CLEAN GREEN MOTORING SMART PLANT PUMP IT UP - Cryostar

CLEAN GREEN MOTORING SMART PLANT PUMP IT UP - Cryostar

CLEAN GREEN MOTORING SMART PLANT PUMP IT UP - Cryostar

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

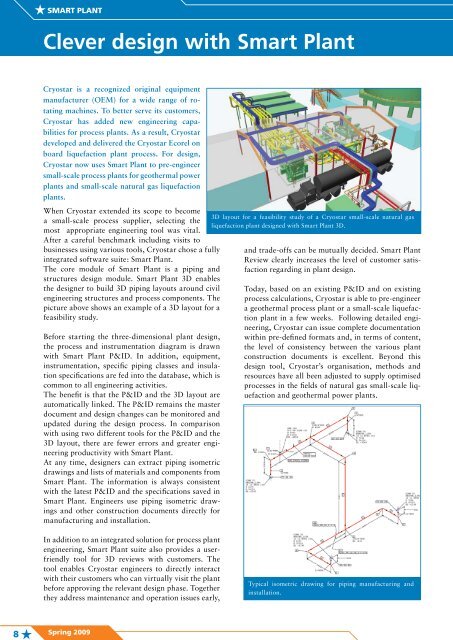

<strong>SMART</strong> <strong>PLANT</strong>Clever design with Smart Plant<strong>Cryostar</strong> is a recognized original equipmentmanufacturer (OEM) for a wide range of rotatingmachines. To better serve its customers,<strong>Cryostar</strong> has added new engineering capabilitiesfor process plants. As a result, <strong>Cryostar</strong>developed and delivered the <strong>Cryostar</strong> Ecorel onboard liquefaction plant process. For design,<strong>Cryostar</strong> now uses Smart Plant to pre-engineersmall-scale process plants for geothermal powerplants and small-scale natural gas liquefactionplants.When <strong>Cryostar</strong> extended its scope to becomea small-scale process supplier, selecting themost appropriate engineering tool was vital.After a careful benchmark including visits tobusinesses using various tools, <strong>Cryostar</strong> chose a fullyintegrated software suite: Smart Plant.The core module of Smart Plant is a piping andstructures design module. Smart Plant 3D enablesthe designer to build 3D piping layouts around civilengineering structures and process components. Thepicture above shows an example of a 3D layout for afeasibility study.Before starting the three-dimensional plant design,the process and instrumentation diagram is drawnwith Smart Plant P&ID. In addition, equipment,instrumentation, specific piping classes and insulationspecifications are fed into the database, which iscommon to all engineering activities.The benefit is that the P&ID and the 3D layout areautomatically linked. The P&ID remains the masterdocument and design changes can be monitored andupdated during the design process. In comparisonwith using two different tools for the P&ID and the3D layout, there are fewer errors and greater engineeringproductivity with Smart Plant.At any time, designers can extract piping isometricdrawings and lists of materials and components fromSmart Plant. The information is always consistentwith the latest P&ID and the specifications saved inSmart Plant. Engineers use piping isometric drawingsand other construction documents directly formanufacturing and installation.3D layout for a feasibility study of a <strong>Cryostar</strong> small-scale natural gasliquefaction plant designed with Smart Plant 3D.and trade-offs can be mutually decided. Smart PlantReview clearly increases the level of customer satisfactionregarding in plant design.Today, based on an existing P&ID and on existingprocess calculations, <strong>Cryostar</strong> is able to pre-engineera geothermal process plant or a small-scale liquefactionplant in a few weeks. Following detailed engineering,<strong>Cryostar</strong> can issue complete documentationwithin pre-defined formats and, in terms of content,the level of consistency between the various plantconstruction documents is excellent. Beyond thisdesign tool, <strong>Cryostar</strong>’s organisation, methods andresources have all been adjusted to supply optimisedprocesses in the fields of natural gas small-scale liquefactionand geothermal power plants.In addition to an integrated solution for process plantengineering, Smart Plant suite also provides a userfriendlytool for 3D reviews with customers. Thetool enables <strong>Cryostar</strong> engineers to directly interactwith their customers who can virtually visit the plantbefore approving the relevant design phase. Togetherthey address maintenance and operation issues early,Typical isometric drawing for piping manufacturing andinstallation.8 Spring 2009