Alternative Cooling Processes 1 Classification of Refrigeration Cycles

Alternative Cooling Processes 1 Classification of Refrigeration Cycles

Alternative Cooling Processes 1 Classification of Refrigeration Cycles

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

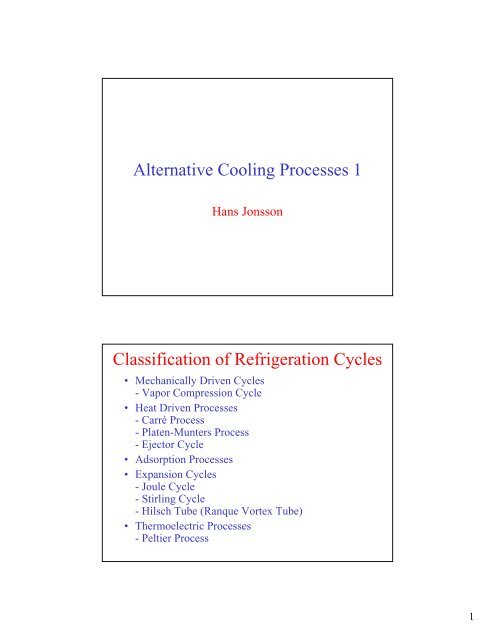

<strong>Alternative</strong> <strong>Cooling</strong> <strong>Processes</strong> 1Hans Jonsson<strong>Classification</strong> <strong>of</strong> <strong>Refrigeration</strong> <strong>Cycles</strong>• Mechanically Driven <strong>Cycles</strong>- Vapor Compression Cycle• Heat Driven <strong>Processes</strong>- Carré Process- Platen-Munters Process- Ejector Cycle• Adsorption <strong>Processes</strong>• Expansion <strong>Cycles</strong>- Joule Cycle- Stirling Cycle- Hilsch Tube (Ranque Vortex Tube)• Thermoelectric <strong>Processes</strong>- Peltier Process1

Agenda• <strong>Classification</strong> <strong>of</strong> Refrigerating <strong>Cycles</strong>• Heat Driven <strong>Processes</strong>- Carré Process- Platen-Munters Process- Ejector Cycle• Adsorption <strong>Cooling</strong>Heat Driven <strong>Processes</strong> 1• Driven mainly, or entirely, by heat• Most heat driven processes are absorptionrefrigeration processes• Absorption means that the refrigerant isabsorbed by another media, and transportedas a liquid solution during a part <strong>of</strong> thecycle.• An absorption process hence consists <strong>of</strong> amedia pair. One refrigerant and oneabsorbator.2

Carré <strong>Processes</strong> 2• Condenser, Expansion Device, and Evaporatoridentical to vapor compression cycle.• Compressor <strong>of</strong> vapor compression cyclereplaced by ”thermal compressor”.• Thermal compressor: Absorber vessel, pump,generator, regulation valve, heat exchanger.• Mainly heat driven.• Pressure increase done in liquid phase =>Considerably less mechanical energy required!Carré <strong>Processes</strong> 3COP ?For heat driven processes, COP H is defined<strong>Cooling</strong> capacity Refrigerant mass flow Latent heat <strong>of</strong> evaporationCOPSHQ&=Q&R2Hm&=m&⋅HOSR⋅ r( r + L)Generator heat input Solution mass flow Heat <strong>of</strong> mixingm& = m&+ m&⇒ m&> m&Hence COP H < 12SR4

Carré <strong>Processes</strong> 4Carré <strong>Processes</strong> 5Multi-stage systems improve COP H5

Carré <strong>Processes</strong> 6Carré <strong>Processes</strong> 7• If there is a heat source available then coolingcan be obtained at low cost.• Many sustainability aspects involved here…• Access to process waste heat, combustion gasesetc means that you recover heat losses andgenerate a refrigerating effect instead.• Solar driven cooling! <strong>Cooling</strong> demand increaseswith solar load…With these systems, coolingcapacity increses with solar load!• Robust technology!6

COP H vs COP 2 -1• Is the performance <strong>of</strong> an absorption processnecessarily worse than a vapor compressioncycle?COP H vs COP 2 -2The mechanical energy (electricity) for thevapor compression cycle has to be produced!7

