFPA 130Standard for fixed Guideway transit and Passenger Rail SystemsDocument No.3. Technical Specificati<strong>on</strong>s ‐5‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELCETUSRTEN 50128EN 50126Guidelines for fire safe designEuropean Associati<strong>on</strong> for Railway InteroperabilityTechnical Specificati<strong>on</strong> for Interoperability Safety in Railway TunnelsCENELEC S<str<strong>on</strong>g>of</str<strong>on</strong>g>twareRAMS Plan1.8 ELECTRIFICATION STANDARDS (ONLY FOR THE AKKO‐CARMIEL AND HERZELYA‐KEFAR SABA LINES)There are several organizati<strong>on</strong>s which create the standards for electrificati<strong>on</strong>:50367 Railway applicati<strong>on</strong>s ‐ Current collecti<strong>on</strong> systems ‐ Technical criteria for theinteracti<strong>on</strong> between pantograph and overhead line (to achieve free access).50388 Railway applicati<strong>on</strong>s ‐ Power supply and rolling stock ‐ Technical criteria for thecoordinati<strong>on</strong> between power supply (substati<strong>on</strong>) and rolling stock to achieveinteroperability.1.8.3 TSI2008/284/CETechnical <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> for interoperability relating to the ‘energy’ sub‐system <str<strong>on</strong>g>of</str<strong>on</strong>g> thetrans‐European high‐speed rail system. 2008.European Committee for Electro<str<strong>on</strong>g>technical</str<strong>on</strong>g> Standardizati<strong>on</strong> (CENELC, European Norms)Technical Specificati<strong>on</strong> for Interoperability (TSI)2011/274/EUTechnical <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> for interoperability relating to the ‘energy’ subsystem <str<strong>on</strong>g>of</str<strong>on</strong>g> thetrans‐European c<strong>on</strong>venti<strong>on</strong>al rail system. 2011.Internati<strong>on</strong>al Electro<str<strong>on</strong>g>technical</str<strong>on</strong>g> Commissi<strong>on</strong> (IEC – CEI)Internati<strong>on</strong>al Uni<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Railways (UIC)1.8.4 CEI IEC913 (60913) Electric tracti<strong>on</strong> overhead lines1.8.2 EN50119 Railway applicati<strong>on</strong>s ‐ Fixed installati<strong>on</strong>s ‐ Electric tracti<strong>on</strong> overhead c<strong>on</strong>tact lines.50121‐1 Railways appplicati<strong>on</strong> ‐ Electromagnetic Compatibility50121‐2 Railways appplicati<strong>on</strong> ‐ Electromagnetic Compatibility50122‐1 Railways appplicati<strong>on</strong> ‐ Fixed installati<strong>on</strong>s ‐ Part 1: Protective provisi<strong>on</strong>s relating toelectrical safety and earthing50124‐1 Railway applicati<strong>on</strong>s ‐ Insulati<strong>on</strong> coordinati<strong>on</strong> ‐ Part 1: Basic requirements.Clearances and creepage distances for all electrical and electr<strong>on</strong>ic equipment50125‐2 Railway applicati<strong>on</strong>s ‐ Envir<strong>on</strong>mental c<strong>on</strong>diti<strong>on</strong>s for equipment ‐ Part 2: Fixedelectrical installati<strong>on</strong>s.50149 Railway applicati<strong>on</strong>s ‐ Fixed installati<strong>on</strong>s ‐ Electric tracti<strong>on</strong> ‐ Copper and copper alloygrooved c<strong>on</strong>tact wires.50152‐2 Railway applicati<strong>on</strong> ‐ Fixed installati<strong>on</strong> ‐ Particular requirements for AC switchgear ‐Part 2: Single Phase Disc<strong>on</strong>nectors, earthing switches and switches with UM above1 Kv.50153 Railway applicati<strong>on</strong>s ‐ Rolling stock ‐ Protective provisi<strong>on</strong>s relating to electricalhazards.50163 Railway applicati<strong>on</strong>s ‐ Supply voltages <str<strong>on</strong>g>of</str<strong>on</strong>g> tracti<strong>on</strong> systems.60050 Internati<strong>on</strong>al Electro<str<strong>on</strong>g>technical</str<strong>on</strong>g> Vocabulary60364 Low‐voltage electrical installati<strong>on</strong>s61000‐5‐2 Electromagnetic