It's Here! - CablePrice

It's Here! - CablePrice

It's Here! - CablePrice

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

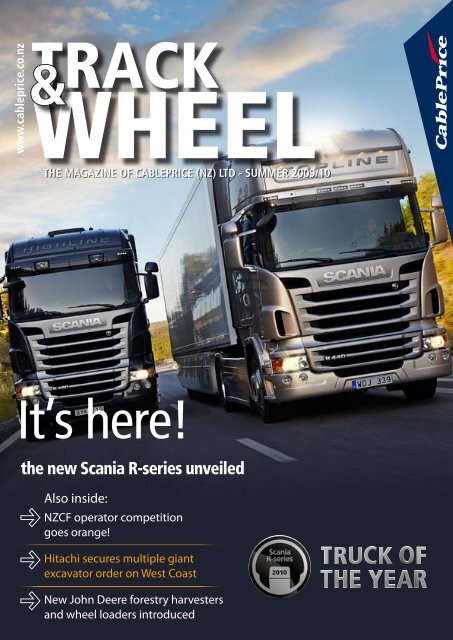

www.cableprice.co.nzTHE MAGAZINE OF CABLEPRICE (NZ) LTD - SUMMER 2009/10It’s here!the new Scania R-series unveiledAlso inside:NZCF operator competitiongoes orange!Hitachi secures multiple giantexcavator order on West CoastNew John Deere forestry harvestersand wheel loaders introduced

TRACK & WHEELTRACK&WHEELTHE MAGAZINE OF CABLEPRICE (NZ) LTDSUMMER 2009/10<strong>CablePrice</strong> BranchesWhangarei43 South End Avenue P 09-470 0433PO Box 11094 Port Whangarei F 09-470 0434North Shore39 Anvil Road, P 09-426 1280Silverdale F 09-426 1281Track & Wheel is published on behalf of:<strong>CablePrice</strong> (NZ) LtdSales & Marketing DivisionHead Office3 Tunnel GroveGracefieldLower HuttWellingtonNew ZealandTelephone: 04 568 4289Facsimile: 04 568 4283Email:sales@cableprice.co.nzWebsite: www.cableprice.co.nzEditor:<strong>CablePrice</strong> (NZ) Ltd; Glenn CroasdaleDesign & Printing: Blue Star GroupCopyright: <strong>CablePrice</strong> (NZ) Ltd 2009,all rights reserved.Auckland1102 Great South Road, Westfield P 09-270 1360PO Box 14 528 Panmure F 09-270 1363Rotorua171-131 Tallyho Street, P 07-349 0610PO Box 747 F 07-349 0611Hamilton87 Ruffell Road, Te Rapa P 07-850 8429Gisborne2-4 Tuapaea Street, Awapuni P 06-867 0928PO Box 341 Gisborne F 06-867 1376HastingsHenderson Road, P 06-879 8170PO Box 22 29, Stortford Lodge F 06-879 8172Palmerston North7 Bisley Street, P 06-356 1880PO Box 4468 F 06-356 1824Wellington3 Tunnel Grove, Gracefield, P 04-568 4289PO Box 38-040 F 04-568 4283Nelson5 Kotua Place, P 03-541 0200Richmond F 03-541 019912Christchurch29 Waterloo Road, P 03-349 0610Hornby, PO Box 6030 F 03-349 0310Greymouth65 Preston Road, Blaketown P 03-769 9005PO Box 335 F 03-768 7057Invercargill203 Clyde Street, P 03-214 4439PO Box 908 F 03 214 44342

TRACK & WHEELContents12 Hitachi AH500D finds tractionon the West CoastFollowing a demonstration of the world’s largest ArticulatedDump Truck in Hamilton in November 08, Birchfield Coal MinesLtd from the West Coast became the country’s first owners ofthe 50-ton Hitachi AH500D. Track & Wheel visited the familyowned Giles Creek Mine North-West of Reefton, to see howthe truck was going.16 Cutting out the RecessionCMA Recycling recently turned to Hitachi to help boostoperational productivity in their Auckland recycling facility.Auckland Area Manager, Brett Howlett finds the Hitachi isgiving him a trouble-free ride.19 Multiple Giant Mining Excavator DealIn September the newly formed Stockton Alliance announcedthe purchase of four large Hitachi mining excavators. TheAlliance announced that two Hitachi EX1200-6 and twoHitachi EX1900-6 mining excavators (110 tonne and 190 tonnerespectively) had beaten off stiff competition to form the coreof the excavation fleet at Stockton.20 It’s a dirty job but someone has to doze itThe Wellington City Council recently selected the John Deere 850Jlow ground pressure dozer to help them mitigate odour issue in theirSouthern Landfill, and fulfil their obligations to their surroundingcommunity as a responsible neighbour under the RMA.22 Revolution in ForestryJohn Deere Forestry has released the new E-Series – an all newrange of forestry harvesters and forwarders redesigned from theground up. We look into what’s changed and how it will helpimprove your productivity in the bush.25 Unveiling the new Scania R-SeriesIn September 2009, Scania launched the new R-series truckrange, featuring improved aerodynamics, greater cooling, anergonomic design and luxurious interior styling, a new 2-pedalautomated Opticruise transmission and the premier of theworld-first Scania driver support system. Track & Wheel takesa 12-page look into the innovations that make up the newtruck, which also helped get the new R-series awarded theinternational Truck of the Year for 2010.38 Living the DreamPalmerston North based distributors, contracting to Foodstuffsunder the AF logistics banner, the Winiata brother talk to Track& Wheel about their beginnings, their fathers’ influence on theirlives and businesses, and the whole families’ love of Scania.22 25Copyright: <strong>CablePrice</strong> (NZ) Ltd 2009/2010, all rights reserved. Reproduction in whole or in part is forbidden except with the written permission of the publisher. The opinionsand thoughts expressed in this publication, whether factual or otherwise, are those of the individual writer and do not necessarily reflect those held by <strong>CablePrice</strong> (NZ) Ltd.While every effort is made to ensure the accuracy of information published in Track & Wheel, <strong>CablePrice</strong> (NZ) Ltd accept no responsibility for inaccuracies or omissions.3

TRACK & WHEELChanging rules of business2009 has been a year of significant change. The economy wentfrom record growth over the past decade to an unparalleleddecline in business activity and consumer confidence in the spaceof a year. The world watched while businesses struggled tosurvive under tight credit controls, economic stimulus packagesand contentious government bail outs, and saw others innovate,restructure and reinvent themselves to survive.At the same time many of the worlds leading economiesexperienced shifts in their political landscape. In New Zealand,the National Party became the ruling party for the first time ina decade, while the Democratic Party took back control of theSenate and Oval Office in the United States. In Japan, after62 years in the political wilderness the Democratic Party alsoregained ruling power. We know from experience that politicalchange is cyclical, yet for many this recession has been the firstmajor realisation that economics, too, seem to share such a fate.The impact of the global recession can not really be understated;it has been the largest economic recession since the 1930’s andthere is no hiding that it cut deep into world economies andbusinesses alike. I liken the recession to the effects of sufferingfrom the flu. At first, the symptoms are not easily diagnosed,but gradually you feel worse, your body begins aching, and acough and fever may develop into a more serious illness suchas pneumonia, if not treated properly and promptly. Althoughwe can find medicines such as Tamiflu or Relenza for influenza(though not a cure-all) there are no ready-made vaccines for asick business world. We must create our own medicines or findsolutions by ourselves.This past year <strong>CablePrice</strong> has been doing just that. When otherswere scaling back we stepped it up. We aggressively supportedour industries at T.H.E Expo, Fieldays, as the major sponsor ofthe NZCF excavator competitions and through sponsorships ofindustry conference. We provided multiple solutions to customerswith promotions such as the Hitachi Big Box package, trailerservicing campaign, parts and service specials, and so forth. Wehave emphasized the importance of after sales and preventativemaintenance and worked hard to keep in regular contact withour customers. Even in these trying times, we have continuedto invest in staff training and new product developments (theintroduction of the new Scania R-series, John Deere K-serieswheel loaders, JH series harvesters and now E series forwarders).This year also saw more <strong>CablePrice</strong> technicians obtain <strong>CablePrice</strong>Master Technician status under the training and developmentprogram launched in 2007, aimed at developing the highestlevel of skilled technicians in the industry, and we opened newbranches in Hamilton and Gisborne - all of which focused aroundenhancing the support we can provide our customers. And we’renot stopping there - we have more solutions planned to kick offthe New Year that will make it easier for you to invest in yourbusiness with new plant - and support it more efficiently.Like the medical analogy I referred to above, sometimes the cureto our illness is not always painless and when making changes wehave to make some sacrifices, but that’s not to say that change isalways a bad thing. Without it complacency can infiltrate withunnatural stealth. Being forced to stop and reflect on where youare and how you got there can often help you refocus on whereyou want to be and how best you can get there.Whether the economy is strong or weak our “First Choice”mission at <strong>CablePrice</strong> will never change. We consistently pursuethe goal of being the number one provider to our customers.How we get there is another thing altogether, and while I can notpredict what 2010 and beyond has in-place for us all, I can assureyou that <strong>CablePrice</strong> will continue to listen to our customers,evolve along with our rapidly developing products, and change asand where change is required to ensure we fulfill our mission andcommitment to you.I believe we are all recovering from a serious flu and hopeeverybody can now enjoy some sunny summer weather withfamily and friends and lots of energy - and carry this sunny andpositive disposition into the New Year!Merry Christmas & a Prosperous New Year.Shunya (Sean) HashimotoManaging Director4 TRACK & WHEEL

