Power Connection Systems Catalogue - F C Lane

Power Connection Systems Catalogue - F C Lane

Power Connection Systems Catalogue - F C Lane

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Catalog C-014 Rev E3

POSITRONIC INDUSTRIESAbout UsFounded in 1966, Positronic Industries is a vertically integrated manufacturer of high quality interconnect products.Positronic has earned the worldwide reputation as a service oriented, quick-reaction, top quality connector supplier. Weare committed to maintaining this reputation by continuous implementation of our Complete Capability concept.Complete CapabilityDesign & Development• Designs new connectors and modifies existing connectors to meet industry requirements• Continuously conducts marketing studies to identify industry needs for new products• Ongoing interest in unique connector designsToolingMachining• Tooling support for all manufacturing areas within company• Provides 80% of new tooling, punch press dies, molds, jigs and fixtures used at Positronic factory locations worldwideMachining• Automatic screw machines produce finely crafted contacts and hardware for connector bodies• Trained technicians operate machines from Tornos, Bechler and Brown & SharpeMolding• Molds all plastic connector components such as insulators, hoods, angle brackets and more• Overmold capability availablePlating• Applies gold and other metal finishes to connector components to any required thicknessMolding• Plating conforms to all military specificationsQuality Assurance Lab• Quality assurance system certified to ISO 9001• Maintains aggressive TQM program• Able to test to IEC, EIA, UL, MIL-DTL-24308, MIL-DTL-28748, SAE AS 39029 and MIL-C-85049 requirementsFinished Stock Inventory• Each main factory location maintains a large inventory of connector components and accessories• Same day shipments available on many standard connector products• Stocking agreements available for qualified customersWorldwide Sales & Service• Responsive attitude toward customer needs• Fully trained sales staff located worldwideFinished Stock Inventory• Facilities located in USA, France, India, Puerto Rico, and Singapore.Products described within this catalog may beprotected by one or more of the following US. patents:#4,900,261 #5,255,580 #5,329,697#6,260,268 #6,835,079 #7,115,002Patented in Canada, 1992Other Patents PendingUnless otherwise specified, dimensional tolerances are:1) ±0.001 inches [0.03 mm] for male contact mating diameters.2) ±0.003 inches [0.08 mm] for contact termination diameters.3) ±0.005 inches [0.13 mm] for all other diameters.4) ±0.015 inches [0.38 mm] for all other dimensions.Information in this catalog is proprietary to Positronic and its subsidiaries. Positronic believes the data contained herein to be reliable. Since thetechnical information is given free of charge, the user employs such information at his own discretion and risk. Positronic Industries assumes noresponsibility for results obtained or damages incurred from use of such information in whole or in part.Positronic Industries’ FEDERAL SUPPLY CODE (Cage Code) FOR MANUFACTURERS is 28198

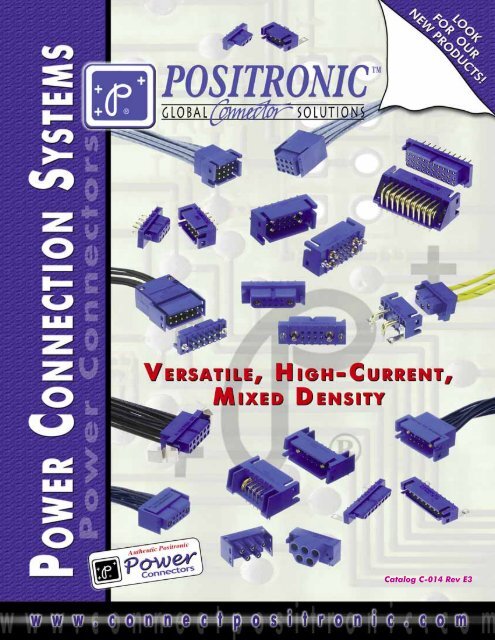

P O S I T R O N I C I N D U S T R I E SProven PerformanceNEW!In 1989, Positronic Introduced the <strong>Power</strong><strong>Connection</strong> <strong>Systems</strong> series. Since that timePCS has been the power connector of choicein a wide variety of applications. Thepopularity of PCS is due to a growing list offeatures, they include:**Low Contact Resistance****Sequential Mating Options****Discriminating Locking System****Board to Board / Board -Cable / Cable - Cable****Size 12 Contacts withScrew Terminations****Safety Shrouded Options****Many Connector VariantsAvailable From Stock****Mixed Density Variants**NEW!RoHSCompliant• per EU Directive 2002/95/EC•RoHS Compliantoptions available!DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.i

GENERAL INFORMATION PCS SERIES SAFETY SHROUD POWER INPUTPositronic Industriesconnectpositronic.comTABLE OF CONTENTSG E N E R A L I N F O R M A T I O N<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>Typical <strong>Connection</strong> <strong>Systems</strong> .............................................................................................................. 1-3Demystifying Current Ratings ............................................................................................................ 4Large Surface Area Contact Mating System ..................................................................................... 5Compliant Terminations...................................................................................................................... 6P C S S E R I E SCustomer Specified Arrangements .................................................................................................... 7Technical Information ......................................................................................................................... 8Temperature Rise Curves .................................................................................................................. 9Mating Dimensions............................................................................................................................. 10Straight Solder Printed Board Connectors......................................................................................... 11-12Compliant Press-Fit <strong>Power</strong> Connectors ............................................................................................. 13Straight Solder And Compliant Contact Hole Pattern........................................................................ 14-15Right Angle (90°) Solder Printed Board Connectors ......................................................................... 16-17Right Angle (90°) Press-Fit Connectors............................................................................................. 18Right Angle (90°) Printed Board Contact Hole Pattern...................................................................... 19-20Panel Mount Connectors with Solder Cup Contacts.......................................................................... NEW!20Cable Connectors with Removable Contacts..................................................................................... 21-22Panel Mount Connectors with Removable Contacts.......................................................................... 23-24Sequential Mating System ................................................................................................................. 25Ordering Information .......................................................................................................................... 26S A F E T Y S H R O U D S E R I E STechnical Information ......................................................................................................................... 27Connector <strong>Systems</strong> and Cable Connector......................................................................................... 28Panel Mount Connector ..................................................................................................................... 29Straight Solder and Right Angle (90°) Solder Printed Board Mount Connector ................................ 30Ordering Information .......................................................................................................................... 31P O W E R I N P U T S E R I E STechnical Information ......................................................................................................................... 32<strong>Connection</strong> <strong>Systems</strong> and Temperature Rises Curves ....................................................................... 33Cable and Panel Mount Connector.................................................................................................... 34Straight Solder Printed Board Mount,Compliant Press-Fit Connector, and Contact Hole Pattern ............................................................... 35Right Angle (90°) Printed Board Mount Connector and Contact Hole Pattern.................................. 36Screw Termination and Sequential Mating Contacts ......................................................................... 37Ordering Information .......................................................................................................................... 38iiDIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>TABLE OF CONTENTSPositronic Industriesconnectpositronic.comP C S M I X E D D E N S I T Y S E R I E STechnical Information ......................................................................................................................... 39-40Temperature Rises Curves................................................................................................................. 40Cable Connector ................................................................................................................................ 41NEW!Panel Mount Connector ..................................................................................................................... 42Straight Printed Board Mount Connector and Contact Hole Pattern ................................................. 43Right Angle (90°) Printed Board Mount Connector and Contact Hole Pattern.................................. 44Compliant Press-Fit Connector.......................................................................................................... 45Ordering Information .......................................................................................................................... 46R E M O V A B L E C O N T A C TRemovable Contact Technical Information......................................................................................... 47Removable Contact Technical Information and Removable Crimp Signal Contact Size 20 .............. 48Removable Crimp Contact and Solder Cup Contact Size 16 ............................................................ 49Removable Shielded Contact Size 16 and Removable Crimp Contact Size 12................................ 50Removable Solder Cup Contact Size 12 and Removable Crimp Contact Size 8.............................. NEW! 51Removable Solder Cup and Removable High Voltage Contact Size 8.............................................. 52Removable Shielded Contact Size 8.................................................................................................. 53A P P L I C A T I O N T O O L SCrimping Information for Removable Crimp Contacts ....................................................................... 54-55Soldering and Crimping Information for Shielded Contacts............................................................... 56Contact Crimp Tools and Accessories ............................................................................................... 57Contact Application Tools Cross Reference List ................................................................................ NEW!58-59Press-Fit User Information and Connector Installation Tooling.......................................................... 60Compliant Press-fit Connectors Printed Board Hole Sizes................................................................ 61PCS MIXED DENSITYREMOVABLE CONTACTAPPLICATION TOOLSA C C E S S O R I E SRight Angle (90°) Metal and Plastic Mounting Brackets .................................................................... 62Push-on Fasteners and Mounting Screws ......................................................................................... 63Connector Hoods ............................................................................................................................... 64Quick Release Mounting Clip and Panel Cutout................................................................................ NEW!65Fixed Style Mounting Clip and Panel Cutout ..................................................................................... 66Panel Mount Cutout ........................................................................................................................... 67Blind Mating System and Panel Cutout ............................................................................................. 68ACCESSORIESDIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.iii

POSITRONIC CABLIZED CONNECTORSSAVE TIME AND MONEY! Let Positronic support yourconnector requirements by cablizing your <strong>Power</strong> connectorselection. Positronic offers technical support andmanufacturing capability for cablized connectors. Contactyour factory direct sales representative for details!Quality AssuranceEngineering ManagementDesign and Testing ServicePositronic Industries’ Engineering Department:1. Works closely with customers.Springfield Cable AssemblyPuerto Rico Cable Assembly2. Prepares component and cablized connectorsystems, hardware design, and performancespecifications.3. Designs each system in accordance withapplicable customer, domestic, and internationalstandards.4. Defines and directs required performance andverification testing.Connectors Designed To Customer SpecificationsPositronic connectors can be modified to customers specifications.Examples: select loading of contacts for cost savings or to gain creepage andclearance distances; longer PCB terminations; customer specified hardware.Positronic can develop and tool new connector designswith reasonable price and delivery.Contact Technical Sales with your particular requirements.ivDIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>SYSTEM 1MOTHER BOARD-DAUGHTER BOARDPRINTED BOARD TO PRINTEDBOARD CONNECTION SYSTEMSPLB06M300A1 Straight solder orPLB06M92ST20A1 Complianttermination press-fitPositronic Industriesconnectpositronic.comGENERAL INFORMATIONPLB06F4BN0A1PLB06M4BN0A2SYSTEM 2SIDE TO SIDEBOARD MOUNTINGPLB06F300A1 Straightsolder orPLB06F94ST40A1Compliant terminationpress-fitPLB06F4BN0C1PLB06M4BN0C1SYSTEM 3STACKABLEBOARD MOUNTINGPLB06F42BN0C1SYSTEM 4SANDWICHBOARD MOUNTINGPLB06F32N0C1PLB06M300A1 Straightsolder or PLB06M93ST30A1Compliant termination press-fitPLB06F3N0C1PLB06F300A1 Straightsolder or PLB06F93ST30A1Compliant termination press-fit1

