Vacuum Components Catalog - ULVAC Technologies

Vacuum Components Catalog - ULVAC Technologies

Vacuum Components Catalog - ULVAC Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

<strong>Vacuum</strong> Pump<br />

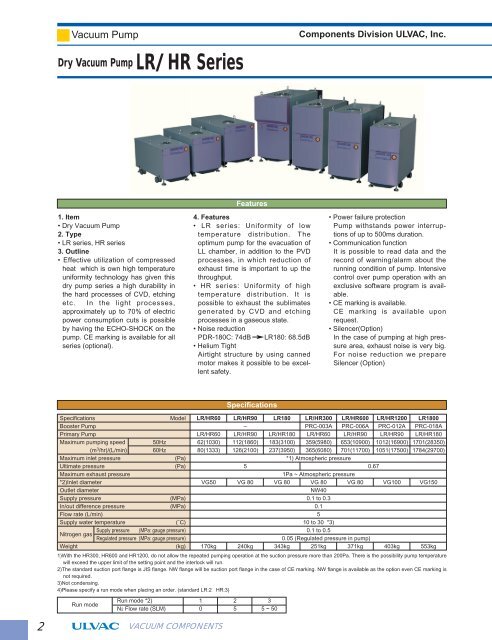

Dry <strong>Vacuum</strong> Pump LR/HR Series<br />

1. Item<br />

• Dry <strong>Vacuum</strong> Pump<br />

2. Type<br />

• LR series, HR series<br />

3. Outline<br />

• Effective utilization of compressed<br />

heat which is own high temperature<br />

uniformity technology has given this<br />

dry pump series a high durability in<br />

the hard processes of CVD, etching<br />

etc. In the light processes,<br />

approximately up to 70% of electric<br />

power consumption cuts is possible<br />

by having the ECHO-SHOCK on the<br />

pump. CE marking is available for all<br />

series (optional).<br />

VACUUM COMPONENTS<br />

Features<br />

4. Features<br />

• LR series: Uniformity of low<br />

temperature distribution. The<br />

optimum pump for the evacuation of<br />

LL chamber, in addition to the PVD<br />

processes, in which reduction of<br />

exhaust time is important to up the<br />

throughput.<br />

• HR series: Uniformity of high<br />

temperature distribution. It is<br />

possible to exhaust the sublimates<br />

generated by CVD and etching<br />

processes in a gaseous state.<br />

• Noise reduction<br />

PDR-180C: 74dB LR180: 68.5dB<br />

• Helium Tight<br />

Airtight structure by using canned<br />

motor makes it possible to be excellent<br />

safety.<br />

Specifications<br />

<strong>Components</strong> Division <strong>ULVAC</strong>, Inc.<br />

• Power failure protection<br />

Pump withstands power interruptions<br />

of up to 500ms duration.<br />

• Communication function<br />

It is possible to read data and the<br />

record of warning/alarm about the<br />

running condition of pump. Intensive<br />

control over pump operation with an<br />

exclusive software program is available.<br />

• CE marking is available.<br />

CE marking is available upon<br />

request.<br />

• Silencer(Option)<br />

In the case of pumping at high pressure<br />

area, exhaust noise is very big.<br />

For noise reduction we prepare<br />

Silencer (Option)<br />

Specifications Model LR/HR60 LR/HR90 LR180 LR/HR300 LR/HR600 LR/HR1200 LR1800<br />

Booster Pump – PRC-003A PRC-006A PRC-012A PRC-018A<br />

Primary Pump LR/HR60 LR/HR90 LR/HR180 LR/HR60 LR/HR90 LR/HR90 LR/HR180<br />

Maximum pumping speed 50Hz 62(1030) 112(1860) 183(3100) 359(5980) 653(10900) 1012(16900) 1701(28350)<br />

(m3 /hr)/(L/min) 60Hz 80(1333) 126(2100) 237(3950) 365(6080) 701(11700) 1051(17500) 1784(29700)<br />

Maximum inlet pressure (Pa) *1) Atmospheric pressure<br />

Ultimate pressure (Pa) 5 0.67<br />

Maximum exhaust pressure 1Pa ~ Atmospheric pressure<br />

*2)Inlet diameter VG50 VG 80 VG 80 VG 80 VG 80 VG100 VG150<br />

Outlet diameter NW40<br />

Supply pressure (MPa) 0.1 to 0.3<br />

In/out difference pressure (MPa) 0.1<br />

Flow rate (L/min) 5<br />

Supply water temperature (˚C) 10 to 30 *3)<br />

Supply pressure (MPa: gauge pressure)<br />

Nitrogen gas<br />

Regulated pressure (MPa: gauge pressure)<br />

0.1 to 0.5<br />

0.05 (Regulated pressure in pump)<br />

Weight (kg) 170kg 240kg 343kg 251kg 371kg 403kg 553kg<br />

1)With the HR300, HR600 and HR1200, do not allow the repeated pumping operation at the suction pressure more than 200Pa. There is the possibility pump temperature<br />

will exceed the upper limit of the setting point and the interlock will run.<br />

