Specifications and additional Information - Boral

Specifications and additional Information - Boral

Specifications and additional Information - Boral

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hydrapave Permeable Paving<br />

BOOK<br />

3<br />

PAGE<br />

F8<br />

Materials Specification<br />

Subgrade<br />

The subgrade must have a minimum CBR of 5. Engineering<br />

advice should be obtained where the subgrade does not meet<br />

this specification.<br />

Membrane/Filter Fabric<br />

Membrane (typical)<br />

Typical Dimensions: 4m x 12.5m x 50µm - 23kg.<br />

Tear Resistance: 40N/mm minimum.<br />

Tensile Strength: 14.4mPa.<br />

Durability: The membrane must remain flexible <strong>and</strong> not<br />

degrade. It shall be resistant to U.V. light <strong>and</strong> puncturing.<br />

Where methane or a high water table is present in the<br />

subgrade it will be necessary to use a heavy-duty membrane<br />

<strong>and</strong> to weld the joints.<br />

The membrane should be protected against puncturing.<br />

Filter Fabric<br />

The grade will vary according to the precise application.<br />

Refer to the project hydraulic or stormwater engineer for<br />

specifications.<br />

Sub-base<br />

A sub-base of 350mm as detailed on page F7 will enable the<br />

Hydrapave system to have a holding capacity of 1m 3 of water<br />

for every 10m 2 of paved area. The permeability of the pavers<br />

themselves is 9,000L/m 2/hour. The depth of sub-base can<br />

accordingly be varied at the discretion of the engineer.<br />

The granular sub-base material shall comprise crushed<br />

gravel, rock or concrete possessing well defined edges. It must<br />

be sound, clean, non friable <strong>and</strong> free from clay or other<br />

deleterious matter.<br />

The material must be non-plastic.<br />

The crushed stone used for the laying course <strong>and</strong> sub-base<br />

must have a minimum 10% fines value of 150kN.<br />

The selected test samples shall not be oven dried <strong>and</strong> should<br />

be soaked in water at room temperature for 48 hours before<br />

the test.<br />

Sub-base — Lower Layer<br />

A 250mm deep layer of stone. Grading to comply with:<br />

Sieve Size % Passing<br />

100mm 100<br />

63mm 90-100<br />

37.5mm 60-80<br />

20mm 15-30<br />

10mm 0-5<br />

Sub-base — Upper Layer<br />

A 100mm deep layer of graded 20-5mm crushed stone.<br />

Filter Fabric<br />

The upper filter fabric grade will vary according to the precise<br />

application. For information on geotextiles <strong>and</strong> filter fabrics<br />

contact Polyfabrics Australia Pty Ltd (02) 4627 6444.<br />

Laying Course<br />

50mm depth of 2 - 5mm single size (near as possible) clean<br />

crushed stone.<br />

Paver<br />

Pavers are to be Hydrapave as manufactured by <strong>Boral</strong><br />

Masonry. Colour to be specified by project engineer.<br />

Joint Filling<br />

2 - 5mm single size clean stone applied at the rate of<br />

approximately 1 - 2 kg/m 2.<br />

Strip Drain<br />

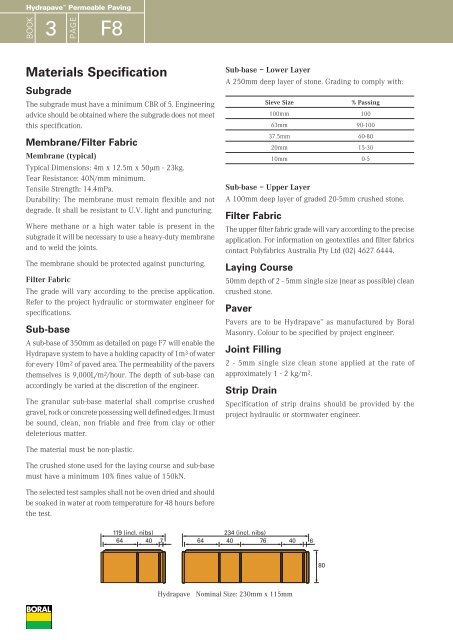

119 (incl. nibs) 234 (incl. nibs)<br />

64 40 7<br />

64 40 76 40 6<br />

Specification of strip drains should be provided by the<br />

project hydraulic or stormwater engineer.<br />

Hydrapave Nominal Size: 230mm x 115mm<br />

80