GENERAL INFORMATIONPositronic Industriesconnectpositronic.comSYSTEM 5CABLE TO RIGHT ANGLE(90°) BOARD MOUNTINGCABLECONNECTION SYSTEMSPLB06F4BN0A1PLB06M0000With contacts installed<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>Crimp or solder terminationPLB06F0000With contacts installedPLB06M4BN0A2Crimp or solder terminationLock holeLock tabTypical for connectionsystems 5, 6, 7 and 8SYSTEM 6CABLE TO STRAIGHTBOARD MOUNTINGPLB06F300C1 Straight solder orPLB06F92ST20C1 Complianttermination press-fitPLB06M0000With contacts installedCrimp or solderterminationPLB06M300C1 Straight solder orPLB06M92ST20C1 Complianttermination press-fitPLB06F0000With contacts installedSYSTEM 7CABLE TO CABLECrimp or solder terminationPLB06F0000With contacts installedPLB06M0000With contacts installedCrimp or solder termination2

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>SYSTEM 8PANEL MOUNTED TO CABLECABLE AND INTEGRALFEED THROUGH CONNECTION SYSTEMSPLB06F206A1Mounting clipPANEL MOUNT AND CABLE ADAPTERSPositronic Industriesconnectpositronic.comSYSTEM 9CABLE CONNECTORWITH CABLE ADAPTERGENERAL INFORMATIONPLB06F0050Non-removable fixedcontacts with 18 AWG[1.0mm 2 ] solder wireterminations or crimpcontact terminations forwire sizes 12 AWG[4.0mm 2 ] through 32AWG [0.03mm 2 ]PLB06M0000With contactsinstalledCrimp or solderterminationINTEGRAL FEED THROUGH CONNECTION SYSTEMALLOWS THREE WAY INTERFACE• PCB FRONTSIDE TO A CONNECTOR• PCB BACKSIDE TO A CONNECTOR• PRESS-FIT CONNECTIONS WITH PCBFRONTSIDECONNECTORINTERFACESOLID FEEDTHROUGH CONTACTHAS A PRESS-FIT ZONE TOINTERFACE TO PCBCONTACT TECHNICALSALES FOR MOREINFORMATION.BACKSIDECONNECTORINTERFACEDIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.3

GENERAL INFORMATIONPositronic Industriesconnectpositronic.comDEMYSTIFYING CURRENT RATINGS<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>Connector current ratings seem to be shrouded in mystery at times. The user wonders how a listed current ratingis relevant to a particular application. Perhaps more mysterious is how similar connectors from various manufacturerslist different current rating values. While it is true that material choices and design can enhance a connector’s currentrating, the test method by which the rating was developed must be understood when evaluations are made.Users of connectors for power applications are entitled to current rating test details in order to make an informedchoice. Ideally, a connector’s current rating should be developed within the application for which it is being considered.Although ideal, this approach is not always practical given the many differing applications. In order for connector manufacturersto give potential product users an idea of what can be expected, connectors are given current ratings basedon a specific test method.A wide variety of test methods are employed in order to develop current ratings for connectors. Some of thesemethods come from standards that are recognized industry-wide, while others are unique to the manufacturer or user.These various test methods can produce different results for the same product. It is no wonder confusion sometimesresults.There are key factors that, when understood, can help in choosing the right power connector. All test methods usedto rate current have similarities; however, there are variables in applying the test methods which explain differingresults.Current ratings are usually established by first developing a temperature rise curve. This curve plots temperaturerise against increasing current levels. The curve is a reliable tool in understanding heat generation of the connector atvarious currents. When a defined failure is reached, the test ends. The highest current level achieved is usually listedas the current rating.The temperature rise curve, and therefore the current rating, will change when certain key factors are varied.These are:●DEMYSTIFYINGCURRENT RATINGSWhere is the temperature sensing probe placed? If placed on the contact in the matingarea (the hottest spot), the results will be quite different than if placed on the outside of theconnector body.●Are the contacts being tested and rated in free air or are they contained within theconnector housing? Contacts will obviously be cooler in free air.●Are all of the contacts in the connector under load? If only part of the contactsare under load, the temperature rise could be less.●What is the defined failure? Does the test end when the temperature rise reaches 30°C, 40°C,or some other number? Does it end when the temperature rise plus ambient temperatureequal the operating limit of the connector housing? The current rating will be fixed by thedefined failure point.●How were the test samples prepared? Were the samples energized through a P.C. board?How many layers? How large were the traces? What was the weight of the copper? Werethe samples energized through wire? What size was the wire? How long was the wire? Wasthe sample tested in static or forced air conditions? All of these factors can affect coolingcharacteristics.Clearly, a current rating value alone is not enough, and must be viewed in the context of the test used to developthe rating. When the test method is understood, evaluating and comparing power connectors for specific applicationsbecomes much less of a mystery.4DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>THE PCS SERIES utilizes Positronic Industries’LARGE SURFACE AREA CONTACT MATING SYSTEM●●●●●LARGE SURFACE AREACONTACT MATING SYSTEMSeparates mechanical and electrical functions for superior performanceLow contact resistance provides minimized voltage drop across the contact“Closed Entry” design prevents damage to female contacts and will not allowmisaligned or bent contacts to enterPrecision machined from solid, high conductivity copper alloyUniform insertion/withdrawal forces through repeated mating cyclesPositronic Industriesconnectpositronic.comGENERAL INFORMATIONWHY IS THE L.S.A. SYSTEM SUPERIOR?The primary function of connector contact is electricalconductivity. Also, a mechanical function is required toprovide normal force between male and female contacts.In order to provide for proper mechanical characteristics,material that has good memory or “springiness” mustbe chosen. This will ensure contact normal force in a coupledcondition and allow for repeated coupling and uncoupling.Unfortunately, many materials that have good memorycharacteristics have low electrical conductivity. Forinstance, beryllium copper is a good choice for mechanicalfunction; however, some beryllium copper alloys are poorconductors and have relatively low conductivity rates.The conductivity path of many contact designsgoes directly through materials that have been chosenbased on mechanical need. If these materials havea low conductivity rating, increased contact resistance willresult.Positronic Industries Large Surface Area ContactSystem separates the mechanical and electrical functions.A spring retention member provides normal forces,while the electrical conductivity path is through highlyconductive contact material. See above detail.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.5

GENERAL INFORMATIONPositronic Industriesconnectpositronic.comCOMPLIANT TERMINATIONSReliable, solderless connections from connectors tobackplanes started with solid press-fit technology.Although these are still used today, concerns about boarddamage led to the use of compliant press-fit technology.This technology allows the connection to be made throughcompliance of the contact termination along with P.C.board hole deformation. Although risk of damaged P.C.boards and backplanes is lessened, damage can still<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>POSITRONIC INDUSTRIES’ BI-SPRING POWERPRESS-FIT TERMINATIONSThe Next Evolution In Compliant Technology. Fully Compliant, Fully Reliable.occur due to relatively high insertion and extraction forces.The next step in press-fit technology is a highly reliableconnection between the contact termination andbackplane that is accomplished with reduced insertionand extraction forces. This eliminates risk of P.C. boardand backplane damage. This technology exists todaywith Positronic Industries Bi-Spring <strong>Power</strong> Press-Fit termination.Bi-Spring <strong>Power</strong>Press-Fit CompliantTerminations●●●Average insertion and extraction forces of size 16 contacts are 22N [5 lbs.] percontact and do not produce stresses in P.C. boards and backplanes that can occurwith higher insertion forces. These stresses can cause board warpage and holedamage.Connector systems utilizing Bi-Spring terminations use mounting screws to securethe connector to the P.C. board or backplane. Stresses that occur during coupling,uncoupling or shock and vibration of systems are not transferred to the P.C. boards orbackplanes through the press-fit connection. The electrical integrity of the connectorto board interface is maintained; this is particularly important in power applications.Bellcore GR1217 details a preference for mounting hardware when using press-fit terminations.Size 16 Bi-Spring terminations are designed to meet the performance requirementsand hole diameters as listed in the internationally recognized specificationIEC60352-5.●Lower insertion and extraction forces eliminate the need for expensive pressing equipment.COMPLIANT TERMINATION PRESS-FIT CONNECTOR0.155 [3.94]dp. x ø0.076 [1.93]mounting holetyp.Polarizing grooveFixed member ordiscriminatinglocking systemAB#2 self tapping mounting screwsSteel, zinc plate or stainless steel, passivatedContact lead-in diameter 0.047 [1.19]Contact termination diameter 0.069 [1.76]6DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>CUSTOMER SPECIFIEDARRANGEMENTSPositronic Industriesconnectpositronic.comThe design of <strong>Power</strong> <strong>Connection</strong> <strong>Systems</strong> Series connectors allows for the development of application specificcontact arrangements in a timely manner and at a reasonable price. Thirteen connector housing sizes exist that mayaccommodate size 20, size 16, size 12, or size 8 contacts (see the <strong>Power</strong> <strong>Connection</strong> <strong>Systems</strong> catalog for connectorhousing dimensions). After reviewing the dimensions and the following basic information, contact Technical Sales withyour current, voltage, and safety requirements. We look forward to working with you to develop a connector for yourspecific needs.BASIC CONNECTOR DIMENSIONSMale Connector DimensionsPART NUMBERAFemale Connector DimensionsA±0.020 [0.51]0.408[10.36]PLA03**00A1PLAH03**00A1PLA04**00A1PLAH04**00A1PLA06**00A1PLAH06**00A1PLA08**00A1PLAH08**00A1PART NUMBER1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]A0.408[10.36]A±0.020 [0.51]PCS SERIESA±0.020 [0.51]0.606[15.39]NEW!PLB06**00A1PLBH06**00A1PLB08**00A1PLBH08**00A1PLB12**00A1PLBH12**00A1PLB16**00A1PLBH16**00A1PLB20**00A1PLBH20**00A11.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]0.606[15.39]A±0.020 [0.51]PART NUMBERAA±0.020 [0.51]0.802[20.37]PLC09**00A1PLCH09**00A1PLC12**00A1PLCH12**00A1PLC18**00A1PLCH18**00A1PLC24**00A1PLCH24**00A1PLC30**00A1PLCH30**00A11.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]0.802[20.37]A±0.020 [0.51]Four Contact Sizes to Choose FromNEW!Size 8 contactØ0.142 [3.61]Ø0.094 [2.39]Many Termination Types Can Be SuppliedStraight Solder or Press-FitRight Angle (90°) SolderCrimp RemovableRemovable Solder CupSize 12 contactØ0.062 [1.57]Popular OptionsSequential MatingSelective LoadingSize 16 contactNEW!Size 20 contactØ0.040 [1.00]Contact sizes and termination types may bemixed within a single connector.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.7