TRACK & WHEELHelping RebuildSamoaOn the 29th September, life changedforever for thousands of people affectedby the Tsunami that hit Samoa and Tongaand devastated the small quiet islands.In Samoa over 150 people were killed,including 7 Kiwis. Over 400 families losttheir homes and businesses.Habitat for Humanity New Zealand(HFHNZ) responded immediately to theTsunami by sending a team to Samoa toassess the situation and to position itself asthe primary NGO working in partnershipwith the Samoan government and otherNGOs in the repair and construction ofemergency and long term shelter.Having now been asked to manage theconstruction of 400 traditional homes,called fale, in Samoa, HFHNZ has sentan initial team of 10 builders, plumbersand electricians to begin renovations ofa church hall in Lepa, on the southeastcoast of Upolu, for accommodating upto 50 Kiwi volunteers at one time. Theteam will also set up a HFHNZ ResourceCentre at Lepa, where core house kit-setscontaining all the materials needed tobuild a traditional house will be massproducedand sent to final sites for quickbuilding.After seeing news articles and reportson the impact the natural disaster hadon the small island community, Wanakabased contractor Graham Lee approachedHabitat for Humanity and generouslyoffered his contracting services in thepreliminary stages of the infrastructurerebuild project - being prepared to go toSamoa for a couple of months and assistwith vital earthworks and infrastructurereconstruction projects.When approached by Graham Lee,for logistical advise on moving hisown Hitachi excavator from Wanakato Auckland (ready for shipment toSamoa) to assist in his efforts forthe rebuild operation, ManagingDirector of <strong>CablePrice</strong> (NZ) Ltd, SeanHashimoto, says “the company saw agreat opportunity to offer more than justadvice.”Graham initially contacted <strong>CablePrice</strong>’sAuckland Sales Specialist, MalcolmPascoe, and advised Malcolm of hisintentions to work with HFHNZ. “Iknew that Hitachi had supported theAsian Tsunami recovery effort withgenerous donations of machinery”says Malcolm, “so I asked around andeventually propositioned our ManagingDirector as to whether Hitachi wouldconsider such support again.” Withouthesitation Sean Hashimoto respondedthat as the disaster occurred within<strong>CablePrice</strong>’s regional territory, and as awholly owned subsidiary of Hitachi, hefelt it was <strong>CablePrice</strong>’s responsibility torepresent Hitachi on this occasion, andsaid <strong>CablePrice</strong> would be keen to help.<strong>CablePrice</strong> offered Graham the completeuse of a Hitachi EX120-5 12 tonneexcavator from their Auckland branchfor his three month venture to Samoa.The company also covered the costs offreighting the excavator to the devastatedpacific island.In mid November, following a thoroughinspection and service by <strong>CablePrice</strong>’sAuckland workshop, the Hitachiexcavator was shipped to Samoa, arrivingin Apia around the end of November. Inearly December, Graham Lee assembleda team and flew to Samoa to join theexcavator and began their earthworksrestoration efforts, in cooperation withHabitat for Humanity New Zealand.Whilst there, Graham has and willcontinue to work on reconstructionand clearance projects based aroundrebuilding Samoa’s vital infrastructurenetwork.Interested in helping in Samoa?As the Resource Centre takesshape in Lepa HFHNZ are lookingfor people to go to Samoa forapprox two week periods andhelp in this work. If your businesscould provide a team, go to theirwebsite www.habitat.org.nz orcontact Devie at the Habitat office09 579 4111 ext 209 for moreinformation.5

TRACK & WHEEL2009: A year to shineWhile 2009 has certainly been a year of challenges, for <strong>CablePrice</strong> it has also been a year of significant milestones…T.H.E Expo, March 2009While the economy was beginningto get itchy feet about the scale andlength of a possible global recession,<strong>CablePrice</strong> kicked into the Transport& Heavy Equipment (T.H.E) expowith the largest and most impressivedisplay in its recent history. On top ofrecreating a Hollywood-style branch onsite, <strong>CablePrice</strong> also showcased Svempalimited edition Scania trucks as well asScanias’ Euro 4 and 5 technologies -including their SCR 620hp R-series. Andwho can forget the rumble and sound ofSvempa’s 1,000 hp Scania R999 – theshow stopper!On top of winning best site award,<strong>CablePrice</strong> also picked up best livedemonstration for its use of Hitachiexcavators, wheel loaders and ADT’sin a professional and realistic workingdemonstrations.NZCF Excavator OperatorCompetitionProud new sponsors of the NZCFExcavator Operator competition,<strong>CablePrice</strong> supplied machinery, technicalsupport and prizes for the National Finalof the 08/09 competition at Mansfield Parkin Fielding in March. In recent historyHitachi operators have dominated thefinal and it was a proud Brett Hollymanfrom the Hawkes Bay who eventuallyoutscored the highly regarded and reigningchampion, Brian Hoffman, to be awardedthe new excavator operator championstitle. Continuing the sponsorship in2009/10 <strong>CablePrice</strong> have supportedregional events in the build up to March2010 to find the next excavator operatorchampion. Read more on page 15.First Hitachi AH500DFollowing a successful demonstrationof the world’s only 50-ton articulateddump truck to prospective customers inHamilton in November 08, <strong>CablePrice</strong>delivered the country’s first HitachiAH500D ADT into Birchfield Coal’sWest Coast based mining operation. Readmore about it on page 12.New Scania R-SeriesIn launching the new R-series, Scania became theonly manufacture to launch a new truck during theglobal recession. The new R-series features improvedaerodynamics, greater cooling, an ergonomic designand luxurious interior styling, a new 2-pedal automatedOpticruise transmission and the premier of the world-firstScania driver support system. Read all about the newmodel in our exclusive 12 page feature from page 25.6

TRACK & WHEELNew John Deere products2009 saw three new John Deere productranges introduced into the country; firstSteve Lee of Lee Logging in NorthCanterbury purchased a purpose built753JH harvester to improve his woodproduction and lead the charge towardsmechanisation in the forest - the future offorestry in NZ. This was closely followedby Mark Lealand of Rotorua whobecame the owner of the first K-serieswheel loader – the 15-ton 624K - for hislogging operation in Kaingaroa. Finally,in late 2009 <strong>CablePrice</strong> announced theintroduction of the third new John Deereproduct available for our market, the Eseries wheeled harvesters and forwarders.Read more about these on page 22.2009 Road showsFollowing the success of the T.H.E Expo,Svempa and his amazing R999 touredthe country burning up their tarmac ofa number of <strong>CablePrice</strong> branches anddelighting customers who came fora closer look at the beautifully handcrafted masterpiece. The R999 toured NZfor two weeks post-T.H.E expo beforesailing to Australia to be on display at theMelbourne truck show. The R999 roadshow was followed by an R620 SvempaLimited Edition Scania, on a nationalcustomer demonstration tour. The truckwas sold half way through the tour!FieldaysOne of the wettest Fieldays in recenthistory, and right in the middle of therecession, <strong>CablePrice</strong> bucked the trend ofdropping out of industry events such asthese, and launched the Hitachi Big Boxpromotion with great success. Even withthe bad weather and recessionary moodof many, attendances were only down by10% and enquiry remained strong. Thecompany also sponsored the Hamiltonexcavator competition at this event.Conference SeasonAlthough the economic climate saw ascaling back in some industry conferencesas well as the cancellation of theAustralian destined RTF conference,<strong>CablePrice</strong> were proud to continuesponsoring the Groundspreaders,Contractors, IOQ / AQA and NZBCAconferences in 2009. <strong>CablePrice</strong> remainscommitted to the industries we support inboth the good and bad times.7

