Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

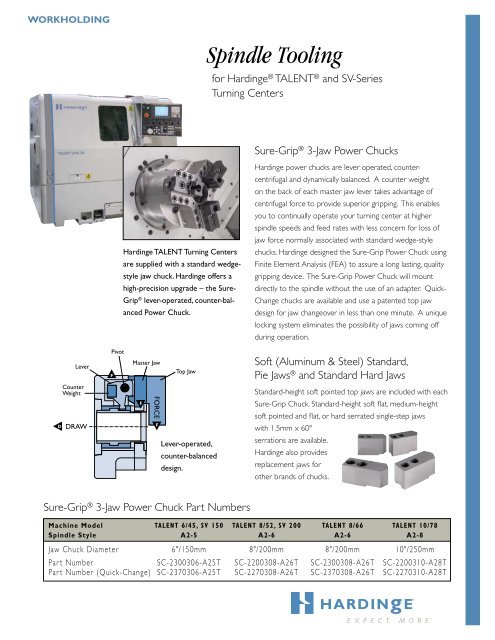

WORKHOLDINGSpindle Toolingfor <strong>Hardinge</strong> ® TALENT ® and SV-SeriesTurning CentersSure-Grip ® 3-Jaw Power Chucks<strong>Hardinge</strong> TALENT Turning Centersare supplied with a standard wedgestylejaw chuck. <strong>Hardinge</strong> offers ahigh-precision upgrade – the Sure-Grip ® lever-operated, counter-balancedPower Chuck.<strong>Hardinge</strong> power chucks are lever operated, countercentrifugaland dynamically balanced. A counter weighton the back of each master jaw lever takes advantage ofcentrifugal force to provide superior gripping. This enablesyou to continually operate your turning center at higherspindle speeds and feed rates with less concern for loss ofjaw force normally associated with standard wedge-stylechucks. <strong>Hardinge</strong> designed the Sure-Grip Power Chuck usingFinite Element Analysis (FEA) to assure a long lasting, qualitygripping device. The Sure-Grip Power Chuck will mountdirectly to the spindle without the use of an adapter. Quick-Change chucks are available and use a patented top jawdesign for jaw changeover in less than one minute. A uniquelocking system eliminates the possibility of jaws coming offduring operation.LeverPivotFMaster JawTop JawSoft (Aluminum & Steel) Standard,Pie Jaws ® and Standard Hard JawsCounterWeightStandard-height soft pointed top jaws are included with eachDDRAWFFORCEFSure-Grip Chuck. Standard-height soft flat, medium-heightsoft pointed and flat, or hard serrated single-step jawswith 1.5mm x 60°Lever-operated,counter-balanceddesign.serrations are available.<strong>Hardinge</strong> also providesreplacement jaws forother brands of chucks.Sure-Grip ® 3-Jaw Power Chuck Part NumbersMachine Model TALENT 6/45, SV 150 TALENT 8/52, SV 200 TALENT 8/66 TALENT 10/78Spindle Style A2-5 A2-6 A2-6 A2-8Jaw Chuck Diameter 6"/150mm 8"/200mm 8"/200mm 10"/250mmPar t Number SC-2300306-A25T SC-2200308-A26T SC-2300308-A26T SC-2200310-A28TPar t Number (Quick-Change) SC-2370306-A25T SC-2270308-A26T SC-2370308-A26T SC-2270310-A28T