Compatibility (EMC) ‐ Part 5: Installati<strong>on</strong> and mitigati<strong>on</strong> guidelines ‐Secti<strong>on</strong> 2. Earthing and cabling61024‐1 Protecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> structures against lightning ‐ Part 1: General principles61936‐1 Power installati<strong>on</strong>s exceeding 1 kV a.c. ‐ Part 1: Comm<strong>on</strong> rules62305 Protecti<strong>on</strong> against lightning1.8.5 UIC608 C<strong>on</strong>diti<strong>on</strong>s to be complied with for the pantographs <str<strong>on</strong>g>of</str<strong>on</strong>g> tractive units used ininternati<strong>on</strong>al services791 Quality assurance <str<strong>on</strong>g>of</str<strong>on</strong>g> overhead line equipment793 Working methods for mechanised overhead line installati<strong>on</strong>794 Pantograph‐overhead line interacti<strong>on</strong> <strong>on</strong> the european high‐speed network795 Minimum installed power ‐ Line categories796 Voltage at the pantographDocument No.3. Technical Specificati<strong>on</strong>s ‐6‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL797 Coordinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> electrical protecti<strong>on</strong> substati<strong>on</strong>s/tracti<strong>on</strong> units799 Characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> a.c. overhead c<strong>on</strong>tact systems for high‐speed lines worked atspeeds <str<strong>on</strong>g>of</str<strong>on</strong>g> over 200 km/h870 Technical <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g> for grooved c<strong>on</strong>tact wires1.9 ENVIRONMENTAL STANDARDS1.9.1 APPLICABLE ISRAELI REGULATIONSENVIRONMENTAL IMPACT REGULATIONS Planning and Building Regulati<strong>on</strong>s (Envir<strong>on</strong>mental Impact Statements) 5763‐20031.9.2 ENVIRONMENTAL PLANNING REGULATIONS Planning and Building Regulati<strong>on</strong>s (Envir<strong>on</strong>mental Impact Statements) 5763‐20031.9.3 NATURE, BIODIVERSITY AND LANDSCAPE REGULATIONS Roads (Affixing <str<strong>on</strong>g>of</str<strong>on</strong>g> Signs) Law, 1966 Nati<strong>on</strong>al Parks, Nature Reserves, Nati<strong>on</strong>al Sites and Memorial Sites Law, 5758‐1998 Roads (Affixing <str<strong>on</strong>g>of</str<strong>on</strong>g> Signs) (Sp<strong>on</strong>sorship) Regulati<strong>on</strong>s, 1999Nati<strong>on</strong>al Parks, Nature Reserves, Nati<strong>on</strong>al Sites and Memorial Sites Proclamati<strong>on</strong> (Protected NaturalAssets), 5765‐20051.9.4 WATER REGULATIONS Water Law <str<strong>on</strong>g>of</str<strong>on</strong>g> 1959 Streams and Springs Authorities Law, 1965 Model Local Authorities By‐Law (Discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> Industrial Sewage into the Sewage System), 1981 Streams and Springs Authorities Order (Kish<strong>on</strong> River Authority), 1994 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Evaporati<strong>on</strong> and Storage P<strong>on</strong>ds), 1997 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Sewage Disposal from Vessels), 1998 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Metals and Other Pollutants), 2000Streams and Springs Authorities Order (Impositi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Stream Authority Duties <strong>on</strong> DrainageAuthorities), 5763‐2003 Business Licensing Regulati<strong>on</strong>s (Salt C<strong>on</strong>centrati<strong>on</strong>s in Industrial Sewage), 2003 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (pH Values <str<strong>on</strong>g>of</str<strong>on</strong>g> Industrial Sewage), 2003 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Usage <str<strong>on</strong>g>of</str<strong>on</strong>g> Sludge), 2004 Public Health Regulati<strong>on</strong>s (Effluent Quality Standards and Rules for Sewage Treatment), 20101.9.5 SOILS REGULATIONS Plant Protecti<strong>on</strong> Law, 19561.9.6 RECYCLING AND