BABY TRACTOR For Odd Jobs - Vintage Projects

BABY TRACTOR For Odd Jobs - Vintage Projects

BABY TRACTOR For Odd Jobs - Vintage Projects

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

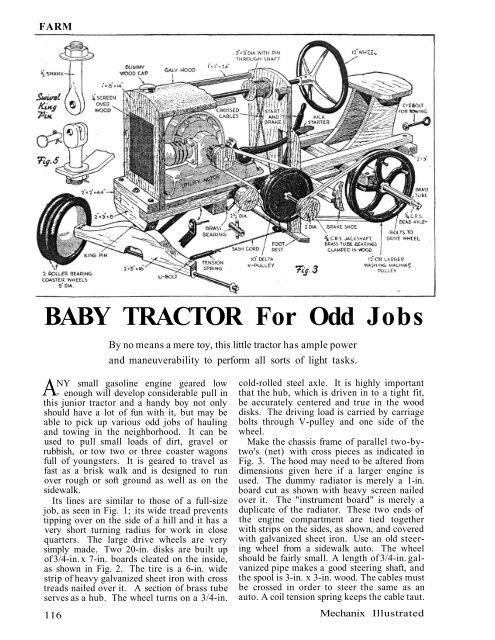

FARMThe rear axle is clampedto the two-by-three crossmembers by means of U-bolts, as is the front axleto its two-by-five inchmember. The 3/4-in. steeljackshaft is carried inbrass-tube bearingsclamped to the frame withwood blocks as shown.Small pulleys on theends of the jackshaftcarry belts to the drivewheels, and as these beltsare not adjusted too tightly,they allow slippage inturning corners, thus serving as a differential.In this connection the writer has found byexperience that a good V-belt is very accomodatingin this way; it will slip if the loadbecomes excessive but pulls like fury whennot overtaxed. A 10-in. (Delta) V-pulley isdriven direct by the engine pulley. The V-belt between the two is adjusted looselyenough to permit the motor to run free. Anidler pulley serves as belt tightener and whenthrown in position the tractor starts in motion.October, 1941The diagram, Fig. 4, illustrates operation.When the lever is forward the idler pulley isfree and the brake shoes engage with the reardrive-pulleys. Drawing the lever back bringsthe idler-pulley against the engine ,belt andtightens it. Note that the idler should beswung on an arm about 3-in. long, and soinstalled that when engaged the arm is pastcenter and is automatically held in this positionuntil released by the operator.[Continued on page 136]117

which—if delivered at ten-pound pressurethrough a 12-inch pipe—would stretch all the wayto the moon and two-thirds of the way back again.The statistically-minded will agree that that'smore than just a lot of hot air.If you joined a party of tourists and went lookingfor the New York Steam Corporation's plant,the chances are you'd be disappointed. It isn'tdistinguished by a maze of pipes, boilers and retorts;if it weren't for four large smokestacks,you'd probably miss the plant completely, sincemore than half of its total assets lie buried beneaththe city's streets and sidewalks.This is the beauty of a central steam plant, asthe founders of the New York company realizedalmost sixty years ago. Coal is delivered to theplant in barges, thus eliminating the rumbling ofcoal trucks through the city streets, and, by beingable te press a button to get his heat or cut it off,Mr. Citizen does his part to do away with ashremoval trucks and the soot that is the scourgeof most big cities.But, even though it is the centralized core of a$10,000,000 enterprise, the company's plant is notthe roaring maelstrom one might expect it to be.Only about 1,800 men—including executives andoffice staff, distribution gangs and the plant force—are required to run this gigantic organization,with less than 300 needed at the plant itself tomanipulate the levers, buttons and switches thatkeep the wheels turning.Probably no business in the world is as dependenton buttons as the New York steam plant.Virtually everything is done with buttons; onebutton starts the scoops that grab up the coalfrom barges and dump it into the crushers; anotherstarts the machinery which pulverizes itinto black dust at the rate of 160 tons an hour;another sets the furnaces into roaring action, and[Continued on page 137]136Baby Tractor <strong>For</strong> <strong>Odd</strong> <strong>Jobs</strong>[Continued jrom page 117]The job can be greatly simplified because thebelt tightener and brake are not absolutely necessary.The slow speed of the tractor does not involveany hazards, especially if the engine beltis always tight, for by shutting off the ignition themotor itself serves as a brake. In starting, theoperator simply works the kick-starter with onehand and pushes the light vehicle forward withthe other until it takes hold, after which he caneasily hop aboard.If one wishes to work over uneven ground thechassis can be made flexible by the use of a swivelledking bolt, Fig. 5. This, however, is a blacksmith'sjob if you haven't the proper equipmentto make it yourself. A brace should be installedas in Fig. 4. In case of a swivelled king bolt thisbrace must also be swivelled at the top connection.<strong>For</strong> greater power use as large pulleys as areavailable on the drive wheels, and as small aspossible for those driving them.Power Tool Bracket[Continued jrom page 123]socket for the post from thicker wood and afterremoving sharp corners with sandpaper, screw itto the edge of the workbench. The post may bestored on a shelf when not required, as it can beslipped into the socket in an instant. Provide apadlock for the hasp so that you may lock thehand piece and prevent use of the tool in yourabsence. By using a clip and hasp of suitable sizeand shape, this bracket is easily adapted for usewith other types of flexible-shaft tools.