Composition of BÃHLER metal powders - Tenica

Composition of BÃHLER metal powders - Tenica

Composition of BÃHLER metal powders - Tenica

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

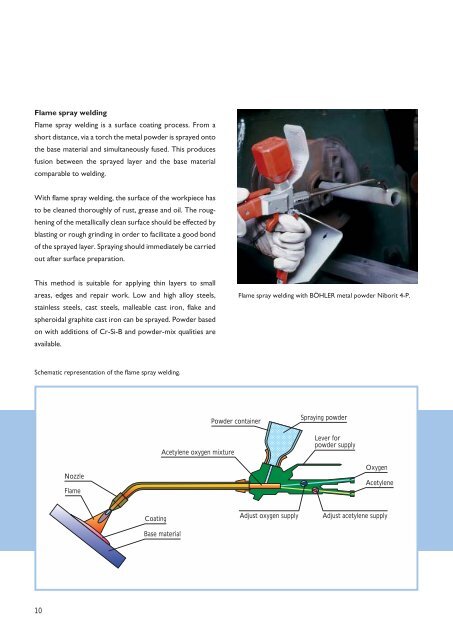

Flame spray weldingFlame spray welding is a surface coating process. From ashort distance, via a torch the <strong>metal</strong> powder is sprayed ontothe base material and simultaneously fused. This producesfusion between the sprayed layer and the base materialcomparable to welding.With flame spray welding, the surface <strong>of</strong> the workpiece hasto be cleaned thoroughly <strong>of</strong> rust, grease and oil. The roughening<strong>of</strong> the <strong>metal</strong>lically clean surface should be effected byblasting or rough grinding in order to facilitate a good bond<strong>of</strong> the sprayed layer. Spraying should immediately be carriedout after surface preparation.This method is suitable for applying thin layers to smallareas, edges and repair work. Low and high alloy steels,stainless steels, cast steels, malleable cast iron, flake andspheroidal graphite cast iron can be sprayed. Powder basedon with additions <strong>of</strong> Cr-Si-B and powder-mix qualities areavailable.Flame spray welding with BÖHLER <strong>metal</strong> powder Niborit 4-P.Schematic representation <strong>of</strong> the flame spray welding.Acetylene oxygen mixturePowder containerSpraying powderLever forpowder supplyNozzleFlameOxygenAcetyleneCoatingBase materialAdjust oxygen supplyAdjust acetylene supply10