WASTE REGULATIONS Model Local Authorities By‐Law (Discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> Industrial Sewage into the Sewage System), 1981Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> Cleanliness Law, 1984 (and its Amendments) Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> Cleanliness Regulati<strong>on</strong>s (Vehicle Signs), 1987Regulati<strong>on</strong>s <strong>on</strong> Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Unreasanoable Air and Smell Polluti<strong>on</strong> from Solid Waste Disposal Sites,1990 Public Health Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances) (Removal <str<strong>on</strong>g>of</str<strong>on</strong>g> Plastic Sheets), 1993 Regulati<strong>on</strong>s <strong>on</strong> Used Oil, 1993 Collecti<strong>on</strong> and Disposal <str<strong>on</strong>g>of</str<strong>on</strong>g> Waste for Recycling Law, 1993 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Evaporati<strong>on</strong> and Storage P<strong>on</strong>ds), 1997 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Sewage Disposal from Vessels), 1998Collecti<strong>on</strong> and Disposal <str<strong>on</strong>g>of</str<strong>on</strong>g> Waste for Recycling Regulati<strong>on</strong>s (Obligati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Waste Disposal forRecycling), 1998 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Metals and Other Pollutants), 2000 Business Licensing Regulati<strong>on</strong>s (Salt C<strong>on</strong>centrati<strong>on</strong>s in Industrial Sewage), 2003 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (pH Values <str<strong>on</strong>g>of</str<strong>on</strong>g> Industrial Sewage), 2003 Water Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Water Polluti<strong>on</strong>) (Usage <str<strong>on</strong>g>of</str<strong>on</strong>g> Sludge), 2004 Tire Disposal and Recycling Law, 2007 Amendment to the Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> Cleanliness Law ‐ Landfill Levy, 2007 Public Health Regulati<strong>on</strong>s (Effluent Quality Standards and Rules for Sewage Treatment), 2010 Amendment to the Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> Cleanliness Law, 2011Document No.3. Technical Specificati<strong>on</strong>s ‐7‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL1.9.7 HAZARDOUS SUBSTANCES REGULATIONS Plant Protecti<strong>on</strong> Law, 1956Safety at Work Regulati<strong>on</strong>s (Occupati<strong>on</strong>al Hygiene and Health <str<strong>on</strong>g>of</str<strong>on</strong>g> the Public and Workers withHarmful Dust), 5744 – 1984 Hazardous Substances Law, 5753‐1993 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Used Oil), 1993 Hazardous Substances Regulati<strong>on</strong>s (Classificati<strong>on</strong> and Exempti<strong>on</strong>) 5756‐1996 Safety at Work Regulati<strong>on</strong>s (Material Safety Data Sheets), 1998Hazardous Substances Regulati<strong>on</strong>s (Implementati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the M<strong>on</strong>treal Protocol <strong>on</strong> Substances thatDeplete the Oz<strong>on</strong>e Layer), 5769‐20091.9.8 AIR QUALITY REGULATIONS Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Law 5721‐1961 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Air Polluti<strong>on</strong> from Premises), 5722‐1962 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Air Polluti<strong>on</strong> from Vehicles), 5723‐1963 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Air Polluti<strong>on</strong> from Vehicles) (Hartridge Test Standard), 5724‐1963 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisance Regulati<strong>on</strong>s (Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Noise) 5752‐1992 Regulati<strong>on</strong>s <strong>on</strong> Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Air Polluti<strong>on</strong> and Noise from Quarries, 1998 