NAVSEA Update - NSRP

NAVSEA Update - NSRP

NAVSEA Update - NSRP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

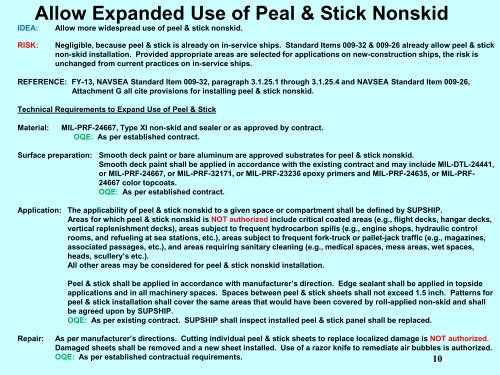

Allow Expanded Use of Peal & Stick NonskidIDEA: Allow more widespread use of peel & stick nonskid.RISK:Negligible, because peel & stick is already on in-service ships. Standard Items 009-32 & 009-26 already allow peel & sticknon-skid installation. Provided appropriate areas are selected for applications on new-construction ships, the risk isunchanged from current practices on in-service ships.REFERENCE: FY-13, <strong>NAVSEA</strong> Standard Item 009-32, paragraph 3.1.25.1 through 3.1.25.4 and <strong>NAVSEA</strong> Standard Item 009-26,Attachment G all cite provisions for installing peel & stick nonskid.Technical Requirements to Expand Use of Peel & StickMaterial:MIL-PRF-24667, Type XI non-skid and sealer or as approved by contract.OQE: As per established contract.Surface preparation: Smooth deck paint or bare aluminum are approved substrates for peel & stick nonskid.Smooth deck paint shall be applied in accordance with the existing contract and may include MIL-DTL-24441,or MIL-PRF-24667, or MIL-PRF-32171, or MIL-PRF-23236 epoxy primers and MIL-PRF-24635, or MIL-PRF-24667 color topcoats.OQE: As per established contract.Application: The applicability of peel & stick nonskid to a given space or compartment shall be defined by SUPSHIP.Areas for which peel & stick nonskid is NOT authorized include critical coated areas (e.g., flight decks, hangar decks,vertical replenishment decks), areas subject to frequent hydrocarbon spills (e.g., engine shops, hydraulic controlrooms, and refueling at sea stations, etc.), areas subject to frequent fork-truck or pallet-jack traffic (e.g., magazines,associated passages, etc.), and areas requiring sanitary cleaning (e.g., medical spaces, mess areas, wet spaces,heads, scullery’s etc.).All other areas may be considered for peel & stick nonskid installation.Peel & stick shall be applied in accordance with manufacturer’s direction. Edge sealant shall be applied in topsideapplications and in all machinery spaces. Spaces between peel & stick sheets shall not exceed 1.5 inch. Patterns forpeel & stick installation shall cover the same areas that would have been covered by roll-applied non-skid and shallbe agreed upon by SUPSHIP.OQE: As per existing contract. SUPSHIP shall inspect installed peel & stick panel shall be replaced.Repair:As per manufacturer’s directions. Cutting individual peel & stick sheets to replace localized damage is NOT authorized.Damaged sheets shall be removed and a new sheet installed. Use of a razor knife to remediate air bubbles is authorized.OQE: As per established contractual requirements.10