P O S I T R O N I C I N D U S T R I E SPositronic Industriesconnectpositronic.comTECHNICAL INFORMATION<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>TECHNICAL CHARACTERISTICSPCS SERIESMATERIALS AND FINISHES:Insulator:Glass-filled polyester, UL 94V-0.Contact technical sales for availability ofhigh temperature insulator material.Contacts:Precision machined copper alloy with goldflash over nickel, or 0.000030 inch [0.76µ]gold over nickel, or 0.000050 [1.27µ] goldover nickel. Solder coated terminationsoptional.Mounting Clip:Beryllium copper with nickel plate.Hood:Glass filled polyester, UL 94V-0.Mounting Bracket:Brass with tin plate.Push-on Fastener:Spring tempered copper alloy, tin plateELECTRICAL CHARACTERISTICS:CONTACT CURRENT RATING:Standard Contact Material:High ConductivityContact Material:INITIAL CONTACT RESISTANCE:See page 9 for detail information.See page 9 for detail information.Standard Contact Material: 0.0016 ohms max. per IEC 512-2, Test 2b.High ConductivityContact Material: 0.0007 ohms max. per IEC 512-2, Test 2b.Insulation Resistance: 5 G ohms per IEC 512-2, Test 3a, Method A.Voltage Proof: 2000 V rms per IEC 512-2, Test 4a, Method C.Creepage Distance:0.157 inch [4 mm] minimum.Clearance Distance:0.125 inch [3.2 mm] minimum.Working Voltage:Designed to meet UL 600 VAC andCSA 600 VAC.Working Temperature:-55°C to +125°CContact technical sales for availability ofhigh temperature insulator material.ELECTRICAL CHARACTERISTICS OF COMPLIANTPRESS-FIT CONNECTION TO PLATED-THROUGH-HOLEOF PRINTED BOARD:0.064 inch [1.63mm] diameter hole of a0.125 inch [3.2mm] thick printed boardInitial Contact Resistanceof <strong>Connection</strong>: Less than 1.0 milliohms per IEC 512-2,Test 2a.Change in ContactResistance of <strong>Connection</strong>After Mechanical, Electricalor Climactic Conditioning:Gas Tight <strong>Connection</strong>sTest:SHIELDED CONTACT TECHNICALCHARACTERISTICS:See page 47.RoHSCompliant• per EU Directive 2002/95/EC•Less than 0.5 milliohms increase per IEC512-2, Test 2a.Less than 0.2 milliohms increase incontact resistance after 1 hour per EIA 364,TP36, Method One.For RoHS optionssee page 26.MECHANICAL CHARACTERISTICS:Removable Contacts:Insert contact to rear face of insulator,release from front face of insulator. Size16, 0.062 inch [1.57 mm] diameter malecontact. Female contact “closed entry”design for highest reliability.Removable Contact Retentionin Insulator: 15 lbs. [67N] per IEC 512-8, Test 15a.Fixed Contacts:Solder cup and printed board terminations.Size 16, 0.062 inch [1.57 mm] diametermale contact. Female contact has “closedentry” design for highest reliability.Fixed Contact Retentionin Insulator:6 lbs. [26N].Resistance to SolderIron Heat:Contact Terminations:Contact Insertion andWithdrawal Forces:<strong>Connection</strong> <strong>Systems</strong>:Sequential Mating System:500˚F [260°C] for 10 seconds duration perIEC 512-6, Test 12e, 25 watt soldering iron.Crimp or solder removable contacts from wiresizes 12 AWG [4.0 mm 2 ] through 24 AWG[0.25 mm 2 ]. Straight and Right Angle (90°)solder printed board mount, 0.062 inch [1.57mm] tail diameter. Compliant terminationpress-fit. Fixed contact solder cup termination,18 AWG [1.0 mm 2 ] maximum.8 oz. [2.2N] nominal per contact.Connector provides cable to cable, cable toprinted board, cable to panel mount andprinted board to printed board application.Cable and printed board mount connectors.Male contacts provide as many as three matinglengths.Locking System:Insulators provide locking between cable tocable, cable to printed board and cable topanel mount applications.Polarizations:Provided in insulator design. Further polarizationin cable connectors can be providedby mixing male contacts in female insulatorsand female contacts in male insulators.Mounting to Printed Board: Rapid installation push-on fasteners.Self-tapping screws for compliant connectors.Mechanical Operations: 500 operations per IEC 512-5.MECHANICAL CHARACTERISTICS OF COMPLIANTPRESS-FIT CONNECTORS:Press-Fit Contact Bi-SpringConstruction, CompliantTermination: 0.0695 inch [1.77mm] diameter with 0.050inch [1.27mm] lead-in diameter. Offeredwith two termination lengths.Contact Retention inInsulator and 0.125 inch[3.2mm] thick printed board:Vibration:Initial Press-In Forceof Individual Contactinto Plated-Through-Hole:Initial Push-Out Force ofIndividual Contact intoPlated-Through-Hole:5 lbs. [22N] minimum combined retentionforces per MIL-STD-2166, Type IIIcompliant contact classification, after thirdrepair- replacement of contact in insulatorand plated-through-hole, 0.064 inch[1.63mm] diameter in a 0.125 inch[3.2mm] thick printed board.No electrical discontinuity of 1µ second orgreater when tested per MIL-STD-1344,Method 2005, Test conditioning.10 lbs. [44N] average when pushed into a0.064 inch [1.63mm] Ø hole in a 0.125inch [3.2mm] thick printed board.8.5 lbs. [38N] average when pushed out ofan 0.064 inch [1.63mm] Ø hole in a 0.125inch [3.2mm] thick printed board.8DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.U.L. Recognized*File #E49351CSA RecognizedFile #LR54219*Note: U.L. Recognized all sizes, except PLB20, consult TechnicalSales for status.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>TEMPERATURE RISE CURVETEMPERATURE RISE CURVEPositronic Industriesconnectpositronic.comRATED CURRENT (AMPS)48444036322824201612STANDARD CONTACT MATERIALSCONNECTORS WITH PL* PREFIX8400 10 20 30 40 50 60 70 80 90 100TEMPERATURE RISE (°C)PLA03PLB12PLC30RATED CURRENT (AMPS)HIGH CONDUCTIVITY CONTACT MATERIALSCONNECTORS WITH PL*H PREFIXOR “S” SUFFIX ON CRIMP CONTACTS48444036322824201612840010 20 30 40 50 60 70 80 90 100TEMPERATURE RISE (°C)PLAH03PLBH12PLCH30Updatedthis chartwith highconductivityinformationPCS SERIESTEST DETAIL: Each curve was developed using individual connector bodies fully loaded with contacts. All powercontacts energized through 12 awg wire. Temperature rise was measured in the contact mating area. Test wasconducted with connectors in static air. Terminations of test connectors were straight compliant press-fit to right angle(90°) solder. See page 4 for more information.CONTACT CURRENT RATINGSCONNECTORVARIANTSTANDARDCONTACTSCONNECTORVARIANTHIGHCONDUCTIVITYCONTACTSPLA03 32 amps PLAH03 42 ampsPLB12 25 amps PLBH12 32 ampsPLC30 18 amps PLCH30 24 ampTemperature rise curves and contact current ratings were developed for the specific connector variants shownwhen tested in accordance with UL1977.This information is provided so that the user can make comparisons between various connector sizes andcontact materials.C-014 Rev E3DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.9

Positronic Industriesconnectpositronic.comMATING DIMENSIONS<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>MATING DIMENSIONS(FULLY MATED)0.830 [21.08]0.830 [21.08] 0.830 [21.08] 0.830 [21.08]Straight Board Mount Maleto Straight Board MountFemaleStraight Board Mount Maleto Right Angle (90°) BoardMount FemaleRight Angle (90°) BoardMount Male to StraightBoard Mount FemaleRight Angle (90°) BoardMount Male to Right Angle(90°) Board Mount FemalePCS SERIES0.790 [20.07] 0.790 [20.07]0.790 [20.07]Straight Board Mount Maleto Panel MountFemalePanel Mount Maleto Straight BoardMount FemaleRight Angle (90°) BoardMount Male to PanelBoard Mount Female0.790 [20.07]0.750[19.05]Panel Mount Maleto Right Angle (90°) BoardMount FemalePanel Mount Maleto Panel MountFemale1.100 [27.94]1.150 [29.21] 1.110 [27.94] 1.150 [29.21]Cable Mount Maleto Straight BoardMount FemaleStraight Board MountMale to CableMount FemaleCable Mount Maleto Right Angle (90°)Board Mount FemaleRight Angle (90°) Board MountMale to Cable MountFemale1.060 [26.92]1.110 [28.19]1.420 [36.07]10Cable Mount MaletoPanel Mount FemalePanel Mount Maleto Cable MountFemaleCable Mount MaletoCable Mount Female