A2-6 to A2-5 16CPart No. 7903-00-00-852000A2-6 to B60Part No. 7860-00-00-852000A2-6 to S20Part No. 7837-00-00-852200A2-6 to 5C Part No. 7805-00-00-8520005C, 16C and 3J Collets<strong>Hardinge</strong> hardened and ground colletsare inspected and measured in a <strong>Hardinge</strong>Super-Precision ® spindle. Collets areavailable in fractional round, hex andsquare sizes, round metric, as well asround serrated fractional and metric sizes.Adjustable, machinable collet stops can beused for accurate part positioning.Step Chucks and Closers**Step Chucks and closers are used toaccurately hold larger diameter parts andare available to use in the A2-5 16C colletchucks.Emergency ColletsEmergency collets have a soft face with apilot hole for customer drilling, boring andstepping out to the exact size required.An optional extended nose permits larger,deeper counterbores when required, andtool clearance for extended work.Dead-Length ® SystemsMaintain part length control by using<strong>Hardinge</strong> Dead-Length Systems. Choosefrom dead-length collet assemblies, thruholecollets, step chucks and spider-stopstep chucks.Style "S" MasterCollets & PadsPads can be changed much quicker thansolid collets can. Pads cost less and useless storage space when compared toa standard solid collet. Choose fromhardened and ground, semi-hard andemergency pads.Other Workholding CapacitiesMachine Model TALENT ® 6/45, SV 150 TALENT 8/52, SV 200 TALENT 8/66 TALENT 10/78Spindle Style: A2-5 A2-6 A2-6 A2-8Master Collets & Pads–Style "S" — S20 S26 S30Round (maximum capacity) — 2" / 50.80 2 5 /8"/66.68 3" 76.20B-Style Collets (maximum capacities) B42 B60 B60 —Round–Smooth & serrated 1 5 /8" / 41.27 2 3 /8" / 60.33 2 3 /8" / 60.33 —Hex–Smooth 1 13 /32" / 35.71 2 3 /64" / 51.99 2 3 /64" / 51.99 —Square–Smooth 1 9 /64" / 28.97 1 43 /64" / 42.47 1 43 /64" / 42.47 —Round Emergency (pilot hole) 1/4" / 6.35 1/4" / 6.35 1/4" / 6.35 —Fixtures – Spindle-Mount Style ** 8 7 /8" / 225.42 — — —Mounts Direct to Spindle:HQC ® Quick-Change Collets (max. capacities) HQC-42 HQC-65 HQC-65 HQC-65Round–Smooth & serrated 1 3 /4" / 44.45 2.559" / 65.00 2.559" / 65.00 2.559" / 65.00Hex–Smooth 1 1 /2" / 38.10 2 5 /32" / 54.77 2 5 /32" / 54.77 2 5 /32" / 54.77Square–Smooth 1 1 /4" / 31.75 1 3 /4" / 44.45 1 3 /4" / 44.45 1 3 /4" / 44.45Sure-Grip ® Expanding Collet Systems 100-600 300-600 300-600 300-600Spindle-Mount Style (working range) 1/8" - 4" / 3.17 - 101.60 1" - 4" / 25.40 - 101.60 1" - 4" / 25.40 - 101.60 1" - 4" / 25.40 - 101.60Sure-Grip ® 3-Jaw Power Chucks (diameter) 6" / 150 8" / 200 8" / 200 10" / 250** for use on spindle-to-spindle adapters Dimensions shown in inch / millimeter

Sure-Grip ®Expanding Collet SystemsSure-grip expanding colletsystems offer internal grippingsolutions for thin wallparts, or workpieces withexterior threading…Expanding collets will handlea variation in size of +.015"to -.001" (+.38 to .025mm)from its specified size –ideal for bar work!Collets are available from1/8" up to 4" diameter (3.18to 101.60 mm) as standard.Hex, square and specialshapedcollets are available.Sure-Grip ® Expanding Collet SystemsThe <strong>Hardinge</strong> Sure-Grip expanding collet provides highprecision internal gripping solutions. Features include trueparallel gripping, instant centering of the part and a widegripping range of each collet head. <strong>Hardinge</strong> precisionmanufacturing process guarantees that the total indicatorreading (TIR) of the arbor will be within .0002" (.00508mm).With the expanding collet mounted on the arbor, the TIR ofthe collet and the arbor will not exceed .0005" (.0127mm).The one-piece spindle arbor construction and the closingmechanism hold the workpiece extremely rigid for bettersurface finishes and concentricity. Mount directly to thespindle without the use of an adapter.HQC ®Quick-Change Collet SystemsHQC Quick-Change ColletSystems offer the shortestoverhang from the spindlewith true parallel grippingand flexible grip range forvariations in bar stock!HQC ® Quick-Change Collet SystemsThe HQC Quick-Change Collet System mount isshorter than collet adaptation chucks and power chucks.Interchangeable quick-change collet heads have a workingrange of ± 1 /64" (.396mm) for under a 2" (50.8mm) diameter,and ± 1 /32" (.793mm) for a 2" (50.8mm) diameter and over,making them ideal for bar work. True parallel gripping affordshigh feed rates and spindle speeds.Replace your 3-Jaw power chuck with the HQC Quick-Change Collet System. The reduction in weight and theunique, efficient design of the HQC system allow you toincrease the spindle rpm without any concern for centrifugalforces. Chucking forces are higher than jaw chucks andstandard solid collets.<strong>Hardinge</strong> <strong>Inc</strong>. One <strong>Hardinge</strong> Drive | P.O. Box 1507 | Elmira, New York 14902-1507 USAUSA: 800-843-8801 | Canada: 800-468-5946 | Fax: 607-734-3886To Order Online: www.hardingetooling.com | Corporate Homepage: www.hardinge.com | E-mail: info@hardingetooling.comAll specifications subject to change without notice. All marks indicated by ® and are trademarks of <strong>Hardinge</strong> <strong>Inc</strong>. Brochure 2366B • Litho in USA • ©<strong>Hardinge</strong> <strong>Inc</strong>. 2006