COP H vs COP 2 -3Assume a thermal efficiency for a steam powerplant, η t = 0.35 and a COP 2 = 2.4 for a vaporcompression cycle.ThenQ&2⎧ Q&2⎫ COPCOPH,VC= = ⎨COP2= ⎬ =Q&H ⎩ E&⎭ Q&⎧ E&⎫ COP2⋅ E&= ⎨ηt= ⎬ = = COP2⋅ηt=⎩ Q&H ⎭ E&ηt= 2 .4⋅0.35= 0.842H⋅ E&=Carré <strong>Processes</strong> 8The Mosquito CoastNovel by Paul TherouxMovie by Peter Weir, 1986Starring: Harrison Ford, HelenMirren, River PhoenixAn eccentric and dogmaticinventor sells his house and takeshis family to Central America tobuild an ice factory in themiddle <strong>of</strong> the jungle. Conflictswith his family, a local preacherand with nature are only smallobstacles to his obsession.8

Platen-Munters <strong>Processes</strong> 1• Originated from a MSc Thesis work here at KTHin 1922.• Absorption process (using three different media)• The process has a constant total pressure in allparts <strong>of</strong> the system.• Different evaporation and condensation pressuresare achieved by introducing an inert gas into thesystem. This will make the partial pressure <strong>of</strong> therefrigerant change in different parts <strong>of</strong> the system.• Completely heat driven!• No moving parts - absolutely silent!Platen-Munters <strong>Processes</strong> 1• For which applications would this system besuitable?• Camping equipment (no electricity needed)• Mini bars in hotel rooms (absolutely silent)•COP H = 0.2 - 0.3• The company Dometic (formerly Electrolux)announced in June 2006 that the havemanufactured their 10 millionth refrigerator intheir plant in Motala, Sweden. Manufacturingstarted 1925.9

Platen-Munters <strong>Processes</strong> 2Platen-Munters <strong>Processes</strong> 3Hydrogen circuitWater circuit10

Platen-Munters EvaporatorAmmonia isgathered inbowls whereevaporationtakes placeRefrigerantinletHydrogen inletEvaporation <strong>of</strong> Ammoniadue to difference in partialpressure <strong>of</strong> Ammonia inthe bowl and in thehydrogen atmospheresurrounding it (comparediffusion in humid air).Hydrogen + AmmoniaoutletFlow downwards is dueto buoyancy effects(natural circulation).Platen-Munters AbsorbatorWater inletWater isgathered inbowls whereAmmonia isabsorbedHydrogenoutletAbsorption <strong>of</strong> Ammonia inthe water due to differencein Ammonia concentrationbetween Ammonia-watersolution in the bowl andthe Hydrogen-Ammoniaatmosphere surrounding it.Water + ammoniaoutletHydrogen + AmmoniainletFlow upwards is due tobuoyancy effects(natural circulation).11

Platen-Munters Thermosyphon PumpHead <strong>of</strong> gasliquidcolumn,H GLHead <strong>of</strong> liquid column, H LHeaterPlaten-Munters Thermosyphon PumpThe heads have to be equal for the pump to work, hence:ρL⋅g⋅ HL= ρGL⋅g⋅HGLBy adding heat in the thermosyphon pump, some <strong>of</strong> theliquid is evaporated in such way that:ρGL= ρLH⋅HLGLThe use <strong>of</strong> a thermosyphon pump in the system was theinvention <strong>of</strong> Baltsar von Platen and Carl Munters!12

Ammonia liquidPlaten-Munters <strong>Processes</strong>Condenser181756Hydrogen19Hydrogen free<strong>of</strong> AmmoniaAbsorberAmmonia vapourand Hydrogen716Strong solutionLow temperature EvaporatorLow temperature Pre-cooler15High temperature EvaporatorHigh temperature Pre-coolerPressure equilization lineWeak solution243912Ammonia vapourRectifier1181Vapour-liquid separatorLift-tubeHeat Exchanger13 10Heat suppliedto BoilerEjector Cycle 113

Ejector cycle• Condenser, Expansion Device, and Evaporator identical tovapor compression cycle.• Compressor <strong>of</strong> vapor compression cycle replaced by”ejector”.• Ejector: Acceleration <strong>of</strong> high pressure vapor causes a lowpressure which creates a suction to remove refrigerant vaporfrom evaporator.• Pressure increase done by compression shock followed by adiffusor.• Mainly heat driven.• Pressure increase done in liquid phase => Considerably lessmechanical energy required!• Heating <strong>of</strong> the generator could be done by waste heat, solarheating etc.Ejector Cycle 114

Sorption <strong>Cooling</strong>15