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>STRAIGHT SOLDER PRINTEDBOARD CONNECTORPositronic Industriesconnectpositronic.comA±0.020 [0.51]PLA STRAIGHT PRINTED BOARD MOUNT CONNECTORSCODE 3, 0.146 [3.71] CONTACT EXTENSIONMALE0.600[15.24]0.146 [3.71]0.146 [3.71]0.600[15.24]FEMALEA±0.020 [0.51]Typical part number:PLA03M300A1PLAH03M300A10.408[10.36]ø0.062 [1.57]ø0.062 [1.57]0.230 [5.84]0.408[10.36]Typical part number:PLA03F300A1PLAH03F300A1*Asterisk determinesgender of connector,M for male,F for female.PLB STRAIGHT PRINTED BOARD MOUNT CONNECTORSCODE 3, 0.146 [3.71] CONTACT EXTENSIONMALEPART NUMBER A PART NUMBER APLA03*300A1PLAH03*300A1PLA04*300A1PLAH04*300A11.126[28.60]1.324[33.63]PLA06*300A1PLAH06*300A1PLA08*300A1PLAH08*300A11.718[43.64]2.112[53.64]Plating- See ordering informationfor contact plating options.For connection systems 1, 4 and 6.FEMALE0.6000.600[15.24][15.24]A±0.020 [0.51]0.146 [3.71]0.146 [3.71]A±0.020 [0.51]PCS SERIESTypical part number:PLB06M300A1PLBH06M300A1*Asterisk determinesgender of connector,M for male,F for female.0.606[15.39]ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLB06*300A1PLBH06*300A1PLB08*300A1PLBH08*300A1PLB12*300A1PLBH12*300A11.126[28.60]1.324[33.63]1.718[43.64]PLB16*300A1PLBH16*300A1PLB20*300A1PLBH20*300A12.112[53.64]2.506[63.65]0.230 [5.84]NEW!0.606[15.39]Typical part number:PLB06F300A1PLAH06F300AIPlating- See ordering informationfor contact plating options.For connection systems 1, 4 and 6.PLC STRAIGHT PRINTED BOARD MOUNT CONNECTORSCODE 3, 0.146 [3.71] CONTACT EXTENSIONFEMALEMALE0.600[15.24]0.600[15.24]A±0.020 [0.51]0.146 [3.71]0.146 [3.71]A±0.020 [0.51]0.802[20.37]ø0.062 [1.57]ø0.062 [1.57]0.802[20.37]Typical part number:PLC09M300A1PLCH09M300A1*Asterisk determinesgender of connector,M for male,F for female.PART NUMBER A PART NUMBER APLC09*300A1PLCH09*300A1PLC12*300A1PLCH12*300A1PLC18*300A1PLCH18*300A11.126[28.60]1.324[33.63]1.718[43.64]PLC24*300A1PLCH24*300A1PLC30*300A1PLCH30*300A12.112[53.64]2.506[63.65]0.230 [5.84]Typical part number:PLC09F300A1PLCH09F300A1Plating- See ordering informationfor contact plating options.For connection systems 1, 4 and 6.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.11

Positronic Industriesconnectpositronic.comSTRAIGHT SOLDER PRINTEDBOARD CONNECTOR<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>A±0.020 [0.51]PLA STRAIGHT PRINTED BOARD MOUNT CONNECTORSCODE 32, 0.377 [9.58] CONTACT EXTENSIONMALE0.600[15.24]0.377 [9.58] 0.377 [9.58]0.600[15.24]FEMALEA±0.020 [0.51]Typical part number:PLA03M3200A1PLAH03M3200A10.408[10.36]ø0.062 [1.57]ø0.062 [1.57]0.230 [5.84]0.408[10.36]Typical part number:PLA03F3200A1PLAH03F3200A1PCS SERIES*Asterisk determinesgender of connector,M for male,F for female.PART NUMBER A PART NUMBER APLA03*3200A1PLAH03*3200A1PLA04*3200A1PLAH04*3200A11.126[28.60]1.324[33.63PLA06*3200A1PLAH06*3200A1PLA08*3200A1PLAH08*3200A11.718[43.64]2.112[53.64]PLB STRAIGHT PRINTED BOARD MOUNT CONNECTORSCODE 32, 0.377 [9.58] CONTACT EXTENSIONPlating- See ordering informationfor contact plating options.For connection systems 1, 3, 4 and 6.MALEFEMALE0.600[15.24]0.600[15.24]A±0.020 [0.51] 0.377 [9.58] 0.377 [9.58]A±0.020 [0.51]Typical part number:PLB06M3200A1PLBH06M3200A1*Asterisk determinesgender of connector,M for male,F for female.0.606[15.39]ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLB06*3200A1PLBH06*3200A1PLB08*3200A1PLBH08*3200A1PLB12*3200A1PLBH12*3200A11.126[28.60]1.324[33.63]1.718[43.64]PLB16*3200A1PLBH16*3200A1PLB20*3200A1PLBH20*3200A12.112[53.64]2.506[63.65]NEW!0.230 [5.84]0.606[15.39]Typical part number:PLB06F3200A1PLBH06F3200A1Plating- See ordering informationfor contact plating options.For connection systems 1, 3, 4 and 6.PLC STRAIGHT PRINTED BOARD MOUNT CONNECTORSMALECODE 32, 0.377 [9.58] CONTACT EXTENSIONFEMALE0.600[15.24]0.600[15.24]A±0.020 [0.51] 0.377 [9.58] 0.377 [9.58]A±0.020 [0.51]0.802[20.37]ø0.062 [1.57]ø0.062 [1.57]0.802[20.37]Typical part number:PLC09M3200A1PLCH09M3200A10.230 [5.84]Typical part number:PLC09F3200A1PLCH09F3200A112*Asterisk determinesPLC09*3200A1gender of connector, PLCH09*3200A1M for male,PLC12*3200A1F for female. PLCH12*3200A1PLC18*3200A1PLCH18*3200A1DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.PART NUMBER A PART NUMBER A1.126[28.60]1.324[33.63]1.718[43.64]PLC24*3200A1PLCH24*3200A1PLC30*3200A1PLCH30*3200A12.112[53.64]2.506[63.65]Plating- See ordering informationfor contact plating options.For connection systems 1, 3, 4 and 6.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>A±0.020 [0.51]Typical part number:PLA03M93ST30A1PLAH03M93ST30A1**Asterisks determinegender of connector,M for male,F for female andcontact code 92 or 93.MALE0.408[10.36]MALEPLA COMPLIANT PRESS-FIT CONNECTORSCODE 92 OR CODE 93FEMALE0.600[15.24]PARTNUMBERPLA03**00A1PLAH03**00A1PLA04**00A1PLAH04**00A1PLA06**00A1PLAH06**00A1PLA08**00A1PLAH08**00A1A1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]COMPLIANT PRESS-FITCONNECTORPositronic Industriesconnectpositronic.com0.600[15.24]L LA±0.020 [0.51]See page 60for Installation Tooling.Plating- See ordering information forcontact plating options.For connection systems 1,4 and 6.* MOUNTING SCREWS CAN BE SUP-PLIED WITH CONNECTORS USINGSTEP 5 IN ORDERING INFORMATIONON PAGE 26. MOUNTING SCREWSCAN ALSO BE ORDERED SEPARATELYBY PART NUMBER. SEE PAGE 63.0.408[10.36]0.6000.600[15.24][15.24]A±0.020 [0.51] LLA±0.020 [0.51]0.230[5.84]CONTACTCODEPLB COMPLIANT PRESS-FIT CONNECTORSCODE 92 OR CODE 93FEMALE9293Typical part number:PLA03F93ST30A1PLAH03F93ST30A1PCB SCREWLTHICKNESS CODE *0.183[4.65]0.218[5.54]0.093[2.36]0.125[3.18]ST2SS2ST3SS3ST4SS4NEW!GENERAL INFORMATIONPCS SERIES0.606[15.39]0.606[15.39]Typical part number:PLB06M93ST30A1PLBH06M93ST30A1**Asterisks determinegender of connector,M for male,F for female andcontact code 92 or 93.NEW!PARTNUMBERPLB06**00A1PLBH06**00A1PLB08**00A1PLBH08**00A1PLB12**00A1PLBH12**00A1PLB16**00A1PLBH16**00A1PLB20**00A1PLBH20**00A1A1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]See page 60for Installation Tooling.Plating- See ordering information forcontact plating options.For connection systems 1,4 and 6.* MOUNTING SCREWS CAN BE SUP-PLIED WITH CONNECTORS USINGSTEP 5 IN ORDERING INFORMATIONON PAGE 26. MOUNTING SCREWSCAN ALSO BE ORDERED SEPARATELYBY PART NUMBER. SEE PAGE 63.0.230[5.84]CONTACTCODE9293L0.183[4.65]0.218[5.54]Typical part number:PLB06F93ST30A1PLBH06F93ST30A1PCBTHICKNESS0.093[2.36]0.125[3.18]SCREWCODE *ST2SS2ST3SS3ST4SS4NEW!MALEPLC COMPLIANT PRESS-FIT CONNECTORSCODE 92 OR CODE 93FEMALE0.600[15.24]0.600[15.24]A±0.020 [0.51] LLA±0.020 [0.51]0.802[20.37]0.802[20.37]Typical part number:PLC09M93ST30A1PLCH09M93ST30A1**Asterisks determinegender of connector,M for male,F for female andcontact code 92 or 93.PARTNUMBERPLC09**00A1PLCH09**00A1PLC12**00A1PLCH12**00A1PLC18**00A1PLCH18**00A1PLC24**00A1PLCH24**00A1PLC30**00A1PLCH30**00A1A1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]See page 60for Installation Tooling.Plating- See ordering information forcontact plating options.For connection systems 1,4 and 6.* MOUNTING SCREWS CAN BE SUP-PLIED WITH CONNECTORS USINGSTEP 5 IN ORDERING INFORMATIONON PAGE 26. MOUNTING SCREWSCAN ALSO BE ORDERED SEPARATELYBY PART NUMBER. SEE PAGE 63.0.230[5.84]CONTACTCODE9293L0.183[4.65]0.218[5.54]Typical part number:PLC09F93ST30A1PLCH09F93ST30A1PCBTHICKNESS0.093[2.36]0.125[3.18]SCREWCODE *ST2SS2ST3SS3ST4SS4NEW!C-014 Rev E3DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.13