Criteria for railroad noise Guidelines for community noise, from the World Health Organizati<strong>on</strong> (WHO)1.9.10 CULTURAL HERITAGE REGULATIONS Mosaics C<strong>on</strong>servati<strong>on</strong> Management Policy Antiquities (enclosure) Rules c<strong>on</strong>cerning museums and historical sites (1959) Antiquities Law, 5738‐1978 Sites inscripted in UNESCO’s World Heritage Site1.9.11 OTHER REGULATIONS Licensing <str<strong>on</strong>g>of</str<strong>on</strong>g> Businesses Law 5728‐1968 (Amendment 1994) Freedom <str<strong>on</strong>g>of</str<strong>on</strong>g> Informati<strong>on</strong> Law 5758‐1998 Envir<strong>on</strong>mental Protecti<strong>on</strong> Law (Polluter Pays) (Legislative Amendments), 5768‐2008 Freedom <str<strong>on</strong>g>of</str<strong>on</strong>g> Informati<strong>on</strong> Regulati<strong>on</strong>s (Public Access to Envir<strong>on</strong>mental Informati<strong>on</strong>) 5769‐2009 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Emissi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Particulate Matter into the Air) 5733‐1972 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Air Quality), 5752‐1992 Regulati<strong>on</strong>s <strong>on</strong> Used Oil, 5753‐1993 Regulati<strong>on</strong>s <strong>on</strong> Preventi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Air Polluti<strong>on</strong> and Noise from Quarries, 5758‐1998 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Air Polluti<strong>on</strong> from Vehicles <strong>on</strong> a Road), 5761‐2001 Clean Air Law 5768‐2008 Clean Air Regulati<strong>on</strong>s (Emissi<strong>on</strong> permits 2010)1.9.9 NOISE REGULATIONS Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Law 5721‐1961 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Unreas<strong>on</strong>able Noise from C<strong>on</strong>structi<strong>on</strong> Equipment) 5739‐1979 Abatement <str<strong>on</strong>g>of</str<strong>on</strong>g> Nuisances Regulati<strong>on</strong>s (Unreas<strong>on</strong>able Noise) 5750‐1990Document No.3. Technical Specificati<strong>on</strong>s ‐8‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL2 WORK DESCRIPTIONThis line will enlarge the existing railway network to the East <str<strong>on</strong>g>of</str<strong>on</strong>g> Israel, providing c<strong>on</strong>necti<strong>on</strong> between thecoastal railway around Akko and Carmiel Stati<strong>on</strong> by means <str<strong>on</strong>g>of</str<strong>on</strong>g> an electrified double line.Akko ‐ Carmiel line is 21.6 km l<strong>on</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> double electrified track from K.P. 0+400 (Akko) to K.P. 21+584.425(Carmiel). It is expected that this line is going to be used by mixed traffic, passenger and freight trains.All the line is going to be c<strong>on</strong>structed <strong>on</strong> ballast but Gil<strong>on</strong> Tunnels, which will be assembled with slab track.Gil<strong>on</strong> Tunnels are two tunnels for a single track each. The exact KP where they start and finish are:There is just <strong>on</strong>e level crossing al<strong>on</strong>g the line which will be temporary in K.P. 19+675. It will be used during thec<strong>on</strong>structi<strong>on</strong> period but it could probably be used also during the service period.2.1.1 TRACK LAYOUTThis line will enlarge the existing railway network to the East <str<strong>on</strong>g>of</str<strong>on</strong>g> Israel, providing c<strong>on</strong>necti<strong>on</strong> between thecoastal railway around Akko and Carmiel Stati<strong>on</strong> by means <str<strong>on</strong>g>of</str<strong>on</strong>g> an electrified double line.The main characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> this line are:Double track.INITIAL KP (*) FINAL KP (*) LENGTH (M)Gil<strong>on</strong> tunnel 12+532.997 17+163.000 4,630.003(*)Mileage referred to Track 1Electrified.Mixed traffic: passenger and freight trains.22 km l<strong>on</strong>g approximately.The layout has been designed for a maximum speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 160 km/h. The maximum speed al<strong>on</strong>g the line variesbetween 50 and 160 km/h.There are two stati<strong>on</strong>s in this line:STATIONS KPO(*) KPF(*) STATION KP PLATFORM LENGTH (M)Achihud Stati<strong>on</strong> 9+312.941 9+645.249 9+483.766 300Carmiel Stati<strong>on</strong> 21+121.457 21+460.600 21+241.75 300The bridges in this line are:Track NUMBERInitial K.P.