TRACK & WHEELtimeTO recogniSEBaby boomers are gearing up for their retirement andwill likely leave the country with a shortage of skilledcandidates for their replacement. They have lived through anumber of market depressions and account for the majority ofsenior positions and directorships within the workforce - builtupon a solid foundation of hard-work and strong businessacumen from years of experience. The term Generation Xwill be a well known phrase to many. This segmentationof people born within a mid 1960’s – 1980 birth-range areregarded as quiet yet determined hard workers, with manytypically making up middle management positions andholding ambitions for greater recognition in the near future(although possibly viewed as aggressive by their senior Babyboomer generation). Gen Y are the new graduates and currententrants into the workforce, and do not get off as lightly onthe criticism front. They have been grouped together byphysiologists and human behavioural experts based upon theirbirth range being post 1981 and labelled as selfish, time poor,non-committal and transient, commonly referred to as the ‘Yme’ generation. On the other hand, they are also consideredextremely technologically savvy, very efficient communicators(albeit in undistinguishable txt codes) and dogmaticallydetermined.While each generation has its own particular strengths andweaknesses, our economy is at a cross-road and at the presenttime, each generation plays a valuable part in the workforces’diversity, experience and future direction - with all threecontinuing to play a significant role in most organisations forat least the next decade.With an increasingly transient workforce and the growingcosts of recruiting and training staff in an increasinglycomplex world, employers are looking to ways to developemployee loyalty – a concept that is thought to be, by some, adissipating trend – especially in the younger generations.At <strong>CablePrice</strong>, the company’s management undertookmidway through 2009 (a difficult year for all businesses – andstaff alike) to recognise and reward its long standing loyalemployees and further promote and develop staff loyalty.In launching a new long service recognition programme,Managing Director Sean Hashimoto commented, “while thecurrent economic environment has called on us all to makesacrifices, we can not lose focus of what is most important andvalued to us as a company.”“The old saying that employees are a company’s greatest assetis only an old saying because its foundations are rooted inhistory and experience - it has stood the test of time.”“The relevance of the experienced, loyal and motivatedemployee is never more essential than when market conditionsare at their lowest, and as a company we must recognise andclearly display the value we hold for their loyalty and skills”.The new long service recognition programme launched inAugust, formally recognises milestones at 10, 20, 30 and 40years of service with monetary rewards increasing in value andadditional leave entitlements, once specific levels of servicehave been reached. Additionally, on their anniversary theregion or department are provided a morning tea to celebratethe employee’s service, and recognise their contributions tothe company.This year alone, <strong>CablePrice</strong> has been honoured to havetwenty-one staff reach significant milestones of long service.“The experience our long serving employees possess, andtheir continued loyalty, are one of the fundamental strengthsof <strong>CablePrice</strong> as a company” exclaimed Mr. Hashimoto,before continuing “22% of the company’s current workforcehas been with the company for over 10 years. Such loyaltyreflects positively on <strong>CablePrice</strong> as a good place to work anda company offering real opportunities for career development.8

TRACK & WHEELAt 46 years of consecutive employment with <strong>CablePrice</strong>, Beverly Cooper is thecompany’s longest serving employee. Beverly is the Upper Northern RegionsAdministration Manager based out of our Auckland branch on Great South Road.Our high levels of staff loyalty also reflect the value thecompany places on being a good employer who looks afterand rewards their employees.”Exemplary Service AwardAlso announced at the same time was the introduction ofa bi-monthly service excellence recognition award wherenominations are made by employees and their peers. Thereward was developed to recognise the many situations whereindividuals and teams within the company go the extra mile inthe effort to provide exemplary service to the customer.Careers @ <strong>CablePrice</strong>For more information on a career at <strong>CablePrice</strong>, and notjust a job, visit the careers section of our website atwww.cableprice.co.nz/careersEmployees who have achieved major milestones since January(including milestones not formally recognised in the reward scheme).Beverly CooperGeoff BellingerBruce ForresterPaul BruhnColin BowdenBarry SheatGlenn GoadGeoff FallowMartin WheldonLesley ForresterTony RyanGraeme PenneyBarry HarveyDerek ChurchesGeorge PongaJames CauserPeter DoldenKeith YoungAlan LogieGary NeillNorman Turnbull46 years & the company’s longest serving employee.40 years30 years30 years25 years25 years25 years20 years15 years15 years15 years15 years15 years15 years15 years10 years10 years10 years10 years10 years10 years9

TRACK & WHEELJOHN DEERE K-SERIESWHEEL LOADERSWith the release of an all new K-Series range of wheel loadersfrom John Deere, <strong>CablePrice</strong> can now offer our customerstwo exceptional wheel loader brands. The new slogan for theK-Series John Deere wheel loaders couldn’t be more spot on –Hard work was never this easy! As the most advanced wheelloader on the market today, the K-Series takes the three tenetsof John Deere machine design – productivity, uptime, and lowerdaily operating costs – to all new levels. This is a machinedesigned to work – day in, day out.All of the models in the K-Series are Loadrite ready, andfeature advantages such as solid state electronics, highly efficientQuad-Cool cooling and advanced diagnostic monitors.Traditional John Deere durability is inherent in the new K-Seriesdesign, including features such as heavy-duty wet-sleeve engines,self-adjusting wet-disc brakes, four-plate loader frames, andarticulation joints with double tapered roller bearings. Boomsand mainframes are so tough they’re warranted for three years or10,000 hours.The largest of the K-Series, the 844K weighing in at almost32-ton and with a bucket capacity of between 4.6 – 6.8m3 , alsofeatures both joystick steering and a steering wheel as standard, aswell as a rear camera / radar object detection system.<strong>CablePrice</strong>’s National Equipment Sales Manager, Andrew Cranesays “the new K-Series are built to last, with amazing features andsuperior operating comfort.” We’re really excited to finally havethe new K-Series available for our market, and to be able to offerour customers the choice of two premium wheel loader brands.”10

TRACK & WHEELMAKE MODEL WEIGHTkgBUCKETm3BreakoutkgfSTATIC TIPFULL TURN KgPOWERkW@rpmJohn Deere 544K Z-Bar 12820 1.9 – 4.5 10278 9434 125@1900 2270John Deere 544K Powerllel 13840 1.9 – 4.5 8604 7554 125@1900 2680John Deere 624K Z-Bar 15185 2.5 – 5 12920 12031 147@1800 2870John Deere 624K Powerllel 16454 2.5 – 5 10759 9257 147@1800 2700John Deere 644K Z-Bar 18160 2.8 – 5.0 15377 13126 173@1700 2840John Deere 644K Powerllel 18547 2.8 – 5.0 13664 11813 173@1700 2790John Deere 724K Z-Bar 19130 3.3 – 5.0 14398 14204 197@1800 2790John Deere 744K Z-Bar 24182 3.8 – 5 19395 17123 227@1500 3050John Deere 824K Z-Bar 26210 4.2 – 6.1 18905 17588 248@1600 3200John Deere 844K Z-Bar 31792 4.6 – 6.8 21709 20282 283@1600 3330DUMP HEIGHT(45o dis.)mm11

TRACK & WHEEL50-TONNEHitachi ADTgains traction in West Coast mine.In late 2008, <strong>CablePrice</strong> held a working demonstration of the worlds largest articulated dump truck- the 50 tonne rated Hitachi AH500D. Present among approximately fifty industry guests for thedemonstration at J.Swap’s Taotaoroa Road Quarry, just outside Cambridge, were Gary Birchfield andhis nephew Steffan Jamieson of Birchfield Coal Mines Ltd.ARTICLE BY GLENN CROASDALE12

TRACK & WHEELGary’s parents, Max and Betty Birchfield, began working theopen cast Giles Creek coal mine in 1984 processing througha flume and a trommel screen, with a capacity of about 15 tonnean hour. Since taking the mine over from their parents around adecade ago, Max’s five children have been focused on increasingthe tonnage going out of the mine by investing in productiveand durable machinery, and are now processing in excess of 300tonnes of coal an hour. With new infrastructure able to processsuch quantities, Gary looked towards his trucks to get a lot morecoal up from the pit to the top site, in a hurry – but wet wintersrestricted his rigid trucks ability to operate, and Gary says the40-tonne ADT’s were not able to carry enough.The mines coal is sub bituminous, low in sulphur and has cleanburning, heat retaining characteristics making it ideal for encloseddomestic burners and inner city industrial use. Giles Creek coalis also perfect for blending with faster burning, higher heatvalue coals as it captures the hotter heat and ensures thorough& economical combustion. There are estimated reserves of 16million tonnes of recoverable coal in the current permitted areaand the mine currently processes coal at a rate of 100,000 tonnesper annum – but the region is also known for some of the harshestand most unpredictable weather in the country.Impressed with the size and performance of the AH500D’s abilityto cart a 50-ton payload in the dry November conditions of thedemonstration, Gary was however, concerned that it would notbe able to foot it in poorer underfoot conditions such as those hefrequently experiences during typically wet West Coast winterswith such a weight on its back. So to prove the trucks ability<strong>CablePrice</strong> took the AH500D to the Birchfield’s Giles Creek Minein the Maimai Valley, North-West of Reefton in early 2009, to putthe truck to the test.A month after the Hitachi AH500D was demonstrated to theBirchfields on their turf, I travelled to the Maimai Valley to visitthe owners of the country’s first 50-tonne ADT at the Birchfield’sGiles Creek mine to discover how the truck was faring in thechallenging West Coast conditions – and I couldn’t have pickeda better day to test it out. It was a miserable Autumn morning,requiring two attempted landings into Hokitika before myflight was able to break through the low-settled cloud denselyblanketing the West Coast. I had arrived in the middle of aweather bomb!Eventually I arrived at the mine and soon got talking with Karen,one of Gary’s sisters and co-shareholder. She says “Gary andSteffan’s presence at the Hamilton demo made a difference, buttesting the truck onsite made the biggest impact. Seeing themachine, operating it and being able to know it would do the jobthey wanted it to do down in the pit, was a big influence.”Gary explained that the Hamilton demo gave him a goodappreciation of just how big a truck the AH500D is, but said “Iwas still worried about putting that sort of weight on the truck,that it wouldn’t hold up. But since having it onsite we’ve foundthat our fears didn’t hold water” and he adds “it handles theground as good as the 40-tonners do.” Prior to the rigid trucksthey were using 40-tonne ADT’s in the mine to cart coal, butfound the smaller trucks just couldn’t cart enough.From Karen’s point of view the fact a new truck would have lessdowntime was attractive, but she says “for the others, its abilityto work in bad weather and its ability to compete on load capacitywith the rigid trucks were also influencing factors.” In fact, oneof the most persuasive arguments for Gary was the ability of theAH500D to carry the same loads as their 50-ton rigid trucks andstill be able to operate in poor underfoot conditions where therigid trucks could not. Today was certainly going to be a goodtest for that. When I arrived at the mine, what I saw palpablyvindicate Gary’s rationale; parked up were two large rigid offroadtrucks whilst with precision timing the AH500D ascendedthe haul road and passed in front of me with a full load of coal onits back, keeping traction and good speed with obvious ease inthe muddy conditions. Later in the morning I would take a ridein the truck and experience it operating comfortably in the pit innear knee-deep mud, in ground conditions which could only bedescribed as atrocious thanks to the deluge of rain that showedlittle sign off abating. Interestingly, the day prior dust was thebiggest problem at the mine!TO THE NEXT PAGE13