Positronic Industriesconnectpositronic.comSTRAIGHT SOLDER AND COMPLIANTCONTACT HOLE PATTERN<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.PLA 03PLA 04PCS SERIES0.737±0.002[18.72±0.05]1.474±0.005[37.44±0.13]PLA 060.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.934±0.002[23.72±0.05]1.868±0.005[47.45±0.13]PLA 080.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.099±0.002[2.51±0.05]0.197±0.002[5.00±0.05]PLB 060.099±0.002[2.51±0.05]0.197±0.002[5.00±0.05]PLB 080.737±0.002[18.72±0.05]1.474±0.005[37.44±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.934±0.002[23.72±0.05]1.868±0.005[47.45±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.099±0.002[2.51±0.05]0.197±0.002[5.00±0.05]PLB 120.099±0.002[2.51±0.05]0.197±0.002[5.00±0.05]PLB 16NEW!0.099±0.002[2.51±0.05]0.197±0.002[5.00±0.05]1.131±0.002[28.73±0.05]2.262±0.005[57.45±0.13]PLB 200.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.SUGGESTED PRINTED BOARD HOLE SIZES:Suggest 0.080 [2.03] Ø holes in printed board for solder contacttermination positions.Suggest 0.100 [2.54] Ø holes in printed board when mountingconnectors with # 2 thread forming screws.Suggest 0.123±0.003 [3.15±0.08] Ø holes in printed board whenmounting connector with push-on fasteners.NOTE: See page 61 for suggested printed board drill hole sizes,recommended plating and finished hole sizes for compliantcontact termination positions.14DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>STRAIGHT SOLDER AND COMPLIANTCONTACT HOLE PATTERNPositronic Industriesconnectpositronic.com0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.394±0.002[10.01±0.05]0.394±0.002[10.01±0.05]0.197±0.002[5.00±0.05]PLC 09 0.197±0.002 PLC 12[5.00±0.05]0.737±0.002[18.72±0.05]0.394±0.002[10.01±0.05]0.197±0.002[5.00±0.05]1.474±0.005[37.44±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.934±0.002[23.72±0.05]0.394±0.002[10.01±0.05]1.868±0.005[47.45±0.13]PLC 18 0.197±0.002PLC 24[5.00±0.05]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.PCS SERIES0.394±0.002[10.01±0.05]0.197±0.002[5.00±0.05]1.131±0.002[28.73±0.05]2.262±0.005[57.45±0.13]PLC 300.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.SUGGESTED PRINTED BOARD HOLE SIZES:Suggest 0.080 [2.03] Ø holes in printed board for solder contacttermination positions.Suggest 0.100 [2.54] Ø holes in printed board when mountingconnectors with # 2 thread forming screws.Suggest 0.123±0.003 [3.15±0.08] Ø holes in printed board whenmounting connector with push-on fasteners.NOTE: See page 61 for suggested printed board drill hole sizes,recommended plating and finished hole sizes for compliant contacttermination positions.Connectors Designed To Customer SpecificationsPositronic connectors can be modified to customers specifications.Examples: select loading of contacts for cost savings or to gain creepage andclearance distances; longer PCB terminations; customer specified hardware.Positronic can develop and tool new connector designswith reasonable price and delivery.Contact Technical Sales with your particular requirements.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.15

Positronic Industriesconnectpositronic.comRIGHT ANGLE (90°) SOLDER PRINTEDBOARD CONNECTORPLA RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 4, 0.146 [3.71] CONTACT EXTENSION<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>0.408[10.36]0.146 [3.71]0.600[15.24]A±0.020 [0.51] 0.098 [2.49]0.098 [2.49]A±0.020 [0.51]Typical part number:PLA03M4BN0A1PLAH03M4BN0A1MALEø0.062 [1.57]ø0.062 [1.57]0.600[15.24]0.146 [3.71]FEMALE0.408[10.36]Typical part number:PLA03F4BN0A1PLAH03F4BN0A1PCS SERIES*Asterisk determinesgender of connector,M for male,F for female.A±0.020 [0.51]MALEPART NUMBER A PART NUMBER APLA03*400A1PLAH03*400A1PLA04*400A1PLAH04*400A1PLB RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 4, 0.146 [3.71] CONTACT EXTENSION0.600[15.24]1.126[28.60]1.324[33.630.098 [2.49]PLA06*400A1PLAH06*400A1PLA08*400A1PLAH08*400A10.098 [2.49]0.197 [5.00] 0.197 [5.00]1.718[43.64]2.112[53.64]0.600[15.24]Plating- See ordering information forcontact plating options.For connection systems 1, 2 and 5.FEMALEA±0.020 [0.51]Typical part number:PLB06M4BN0A1PLBH06B4BN0A10.606[15.39]*Asterisk determinesgender of connector,M for male,F for female.0.146 [3.71]ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLB06*400A1PLBH06*400A1PLB08*400A1PLBH08*400A1PLB12*400A1PLBH12*400A11.126[28.60]1.324[33.63]1.718[43.64]PLB16*400A1PLBH16*400A1PLB20*400A1PLBH20*400A12.112[53.64]2.506[63.65]NEW!0.146 [3.71]0.606[15.39]Typical part number:PLB06F4BN0A1PLBH06F4BN0A1Plating- See ordering information forcontact plating options.For connection systems 1, 2 and 5.A±0.020 [0.51]MALEPLC RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 4, 0.146 [3.71] CONTACT EXTENSION0.600[15.24]0.197 [5.00]0.098 [2.49]0.197 [5.00]0.197 [5.00]0.098 [2.49]0.197 [5.00]0.600[15.24]FEMALEA±0.020 [0.51]0.802[20.37]0.802[20.37]Typical part number:PLC09M4BN0A1PLCH09M4BN0A1*Asterisk determinesgender of connector,M for male,F for female.0.146 [3.71]ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLC09*400A1PLCH09*400A1PLC12*400A1PLCH12*400A1PLC18*400A1PLCH18*400A11.126[28.60]1.324[33.63]1.718[43.64]PLC24*400A1PLCH24*400A1PLC30*400A1PLCH30*400A12.112[53.64]2.506[63.65]0.146 [3.71]Typical part number:PLC09F4BN0A1PLCH09F4BN0A1Plating- See ordering information forcontact plating options.For connection systems 1, 2 and 5.16DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>RIGHT ANGLE (90°) SOLDER PRINTEDBOARD CONNECTORPositronic Industriesconnectpositronic.comA±0.020 [0.51]PLA RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 42, 0.377 [9.58] CONTACT EXTENSIONMALEFEMALE0.408[10.36]0.600[15.24]0.098 [2.49]0.098 [2.49]0.600[15.24]0.408[10.36]A±0.020 [0.51]0.377 [9.58]0.377 [9.58]Typical part number:PLA03M42BN0A1PLAH03M42BN0A1*Asterisk determinesgender of connector,M for male,F for female.A±0.020 [0.51]MALE0.600[15.24]ø0.062 [1.57]0.197 [5.00]0.098 [2.49]ø0.062 [1.57]PART NUMBER A PART NUMBER APLA03*4200A1PLAH03*4200A1PLA04*4200A1PLAH04*4200A11.126[28.60]1.324[33.63]PLA06*4200A1PLAH06*4200A1PLA08*4200A1PLAH08*4200A11.718[43.64]2.112[53.64]PLB RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 42, 0.377 [9.58] CONTACT EXTENSION0.197 [5.00]0.098 [2.49]0.600[15.24]Typical part number:PLA03F42BN0A1PLAH03F42BN0A1Plating- See ordering information forcontact plating options.For connection systems 1,2,3 and 5.FEMALEA±0.020 [0.51]PCS SERIES0.606[15.39]0.606[15.39]0.377 [9.58]0.377 [9.58]Typical part number:PLB06M42BN0A1PLBH06M42BN0A1*Asterisk determinesgender of connector,M for male,F for female.ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLB06*4200A1PLBH06*4200A1PLB08*4200A1PLBH08*4200A1PLB12*4200A1PLBH12*4200A11.126[28.60]1.324[33.63]1.718[43.64]PLB16*4200A1PLBH16*4200A1PLB20*4200A1PLBH20*4200A12.112[53.64]2.506[63.65]NEW!Typical part number:PLB06F42BN0A1PLBH06F42BN0A1Plating- See ordering information forcontact plating options.For connection systems 1,2,3 and 5.A±0.020 [0.51]PLC RIGHT ANGLE (90°) PRINTED BOARD MOUNTCODE 42, 0.377 [9.58] CONTACT EXTENSIONMALEFEMALE0.802[20.37]0.600[15.24]0.197 [5.00]0.098 [2.49]0.197 [5.00]0.197 [5.00]0.098 [2.49]0.197 [5.00]0.600[15.24]0.802[20.37]A±0.020 [0.51]0.377 [9.58]0.377 [9.58]Typical part number:PLC09M42BN0A1PLCH09M42BN0A1*Asterisk determinesgender of connector,M for male,F for female.ø0.062 [1.57]ø0.062 [1.57]PART NUMBER A PART NUMBER APLC09*4200A1PLCH09*4200A1PLC12*4200A1PLCH12*4200A1PLC18*4200A1PLCH18*4200A11.126[28.60]1.324[33.63]1.718[43.64]PLC24*4200A1PLCH24*4200A1PLC30*4200A1PLCH30*4200A12.112[53.64]2.506[63.65]Typical part number:PLC09F42BN0A1PLCH09F42BN0A1Plating- See ordering information forcontact plating options.For connection systems 1,2,3 and 5.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.17

Positronic Industriesconnectpositronic.comRIGHT ANGLE (90°) PRESS-FIT CONNECTORFOR USE WITH “FLAT ROCK” TOOLING<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>PCS SERIESA±0.020 [0.51]Typical part number:PLA03M63B30A1PLAH03M63B30A1A±0.020 [0.51]PLA RIGHT ANGLE (90°) PRESS-FIT CONNECTORCODE 62 OR CODE 63MALEFor connection systems 1,2 and 5.FEMALE0.408[10.36]0.606[15.39]L0.560[14.22]PART NUMBER A PART NUMBER APLA03**B30A1PLAH03**B30A1PLA04**B30A1PLAH04**B30A11.126[28.60]1.324[33.63]0.560[14.22]0.138 [3.51] 0.138 [3.51]Plating- See orderinginformation forcontact platingoptions.**Asterisk determines gender of connector, M for male, F for female, and contact code 62 or 63.MALEPLA06**B30A1PLAH06**B30A1PLA08**B30A1PLAH08**B30A11.718[43.64]2.112[53.64]0.560[14.22]PLB RIGHT ANGLE (90°) PRESS-FIT CONNECTORCODE 62 OR CODE 63For connection systems 1,2 and 5.Plating- See orderinginformation forcontact platingoptions.CONNECTORS AREDESIGNED TO BEMOUNTED TO THE PCBWITH SCREWS, SEESCREW CODE.0.560[14.22]0.408[10.36]0.606[15.39]A±0.020 [0.51]LTypical part number:PLA03F63B30A1 PLAH03F63B30A1CONTACTCODE6263L0.183[4.65]0.219[5.56]FEMALEPCBTHICKNESS0.093[2.36]0.125[3.18]A±0.020 [0.51]SCREWP/N *Mountingscrews areorderedseparately.See page63.Typical part number:PLB06M63B30A1PLBH06M63B30A1L0.138 [3.51]0.197 [5.00]PART NUMBER A PART NUMBER APLB06**B30A1PLBH06**B30A1PLB08**B30A1PLBH08**B30A11.126[28.60]1.324[33.63]PLB12**B30A1PLBH12**B30A1PLB16**B30A1PLBH16**B30A11.718[43.64]2.112[53.64]CONNECTORS AREDESIGNED TO BEMOUNTED TO THE PCBWITH SCREWS, SEESCREW CODE.**Asterisk determines gender of connector, M for male, F for female, and contact code 62 or 63.L0.138 [3.51]0.197 [5.00]CONTACTCODE6263L0.183[4.65]0.219[5.56]Typical part number:PLB06F63B30A1PLBH06F63B30A1PCBTHICKNESS SCREWP/N *0.093[2.36]0.125[3.18]Mountingscrews areorderedseparately.See page63.PLC RIGHT ANGLE (90°) PRESS-FIT CONNECTORCODE 62 OR CODE 63MALEFor connection systems 1,2 and 5.FEMALEA±0.020 [0.51]0.560[14.22]Plating- See orderinginformation forcontact platingoptions.0.560[14.22]A±0.020 [0.51]0.802[20.37]0.802[20.37]LLTypical part number:PLC09M63B30A1PLCH09M63B30A10.138 [3.51]0.197 [5.00]0.197 [5.00]0.138 [3.51]0.197 [5.00]0.197 [5.00]Typical part number:PLC09F63B30A1PLCH09F63B30A118PART NUMBER A PART NUMBER APLC09**B30A1PLCH09**B30A1PLC12**B30A1PLCH12**B30A1PLC18**B30A1PLCH18**B30A11.126[28.60]1.324[33.63]1.718[43.64]PLC24**B30A1PLCH24**B30A1PLC30**B30A1PLCH30**B30A112.112[53.64]2.506[63.65]CONNECTORS AREDESIGNED TO BEMOUNTED TO THE PCBWITH SCREWS, SEESCREW CODE.**Asterisk determines gender of connector, M for male, F for female, and contact code 62 or 63.CONTACTCODE6263L0.183[4.65]0.219[5.56]PCBTHICKNESS SCREWP/N *0.093[2.36]0.125[3.18]Mountingscrews areorderedseparately.See page63.C-014 Rev E3

