design standards and engineering specifications ... - Apache County

design standards and engineering specifications ... - Apache County

design standards and engineering specifications ... - Apache County

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

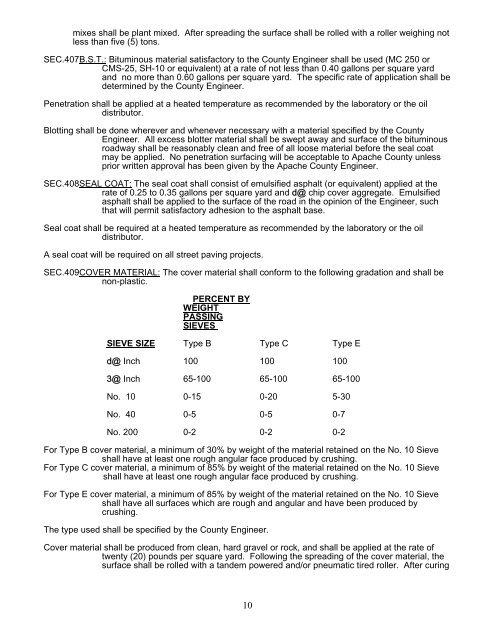

mixes shall be plant mixed. After spreading the surface shall be rolled with a roller weighing notless than five (5) tons.SEC.407B.S.T.: Bituminous material satisfactory to the <strong>County</strong> Engineer shall be used (MC 250 orCMS-25, SH-10 or equivalent) at a rate of not less than 0.40 gallons per square yard<strong>and</strong> no more than 0.60 gallons per square yard. The specific rate of application shall bedetermined by the <strong>County</strong> Engineer.Penetration shall be applied at a heated temperature as recommended by the laboratory or the oildistributor.Blotting shall be done wherever <strong>and</strong> whenever necessary with a material specified by the <strong>County</strong>Engineer. All excess blotter material shall be swept away <strong>and</strong> surface of the bituminousroadway shall be reasonably clean <strong>and</strong> free of all loose material before the seal coatmay be applied. No penetration surfacing will be acceptable to <strong>Apache</strong> <strong>County</strong> unlessprior written approval has been given by the <strong>Apache</strong> <strong>County</strong> Engineer.SEC.408SEAL COAT: The seal coat shall consist of emulsified asphalt (or equivalent) applied at therate of 0.25 to 0.35 gallons per square yard <strong>and</strong> d@ chip cover aggregate. Emulsifiedasphalt shall be applied to the surface of the road in the opinion of the Engineer, suchthat will permit satisfactory adhesion to the asphalt base.Seal coat shall be required at a heated temperature as recommended by the laboratory or the oildistributor.A seal coat will be required on all street paving projects.SEC.409COVER MATERIAL: The cover material shall conform to the following gradation <strong>and</strong> shall benon-plastic.PERCENT BYWEIGHTPASSINGSIEVESSIEVE SIZE Type B Type C Type Ed@ Inch 100 100 1003@ Inch 65-100 65-100 65-100No. 10 0-15 0-20 5-30No. 40 0-5 0-5 0-7No. 200 0-2 0-2 0-2For Type B cover material, a minimum of 30% by weight of the material retained on the No. 10 Sieveshall have at least one rough angular face produced by crushing.For Type C cover material, a minimum of 85% by weight of the material retained on the No. 10 Sieveshall have at least one rough angular face produced by crushing.For Type E cover material, a minimum of 85% by weight of the material retained on the No. 10 Sieveshall have all surfaces which are rough <strong>and</strong> angular <strong>and</strong> have been produced bycrushing.The type used shall be specified by the <strong>County</strong> Engineer.Cover material shall be produced from clean, hard gravel or rock, <strong>and</strong> shall be applied at the rate oftwenty (20) pounds per square yard. Following the spreading of the cover material, thesurface shall be rolled with a t<strong>and</strong>em powered <strong>and</strong>/or pneumatic tired roller. After curing10