‘Designers are starting to treat concreteas a highly engineered material.’spandrel-arch bridge over the PayetteRiver between Boise and Cascade, Idaho,was rehabilitated. CH2M Hill providedboth design and construction servicesfor the $2.9-million project, whichinvolved reconstruction of corrosiondamageddeck-stringer ends and repairof columns, piers, and arches. Existingdecorative bridge rails also were replacedwith an identical railing. Throughout thedesign, the original historic fabric of thebridge was retained whenever possible.CH2M Hill supplied designbuildservices for the newI-5/41st Street Interchange(at center) and a new flyoverbridge (far left) that replacedan outdated left lane exitin Everett, Washington. <strong>The</strong>project included the wideningof about 10 miles of highwayand rebuilding bridges andinterchanges.<strong>Concrete</strong> Helps MeetChallenges<strong>Concrete</strong> materials can help meet anumber of the challenges presented bythese trends—and that, too, has beena trend for some time, he states. “<strong>The</strong>industry has been headed toward moreconcrete designs for the past 30 or 40years.” Earlier, virtually every interstateoverpass, especially spans of more than100 ft, was constructed with steel girders.“Everything is changed now. We’reseeing precast, prestressed concrete usedmuch more often, with box girder spansas short as 80 ft. At the same time,some prestressed spliced girders areextending to 350-ft-long spans. Splicedgirdersand segmental technology haveexpanded the use of concrete in bridges,and post-tensioning is more widespreadthan ever.”<strong>The</strong> concrete industry has changeddramatically in recent years, he adds,increasing its capabilities significantly.In the 1980s and 1990s, many of theadvances in bridge engineering couldbe attributed to computer software thatallowed designs to be modeled and betterforecasts and calculations to be created.“But in the last 5 to 10 years, the changeswe’ve seen have been due to changes inmaterials and better performance, andthat includes concrete.”High performance concrete is a keyexample. “Designers are starting totreat concrete as a highly engineeredmaterial, and that’s an evolving change.<strong>The</strong>se advances affect what can beaccomplished with bridge engineering,and that’s really exciting.” <strong>The</strong> changeshave been particularly notable in theprecast concrete field, with techniquesachieved with formliners, coloring, andother aesthetic options. “<strong>The</strong>re really area lot of new options being created.”It’s up to designers to stay up to dateand incorporate new ideas whenapplicable, he stresses. “Designersare gaining awareness, and they’reasking questions about what can beaccomplished.” For that reason, CH2MHill works closely with concrete suppliersearly in the design process. “We don’twant to overspecify materials, so wework closely with concrete producers,and they’re very constructive with helpat the concept level. And since we alsoare contractors, we can integrate theideas throughout the process.”<strong>The</strong> new concepts are expandingconcrete applications in new directions,12 | <strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>08</strong>