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>RIGHT ANGLE (90°) PRINTED BOARDCONTACT HOLE PATTERNPositronic Industriesconnectpositronic.com0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.237±0.015[6.02±0.38]PLA 030.237±0.015[6.02±0.38]PLA 040.737±0.002[18.72±0.05]0.237±0.015[6.02±0.38]1.474±0.005[37.44±0.13]PLA 060.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.934±0.002[23.72±0.05]0.237±0.015[6.02±0.38]1.868±0.005[47.45±0.13]PLA 080.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.PCS SERIES0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.040±0.015[1.02±0.38]0.237±0.015[6.02±0.38]PLB 060.040±0.015[1.02±0.38]0.237±0.015[6.02±0.38]PLB 080.737±0.002[18.72±0.05]1.474±0.005[37.44±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.934±0.002[23.72±0.05]1.868±0.005[47.45±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.040±0.015[1.02±0.38]0.197±0.015[5.00±0.38]PLB 120.040±0.015[1.02±0.38]0.237±0.015[6.02±0.38]PLB 16NEW!1.131±0.002[28.73±0.05]2.262±0.005[57.45±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.441±0.002[11.20±0.05]0.882±0.005[22.40±0.13]0.197±0.002[5.00±0.05]TYP.0.040±0.015[1.02±0.38]0.237±0.015[6.02±0.38]PLB 200.157±0.015[3.99±0.38]0.040±0.015[1.02±0.38]0.237±0.015[6.02±0.38]PLC 09See page 20 for suggested printed board hole sizes.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.19

Positronic Industriesconnectpositronic.comRIGHT ANGLE (90°) PRINTED BOARD CONTACTHOLE PATTERN AND PANEL MOUNT CONNECTORWITH SOLDER CUP CONTACTS<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>0.540±0.002[13.72±0.05]1.080±0.005[27.43±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.737±0.002[18.72±0.05]1.474±0.005[37.44±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.157±0.002[3.99±0.05]0.040±0.002[1.02±0.05]0.237±0.002[6.02±0.05]PLC 120.157±0.002[3.99±0.05]0.040±0.002[1.02±0.05]0.237±0.002[6.02±0.05]PLC 18PCS SERIES0.934±0.002[23.72±0.05]1.868±0.005[47.45±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.1.131±0.002[28.73±0.05]2.262±0.005[57.45±0.13]0.197±0.002[5.00±0.05]0.099±0.002[2.51±0.05]TYP.0.157±0.002[3.99±0.05]0.040±0.002[1.02±0.05]0.237±0.002[6.02±0.05]PLC 240.157±0.002[3.99±0.05]0.040±0.002[1.02±0.05]0.237±0.002[6.02±0.05]PLC 30SUGGESTED PRINTED BOARD HOLE SIZES:Suggest 0.080 [2.03] Ø holes in printed board for solder contact termination positions.Suggest 0.123±0.003 [3.15±0.08] Ø holes in printed board when mounting connector with push-on fasteners.NOTE: See page 61 for suggested printed board drill hole sizes, recommended plating and finished hole sizesfor compliant contact termination positions.200.600[15.24]B0.200[5.08]NEW!MALEA±0.020 [0.51]PANEL MOUNT CONNECTORS WITH SOLDER CUP CONTACTS18 AWG max.[1.0 mm 2]TYPICAL PART NUMBER:PLB06M200A1DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.For connection system 8.CODE 2, 18 AWG [1.00mm 2 ] MAX.18 AWG max.[1.0 mm 2]FEMALEA±0.020 [0.51]0.600[15.24]TYPICAL PART NUMBER:PLB06F200A1B0.200[5.08]NEW!CONNECTORVARIANTSPLA03PLA04PLA06PLA08PLB06PLB08PLB12PLB16PLB20PLC09PLC12PLC18PLC24PLC30A1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]1.126[28.60]1.324[33.63]1.718[43.64]2.112[53.64]2.506[63.65]B0.408[10.36]0.408[10.36]0.408[10.36]0.408[10.36]0.606[15.39]0.606[15.39]0.606[15.39]0.606[15.39]0.606[15.39]0.802[30.37]0.802[30.37]0.802[30.37]0.802[30.37]0.802[30.37]

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>MALE INSULATOR DIMENSIONSFOR CABLE CONNECTORSPositronic Industriesconnectpositronic.comMALE INSULATOR DIMENSIONSFOR CABLE CONNECTORS WITH SIZE 16 REMOVABLE CONTACTSCODE 0 OR CODE 7CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELY0.500 [12.70]0.870±0.020[22.10±0.51]12345 67 80.986±0.020[25.04±0.51]1.184±0.020[30.07±0.51]1.578±0.020[40.08±0.51]1.972±0.020[50.09±0.51]PCS SERIES1230.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]1 2 3 4 1 2 34 5 6 1 2 3 4 5 6 7 80.408±0.015[10.36±0.38]PLA 03 PLA 04 PLA 06 PLA 080.986±0.020[25.04±0.51]1.184±0.020[30.07±0.51]1.578±0.020[40.08±0.51]1.972±0.020[50.09±0.51]1425360.606±0.015[15.39±0.38]1 23 40.606±0.015[15.39±0.38]1 2 34 5 60.606±0.015[15.39±0.38]1 2 3 45 6 7 85 6 7 8 7 8 910 11 129 10 11 12 13 14 15 160.606±0.015[15.39±0.38]PLB 06PLB 08PLB 12PLB 160.986±0.020[25.04±0.51]1.184±0.020[30.07±0.51]1.578±0.020[40.08±0.51]1.972±0.020[50.09±0.51]14 5 67 8 9230.802±0.015[20.37±0.38]12340.802±0.015[20.37±0.38]1 234 5 60.802±0.015[20.37±0.38]1 2 3 455 67 8 7 8 9 10 11 129 10 11 12 13 14 15 169 1011 1213 14 1516 17 1817 18 19 20 21 22 23 246780.802±0.015[20.37±0.38]PLC 09 PLC 12 PLC 18PLC 24For information regardingsize 16 removable contacts,see Removable Contact section,pages 47-53.1 2 3 4 5 6 711 12 13 14 1521 22 23 24 252.366±0.020[60.10±0.51]1626PLC 3017278 9 1018 19 2028 29 300.802±0.015[20.37±0.38]DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.21

Positronic Industriesconnectpositronic.comFEMALE INSULATOR DIMENSIONSFOR CABLE CONNECTORS<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>FEMALE INSULATOR DIMENSIONSFOR CABLE CONNECTORS WITH SIZE 16 REMOVABLE CONTACTSCODE 0 OR CODE 7CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELY0.550 [13.97]0.920±0.020[23.37±0.51]4 3 218 7 6 5PCS SERIES0.876±0.020[22.25±0.51]1.074±0.020[27.28±0.51]1.468±0.020[37.29±0.51]1.862±0.020[47.29±0.51]32 1 0.408±0.015[10.36±0.38]4 3 2 10.408±0.015[10.36±0.38]6 5 4 3 2 10.408±0.015[10.36±0.38]8 7 6 5 4 3 2 10.408±0.015[10.36±0.38]PLA 03 PLA 04 PLA 06 PLA 080.876±0.020[22.25±0.51]1.074±0.020[27.28±0.51]1.468±0.020[37.29±0.51]1.862±0.020[47.29±0.51]3 216 5 40.606±0.015[15.39±0.38]438 7216 50.606±0.015[15.39±0.38]6 5 43 2 112 11 109 8 70.606±0.015[15.39±0.38]8 7 6 5 4 3 2 116 15 14 1312 11 10 90.606±0.015[15.39±0.38]PLB 06PLB 08PLB 12PLB 160.876±0.020[22.25±0.51]1.074±0.020[27.28±0.51]1.468±0.020[37.29±0.51]1.862±0.020[47.29±0.51]3692581470.802±0.015[20.37±0.38]4 32 18 76 512 110.802±0.015[20.37±0.38]6 5 43 2 112 11 109 8 710 918 17 1615 14 130.802±0.015[20.37±0.38]8 716 1524 236 54 3 2 114 1312 11 10 922 2120 19 18 170.802±0.015[20.37±0.38]PLC 09PLC 12 PLC 18PLC 242.256±0.020[57.30±0.51]10 9 8 7 6 5 4 3 2 120 19 18 17 1615 14 13 12 1130 29 28 27 26 25 24 23 22 21PLC 300.802±0.015[20.37±0.38]For information regardingsize 16 removable contacts,see Removable Contact section,pages 47-53.22DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>MALE INSULATOR DIMENSIONSFOR PANEL MOUNT CONNECTORSPositronic Industriesconnectpositronic.comMALE INSULATOR DIMENSIONSFOR PANEL MOUNT CONNECTORS WITH SIZE 16 REMOVABLE CONTACTSCODE 1 OR CODE 8CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELY0.190±0.020[4.83±0.51]0.560±0.020[14.22±0.51]0.870±0.020[22.10±0.51]12 341.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]5 67 81.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]PCS SERIES0.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]1 2 3 1 2 3 4 1 2 3 4 5 6 1 2 3 45 6 7 80.408±0.015[10.36±0.38]PLA 03 PLA 04 PLA 06 PLA 081.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]1.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]1 2 345 60.606±0.015[15.39±0.38]1 2 35 67480.606±0.015[15.39±0.38]1 2 34 5 61 27 891011120.606±0.015[15.39±0.38]9103114125136147158160.606±0.015[15.39±0.38]PLB 06PLB 08PLB 12PLB 161.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]1.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]1 2 34 5 67 8 90.802±0.015[20.37±0.38]1 2 3 45 67 89 1011 120.802±0.015[20.37±0.38]1 2 34 5 67 8 9 10 11 1213 14 15 16 17 180.802±0.015[20.37±0.38]1 2 3 45 6 7 89 10 11 12 13 14 15 1617 18 19 20 21 22 23 240.802±0.015[20.37±0.38]PLC 09 PLC 12 PLC 18PLC 242.506±0.020[63.65±0.51]For informationregarding panelcutouts, seepage 67.1 2 3 411 12 13 1421 22 23 245 6 7 8 915 162526PLC 3017 18 1927 28 291020300.802±0.015[20.37±0.38]For information regardingsize 16 removable contacts,see Removable Contact section,pages 47-53.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.23

