Multi-scale methods in material mechanics

Multi-scale methods in material mechanics

Multi-scale methods in material mechanics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

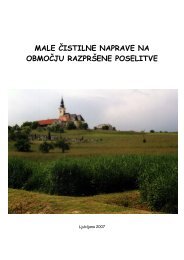

Characterization of Heterogeneous Materialsby<strong>Multi</strong>-Scale SimulationsP. Wriggers,I. Temizer, M. Ha<strong>in</strong> & S. LöhnertInstitute of Cont<strong>in</strong>uum MechanicsLeibniz Universität HannoverLjubljana - 24.3.2009Heterogeneous Material: Concrete[cm][m][µm][nm]

Micro-Structure of MaterialsCement pasteGranular <strong>material</strong> (e.g. sand)Alum<strong>in</strong>ium-Boron-Alloy (x250) Woven fabrics Contact surfacesOutl<strong>in</strong>e and Goals• Micro-<strong>scale</strong> modell<strong>in</strong>g leads to better understand<strong>in</strong>g offailure mechanism and hence leads to better <strong>material</strong>descriptions• Material behaviour is different on different length <strong>scale</strong>s=> <strong>Multi</strong>-Scale Analysis• Difficulty: Not all data are known for micro-<strong>scale</strong>computation (e.g. constitutive data)• Homogenization is often necessary for practicalapplications (possible way out: model adaptivity)• Statistical analysis is necessary

Modell<strong>in</strong>g of Microstructure/Homogenizationvolumetric:Torquato (2002)Nemat-Nasser (2004)Zohdi/Wriggers (2005)contact:Orlik (2004)Stupkiewicz (2007)Temizer/Wriggers (2008)th<strong>in</strong> structures:Geers et al. (2007)Hirschberger et al. (2008)Grytz/Meschke (2008)Löhnert/Wriggers (2008)• Bulk Inhomogeneities: high oscillatory stress fields• Volumetric homogenization:➡ reduces the complexity of the macrostructural analysis➡ construction of an effective <strong>material</strong> micromechanical test<strong>in</strong>gHomogenization Procedure for a MaterialValidationbyExperimentsMicrostructureMacroscopicMaterial EquationNumerical Modeland AnalyisUpscal<strong>in</strong>g

Requirements for Homogenization• Statistical representativenessL1 >> L2 >> L3• 3-D Computations for quantitativeresults• Converg<strong>in</strong>g f<strong>in</strong>ite element model• Sufficient number of particles• Monte Carlo simulations forstatistical evaluation

• volume fraction2 Vol% unhydrated cl<strong>in</strong>ker84 Vol% hydration products14 Vol% pores• elastic propertiesAcker [2001]; Constant<strong>in</strong>ides, Ulm [2004]• f<strong>in</strong>ite-element representation• pr<strong>in</strong>cipal stress64 µm64 µm64³ hexahedron elements820 000 DOFssolution time 5m<strong>in</strong>Homogenizationnumerical SimulationHomogenizationGoal: Material parameters of effective <strong>material</strong>12

Elastic Behaviour„Natural“ b.c. (w<strong>in</strong>dow-method)- RVE is embedded <strong>in</strong> a matrix of averaged stiffness- Discretization 3dHomogenization- correlation between mean values- volume average RVE- bounds for displacement and stress b.c.can also be obta<strong>in</strong>ed for f.e. simulations [Zohdi & Wriggers (2001)]Numerical homogenization- 3D isotropic <strong>material</strong>

• 3D isotropic <strong>material</strong>• 2D isotropic <strong>material</strong>- width of w<strong>in</strong>dow- size of RVE• isotropy of RVE• 3D isotropic <strong>material</strong>:- probability density of 9 200 RVEs (each 820 000 DOFs)• comparison withexperimental dataexperiments from IBAC

• meso-scopic elastic constituents fluctuate statistically• <strong>in</strong>homogeneous meso-scopic behavior160 mmone representation ofYoung‘s modulusone representation ofpr<strong>in</strong>cipal stressHomogenization of a Neo-Hooke MaterialRVE with particles73 particles915.864 dofsdeformation due todisplacement b.c.

Upscal<strong>in</strong>g: Micro- and homogenised structurePlate with particles of different sizeDeformation and StressesLöhnert & Wriggers 2008Upscal<strong>in</strong>g: Micro- and homogenised structurePlate with particles of different size216 particles1802490 dofsDeformed state and stressesLöhnert & Wriggers 2008

outl<strong>in</strong>eSimulation of water permeabilityKoster, Brameshuber (2007)network of connected tubes- pore-size distribution

Simulation of water permeabilityDegreee of water fill<strong>in</strong>gKoster, Brameshuber (2007)256 µmwh=0.70wh=0.80Simulation of damage due to freez<strong>in</strong>gConstitutive model for water filled poresK<strong>in</strong>ematic splitL<strong>in</strong>ear elastic constitutive equationσ = C ɛ uConstitutive data of iceJ. Pohe 1993G. W. Scherer, 1999No visco-plastic effects d<strong>in</strong>ce not known formicro pores

Constitutive model for water filled poresthermal stra<strong>in</strong>freez<strong>in</strong>g temperature depend<strong>in</strong>g on radiiStockhausen [1981]Damage at micro-structural levelPr<strong>in</strong>cipal stressesDamageDef<strong>in</strong>ition of homogenized damage