(*)Mileage referred to Track 1bridgesFinal K.P.LENGTH (m)Track 1 0+868.942 0+880.244 11.302Track 1 1+694.449 1+731.332 36.883Slab track <strong>on</strong>ly in the Gil<strong>on</strong> tunnels. Ballasted track in the rest.The line is planed throughout a hilly land. The layout is c<strong>on</strong>sequently adapted to it with a sequence <str<strong>on</strong>g>of</str<strong>on</strong>g> straightlines, transiti<strong>on</strong> curves and round curves in layout, and gradients and vertical transiti<strong>on</strong> curves in elevati<strong>on</strong>. Asa result, there will be a series <str<strong>on</strong>g>of</str<strong>on</strong>g> embankments and cuttings.The c<strong>on</strong>necti<strong>on</strong> between ISR and the new line is made at KP 0+400 <str<strong>on</strong>g>of</str<strong>on</strong>g> the new mileage although the tracklayout definiti<strong>on</strong> starts at the KP 0+000 is placed at the fr<strong>on</strong>t <str<strong>on</strong>g>of</str<strong>on</strong>g> the turnout which links track 1 with thecoastal line.This definitive layout has been developed from the next sources: Infrastructure Project <str<strong>on</strong>g>of</str<strong>on</strong>g> DP1 stretch ............................................................................... 3rd May 2012 Infrastructure Project <str<strong>on</strong>g>of</str<strong>on</strong>g> DP2 stretch ............................................................................. 14th May 2012 Infrastructure Project <str<strong>on</strong>g>of</str<strong>on</strong>g> DP3 stretch .............................................................................. 2nd May 2012 Infrastructure Project <str<strong>on</strong>g>of</str<strong>on</strong>g> DP4 stretch ......................................................................... 27th August 2012Track layout has been organised in different tracks as represented in the following track diagram:Track 1 2+171.223 2+252.348 81.125Track 1 3.081.78 3+092.200 10.420Track 1 8+798.45 8+890.75 92.3Track 1 8+946.03 9+085.12 139.09Track 1 10+271.487 10+303.651 32.164Document No.3. Technical Specificati<strong>on</strong>s ‐9‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELDocument No.3. Technical Specificati<strong>on</strong>s ‐10‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELAs a summary, the following table shows the characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> each track:TRACK NAME DEFINITION INITIAL KP FINAL KP LENGTH (m) KIND OF TRACKTrack 1 C<strong>on</strong>necti<strong>on</strong> with Coastal Line (right track) 0+000.000 21+589.430 21,589.430 Single trackTrack 2 C<strong>on</strong>necti<strong>on</strong> with Coastal Line (left track) 0+000.000 21+532.736 21,532.736 Single trackTrack 3 Dead end track, c<strong>on</strong>necti<strong>on</strong> with track 1 0+088.457 0+206.542 118.085 Single trackTrack 5 Siding in Carmiel Stati<strong>on</strong>, c<strong>on</strong>necti<strong>on</strong> with track 1 20+860.427 21+588.959 728.532 Single trackTrack 8Dead end track in Carmiel Stati<strong>on</strong>, c<strong>on</strong>necti<strong>on</strong> withtrack 5 20+812.926 20+948.715 135.789Single trackAlthough both 1 and 2 axis are defined from KP 0+000.000 respectively, the c<strong>on</strong>necti<strong>on</strong> between ISR and thenew line is made at KP 0+400 <str<strong>on</strong>g>of</str<strong>on</strong>g> the new mileage.2.1.2 WORKBASEThe work base is located between the K.P. 3+140 and the K.P. 3+940. It is almost at the beginning <str<strong>on</strong>g>of</str<strong>on</strong>g> the lineso it is close to the coast. It means that the materials arrive to the harbour near the work base and thetransport costs are reduced.The work base is <strong>on</strong> the left side <str<strong>on</strong>g>of</str<strong>on</strong>g> the main track and it is c<strong>on</strong>nected to the track no.2 by a 1/8 turnout.Due to the line is approximately 22 km l<strong>on</strong>g, the c<strong>on</strong>structi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> this work base is enough to carry out thetrack assembly.This work base is temporary so the c<strong>on</strong>necti<strong>on</strong> to the siding will be dismantled after the c<strong>on</strong>structi<strong>on</strong> period.Most <str<strong>on</strong>g>of</str<strong>on</strong>g> the materials which will be used for the assembly <str<strong>on</strong>g>of</str<strong>on</strong>g> the line are stocked in this place while others aredirectly place <strong>on</strong> site.The work base target is not <strong>on</strong>ly to store material but to form the grids before placing them in the track.2.1.3 SUPPLY LOGISTICSThe following diagram shows the operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the track material until they are place <strong>on</strong> site.The materials will arrive to the work base by truck. These trucks can gain access to the work base from theSouth, al<strong>on</strong>g the infrastructure service road.An internal road network that provides access to the camps and the installati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the base has beenplanned inside the base, which will be c<strong>on</strong>nected to the infrastructure service road.In additi<strong>on</strong>, an internal road network that provides access to the camps and the installati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the base hasbeen planned inside the base.It is important to take into account that this way <str<strong>on</strong>g>of</str<strong>on</strong>g> operati<strong>on</strong> is just a hypothesis. The C<strong>on</strong>tractor shouldstudy and decide this operati<strong>on</strong> way and the proposed staff according to the machinery availability and hisown requirements.2.1.4 TRACK ASSEMBLY METHODThere are different kinds <str<strong>on</strong>g>of</str<strong>on</strong>g> secti<strong>on</strong>s al<strong>on</strong>g the line. Depending <strong>on</strong> the type, the track assembly method canchange.It is important to remark that the slab track assembly method is a general <strong>on</strong>e due to the fact that the finalslab track system is not decided and it will finally be a C<strong>on</strong>tractor decisi<strong>on</strong>.Next sketch shows the way <str<strong>on</strong>g>of</str<strong>on</strong>g> assembling al<strong>on</strong>g Akko ‐ Carmiel line.Document No.3. Technical Specificati<strong>on</strong>s ‐11‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELTo give coverage to Gil<strong>on</strong> tunnel it is required to add four sites inside the tunnel at theinterc<strong>on</strong>necti<strong>on</strong> tunnels 3, 7, 12, 16.The Detailed Design provided by Motorola is attached in this document. It is noteworthy that for the delivery<str<strong>on</strong>g>of</str<strong>on</strong>g> the Mobile Communicati<strong>on</strong>s Detailed Design more detailed informati<strong>on</strong> should be given, that is: moreinformati<strong>on</strong> about the system, prices, <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the equipment, etc.2.1.7 SIGNALLINGThe new line begins at KP 17+490.67 <str<strong>on</strong>g>of</str<strong>on</strong>g> the existing line Tel Aviv ‐ Naharya and ends in the buffers <str<strong>on</strong>g>of</str<strong>on</strong>g> Carmielnew stati<strong>on</strong>.The new line has a double track with facilities for trains circulating in both directi<strong>on</strong>s.The project c<strong>on</strong>siders the following items:A halt, that will be Achihud's future stati<strong>on</strong>Electr<strong>on</strong>ic Interlocking at Carmiel stati<strong>on</strong>Akko has an electric interlocking (relays) and the project will include an interface to c<strong>on</strong>nect the newline with the existing <strong>on</strong>e.The Project will be projected and build by THALES company. This company is resp<strong>on</strong>sible for the signaling <str<strong>on</strong>g>of</str<strong>on</strong>g>the stati<strong>on</strong>s and the c<strong>on</strong>necti<strong>on</strong>s with the existing network.As this line will be electrified, it must be equipped with the necessary protecti<strong>on</strong>s for signaling systems.2.1.5 FIXED COMMUNICATIONThe analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> the fixed communicati<strong>on</strong> is developed in Annexe 12.2.1.6 MOBILE COMMUNICATIONMotorola has designed a soluti<strong>on</strong> to provide coverage to this railway line, having into c<strong>on</strong>siderati<strong>on</strong> that whenpassing through Gil<strong>on</strong> tunnel, communicati<strong>on</strong> with emergency services is also needed.The system proposed by Motorola is an existing analogue wireless communicati<strong>on</strong> system that providesanalogue communicati<strong>on</strong> from the locomotive to the centre <str<strong>on</strong>g>of</str<strong>on</strong>g> the system at “Massua” and LOD.According to the Detailed Design provided by Motorola:Two external sites must be added to give full coverage to Akko‐Carmiel line:Besides, the new line will run through the Gil<strong>on</strong> tunnels.2.1.8 TUNNEL SYSTEMSIt will be necessary for appropriate accomplishment <str<strong>on</strong>g>of</str<strong>on</strong>g> protecti<strong>on</strong> to have several security installati<strong>on</strong>s inorder to detect as so<strong>on</strong> as possible the incidents.These facilities included <strong>on</strong> this project are:POWER SUPPLY: It will supply the energy to the facilities. It Will have two power c<strong>on</strong>necti<strong>on</strong>sthrough two different power lines. It will exist a specific electrical building close to the East end withall the facilities and <str<strong>on</strong>g>technical</str<strong>on</strong>g> rooms dedicated to the energy system. VENTILATION SYSTEM: It Will provide the mechanical smoke c<strong>on</strong>trol in case <str<strong>on</strong>g>of</str<strong>on</strong>g> fire. There will be 30Jet Fans per each tunnel. According to the last CFD report the system will be able to c<strong>on</strong>trol firepower <str<strong>on</strong>g>of</str<strong>on</strong>g> 52 MW.−−One site at Carmiel railway stati<strong>on</strong>One site at Ahihud railway stati<strong>on</strong>.GSM COMMUNICATIONS: This facility will provide GSM cellular communicati<strong>on</strong>s in the tunnel inorder have radio communicati<strong>on</strong>s for general‐purpose: normal and emergency communicati<strong>on</strong>s.Document No.3. Technical Specificati<strong>on</strong>s ‐12‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIELSMOKE AND FIRE DETECTION SYSTEM: This facility c<strong>on</strong>trols the ventilati<strong>on</strong> system and it will be ableto measure the air quality and toxic gases like CO2 or NOx. On the other hand, the linear detecti<strong>on</strong>system is c<strong>on</strong>stantly measuring the temperature al<strong>on</strong>g the tunnel and it’s able to detect fastgradient increasing temperature or unusual temperature values.