Positronic Industriesconnectpositronic.comFEMALE INSULATOR DIMENSIONSFOR PANEL MOUNT CONNECTORS<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>FEMALE INSULATOR DIMENSIONSFOR PANEL MOUNT CONNECTORS WITH SIZE 16 REMOVABLE CONTACTSCODE 1 OR CODE 8CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELY0.190±0.020[4.83±0.51]0.560±0.020[14.22±0.51]0.920±0.020[23.37±0.51]PCS SERIES1.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]4 38 726151.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]0.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]0.408±0.015[10.36±0.38]3 214 3 2 1 6 5 4 3 2 18 7 6 54 3 2 10.408±0.015[10.36±0.38]PLA 03 PLA 04 PLA 06 PLA 081.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]1.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]3 216 5 40.606±0.015[15.39±0.38]483726150.606±0.015[15.39±0.38]6 5 412 11 103928170.606±0.015[15.39±0.38]8 7 6 54 3 2 116 15 14 13 12 11 10 90.606±0.015[15.39±0.38]PLB 06PLB 08PLB 12PLB 161.126±0.020[28.60±0.51]1.324±0.020[33.63±0.51]1.718±0.020[43.64±0.51]2.112±0.020[53.64±0.51]3 216 5 49 8 70.802±0.015[20.37±0.38]4 3 2 18 7 6 50.802±0.015[20.37±0.38]6 5 43 2 112 11 109 8 712 11 10 9 18 17 161514 130.802±0.015[20.37±0.38]8 716 1524 23614225132141220311192101819170.802±0.015[20.37±0.38]PLC 09 PLC 12 PLC 18PLC 242.506±0.020[63.65±0.51]For informationregarding panelcutouts, seepage 67.10 9 8 7 620 19 18 17 1630 29 28 27 2651525PLC 30414243 2 113 12 1123 22 210.802±0.015[20.37±0.38]For information regardingsize 16 removable contacts,see Removable Contact section,pages 47-53.24DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>SEQUENTIAL CONTACTMATING CONNECTORPositronic Industriesconnectpositronic.comSEQUENTIAL MATING SYSTEM*REMOVABLE CONTACTS FOR CABLE CONNECTORS MUST BE ORDERED SEPARATELYFOR CONTACT SELECTION, SEE SIZE 16 CONTACTS ON PAGE 49EXAMPLE 1 EXAMPLE 21 2 3 4 5 6 1 2 3 4 5 6 7 8"X"LENGTHCODE“X”CONTACT LENGTHA 0.370 [9.40]B 0.330 [8.38]C 0.310 [7.87]D 0.290 [7.37]E 0.250 [6.35]POSITIONNUMBER"X"Typical Part Number:PLA06M300A1-E1B2BMATINGCONNECTOR TYPE CONTACTOPTIONSBoard to BoardBoard to Cable*Cable to Cable*B, D, EA, C, EA, DTypical Part Number:PLA08M4B0C1-D8BPCS SERIESWIRE SIZEAWG/[mm 2 ]12 - 14[4.0 - 2.5]16 - 18 - 20[1.5 - 1.0 - 0.5]LENGTHCODE “A”SEQUENTIAL MATING SYSTEMCRIMP REMOVABLE CONTACT PART NUMBERSLENGTHCODE “C”LENGTHCODE “D”LENGTHCODE “E”MC112N-133.3 MC112N-133.2 MC112N-133.1 MC112N-133.0MC116N-133.3 MC116N-133.2 MC116N-133.1 MC116N-133.0For information regardingsize 16 removable contacts,see Removable Contact section,pages 47-53.SELECTION GUIDE FOR ORDERING DIFFERENT CONTACT LENGTHSSTEP 9 OF ORDERING INFORMATIONSELECT CONNECTOR USING ORDERING INFORMATION ON PAGE 26THEN CHOOSE STEPS BELOW FOR SEQUENTIAL MATING SYSTEM CONTACTSSTEPEXAMPLESTEP 1Specify code for most frequentlyused contact mating length. Thislength is used for all contacts notspecified in steps 2 through 9.STEP 2Position number for first speciallength contact.STEP 3Length of contact specified in step 2.(Choose from length code chart)STEP 4Position number for second speciallength contact.1 2 3 4 5 6 7 8 9E 1 B 2 B 3 D 4 DSTEP 9Length of contact specified in step 8(Choose from length code chart).STEP 8Position number for fourth special lengthcontact.STEP 7Length of contact specified in step 6 (Choosefrom length code chart).STEP 6Position number for third special length contact.STEP 5Length of contact specified in step 4 (Choose fromlength code chart).DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.25

P O S I T R O N I C I N D U S T R I E SPositronic Industriesconnectpositronic.comPCS SERIES CONNECTORORDERING INFORMATION<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>PCS SERIESSTEP 1 - BASIC SERIESPLA - 1 RowPLAH - 1 Row High conductivity contactsPLB - 2 RowPLBH - 2 Row High conductivity contactsPLC - 3 RowPLCH - 3 Row High conductivity contactsSTEP 2 - CONNECTOR VARIANTS1 Row - 03, 04, 06, 082 Row - 06, 08, 12, 16, **203 Row - 09, 12, 18, 24, 30STEP 3 - CONNECTOR GENDERM - MaleF - FemaleSTEP 5 - MOUNTING STYLE0 - None,B - Metal Right Angle (90°) Mounting Bracket.BN - Metal Right Angle (90°) Mounting Bracket with Push-on Fastener.B3 - Plastic Right Angle (90°) Mounting Bracket with Cross Bar.B3N - Plastic Right Angle (90°) Mounting Bracket with Cross Bar and Push-onFastener.N - Push-On Fastener For Straight Printed Board Mount ConnectorsST2 - Self-tapping steel screws 2-28 x 0.250±0.030 [6.35±0.76] length for 0.093[2.36] thick board. Use with contact code 62, 63, 92 or 93.ST3 - Self-tapping steel screws 2-28 x 0.312±0.030 [7.92±0.76] length for 0.125[3.18] thick board. Use with contact code 62, 63, 92 or 93.ST4 - Self-tapping steel screws 2-28 x 0.375±0.030 [9.53±0.76] length for 0.175[4.45] thick board. Use with contact code 62, 63, 92 or 93.SS2 - Self-tapping stainless steel screws 2-28 x 0.250±0.030 [6.35±0.76] lengthfor 0.093 [2.36] thick board. Use with contact code 62, 63, 92 or 93.SS3 - Self-tapping stainless steel screws 2-28 x 0.312±0.030 [7.92±0.76] lengthfor 0.125 [3.18] thick board. Use with contact code 62, 63, 92 or 93.SS4 - Self-tapping stainless steel screws 2-28 x 0.375±0.030 [9.53±0.76] lengthfor 0.175 [4.45] thick board. Use with contact code 62, 63, 92 or 93.26ORDERING INFORMATION - CODE NUMBERING SYSTEMSpecify Complete Connector By Selecting An Option From Step 1 Through 7STEPEXAMPLEDIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.1 2 3 4 5 6 7 8PLB 06 F 3 0 0 A1 /AASTEP 4 - CONTACT TERMINATION TYPE* 0 - Order contacts separately for cable connectors forconnection systems 5, 6, 7, 8 and 9, see pages 47-53.* 1 - Removable contact, panel mounted connector for connectionsystem 8. Order contacts separately, see pages 47-53.2 - Solder Cup, 18 AWG [1.0mm 2 ] max. for panel mount connector,for connection system 8. Not available as PL*H.3 - Solder, Straight Printed Board Mount with 0.146 [3.71] tail extensionfor connection systems 1, 4 and 6.32 - Solder, Straight Printed Board Mount with 0.377 [9.58] tail extensionfor connection system 3 and systems 1, 4 and 6.4 - Solder, Right Angle (90°) Printed Board Mount with 0.146 [3.71]tail extension for connection systems 1, 2 and 5.42 - Solder, Right Angle (90°) Printed Board Mount with 0.377 [9.58]tail extension for connection system 3 and systems 1,2 and 5.***62- Press-fit, compliant Termination Right Angle (90°) Printed BoardMount, termination length 0.183 [4.65]. Must select “B3” in step 5.***63- Press-fit, compliant Termination Right Angle (90°) Printed BoardMount, termination length 0.219 [5.56]. Must select “B3” in step 5.* 7 - Order contacts separately for cable connectors for connectionsystems 5, 6, 7, 8 and 9, see pages 47-53. Terminating side ofinsulator has 0.165 [4.19] ø cʼbore for large wire sizes.* 8 - Removable contact, panel mounted connector for connectionsystem 8. Order contacts separately, see pages 47-53.Terminating side of insulator has 0.165 [4.19] ø cʼbore for largewire sizes.92 - Straight PCB Mount, Press-Fit, length 0.183 [4.65] for 0.093inch [2.36] thick board.93 - Straight PCB Mount, Press-Fit, length 0.218 [5.54] for 0.125inch [3.18] thick board.C-014 Rev E3RoHSSTEP 8 - ENVIRONMENTALCOMPLIANCEOPTIONSCompliant/AA - Compliant per EU Directive2002/95/EC (RoHS)NOTE: If compliance to environmental legislationis not required, this step will not be used.Example: PLB06F300A1• per EU Directive 2002/95/EC•STEP 7 - CONTACT PLATING FOR PRINTEDBOARD CONNECTORS0 - Crimp Contacts ordered separately, see pages 47-53.A1 - Gold flash over nickel on mating end and termination end.A2 - Gold flash over nickel on mating end and 0.00020 inch[5.00μ] tin-lead solder coat on termination end. Not availablewith code 62, 63, 92 or 93 in step 4.C1 - 0.000030 inch [0.76μ] gold over nickel on mating end andtermination end.C2 - 0.000030 inch [0.76μ] gold over nickel on mating end and0.00020 inch [5.00μ] tin-lead solder coated terminationend. Not available with code 62, 63, 92 or 93 in step 4.D1 - 0.000050 inch [1.27μ] gold over nickel on mating end andtermination end.D2 - 0.000050 inch [1.27μ] gold over nickel on mating end and0.00020 inch [5.00μ] tin-lead solder coated terminationend. Not available with code 62, 63, 92 or 93 in step 4.STEP 6 - HOODS AND PANEL MOUNT0 - None.5 - Top Opening Hood.6 - Panel Mount, quick release.81 - Panel Mount, fixed for 0.040 [1.02] thick panel.82 - Panel Mount, fixed for 0.060 [1.52] thick panel.83 - Panel Mount, fixed for 0.090 [2.29] thick panel.11 - Blind Mating System for 0.040 [1.02] thick panel.12 - Blind Mating System for 0.060 [1.52] thick panel.13 - Blind Mating System for 0.090 [2.29] thick panel.14 - Blind Mating System for 0.120 [3.05] thick panel.NOTE: Once you have made a connector selection, contactTechnical Sales if you would like to receive a drawing in DXF,PDF format or a 3-dimensional IGES file.SK Drawing* For high conductivity contact connectors, order PL*H connectorsand *C112N(2)S contacts** PLB20 variant available with code 2, 3, 32, 4, 42, 92, and 93 only in Step 4.*** Mounting screws are ordered separately. See page 63 for part numbers.9STEP 9 - SPECIAL OPTIONSSequential Mating <strong>Systems</strong>refer to page 25.CONTACT TECHNICAL SALESFOR SPECIAL OPTIONS3-dimensional model

