Spunbond reinforcements for bituminous membranes made of ...

Spunbond reinforcements for bituminous membranes made of ...

Spunbond reinforcements for bituminous membranes made of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Environmental<br />

Product<br />

Declaration<br />

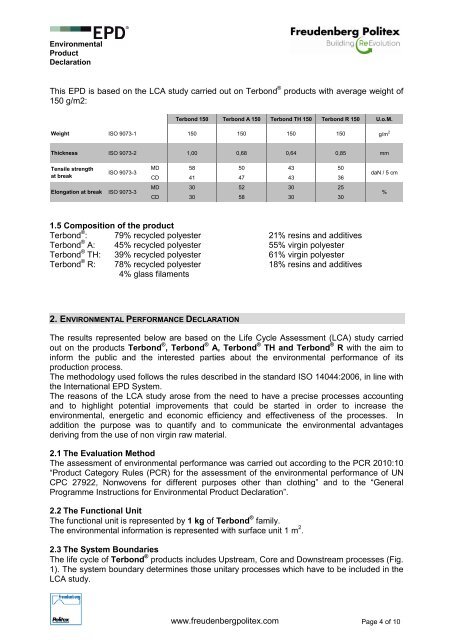

This EPD is based on the LCA study carried out on Terbond ® products with average weight <strong>of</strong><br />

150 g/m2:<br />

Weight<br />

Thickness<br />

Tensile strength<br />

at break<br />

Elongation at break ISO 9073-3<br />

Terbond 150 Terbond A 150 Terbond TH 150 Terbond R 150 U.o.M.<br />

ISO 9073-1 150<br />

150<br />

ISO 9073-2 1,00<br />

0,68 0,64<br />

0,85<br />

mm<br />

ISO 9073-3<br />

MD 58 50 43 50<br />

CD 41 47 43 36<br />

MD 30 52 30 25<br />

CD 30 58 30 30<br />

1.5 Composition <strong>of</strong> the product<br />

Terbond ® : 79% recycled polyester 21% resins and additives<br />

Terbond ® A: 45% recycled polyester 55% virgin polyester<br />

Terbond ® TH: 39% recycled polyester 61% virgin polyester<br />

Terbond ® R: 78% recycled polyester 18% resins and additives<br />

4% glass filaments<br />

2. ENVIRONMENTAL PERFORMANCE DECLARATION<br />

www.freudenbergpolitex.com Page 4 <strong>of</strong> 10<br />

150<br />

150<br />

g/m 2<br />

daN / 5 cm<br />

The results represented below are based on the Life Cycle Assessment (LCA) study carried<br />

out on the products Terbond ® , Terbond ® A, Terbond ® TH and Terbond ® R with the aim to<br />

in<strong>for</strong>m the public and the interested parties about the environmental per<strong>for</strong>mance <strong>of</strong> its<br />

production process.<br />

The methodology used follows the rules described in the standard ISO 14044:2006, in line with<br />

the International EPD System.<br />

The reasons <strong>of</strong> the LCA study arose from the need to have a precise processes accounting<br />

and to highlight potential improvements that could be started in order to increase the<br />

environmental, energetic and economic efficiency and effectiveness <strong>of</strong> the processes. In<br />

addition the purpose was to quantify and to communicate the environmental advantages<br />

deriving from the use <strong>of</strong> non virgin raw material.<br />

2.1 The Evaluation Method<br />

The assessment <strong>of</strong> environmental per<strong>for</strong>mance was carried out according to the PCR 2010:10<br />

“Product Category Rules (PCR) <strong>for</strong> the assessment <strong>of</strong> the environmental per<strong>for</strong>mance <strong>of</strong> UN<br />

CPC 27922, Nonwovens <strong>for</strong> different purposes other than clothing” and to the “General<br />

Programme Instructions <strong>for</strong> Environmental Product Declaration”.<br />

2.2 The Functional Unit<br />

The functional unit is represented by 1 kg <strong>of</strong> Terbond ® family.<br />

The environmental in<strong>for</strong>mation is represented with surface unit 1 m 2 .<br />

2.3 The System Boundaries<br />

The life cycle <strong>of</strong> Terbond ® products includes Upstream, Core and Downstream processes (Fig.<br />

1). The system boundary determines those unitary processes which have to be included in the<br />

LCA study.<br />

%