NAVSEA Update - NSRP

NAVSEA Update - NSRP

NAVSEA Update - NSRP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

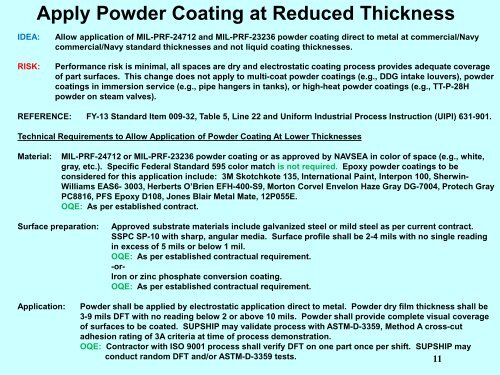

Apply Powder Coating at Reduced ThicknessIDEA:Allow application of MIL-PRF-24712 and MIL-PRF-23236 powder coating direct to metal at commercial/Navycommercial/Navy standard thicknesses and not liquid coating thicknesses.RISK:Performance risk is minimal, all spaces are dry and electrostatic coating process provides adequate coverageof part surfaces. This change does not apply to multi-coat powder coatings (e.g., DDG intake louvers), powdercoatings in immersion service (e.g., pipe hangers in tanks), or high-heat powder coatings (e.g., TT-P-28Hpowder on steam valves).REFERENCE: FY-13 Standard Item 009-32, Table 5, Line 22 and Uniform Industrial Process Instruction (UIPI) 631-901.Technical Requirements to Allow Application of Powder Coating At Lower ThicknessesMaterial:MIL-PRF-24712 or MIL-PRF-23236 powder coating or as approved by <strong>NAVSEA</strong> in color of space (e.g., white,gray, etc.). Specific Federal Standard 595 color match is not required. Epoxy powder coatings to beconsidered for this application include: 3M Skotchkote 135, International Paint, Interpon 100, Sherwin-Williams EAS6- 3003, Herberts O’Brien EFH-400-S9, Morton Corvel Envelon Haze Gray DG-7004, Protech GrayPC8816, PFS Epoxy D108, Jones Blair Metal Mate, 12P055E.OQE: As per established contract.Surface preparation:Approved substrate materials include galvanized steel or mild steel as per current contract.SSPC SP-10 with sharp, angular media. Surface profile shall be 2-4 mils with no single readingin excess of 5 mils or below 1 mil.OQE: As per established contractual requirement.-or-Iron or zinc phosphate conversion coating.OQE: As per established contractual requirement.Application:Powder shall be applied by electrostatic application direct to metal. Powder dry film thickness shall be3-9 mils DFT with no reading below 2 or above 10 mils. Powder shall provide complete visual coverageof surfaces to be coated. SUPSHIP may validate process with ASTM-D-3359, Method A cross-cutadhesion rating of 3A criteria at time of process demonstration.OQE: Contractor with ISO 9001 process shall verify DFT on one part once per shift. SUPSHIP mayconduct random DFT and/or ASTM-D-3359 tests.11