P O S I T R O N I C I N D U S T R I E S<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>SAFETY SHROUDCONNECTORPositronic Industriesconnectpositronic.comSafety Shrouded Connectorto Prevent Unsafe Exposureto High Energy Circuits* Size 12 <strong>Power</strong> Contacts* Large Surface Area Mating System* Discriminating Locking System* Contact Current Rating to40 Amperes*Board - Cable / Cable - CableTECHNICAL CHARACTERISTICSMATERIALS AND FINISHES:Insulator:Glass-filled polyester, UL 94V-0.Contact technical sales for availabilityof high temperature insulator material.Contacts:Precision machined copper alloy withgold flash over nickel, or 0.000030 inch[0.76µ] gold over nickel, or 0.000050[1.27µ] gold over nickel. Solder coatedterminations optional.Push-on Fastener: Spring tempered copper alloy, tin plate.ELECTRICAL CHARACTERISTICS:Contact Current Rating: 40 amperes continuous,derated per IEC 512-3, test 5b.Higher currents available with highconductivity contacts, contactTechnical SalesInitial Contact Resistance: 0.001 ohms max. per IEC 512-2,test 2b.Insulation Resistance: 5 G ohms per IEC 512-2, test 3a.Voltage Proof:3,000 minimum V r.m.s. per IEC512-2, test 4a, method A.Clearance andCreepage Distance: 0.220 [5.60] minimumWorking Voltage:600 minimum V. r.m.s.Hot Pluggable [50couplings per UL 1977paragraph 15]:250 VAC at 20 amperesWorking Temperature: -55˚C to +125˚CContact technical sales for availabilityof high temperature insulator material.MECHANICAL CHARACTERISTICS:Removable Contacts: Rear insertion/ front release. Femalecontact features “Closed Entry” designfor highest reliability. 0.094 [2.39] diametermale contact.Removable ContactRetention in Insulator: 15 lbs. [67N] per IEC 512-8, test 15a.Fixed Contacts:Printed board terminations, bothstraight and 90˚. Female contactfeatures “Closed Entry” design forhighest reliability. 0.094 [2.39] diametermale contact.Fixed ContactRetention in Insulator: 15 lbs. [67N], minimum.Resistance to SolderingIron Heat:500˚F [260˚C] for 10 seconds durationper IEC 512-6, test 12e, 25 wattsoldering iron.Contact Terminations: Crimp removable contacts for wire size12 AWG [4.0 mm 2 ]. Straight and rightangle (90°)solder printed board mount,0.090 [2.29] tail diameter.<strong>Connection</strong> <strong>Systems</strong>: Cable to cable, cable to printed boardand cable to panel mount.Locking System:Insulators provide locking betweencable to cable, cable to printed boardand cable to panel mount applications.Polarization:Provided in insulator design.Mounting to P.C. Board: Rapid installation push-onfasteners.Mechanical Operations: 500 operationsSAFETY SHROUDRoHSCompliant• per EU Directive 2002/95/EC•For RoHS optionssee page 31.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.27

Positronic Industriesconnectpositronic.comCONNECTION SYSTEMSAND CABLE CONNECTOR<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>CONNECTION SYSTEMSSystem 5Cable to RightAngle (90°)Board MountSystem 6Cable to StraightBoard MountSystem 7Cable to CableSystem 8Panel Mountingto CableCONNECTOR VARIANTSFACE VIEW OF MALE OR REAR VIEW OF FEMALE CONNECTOR32 14 3 2 1547 65SAFETY SHROUDPLS5W5PLS7W7FEMALE CABLE CONNECTORFOR CABLE CONNECTORS WITH SIZE 12 REMOVABLE CONTACTSCODE 0CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELYPART NUMBERAPLS5W5F00001.655[42.04]0.494 [12.54]0.913 [23.19]PLS7W7F00002.072[52.64]Typical part number:PLS5W5F00000A ±0.020 [0.51]0.802 [20.38]For information regarding size 12 removable contacts, see Removable Contact section, pages 47-53.28DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.

<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>PANEL MOUNTCONNECTORPositronic Industriesconnectpositronic.comMALE PANEL MOUNT CONNECTORFOR PANEL MOUNT CONNECTORS WITH SIZE 12 REMOVABLE CONTACTSCODE 1CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELY0.802 [20.38]0.401 [10.19]Typical part number:PLS5W5M100002X ø0.100 [ø2.54]THRUBA±.020 [0.51]PART NUMBER A B1.013 [25.73]0.446 [11.33]PLS5W5M10000PLS7W7M100001.795[45.60]2.213[56.20]1.295[32.90]1.713[43.50]FEMALE PANEL MOUNT CONNECTORFOR PANEL MOUNT CONNECTORS WITH SIZE 12 REMOVABLE CONTACTSCODE 1CONTACTS ARE NOT SUPPLIED WITH CONNECTOR AND MUST BE ORDERED SEPARATELYTypical part number:PLS5W5F100000.494 [12.54]1.295 [32.90]0.952 [24.18]SAFETY SHROUD*CONTACT TECHNICAL SALESFOR AVAILABILITY OF 7W7 VARIANT.ø0.100 [2.54] THRU1.795 [45.60]0.802 [20.38]0.352 [8.94]For information regarding size 12 removable contacts, see Removable Contact section, pages 47-53.DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.29

Positronic Industriesconnectpositronic.comSTRAIGHT SOLDER AND RIGHT ANGLE (90°)SOLDER PRINTED BOARD CONNECTOR<strong>Power</strong><strong>Connection</strong><strong>Systems</strong>MALE STRAIGHT PRINTED BOARD MOUNT CONNECTORCODE 3, 0.146 [3.71] CONTACT EXTENSION0.401 [10.19]0.802 [20.38]ø0.090±0.003[2.29±0.08]2X ø0.100 [ø2.54]THRUBA±.020 [0.51]0.146 [3.71]Typical part number:PLS5W5M300A10.446 [11.33]PART NUMBER A B1.013 [25.73]PLS5W5M300A1PLS7W7M300A11.795[45.60]2.213[56.20]1.295[32.90]1.713[43.50]MALE RIGHT ANGLE (90°) PRINTED BOARD MOUNT CONNECTORCODE 4, 0.146 [3.71] CONTACT EXTENSION0.275 [6.98]0.386 [9.80]0.802 [20.38]0.146 [3.71]Typical part number:PLS5W5M400A1A±0.020 [0.51]ø0.090±0.003[2.29±0.08]SAFETY SHROUD1.013 [25.73]0.264 [6.70]0.446 [11.33]ø0.100 [ø2.54]X 0.348 [8.83] DEEPPART NUMBER A BPLS5W5M400A1PLS7W7M400A1PRINTED BOARD CONTACT HOLE PATTERNS1.795[45.60]2.213[56.20]1.295[32.90]1.713[43.50]STRAIGHT SOLDER2X 0.209 [5.30]2X 0.417 [10.60]3X 0.386 [9.80]PLS5W52X 0.209 [5.30]5X ø0.114 [2.90]2X 0.417 [10.60]3X 0.386 [9.80]PLS5W52X 0.193 [4.90]5X ø0.114 [2.90]2X 0.648 [16.45]2X ø0.123±0.003[3.12±0.08]2X 0.578 [14.69]2X ø0.123±0.003[3.12±0.08]2X 0.648 [16.45]2X 0.626 [15.90]2X 0.209 [5.30]4X 0.386 [9.80]PLS7W77X ø0.114 [2.90]2X 0.626 [15.90]2X 0.209 [5.30]4X 0.386 [9.80]PLS7W73X 0.193 [4.90]7X ø0.114 [2.90]2X 0.856 [21.75] 2X 0.417 [10.60]2X ø 0.123±0.003[3.12±0.08]2X 0.578 [14.69]2X ø0.123±0.003[3.12±0.08]2X 0.856 [21.75] 2X 0.417 [10.60]30DIMENSIONS ARE IN INCHES [MILLIMETERS].ALL DIMENSIONS ARE SUBJECT TO CHANGE.