Statistical tests of 64 RVEs (wh=0.80)64 µmdamage with<strong>in</strong> RVEPolygons for median value and standard deviationHa<strong>in</strong> & Wriggers 2008Homogenized damage due to frostfluctuates statistically

HomogenizationLimits• RVE concept does not work for- <strong>material</strong> <strong>in</strong>stabilities and localization- local buckl<strong>in</strong>g- occurance of cracks- dynamics• Way out- true multi-<strong>scale</strong> method- model adaptivity<strong>Multi</strong>-Scale Analysis

<strong>Multi</strong>-Scale Analysis<strong>Multi</strong>-Scale Analysis

<strong>Multi</strong>-Scale Analysis<strong>Multi</strong>-Scale Analysis

Material Map ApproachInterpolationMaterial Map ApproachVirtual experimentsat RVEstorage <strong>in</strong> a DatabaseComponent of the2. Piola-Kirchhoff stressesEffective stra<strong>in</strong> energy

Material Map ApproachComparision map to direct RVE approachInelastic behavior of hydration productscont<strong>in</strong>uum mechanical approachfor a virg<strong>in</strong> <strong>material</strong>for a non-virg<strong>in</strong> <strong>material</strong>Verfication through multi-<strong>scale</strong> model

<strong>Multi</strong>-<strong>scale</strong> analysis★ perform micro-structural analysis at each<strong>in</strong>tegration po<strong>in</strong>t★ ALGO:• Obta<strong>in</strong> stra<strong>in</strong>s and microstructures atGauss <strong>in</strong>tegration po<strong>in</strong>t• Apply• Nonl<strong>in</strong>ear f<strong>in</strong>ite element solution ofmicrostructural model• Obta<strong>in</strong> effective values• Compute on Macro-level<strong>Multi</strong>-<strong>scale</strong> analysissecant moduli is obta<strong>in</strong>ed directly from homogenizationNumerical Simulation(on 8 processor SMP)Model 1:128 multi-<strong>scale</strong> elements16³ RVE per <strong>in</strong>tegration po<strong>in</strong>t1 week CPU time (speed-up 7.4)820 MB history data64 µmModel 2:16 multi-<strong>scale</strong> elements64³ RVE per <strong>in</strong>tegration po<strong>in</strong>t6 weeks CPU time (speed-up 7.2)2.1 GB history datadamage with<strong>in</strong> specimenon micro-<strong>scale</strong>

<strong>Multi</strong>-<strong>scale</strong> analysis<strong>material</strong> parametersNumerical effort for 2 <strong>scale</strong>sEmbedded multi-<strong>scale</strong>: FE 2• Micro-<strong>scale</strong> model 100x100x100 FE• Same resolution for macro-<strong>scale</strong>• Each macro-<strong>scale</strong> f<strong>in</strong>ite elementconta<strong>in</strong>s complete micro-<strong>scale</strong>Coupled multi-<strong>scale</strong> computation• Mikro-Skale:• Macro-Scale:FEFEDevelopment of adaptive <strong>methods</strong>for efficient FE 2 multi-<strong>scale</strong> analysis

Adaptive multi-<strong>scale</strong> analysisAdaptive multi-<strong>scale</strong> analysis

Adaptive multi-<strong>scale</strong> analysisdoes not result <strong>in</strong> a gradient-sensitivity for homogeneous micro-structuresGradient sensitivityAdaptive multi-<strong>scale</strong> analysis

Adaptive multi-<strong>scale</strong> analysisAdaptive multi-<strong>scale</strong> analysis

Adaptive multi-<strong>scale</strong> analysisAdaptive multi-<strong>scale</strong> analysis

Adaptive multi-<strong>scale</strong> analysisAdaptive multi-<strong>scale</strong> analysisLöhnert & Belytschko 2007Löhnert et al. 2008

Conclusion• Homogenization schemes:– Constitutive parameters– Random distribution of constitutive data• FE 2 is expensive– Understand<strong>in</strong>g of <strong>material</strong> behaviour at micro<strong>scale</strong>– Pre-computed maps of constitutive data– Adaptive schemesReferences• M. Ha<strong>in</strong> and P. Wriggers: Computational Homogenization of micro- structuralDamage due to Frost <strong>in</strong> Hardened Cement Paste, F<strong>in</strong>ite Elements <strong>in</strong> Analysis andDesign, 44, 233-244, 2008• M. Ha<strong>in</strong> and P. Wriggers: On the numerical homogenization of hardened cementpaste, Computational Mechanics, 42, 197-212, 2008• I. Temizer and P. Wriggers: An adaptive method for homogenization <strong>in</strong> orthotropicnonl<strong>in</strong>er elasticity, CMAME, 196, 3409-3423, 2007• S. Löhnert and P. Wriggers:” Effective behaviour of elastic heterogeneous th<strong>in</strong>structures at f<strong>in</strong>ite deformations” Computational Mechanics, 41, 595-606, 2008• I. Temizer and P. Wriggers: “On a mass conservation criterion <strong>in</strong> micro-to-macrotransitions”, Journal of Applied Mechanics - Transaction of the ASME, 75, No.054503, 2008