ASPIRE Spring 08 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 08 - Aspire - The Concrete Bridge Magazine

ASPIRE Spring 08 - Aspire - The Concrete Bridge Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

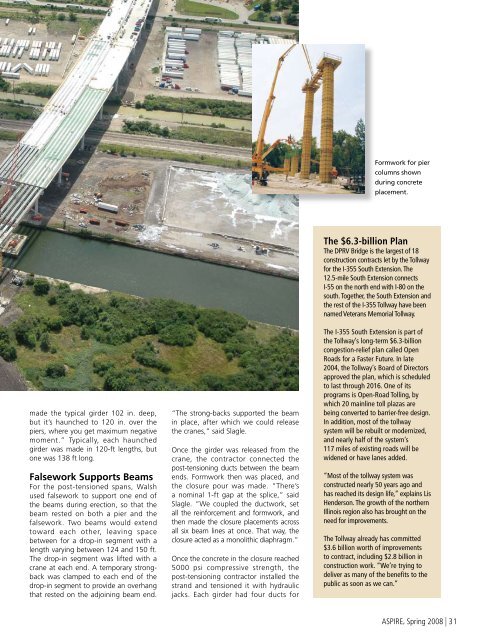

Formwork for piercolumns shownduring concreteplacement.<strong>The</strong> $6.3-billion Plan<strong>The</strong> DPRV <strong>Bridge</strong> is the largest of 18construction contracts let by the Tollwayfor the I-355 South Extension. <strong>The</strong>12.5-mile South Extension connectsI-55 on the north end with I-80 on thesouth. Together, the South Extension andthe rest of the I-355 Tollway have beennamed Veterans Memorial Tollway.made the typical girder 102 in. deep,but it’s haunched to 120 in. over thepiers, where you get maximum negativemoment.” Typically, each haunchedgirder was made in 120-ft lengths, butone was 138 ft long.Falsework Supports BeamsFor the post-tensioned spans, Walshused falsework to support one end ofthe beams during erection, so that thebeam rested on both a pier and thefalsework. Two beams would extendtoward each other, leaving spacebetween for a drop-in segment with alength varying between 124 and 150 ft.<strong>The</strong> drop-in segment was lifted with acrane at each end. A temporary strongbackwas clamped to each end of thedrop-in segment to provide an overhangthat rested on the adjoining beam end.“<strong>The</strong> strong-backs supported the beamin place, after which we could releasethe cranes,” said Slagle.Once the girder was released from thecrane, the contractor connected thepost-tensioning ducts between the beamends. Formwork then was placed, andthe closure pour was made. “<strong>The</strong>re’sa nominal 1-ft gap at the splice,” saidSlagle. “We coupled the ductwork, setall the reinforcement and formwork, andthen made the closure placements acrossall six beam lines at once. That way, theclosure acted as a monolithic diaphragm.”Once the concrete in the closure reached5000 psi compressive strength, thepost-tensioning contractor installed thestrand and tensioned it with hydraulicjacks. Each girder had four ducts for<strong>The</strong> I-355 South Extension is part ofthe Tollway’s long-term $6.3-billioncongestion-relief plan called OpenRoads for a Faster Future. In late2004, the Tollway’s Board of Directorsapproved the plan, which is scheduledto last through 2016. One of itsprograms is Open-Road Tolling, bywhich 20 mainline toll plazas arebeing converted to barrier-free design.In addition, most of the tollwaysystem will be rebuilt or modernized,and nearly half of the system’s117 miles of existing roads will bewidened or have lanes added.“Most of the tollway system wasconstructed nearly 50 years ago andhas reached its design life,” explains LisHenderson. <strong>The</strong> growth of the northernIllinois region also has brought on theneed for improvements.<strong>The</strong> Tollway already has committed$3.6 billion worth of improvementsto contract, including $2.8 billion inconstruction work. “We’re trying todeliver as many of the benefits to thepublic as soon as we can.”<strong>ASPIRE</strong>, <strong>Spring</strong> 20<strong>08</strong> | 31