2)The standard suction port flange is JIS flange. NW flange will be suction port flange in the case of CE marking. NW flange is available as the option even CE marking is<br />

not required.<br />

3)Not condensing.<br />

4)Please specify a run mode when placing an order. (standard LR:2 HR:3)<br />

Run mode<br />

Run mode *2) 1 2 3<br />

N2 Flow rate (SLM) 0 5 5 ~ 50

Pumping Speed<br />

L/min m3/ h<br />

5000 300<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

250<br />

200<br />

150<br />

100<br />

LR/HR60<br />

318<br />

370<br />

378<br />

LR/HR90<br />

368<br />

420<br />

428<br />

LR180<br />

468<br />

520<br />

528<br />

50<br />

Pumping Speed(JIS B8316/1965)<br />

Power : AC200V 50/60Hz dia. 3<br />

Oil : Fomblin Y-LVA C 25/6<br />

BARRIERTA ® J100F<br />

Grease : BARRIERTA ® IS-V<br />

Gauge : Pirani<br />

Capasitance Manometer<br />

LR180<br />

LR/HR90<br />

LR/HR60<br />

0<br />

10-1 1 10 102 103 104 105 Pa<br />

Suction port<br />

(VG50)<br />

(VG80)<br />

LR/HR300<br />

Suction port<br />

530<br />

480<br />

478<br />

579<br />

523<br />

519<br />

Suction port<br />

(VG80)<br />

645<br />

590<br />

585<br />

Suction port<br />

(VG80)<br />

831<br />

774<br />

771<br />

284 579<br />

694<br />

824<br />

900<br />

304 626<br />

754<br />

888<br />

967<br />

317 682<br />

820<br />

959<br />

1036<br />

910<br />

284 579<br />

318<br />

694<br />

370 824<br />

378<br />

900<br />

Pressure<br />

279<br />

Exhaust port<br />

(NW40)<br />

A heater is<br />

attached to<br />

HR series.<br />

50Hz<br />

60Hz<br />

50Hz<br />

60Hz<br />

216<br />

Exhaust port<br />

(NW40)<br />

264<br />

50Hz<br />

40<br />

122 40<br />

201<br />

Exhaust port<br />

(NW40)<br />

264<br />

279<br />

221<br />

142 40<br />

Exhaust port<br />

(NW40)<br />

216<br />

137<br />

40<br />

137<br />

60Hz<br />

140<br />

165<br />

215<br />

Pumping Speed Curve<br />

LR/HR60, 90, LR180 LR/HR300, 600, 1200, LR1800<br />

N2 purge gas port<br />

Cooling Water Inlet<br />

Cooling Water Outlet<br />

Pumping Speed<br />

Power<br />

Remote Control<br />

RS485 or RS232C<br />

Breaker Switch<br />

L/min m3/ h<br />

2000<br />

30000 1800<br />

25000<br />

20000<br />

15000<br />

10000<br />

5000<br />

0<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

External Dimension Diagram<br />

140<br />

LR/HR600<br />

368<br />

420<br />

470<br />

368<br />

420<br />

470<br />

<strong>Components</strong> Division <strong>ULVAC</strong>, Inc.<br />

LR1800<br />

LR/HR1200<br />

50Hz<br />

60Hz<br />

50Hz<br />

LR/HR600 60Hz<br />

50Hz<br />

LR/HR300<br />

60Hz<br />

10-1 1 10 10 2 10 3 10 4 10 5<br />

Suction port<br />

(VG80)<br />

LR/HR1200<br />

LR1800<br />

468<br />

520<br />

528<br />

951<br />

894<br />

891<br />

Suction port<br />

(VG100)<br />

951<br />

894<br />

891<br />

Suction port<br />

(VG150)<br />

1037<br />

980<br />

977<br />

Pressure<br />

987<br />

304 626<br />

754<br />

888<br />

967<br />

987<br />

304 626<br />

754<br />

888<br />

967<br />

1213<br />

392 682<br />

820<br />

959<br />

1036<br />

60Hz<br />

50Hz<br />

264<br />

264<br />

264<br />

Exhaust port<br />

(NW40)<br />

201<br />

122<br />

VACUUM COMPONENTS 3<br />

201<br />

40<br />

Exhaust port<br />

(NW40)<br />

142 40<br />

221<br />

40<br />

122<br />

Exhaust port<br />

(NW40)<br />

215<br />

165<br />

165<br />

Pa<br />

(unit: mm)