TRACK & WHEELFROM THE PREVIOUS PAGE“Looking out her porta-com office window at the low fog andheavy precipitation Karen says “it can stay like this for weekshere. So for all weathers with that capacity, we were quiteimpressed.” Gary says “Because the articulated trucks can keepworking in the wet, the pit can stay open and it gives us thecontinuity of supply for our customers that we had been lookingfor. We now have the ability to access the deepest parts of the pitwith a 50 ton capacity truck.”Additional to the Hitachi AH500D’s ability to work through thebad weather, another of its benefits according to <strong>CablePrice</strong>’sNational Equipment Sales Manager Andrew Crane, lies in itsability to move more tonnes per litre burnt. With fuel prices asthey are today there is potential for real savings in this area – andthat’s a point the Birchfield’s agree strongly with.Both Gary and Steffan came back from the Hamilton trial veryimpressed with the fuel consumption figures the AH500D wasproducing - which were easily downloaded from the truckscomputer during the two day event. Gary comments “the way theprice of fuel was going…fuel consumption had a big bearing onour decision – from my point of view anyway.”Operating the AH500D is one of the mines youngest staffmembers, and a female. With quality training and a delicatefemale touch, 20 year-old operator Danielle Lineham has quicklyfound herself at home in the company’s newest piece of mobileplant. Having come off an old rigid truck she says of her newworkstation; “It’s pretty nice compared to the older rigid I was in.It’s a lot more comfy and has a real smooth ride.”Highlighting what had quickly become obvious to me as Itravelled around the mine in the surprisingly spacious andcomfortable cabin with Danielle, she says “when it rains like thisthe roads as you can see, can become difficult, and so it makes it alot nicer being in this compared with all the other vehicles.”Although Danielle says, “it’s a bit slower because it’s biggerand it takes more time to turn around” [than the 40-ton ADT’soperating at Giles Creek] she points out “it’s carting a lot more atthe same time though”, which makes it much more productive.Waiting at the bottom of the pit while the 28.2m3 capacity binwas being loaded with overburden from a 40 tonne excavatorat the pond edge, and looking ahead of us at the steep andincreasingly slippery haul road caused by the persistent rain,Danielle says “today the rigid’s wouldn’t have a chance ofclimbing this.” Once loaded she gets the toot from the excavatoroperator and depresses the accelerator pedal. Immediately theV8 rumbles to life and the 512hp German engineered MercedesBenz engine begins pulling us out from the base of the pit. Fullyloaded the six-wheel drive AH500D comfortably ascends thesteep access road 80m above the base of the pit to the overburdendumping site approximately 200m ahead of us, without strain.When carting coal Danielle travels the 2.5km haul road, climbinga further 120m to the coal processing plant near the minesentrance.As Danielle completes a tipping cycle and the automatic binlowering mechanism kicks in to cushion a soft bin lowering, shecomments one of the other things she likes about the truck is itssimplicity of use. The AH500D features a fully automatic Allisontransmission with touch pad shift control, automatic downshiftsand retarder activation, and abuse-proof Controlled TractionDifferentials (CTD). Danielle says she likes how the trucksdesign and simplicity to operate means that the operator canconcentrate on the job at hand, and believes it means “the Hitachiwill last a little longer than others.”Due to the dependency the rest of the mine has on the trucksto meet demand and fulfil their orders; a vital criterion for theBirchfields was reliability. With a long history of having runHitachi product in their operations the Birchfield’s had a lot offaith in both the brand and <strong>CablePrice</strong> as their service provider.Because of their relative isolation they also took out a fouryear extended warranty and service contact on the AH500Dwith <strong>CablePrice</strong>. Gary says the extended warranty and servicecontracts were important, suggesting it meant the truck was beingproperly serviced and importantly, it allowed them to concentrateon mining. Gary adds that he likes how a service contact alsotakes the hassle away from servicing and holding stock of oils andfilters.With the rigid trucks parked up on a day like today, it’s theAH500D’s ability to keep the mine running that was so enticingfor the Birchfield’s. Their ability to match load capacity with therigids and leave smaller ADT’s for dead in the productivity stakes,whilst still maintaining strong fuel efficiency and the renownedADT ability to go anywhere, all add up to the total package thatwas so evidently being displayed at the Giles Creek mine. Withthe Birchfield’s having invested so much into the infrastructureof the mine - over the past five years especially - Gary says “nowwe’re reaching a stage where we’re going deeper in the pit, itsgood to know that with the AH500D we have that continuityof supply during bad weather – being able to work through theweather bomb proved that!”14

TRACK & WHEEL<strong>CablePrice</strong> and Hitachidig into Operator CompetitionAs the global economic crisis bit into thelocal economy, charities, clubs, groupsand associations have felt the harsh biteof its teeth. Many companies have cutmost-if-not-all marketing, sponsorshipand/or donations spending as they try tocurb the effects of declining sales.In late 2008/early 2009, the New ZealandContractor’s Federation found themselvesin this exact position. Their previous longterm sponsor had pulled support of theregional and national excavator operatorcompetition at the last minute, leaving thefederation without a sponsor for the finalrounds of its regional competition andscurrying to find a new sponsor in timefor the national finals at Mansfield Park inFeilding, during March 2009.Having been involved with the excavatorcompetition during its early inceptionmany years ago, National Marketing &Brand Manager for <strong>CablePrice</strong>, GlennCroasdale, says “<strong>CablePrice</strong> were excitedabout the opportunity of the machinerysponsorship finally becoming available.”“We were disappointed that ourassociation with the event had beensqueezed out years earlier, but did notthink the main sponsorship opportunitywould become available. So whenMalcolm Abernethy approached us,we were delighted for the opportunityto support the event – and importantly,provide machinery to ensure the eventscontinuation”, says Croasdale.“Since signing on, we have been involvedin the national final in March, andalmost every regional event to date. Wehave received amazing support fromcontractors for our commitment to theevent, with many saying it was abouttime they saw more orange at the event– after all, the winners podium has beendominated by Hitachi operators for thepast few years”, Croasdale adds.A Hitachi ZX120-3 12 tonne excavatorand a 6 tonne ZX60USB short radius tailswing mini excavator have travelled thecountry following the regional events anddemonstrating the speed and power ofHitachi’s Zaxis-3 design technology. Bymid November the machines had beento the Hamilton branch competition inJune at the National Fieldays at MysteryCreek, and been used by Gisborne,Hasting, Taranaki and Canterbury NZCFregions to find the first five finalists forMarch 2010.The winners of the regional events for09/10 (up until Mid Nov):Defending ChampBrett Hollyman, Contrax, HastingsHawkes BayStacey Pompey, Quality Roading &Services (Wairoa) LtdWaikatoTim Graham, Hypace Earthworks LtdGisborneAdrian Friar , Paul White LtdTaranakiJonathon NoonanCanterburyHamish Waddell , Calcon LtdNZCF Excavator OperatorCompetitions for the remainderof 2009/10 season.23 January 2009 Otago Regional ExcavatorCompetition, 150th TaieriA&P Show, Mosgiel10 – 12 February Southland RegionalExcavator Competition,Southern Field Days13 February Bay of Plenty RegionalExcavator Competition, TePuke A&P Show20 – 21 February Auckland RegionalExcavator Competition,Franklin A&P Show27 February Wellington/WairarapaRegional ExcavatorOperator Competition.Summer Carnival,Upper Hutt28 February Manawatu RegionalExcavator OperatorCompetition, Esplanade DayPalmerston North5 March Northland RegionalExcavator OperatorCompetition (Location TBC)19 – 20 March National Final, CentralDistricts Field Days. Feilding15