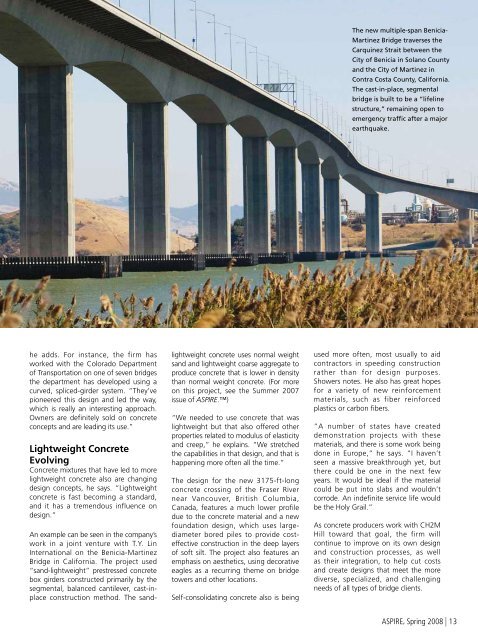

<strong>The</strong> new multiple-span Benicia-Martinez <strong>Bridge</strong> traverses theCarquinez Strait between theCity of Benicia in Solano Countyand the City of Martinez inContra Costa County, California.<strong>The</strong> cast-in-place, segmentalbridge is built to be a “lifelinestructure,” remaining open toemergency traffic after a majorearthquake.he adds. For instance, the firm hasworked with the Colorado Departmentof Transportation on one of seven bridgesthe department has developed using acurved, spliced-girder system. “<strong>The</strong>y’vepioneered this design and led the way,which is really an interesting approach.Owners are definitely sold on concreteconcepts and are leading its use.”Lightweight <strong>Concrete</strong>Evolving<strong>Concrete</strong> mixtures that have led to morelightweight concrete also are changingdesign concepts, he says. “Lightweightconcrete is fast becoming a standard,and it has a tremendous influence ondesign.”An example can be seen in the company’swork in a joint venture with T.Y. LinInternational on the Benicia-Martinez<strong>Bridge</strong> in California. <strong>The</strong> project used“sand-lightweight” prestressed concretebox girders constructed primarily by thesegmental, balanced cantilever, cast-inplaceconstruction method. <strong>The</strong> sandlightweightconcrete uses normal weightsand and lightweight coarse aggregate toproduce concrete that is lower in densitythan normal weight concrete. (For moreon this project, see the Summer 2007issue of <strong>ASPIRE</strong>.)“We needed to use concrete that waslightweight but that also offered otherproperties related to modulus of elasticityand creep,” he explains. “We stretchedthe capabilities in that design, and that ishappening more often all the time.”<strong>The</strong> design for the new 3175-ft-longconcrete crossing of the Fraser Rivernear Vancouver, British Columbia,Canada, features a much lower profiledue to the concrete material and a newfoundation design, which uses largediameterbored piles to provide costeffectiveconstruction in the deep layersof soft silt. <strong>The</strong> project also features anemphasis on aesthetics, using decorativeeagles as a recurring theme on bridgetowers and other locations.Self-consolidating concrete also is beingused more often, most usually to aidcontractors in speeding constructionrather than for design purposes.Showers notes. He also has great hopesfor a variety of new reinforcementmaterials, such as fiber reinforcedplastics or carbon fibers.“A number of states have createddemonstration projects with thesematerials, and there is some work beingdone in Europe,” he says. “I haven’tseen a massive breakthrough yet, butthere could be one in the next fewyears. It would be ideal if the materialcould be put into slabs and wouldn’tcorrode. An indefinite service life wouldbe the Holy Grail.”As concrete producers work with CH2MHill toward that goal, the firm willcontinue to improve on its own designand construction processes, as wellas their integration, to help cut costsand create designs that meet the morediverse, specialized, and challengingneeds of all types of bridge clients.<strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>08</strong> | 13

- Page 1 and 2: THE CONCRETE BRIDGE MAGAZINESPRING

- Page 4 and 5: EDITORIALPhoto: Ted Lacey Photograp

- Page 6 and 7: READER RESPONSEw w w . a s p i r e

- Page 8 and 9: CONTRIBUTING AUTHORSCONCRETE CALEND

- Page 10 and 11: FOCUSCH2M Hill’sHolisticApproachb

- Page 12 and 13: As the largest highwayconstructionp

- Page 17 and 18: Post-tensioning is being utilized o

- Page 19 and 20: Aesthetic requirements played a key

- Page 21 and 22: Photo: U.S. Fish & Wildlife Service

- Page 23 and 24: Although flame temperatures at this

- Page 25 and 26: HPCSafe, Affordable,and Effi cient2

- Page 27 and 28: within the concrete just inside the

- Page 29 and 30: ReferenceDesign for Fire Resistance

- Page 31 and 32: The 1.3-mile-long Des Plaines River

- Page 33 and 34: Formwork for piercolumns showndurin

- Page 35 and 36: QAEdison Bridge, Fort Myers, Florid

- Page 37 and 38: Cliff FreyermuthManager, ASBIThe or

- Page 39 and 40: ASBI’s Future VisionThe Board of

- Page 41 and 42: A view of the nearlycompleted first

- Page 43 and 44: An ‘Environmentally Friendly’ B

- Page 45 and 46: Visit www.pci.orgSelect News & Even

- Page 47 and 48: This construction provided TxDOT wi

- Page 49 and 50: TxDOT developed a prefabricated sys

- Page 51 and 52: loads include the usual wind, therm

- Page 53 and 54: construction considerations include

- Page 55 and 56: S A F E T Y AND S E R V I C E A B I

- Page 57 and 58: 5. An exemplary ecosystem initiativ

- Page 59 and 60: Silica Fume AssociationThe Silica F

- Page 61 and 62: Arizona uses modified versions of t

- Page 63 and 64: Expanded Shale, Clay, and Slate Ins

- Page 65 and 66:

National Ready Mixed Concrete Assoc

- Page 67 and 68:

Roadmapping Success:In our industry

- Page 69 and 70:

PUYALLUP RIVER Bridge / WASHINGTON

- Page 71 and 72:

Web | ASPIRE, Spring 2008PUYALLUP R

- Page 73 and 74:

Web | ASPIRE, Spring 2008PUYALLUP R

- Page 75 and 76:

Web | ASPIRE, Spring 2008PUYALLUP R

- Page 77 and 78:

Web | ASPIRE, Spring 2008PUYALLUP R

- Page 79 and 80:

Web | ASPIRE, Spring 2008PUYALLUP R

- Page 81 and 82:

Bell island Bridge / oklahoma city,

- Page 83 and 84:

Web | ASPIRE, Spring 2008NORWALK RI

- Page 85 and 86:

Web | ASPIRE, Spring 2008NORWALK RI

- Page 87 and 88:

DES PLAINES RIVER VALLEY Bridge ON

- Page 89 and 90:

PROJECTMAROON CREEK BRIDGE REPLACEM

- Page 91 and 92:

PROJECTLOOP 340 BRIDGES / WACO, TEX

- Page 93 and 94:

PROJECTLOOP 340 BRIDGES / WACO, TEX

- Page 95 and 96:

PROJECTTAXIWAY SIERRA UNDERPASS / S

- Page 97 and 98:

PROJECTTAXIWAY SIERRA UNDERPASS / S

- Page 99 and 100:

ARIZONA All Photos: Arizona Departm

- Page 101 and 102:

ARIZONA All Photos: Arizona Departm

- Page 103 and 104:

ARIZONA All Photos: Arizona Departm