−−−FIRE SUPPRESSION SYSTEM (Fire Protecti<strong>on</strong>)EARTH DETECTION SYSTEM (Fire Protecti<strong>on</strong>)MOTION DETECTION SYSTEM (Fire Protecti<strong>on</strong>)CCTV: This facility will c<strong>on</strong>trol, the human or any other unusual presence, in the tunnels. For safetyreas<strong>on</strong>s in the circulati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> trains it’s very important to detect moving objects.IR TELEFONE: This is the emergency communicati<strong>on</strong>s ph<strong>on</strong>e for fire fighters, military and emergencyteams. It will communicate directly through the emergency c<strong>on</strong>trol room.LIGHTING: It Will provide the safety evacuati<strong>on</strong> route to the passengers in the case <str<strong>on</strong>g>of</str<strong>on</strong>g> suddenly stop<str<strong>on</strong>g>of</str<strong>on</strong>g> the train. The people shall follow the light signaling to arrive into the safety area or to the safetytunnel.PUBLIC ADRESS: It will be used to communicate with the people in case <str<strong>on</strong>g>of</str<strong>on</strong>g> emergency. The peopleshall follow the audio instructi<strong>on</strong> to avoid risky situati<strong>on</strong>s walking in the tunnel.PUMPING WATER SYSTEM (Fire Protecti<strong>on</strong>): This is the facility to protect the tunnel and the peopleagainst the fire. It has several comp<strong>on</strong>ents: tanks, pipes, valves… in order to create a pressurizedemergency water network for fire fighting.FIRE SUPPRESSION SYSTEM. This secti<strong>on</strong> defines the facility <str<strong>on</strong>g>of</str<strong>on</strong>g> fire suppressi<strong>on</strong> and detecti<strong>on</strong> systemin the interc<strong>on</strong>necti<strong>on</strong> galleries and <str<strong>on</strong>g>technical</str<strong>on</strong>g> room in the tunnel.EARTHQUAKE DETECTION SYSTEM: It will be used to detect earthquakes. Small detectors will beinstalled al<strong>on</strong>g the tunnel in order to provide earthquake informati<strong>on</strong>.MOTION DETECTION SYSTEM. The moti<strong>on</strong> detecti<strong>on</strong> system makes it possible to know the trainlocati<strong>on</strong> al<strong>on</strong>g the tunnel in real time.For the Detailed Design Tunnel Integrati<strong>on</strong> systems, all the following informati<strong>on</strong> should be provided by thedesigners <str<strong>on</strong>g>of</str<strong>on</strong>g> the different facilities:−−−−−−−−−POWER SUPPLYVENTILATION SYSTEMGSM COMMUNICATIONSSMOKE AND FIRE DETECTION SYSTEMCCTVIR TELEFONELIGHTINGPUBLIC ADRESSPUMPING WATER SYSTEM (Fire Protecti<strong>on</strong>)Document No.3. Technical Specificati<strong>on</strong>s ‐13‐

NETIVEI ISRAEL – NATIONAL TRANSPORT INFRASTRUCTURE COMPANY LTDDETAILED DESIGNRAILWAY LINE AKKO – CARMIEL3 CONSTRUCTIONS TASKSA great number <str<strong>on</strong>g>of</str<strong>on</strong>g> activities included in this Detailed Design have local <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s in Israel according to thecomm<strong>on</strong> practices in the country. The main groups <str<strong>on</strong>g>of</str<strong>on</strong>g> activities where Israeli <str<strong>on</strong>g>specificati<strong>on</strong></str<strong>on</strong>g>s are applicable are:3 PIPES3.3 PIPES FOR ELECTRIC INSTALATIONS3.4 PIPES FOR WATER SUPPLY3.5 PIPES FOR PLUMBING/SEWAGE1 EARTHWORKS1.1 EXCAVATION1.2 LANDFILL1.3 AGGREGATE SPREADING4 STEEL4.1 STEEL FOR REINFORCED CONCRETE4.2 STRUCTURAL STEEL1.4 AGRICULTURAL SOIL SPREADING1.5 EMBANKMENT1.6 SELECTED FILL1.7 AGGREGATE1.8 EARTHWORKS/TRANSPORTATION1.9 GEOTEXTILES5 PAVEMENTS5.1 BITUMINOUS MATERIAL5.2 COATS5.3 KERB5.4 ROAD SIGNALING1.10 INERTIAL FILL1.11 SUBBASE1.12 BASE COURSE1.13 BIAXIAL GRID6 DRAINAGE6.1 DITCH6.2 MANHOLE6.3 DITCH ON EMBANKMENT2 CONCRETE6.4 WATERPROOFING2.1 REINFORCED CONCRETE2.2 MASS CONCRETE2.3 FORMWORK2.4 CONCRETE DEMOLITION2.5 CONCRETE JOINTS2.6 MORTAR CEMENT7 FENCES7.1 FENCE7.2 DOORS7.3 CCTV7.4 SITE HUT3 PIPES3.1 TRENCH3.2 PIPES FOR DRAINAGEDocument No.3. Technical Specificati<strong>on</strong>s ‐14‐