TRACK & WHEELCutting outthe recessionCMA Recycling turns to Hitachifor increased efficiency.16

TRACK & WHEELIn September of 2005, Australian metal recyclingcompany CMA Recycling bought AucklandbasedScrap Metal Recyclers. Re-branded undertheir Australian parent company’s name, CMAhas entered new markets and expanded theiroperations in the upper North Island of NewZealand by the addition of a Tauranga branch tocompliment the existing Auckland and Hamiltonoperations.Auckland Area Manager, Brett Howlett says “CMA seesrecycling as a key component in the process of modernwaste management. We help to significantly reduce the wasteof potentially useful materials through resale, reduce theconsumption of finite raw materials, energy, and contribute to abetter environment through responsible recycling.”The industry has been through a rollercoaster ride with metalprices over the past couple of years, and although our economyis currently depressed, Brett says CMA is experiencing steadydemand for processed scrap metal. Although you might expectChina to be the major contributor to this demand, he says “itis going to steel mills all over the world, with places like Asiabeing the hungriest for scrap metal, which they use to melt downand recycle into other products – thus the conservation of finitenatural resources.”Although the economic downturn has had an impact on CMA -along with almost every other business in the country – Brett says“the company has continued to invest in plant and machinery toensure a more efficient operation that improves productivity andreduces operating costs. Any efficiency that we can make in anyarea is a bonus. The cheaper we can process scrap material for,the more beneficial it is for us.”An example of this approach has been the introduction of a 33-ton Hitachi ZX330LC-3 excavator fitted with a La Bounty MSD2500R front attachment hydraulic shear. Prior to this CMA useda static shear to cut their steel, as well as gas cutting. Whilethey still do a little manual gas cutting, Brett says “the HitachiZX330LC-3 with shear attachment is a lot more versatile becauseof its mobility and the fact it can rotate”.Prior to their purchase, the Auckland recyclers had littleexperience with Hitachi excavators, yet for their new owners,CMA Recycling in Australia, it was a different story. Specialisingin contracting and demolition CMA attach specialist recyclingattachments to base model excavators, typically in the 20 – 35tonne class. “In Australia the company brought about 12 newmachines off Hitachi last year alone” says Brett.In Auckland CMA Recycling focuses on collection, processingand recycling of predominantly secondary ferrous and non-ferrousmetal products and utilise specialist high-rise-cab scrap recyclingprocessors. So when it came to adding an excavator fitted witha cutting shear to the operation, Brett says the company drew ontheir Australian parents knowledge and experience of Hitachi’sreliability and performance.Brett says the selection of the base model was predetermined bythe size of the shear and the lifting capacity and hydraulic flowrequired for operating it. CMA, in consultation with <strong>CablePrice</strong>,spec’ed the Hitachi ZX330LC-3 with an additional 750kg on topof the standard counterweight, to ensure additional stability andbalance when lifting and using the six-and-a-half-tonne shear. Notsurprisingly for the conditions it works in, additional cab guardingand piping were also specified, as well as a foot pedal control forthe shear.“The machine runs every day and doesn’t give us any trouble atall” says Brett. Having been put to work at the beginning of theyear, the ZX330LC-3 now has just less than 1,400 hours on theclock.TO THE NEXT PAGE17

TRACK & WHEELFROM THE PREVIOUS PAGEBefore talking to the operator Brett comments “they seem happyenough with it. There are certainly no complaints.” He adds“In our industry no complaints is a good thing. Our guys don’ttypically rave about gear, they just get on and do the job. But youcertainly know if something’s not liked by someone because itwon’t get used as much or looked after.”Brett typically likes to keep one man on each machine as muchas possible as he feels they tend to look after it more and takeownership. Vili, the main operator for CMA is a good illustrationof this. Although the machine does not do much walking, it isconsistently slewing, reaching for, and lifting large, and oftenawkward shaped sharp objects whilst surrounded by heavyscrap metal in a confined working space. After nine monthsof operation the machine barely sports a scratch – except onthe shear (which is to be expected in this application), which istestament to Vili, and CMA’s operation in general.Vili says he likes the speed of the Hitachi and of the cuttingshears, which is evident as he cuts through reinforced steel likeit were butter. “I enjoy the comfort. It is very good” says Vili,who also comments that the slew speed and responsiveness of thelevers makes working the shears easy.From a management and health and safety perspective Brett sayshe appreciates the cabin environment and the camera on the back.“That camera on the back is a really good added safety feature inthis kind of application and the ergonomics of the cab are quitewell set out too.”While the market has certainly contracted over the past year,CMA Recycling have looked at their operation and invested inprocesses and machinery that provide long term profitable returnsthrough improved efficiency. Brett says “the timing of thedelivery was unfortunate due to the down-turning economy, yeton the other hand we were happy to just get a new machine withthe shear on it.” With recent economic reports showing NewZealand ended its fifth successive quarter of recession, CMA’sinvestment may just yet prove timely, as with the new HitachiZX330LC-3 and shear cutter they are certainly geared for theupturn and increased production levels.18 TRACK & WHEEL

TRACK & WHEEL<strong>CablePrice</strong>secures multiplegiant excavatordeal at StocktonOn the back of Solid Energy’s announcementthat it has concluded an agreement withDowner EDI Mining to jointly operatethe Stockton coal mine in an alliancearrangement from 3 October 2009,<strong>CablePrice</strong> & Hitachi have secured an orderfrom the Alliance for the purchase of four100+ tonne mining excavators.On 7 September 2009 the Alliance formally announced thepurchase of two Hitachi EX1200-6 and two Hitachi EX1900-6mining excavators (110 tonne and 190 tonne respectively) through<strong>CablePrice</strong> (NZ) Ltd for delivery from December this year. Thefour Hitachi heavy mining excavators will form the core of thenew excavation fleet at Stockton. Decisions about additionalequipment will be taken next year when plans for mining theMillerton and Cypress areas of the mine are more advanced.Solid Energy Chief Executive Officer, Dr Elder says: “We wereextremely pleased to confirm that Stockton Alliance were takingover mining operations from 3 October. At Stockton we havea world-class coal resource of premium coking coal which candeliver substantial export earnings to New Zealand over thenext 20 years. To maximise the mine’s value and to operate itsafely we needed a step change in operational performance. Thisrequired a substantial investment in skilled people, in new fit-forpurposeplant and equipment, and in systems. Stockton Alliance,a new and innovative approach to mining in New Zealand, willbring together one group of people in one team committed toachieving a common set of objectives.”The investment in new plant and machinery, together with the$110 million investment in the coal processing plant, and mineexpansion development and site infrastructure upgrades ofapproximately $14 million, brings Solid Energy’s total investmentin Stockton Mine to about $200 million this year.Managing Director for <strong>CablePrice</strong>, Sean Hashimoto says: “Weare delighted to secure the order of four giant mining excavatorsto Stockton Alliance. I believe this reflects Hitachi’s globalposition as the leading manufacturer of mining excavators andreflects the value and confidence Solid Energy and Downer EDIMining see in our machines. We now look forward to getting themachines to work and demonstrating the exceptional performanceof the products as well as the added value <strong>CablePrice</strong> can providethrough our back-up support.”19

TRACK & WHEELIt’s a dirty job butsomeone’s got to doze itJohn Deere 850J revels in the dirty work!The Southern Landfill, operated by Wellington City Council,is the biggest and busiest landfill in the Wellington region.Although there are additional rubbish facilities in the GreaterWellington Region, the Southern Landfill is the main disposalfacility for residents and businesses in the Capital. Recently theCouncil added a John Deere 850J dozer to its fleet to help thelandfill run smoothly and act as a ‘good neighbour’ by managing itsimpact on nearby residential suburbs.Located in Carey’s Gully – off the cold and desolate, yetironically-named Happy Valley, and just inland from CookStrait, the Southern Landfill is exposed to the elements andis often battered by the region’s notorious winds. Since thelandfill is close to thousands of households, staff are vigilantabout mitigating its environmental impact. The landfill operatesaccording to strict Resource Management Act rules – particularlythose relating to vermin and odour.At the end of every day the Council is required to apply a layerof rock and dirt across the top of the day’s delivery of generalrubbish and sewage sludge (a by-product from the city’s sewagetreatment plants). The layer of earth acts to block the escape ofundesirable odours and prevent vermin from easy access to scrapsand rubbish. It also helps to break down the waste in a more20environmentally efficient way, reducing the environmental impactof the tip.With over 20 years and more than one rebuild on its over-ageddozer, the Council chose to invest in a modern and more efficienthydrostatic driven John Deere 850J dozer to do the job.The Council’s Landfills Operation Manager, Tony Tupaea, says“The main function of the 850J is to cover at the end of the day.It’s part of our resource consent requirement to have a dozer atall times ready to cover the day’s rubbish. We mix all the sludgein the rubbish and at the end of the day we cover it with rock anddirt.”The Council is now landfilling the pungent-smelling sludgewhich, until last year, had been used to help create compost ina huge purpose-built building on the landfill site. The facilityhad operated for almost a decade but had been the subject ofcontinuing complaints from surrounding residents because of thesmells it generated.Tony Tupaea says that before the Council started burying thesludge “we were getting up to 10 complaints a week aboutodours. We started taking it in August last year and would havebeen lucky to have 10 complaints since”.

TRACK & WHEELFrom far left: The 850J LGP dozer making light work of ripping upthe earth at the WCC landfill.Left top: covering rubbish at the landfill.Bottom left: The 850J's instrument cluster.Right: A close up look at the rippers ploughing through the earth with ease.“A dozer was crucial for this kind of work” says Tony. “It’s neededfor ripping virgin ground, pushing over off the batters and coveringup, but its primary function is covering up at the end of the day.”He adds. “Now that we do the sludge, we have to have that”.After pricing and testing a number of machines, Tony says theCouncil considered the John Deere the one most suitable for thelandfill duties. “It had plenty of power for what it did, which wasgood for us because we could bulk stockpile a lot of earth and atthe end of the day just sweep it across our rubbish.” Tony adds“we weren’t prepared to have something that would take two-orthreegoes to get rid of a truckload of dirt.”Tony also mentions the operator cabin as being “friendly”,saying “It’s easy to get in and out of and everything is finger tipcontrolled. “With this one [the 850J] you can just open hand thecontrols and just use our thumbs or the side of our hand. Theprecision is excellent”John Deere say the 850J has ‘best-in-class’ visibility from thespacious cabin with window placement spanning all sides ofthe operator for a full 360 degree panoramic view of the jobsite.“There’s good vision all round” says Tony, adding that theyincluded additional mirrors inside the cabin to minimise theoperators’ need to continually twist their bodies when reversing.Tony’s comments on operator comfort, ergonomics andconvenience are mirrored by those of Mike Paul, one of themachine’s regular operators. As he hopped out of the dozer afterfilling over some rubbish he says “it’s really comfy.” “I like thecontrol you have in it and it’s smoother to operate without manualgear changes”, courtesy of John Deere’s hydrostatic transmission.The 850J’s automatic, dual-path, hydrostatic drivetrain hasa load sensing feature that automatically adjusts speeds andpower to match changing load conditions as well as providing awhole arsenal of hydrostatic advantages, including power turns,counterrotation, and infinitely variable travel speeds. Poweredby a John Deere PowerTech Plus 6090HT engine, the 850JLGP model boasts 200hp (152kW) at 1,800rpm for exceptionalpushing power and 915Nm of torque. “It’s got tonnes of pushingpower” adds Mike, saying “even going up hill it can push througha 40-tonne wall of dirt no problem”.Occasionally driving the dozer himself, Tony agrees, “The poweris excellent. If we want the power, just push the button and it’sright there.” He says going into a hydrostatic driven dozer overthe conventional type takes a little getting used to, but the trainingand support provided by <strong>CablePrice</strong> - with dedicated John Deeretechnical support staff - helped the landfill’s staff to quicklyfamiliarise themselves with the different functions of the machine,which Tony says “has helped us get good use out of it”.The 850J is now due for its first 250-hour service from<strong>CablePrice</strong>. Although the machine is still just bedding itself in,Tony says “it’s been excellent. It’s working well and we haven’thad any need to call <strong>CablePrice</strong> for any big things. Everything isrunning quite well at the moment.”From a regular maintenance point of view the landfill also seemshappy with the dozer. “Everything’s easy to get at, everything’sright there” says Tony. “You don’t want to be climbing up anddown over it, especially in weather like this!” Just as the landfillstaff take their responsibility to the local residents seriously, andseek to protect them from undesirable smells or dangerous byproductsof refuse collection, they also take the health and safetyof their staff very seriously. This philosophy combined with the850J’s excellent ergonomics, safety compliance and serviceabilityall had a bearing of the landfill’s decision to run with John Deere.21

TRACK & WHEELJohn Deere RevolutionNew E-series harvesters and forwarders unveiled.Major investments in R&D coupledwith continuous product updatesand innovations guarantees JohnDeere’s position as the pioneer in forestmachine quality and design. In additionto efficiency, product developmentexperts focus on improving comfortand ergonomics in the operatorsworking environment and minimisingenvironmental impact. Such dedicationhas lead to what John Deere is callinga Revolution in forest machinerydevelopment with the unveiling of theground-up redesigned E-series harvestersand forwarders.With an efficient design and newlyenhanced features, the new John DeereE-series forwarders give forestry operatorsmore comfort, control, and durability thanever before. The operating environmentfeatures a turning and levelling cabin aswell as an enhanced friendly automationsystem. The feature packed E-seriesharvesters and forwarders will deliverhigher productivity, lower daily operatingcosts, and maximise uptime.The most visually noticeable upgradeof the E-series is the introduction of arotating cabin design with a 290o turningenvelope, which enables operators toquickly rotate the entire cabin betweendriving and loading positions, eliminatingthe operator’s need to worry about turningthe seat inside the cab. The rotating cabgives the operator a full 360-degree viewof the machine’s surroundings, so theoperator has the best possible visibility100% of the time, without having tostrain their neck or swivel their seat. Thecabin quickly and smoothly follows themovements of the grapple (or felling headon the new harvesters), making logloading(or processing) accurate, efficientand ergonomic. John Deere says thisminimises operator fatigue and furtherimproves jobsite and operating safety.An optional cab levelling feature isavailable on all E-series harvesters andforwarders. Responding to changes inthe terrain, the levelling cab keeps theoperator in a level working position toallow for faster driving, further boostingproductivity. Settings for the seat, turningand levelling functions are fully adjustableaccording to operator’s preference.The E-series harvester and forwarderengines have been designed and builtspecifically for the demanding conditionsof harvesting and forwarding. Thebest torque in its class coupled withexcellent fuel economy and improvedengine component durability translateinto lower daily operating costs. Acrossthe four harvester and five forwardermodels the new John Deere PowerTech TMTier 3 engines range between 127 – 255horsepower, generating between 530-1250Nm of torque and boast higherengine output and tractive force thanprevious models.John Deere’s forest machine engines,gearboxes and bogies guarantee machineproductivity and reliability as well asthe operators comfort. The unique ECOmode together with a software featurethat automatically optimises the machinesRPM’s means lower fuel consumptionand improved durability. The balancedbogies and heavy duty axles offer asuperior performance in demandingterrain, ensuring efficiency and highspeed in all conditions. The infinitelyadjustable VarioSpeed speed regulatorin forwarders guarantees uninterruptedoperation, which means unfailingoperation from one day to the next. Thenew gear boxes and axles on the E-seriesadd another 10% to the tractive power ofall forwarder models.A new CommandCentre TM displayreplaces the TMC display used onD-series forwarders and features arefined simple and easy to use design.New optional TimberMatic F-09 andTimberLink F automation softwareprograms give the operator easy access toadjustments while continually monitoringthe health and productivity of themachine.22

TRACK & WHEELIn designing the E-series, John Deeresays special attention was paid toensuring that servicing the machinesis as easy and fast as possible, whilstallowing longer intervals betweenservices. “It is particularly importantthat the daily and weekly servicing canbe performed smoothly because timespent on servicing is time away from themachine’s daily uptime”, Andrew Craneof <strong>CablePrice</strong> points out. All parts thatrequire daily maintenance or checks areeasily accessible. For example, all theparts that require lubrication are groupedtogether. All manuals and parts lists aswell as a service advisory system fortroubleshooting can be found on themachines built-in computer. The cab canalso be hydraulically tipped 70 o , allowingeasy access for more major servicing.In addition to product support, servicepersonnel participated in the testing ofthe new E-series and offered numerousimprovement suggestions. All enginecovers are now electronically operatedand they have high-power service lights,and the tilting of the forwarder’s cabinto the servicing position is also doneelectronically.Another of the features that lengthens theservice intervals is the engines PowerCoreair filter, which has a pre-cleaningfunction. Cyclone technology is used toforcefully rotate the air coming into thefilter so that a big part of the impuritiesare removed before they reach the actualfilter. The new models also have ahydraulic radiator fan with a cleaningfunction. The fan automatically rotates inthe opposite direction for a short periodof time at regular intervals, blowing awayimpurities that have accumulated on theradiator. “The radiator had to be cleanedthoroughly and frequently, especially industy operating conditions. In the newmodels, the required daily cleaning ofthe radiator is done automatically”, saysAndrew Crane.The hydraulically operated and fuelconservingautomatic Smart Cool fanand easy maintenance make the enginesproductive and reliable in all types ofweather conditions – from hot and dustyto cold and snowy.Another significant new function relatedto keeping the machine running isthe by-pass filter for hydraulic oil; itremoves moisture and fine particles fromthe hydraulic system. Consequently,components last longer and malfunctionsare reduced considerably.All E-series forwarders now feature a newkind of frame. The V-shape of the bottomimproves the machines manoeuvrabilityover rocky terrain. Durability is alsoimproved by the HD bogie axles.E series forwardersModelCapacity(metric ton)WheelConfigurationPower (hp /kW)810E 9 8W 127/95 5301010E 11 6W / 8W 155/115.5 6451110E 12 6W / 8W 183 / 136 7801210E 13 6W / 8W 183 / 136 7801510E 15 6W / 8W 195 / 145 8001910E 19 6W / 8W 249 / 186 1090E series HarvestersTorque (Nm)Model Boom (m) Reach Head Power (Hp / kw) Torque (Nm)1070E 180S 8.6, 10, 10.8 745, H752, H412, 183 / 136 780H4141170E CH6 10, 11.3 745, H752, H754, 194 / 145 935H412, H4141270E CH7 8.6, 10, 11.7 H270, H752, H754, 228 / 170 1125H414, H758HD, H4801470E CH8 8.6, 10, 11 H270, H290, 758HD,H480255 / 190 125023

TRACK & WHEEL<strong>CablePrice</strong>deliversfirstJohn DeereJH seriesharvesteRIn September <strong>CablePrice</strong> delivered a purpose built John Deere 753JH tracked harvester, complete with WaratahHTH622B processing head, to Canterbury based Lee Logging. The 753JH represents the first JH series John Deeretracked harvester delivered into New Zealand and has quickly gained the confidence of its new owner, Steve Lee.The machine was delivered by <strong>CablePrice</strong> into the BalmoralForest in North Canterbury where Lee Logging has a contractfor the felling, delimbing and processing of post wood. The753JH joins a John Deere 1710D forwarder, Bell 220C triloggerand Hitachi EX225USR-5 as the newest addition in LeeLogging’s fleet – all sold and delivered by <strong>CablePrice</strong>.The 22,400kg harvester is powered by a 6-cylinder turbochargedJohn Deere PowerTech 6081H engine capable of delivering241 hp @ 2,000 rpm. The 753JH also includes 24” single grousershoes, Deere’s own Waratah Timberite measuring system softwareand a heavy duty harvester boom with integrated ‘plug-and-play’commonality between the Harvester and Waratah attachment.The fully integrated measuring system for “plug-and-play” Waratahheads on all JH models is powered by an efficient multifunctionalhydraulic system. This new hydraulic system knows when andwhere the power is needed to get the job done. “Every feature ofthe JH models — from the agile yet strong boom to the reputableheads — enables superb harvesting performance” says AndrewCrane – Equipment Sales Manager for <strong>CablePrice</strong>.The hydraulic system architecture and hydraulic prioritizationmean no waiting for power — or oil. The machine’s hydraulicsystem increases horsepower and flow (greater than 348 L/min)to the attachment, resulting in better grabbing pressure and fasterspeed. The system also prioritises power loads, ensuring essentialtasks like feed speed and multifunctioning always have enoughdedicated flow. “This ensures that not only do you get targetedmaximum power, but moving parts aren’t starved for oil — soyou’ll have less downtime for maintenance, and you can get moredone faster and with more precision, says Crane. “Plus, hydraulicsrun cooler and more efficiently, extending the pumps longevity.”Fitted with the 2,165kg HTH622B Waratah, the head has amaximum cutting capacity of 760mm, so is ideal for big trees,according to Crane. “Whether processing at the landing orharvesting at the stump, you can reliably maximize jobsiteproduction while getting the highest-value cut per stem.”Crane also says, whilst focused on production efficiency, thepurpose built JH series harvesters gives nothing away in comfortor operator safety. “These machines are as impressive on theinside as they are on the outside. They are among the mostspacious in their class and the cab of the 753JH is comfortable,well-appointed, and efficiently arranged for maximumproductivity.” Crane adds “Loggers will appreciate the clearand expansive sight line, as well as the isolation mountings fora smoother and quieter ride.” The cabin also boasts operatorprotection with integral ROPs, FOPs and OPs certification, aswell as a fire suppression system.With only a few hours under its belt, Steve Lee says the speedand performance of the machine is exceptional, commenting “ithandles timber like its grabbing a tiger by the tail – it’s that quick”and he is confident that the purpose built harvester will improvethe efficiency of his operation and has the capacity to increase theoutput as a result of the processing speed.John Deere tracked harvesters include the compact yetpowerful JH Series – 703JH, 753JH, 759JH and the larger853JH, 903JH & 909JH models. Each model features a longboom reach and a choice of heads to match the operation’srequirements. All of these harvesters are great for workingon slopes, especially the 759JH and 909JH. The 759JHhas shift-tilt levelling technology, allowing it to be centredand stable on steeper slopes. And the 909JH boasts the bestlevelling envelope in the industry.John Deere tracked harvesters offer unmatched groundclearance, tractive effort and service access, as well assuperior operator comfort for increased productivity. JohnDeere's tracked harvesters are purpose built for the forestwith a new optimised boom set for exceptional reach anda minimal tail swing design, and include an integratedplug-and-play measuring system for Waratah processingheads, making them ideal for selective cuts and commercialthinning operations.24

TRACK & WHEELTHE NEW R-SERIEShas arrivedIn September 2009, Scania launched new R-series trucks.National Truck Manager for Scania in New Zealand, KarlRelph says the new R-series will cement Scania’s positionas New Zealand’s premium long haul vehicle by introducingnew technologies and greater customer choice to helpdrivers refine their skills and improve their operatingeconomy.” With the first of the new R-series pre-sold, he isexpecting significant demand in the new truck.Welcome to a 12-page in-depth look at the innovationscharacterised by:• A tougher, more distinctive exterior• New cab interior fittings that feature top-flightergonomics and allow greater potential forcustomisation.• The next generation of the path-breaking ScaniaOpticruise automated gearchanging system.• The premiere of the Scania Driver Support system.25

TRACK & WHEELText: Conny Hetting and Per-Ola Knutas Photos: Stefan Almers and Dan Boman Illustration: ScaniaImproved looks,improved productivityand better fuel economy.With the new styling,Scania’s top-of-the-lineR-series gets evensharper.We havemanaged tocombine a sharperlook with improvedcooling andaerodynamics.”Kristofer Hansén, Head of Styling andIndustrial DesignFive years after its launchand with more than 200,000vehicles delivered to marketsacross the globe, thetop-of-the-line Scania R-series isreceiving a new and more dynamicfrontal treatment as well as otherexciting external styling touches.Faithful Scania customers willfeel at home, but will also be struckby the many improvements. Andthe improved fuel economy will bemuch appreciated. With the newR-series, Scania continues a valuedtradition.Additionally, the new optimisedchassis layout with rear-mountedbatteries gives customers maximumflexibility in terms of fuel capacityand on-frame storage.sharpLooking26

TRACK & WHEELThe bigger Scanialogotype boosts theScania identity.The frontal stylingis sharper, withmore pronouncedhorizontal lines,reinforcing theScania identity.A new verticaltheme picks upfrom the windowline and runs allthe way into thebumper.Optional LED daytimerunning lights and highpressureheadlampcleaners are integratedinto the design.9exteriorupdateson the r-seriesThe new bumper designblends into the strength ofthe frontal styling.The grille has considerablylarger openings betweenthe more distinct horizontalbars, accentuating the Scaniaidentity and admitting more airinto the radiator and the enginecompartment, securing highercooling capacity.The sideskirtsare designed toaccommodatelarger fuel tankswith a capacity ofup to 1,500 litres ona 4x2 tractor unit.The aerodynamicshape of thesideskirts improvesfuel consumptionby 0.6 percent.New sideskirts fortractor units, asstandard paintedin the cab colour,harmonise with thesharper frontal stylingand lines from theboarding steps.3questionsto:Kristofer Hansén,Head of Styling andIndustrial DesignWhat are the key styling traitsof the R-series?“With newly developed designlines, we have integrated thefront, the side of the cab, thebumper and the sideskirt intoa unified whole. Every part fitstogether; there are no ‘looseelements’ in the styling. The newinterior is inspired by premiumcars, with upgraded materials.We tuned up the shapes, surfacesand lines to reach a more elegantoverall interior ambience.”What are you most proud of?“That we have taken an alreadyfamiliar cab – the R-series – andgiven it a whole new life. We havemanaged to combine a sharperlook with improved cooling,aerodynamics and other functionalaspects. At the same time wehave a new level of quality in theinterior, closer in style to a luxurycar. It is a truck to make a driverproud.”What were your guidingprinciples during thedevelopment?“To renew and reinforce. Wealso worked on improvingaerodynamics to increase the fuelefficiency. At the same time wewanted to create an aestheticallyattractive styling, keeping andreinforcing the Scania look. In theinterior we wanted to enhance thepremium feeling of the cab whilemaking the truck safer, easierto drive and more efficient andcomfortable.”Early sketches of the new R-series.27

TRACK & WHEELText: Anders Nordner Photo: Carl-Erik Andersson and Stefan AlmersThe interior is provided in four recommended “Designer’s choice” colourcombinations that create a coherent atmosphere.EfficientluxuryBetter sleeping comfort and furtherimprovements in the driver station − that is whatthe new R-series interior gives the driver.Designers, stylists and ergonomists havehelped make the driver’s environment in thenew R-series as comfortable, ergonomic, safeand modern as possible.The objective has been to improve every aspect of driverenvironment. To help the driver while on the road, designershave found smart solutions for easily accessible storage, andhave improved the design of controls and instruments.The whole interior is characterised by higher-qualitymaterials and harmonious colour schemes, with a wide rangeof options to adapt the style to personal taste.The truck also offers substantially improved sleepingcomfort.A stable, completely flat foldouttable on the passengerside for working on a laptopcomputer or having a meal.A new door panel with beverageholder.28

TRACK & WHEELForm, function,design and marketspecialists haveworked together witha driver focus.”Hanna Johansson, head of VehicleErgonomics3questionsto:Hanna Johansson,head of vehicleergonomics.What did you hope to achievewith the new interior?“A comprehensive approach to thedriver’s environment. The new interiorfeels fresh, and its functionality hasbeen adapted to a driver’s everydayneeds. The choice of materials alsoprovides a solid sense of quality.”What do the innovations inthe interior mean to Scania’scustomers?“A substantially better, safer and morecomfortable working environment.We have retained the features thatdrivers appreciate, for example Scania’sunique driving position, while greatlyimproving the functionality of thedriver environment. We have groupedfunctions together and improvedstorage spaces easily accessible todrivers, in order to minimise the timethat their eyes are off the road.”What are you most proud of?“The collaboration between differentdepartments. Form, function, designand market specialists have workedtogether with a focus on the customer.The best example is our innovativesolution for the extendable bed, whichwe also developed together withleading companies in the bed business.Our driving ambition has been to liveup to the wishes of our customers. Theyare worth it.”The centre console featurescup holders, a shelf with integratedstorage for small itemsand an A4 sized drawer.New steering wheel buttonsgive the driver access tocruise control, radio and onboardcomputer functions.A coffee maker that can befactory-installed on thedashboard.An extendable bed with adjustable width andhardness (730 to 900 milllimetres).29

TRACK & WHEELThe Scania Driver Support system coaches drivers to make drivingsafer and more economical while reducing its environmentalimpact. The system, standard equipment in most Scania tractorunits, assesses a driver’s skills in real time and gives detailedhints how they can be improved.Real-timeadvicesaves fuelThe support systemanalyses theperformance of thedriver and suggesthow to furtherimprove driving.Those whouse Scania DriverSupport have a lotto gain in fuel andsafety.”Lars Åström, field test driver with30 years of experience30

TRACK & WHEELOur extensivecrash tests haveresulted in animprovement of5 km/h since 2004.”Lars Andersson, head of Testing andSimulations, Scania Technical CentreIn every new generation of Scaniastrucks the underrun protection system isimproved through crash testings. The newR-series was tested together with Audi.Crash testingfor safertrucksThorough testing makes the R-series cabeven safer – both for the driver and forpassenger cars on the roads.An Audi A3 going 65 km/h collides head-on withthe new Scania cab. But thanks to the truck’s underrunprotection and the passenger protection system in the car,this collision may well not result in any serious personalinjuries.“Our extensive crash tests have resulted in animprovement of 5 km/h since Scania’s last cab launch in2004, when the threshold for avoiding serious personalinjuries was 60 km/h,” explains Lars Andersson, head ofTesting and Simulations at the Scania Technical Centre.Among the reasons for the improvement is that theunderrun protection system on the new cab front has bettercharacteristics for parrying a head-on collision with a car.Crash tests reveal how the underrun protection system32

TRACK & WHEELHigh safety levelfor the driverThe new R-series cab has also undergone sledtests to test portions of the new interior as wellas a special collision test designed to resembleas closely as possible one of the most seriousaccidents a truck driver can experience – drivingstraight into the rear of a stationary truck trailerduring a sudden traffic jam on a motorway.“This is a specially designed test not mandatedby any legal requirements,” Michael Öman says.“Scania has chosen to develop this test on its ownin order to ensure an even higher level of safety.”Controlled deformationBefore – and after. In a computer simulation the head-on collision with an Audithe Scania cab’s new underrun protection system is deformed in a controlledway, reducing the crash energy.and its brackets behave in such a collision and how other vitalfunctions in the truck are affected.In head-on collisions between a truck and a car, the car maybecome wedged under the truck. This usually results in fatalitiesor severe personal injuries to the car’s driver and passengers. Inaddition, the truck may lose its steering ability and turn over.“Our primary requirement for an underrun protectionsystem is that it must prevent the car from driving under thetruck,” says Michael Öman, passive safety expert at Testingand Simulations. “At the same time, the truck must retain itssteering and braking ability.”Before Scania carried out crash testing at Dutchresearch organisation TNO’s facility in Delft, the collisionwas computer-simulated over and over again by mechanicalengineers at the Scania Technical Centre in Södertälje,Sweden. Only after this digital underrun protection system andits brackets had been deformed in a controlled way did Scaniamanufacture the prototype used in the actual physical tests.Scania was the first heavy-truck builder to offer frontalunderrun protection. It was launched in 1995 as standardequipment on Scania’s 4-series long-haul trucks. Laterthe European Union also realised the importance of suchprotection for people in passenger cars, and in 2003 a lawrequiring frontal underrun protection was enacted.To ensure the safety and robustness of the cab structure,various crash and impact tests are carried out. The new R-serieshas a wider radiator that enables it to take in more coolingair, as well as a new front cab suspension. These new featureshad to be tested to ensure that they met both internal safetystandards and legal requirements.Impact tests subject the cab to powerful pendulum blowswith predetermined energy levels from different directions.“Scania cabs meet worldwide ECE R29 standards, as well asSweden’s even tougher safety standards for truck cabs,” Ömanexplains. “The most important difference is that in the Swedishtest, all three separate strength tests that are included must becarried out on the same cab.”33

TRACK & WHEELText: Conny Hetting Photo: Carl-Erik Andersson Illustration: Semcon Informatic Graphic SolutionsOptimal gearingAn automatic clutch, an electro-hydraulic clutch control anda whole new strategy for gear selection – these are the mainingredients in the new Scania Opticruise system.Scania Opticruise, one of thefirst automated gearchangingsystems in the market, has beenrefined in many steps over theyears. Now development of the system istaking a new turn. After four years of development,the concept of a standard mechanicalgearbox remains, but the system hasbeen extensively modified, with improvedmechanical components and entirely newsoftware.The new automatic clutch is based on amarket innovation – an entirely new electrohydraulicclutch actuator that allows precisionclutch control.“The new electro-hydraulic clutch actuatorprovides better control than a pneumaticsystem during starts or manoeuvring as wellas on slippery surfaces,” says Mikael Hanson,head of Transmission Software. “It alsospeeds up gearchanges.”The new Scania Opticruise takes intoaccount not only factors like engine revs,vehicle acceleration, speed and load, but alsothe slope of the road, driving style and otherexternal factors in order to calculate the mostsuitable gear for any situation. When reachinga hill, the new system changes downearly to maintain a higher speed up the hill.All this has been designed to improve driveabilityand simplify work for the driver.“It enables the driver to concentrate on thesurrounding traffic while achieving optimalfuel consumption,” Hanson says.The fundamental principle behindScania Opticruise is that the engine shouldwork at the revs that are the most efficient inevery situation, making the most out of everydrop of fuel.Among other advantages of the new system,the automatic clutch means less clutchwear as well as better operating economy,thanks to new functions that provide optimalfuel consumption. The new gearchangingstrategy includes using low revs whereverpossible, thereby saving fuel without compromisingdriveability.When reaching a hill, the new system changes down early to maintain a higher speed up the hill.Scania Opticruise with all controls in onelever. Switch between automatic and manualmode with A/M at the tip of the lever.10innovations1. Scania Opticruise is now availablewith an automatic clutch.2. A new, smarter gearchanging strategythat provides good driveability inboth economy and power modes.3. High precision for manoeuvringwith the automatic clutch.4. Extra high precision and smoothaccelerator response in manoeuvringmode.5. Automatic starting gear selection,aided by an inclination sensor.6. The option of activating the powertake-off outside the cab.7. Compatibility with Adaptive CruiseControl and Scania Ecocruise, allowingsmoother interaction between speedcontrol and gear selection systems.8. Smart gear selection whenapproaching intersections androundabouts.9. Improved interaction between theScania Retarder and Scania Opticruise,which avoids excessive downchangingduring retarder braking.10. Interaction between ScaniaOpticruise and Hill-hold, which makesstarting on an incline very easy.34