Research and development for industry: Advanced ... - CSIR

Research and development for industry: Advanced ... - CSIR

Research and development for industry: Advanced ... - CSIR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

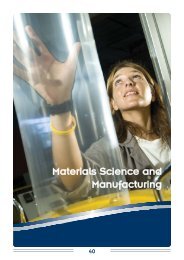

ENABLING TECHNOLOGIES<strong>CSIR</strong> experts in laser sources Kwanele Nyangaza, left, <strong>and</strong>Gary King assembling a state-of-the-art solid-state laser.Water tank leaks atKoeberg Power Stationsealed with new laser process| 64 |<strong>Advanced</strong> photonicsmanufacturing facilityto ensure new laser-based productsThe <strong>CSIR</strong> is set to establish an advanced photonics manufacturing facility to bridge the gap between laboratory demonstrators<strong>and</strong> commercial products. This will allow the transfer of laser technology in the <strong>for</strong>m of advanced photonics products to theSouth African <strong>and</strong> international industries, says Dr Daniel Esser, project manager <strong>and</strong> laser sources research group leader.The <strong>CSIR</strong> is keen tocollaborate with existing <strong>and</strong>new industrial partners todevelop niche products thatcould provide South African<strong>industry</strong> with a competitiveadvantage.“One of the cornerstones of thestrategy is to build <strong>and</strong> supportprogrammes that will stimulategrowth in this importanttechnology sector,” explainsHardus Greyling of the <strong>CSIR</strong>.“The establishment of such afacility will there<strong>for</strong>e directlysupport the photonics strategyby creating an environmentwhere technological innovationcan be transferred in astructured way to industrialpartners.”Esser adds: “This will be awell-equipped facility, with themindset of advanced product<strong>development</strong>, in contrast to aresearch lab.”He says that the goal of the facilitysupports the <strong>CSIR</strong>’s strategyaround advanced manufacturing<strong>and</strong> smart product <strong>development</strong>.The <strong>CSIR</strong> is known <strong>for</strong>demonstrating state-of-the-artlaser technologies. “Our focusnow is to develop these lasers toa state which can be adopted by<strong>industry</strong>,” says Esser. “<strong>Research</strong>ersin this area have already identifiedniche application areas madepossible through the uniqueproperties <strong>and</strong> wavelengths of ourlaser technology.“The unique propositionresulting from our technologyis rugged mountingtechniques, thermalmanagement, <strong>and</strong> in-depthknowledge of solid-state lasersystems,” he says. “This is whathas put our laser technologydemonstrators at the leadingedgeof innovation.”The <strong>CSIR</strong> holds more thanfive world records relating togroundbreaking discoveries inlaser sources, made in recentyears. “These lasers can beused <strong>for</strong> a number of tasks,including medical applications,due to their uniquewavelength,” explains Esser.These world records wererecognised by the internationalcommunity in the <strong>for</strong>mof published papers <strong>and</strong>international invited talks.“More importantly however,we have produced technologydemonstrators <strong>for</strong> each of thenew concepts which havebeen acknowledged by localstakeholders,” says Esser.“The next step is to take thesetechnology demonstratorsto advanced products. Todo this, we need to put inplace an advanced photonicsmanufacturing facility.”– Mzimasi GcukumanaEnquiries:Dr Daniel Esserdesser@csir.co.zaFollowing the successful demonstrationof a world-first laser-cladding processtwo years ago, the <strong>CSIR</strong> <strong>and</strong> Eskomwelding engineers recently testedthis technology during a scheduledmaintenance operation at KoebergPower Station, Cape Town.The provisionally patented laserbeam-welding <strong>and</strong> leak-sealing technologywas developed <strong>for</strong> Eskom in collaborationwith Eskom welding engineers. Thetechnology provides significant support inthe maintenance of South Africa’s powerstations, particularly in sealing <strong>and</strong> repairingleaking water vessels without having todrain them be<strong>for</strong>e conducting the repairwork.During 2011, <strong>CSIR</strong> laser engineers HermanRossouw <strong>and</strong> Corney van Rooyen aswell as Eskom welding engineer PhilipDoubell repaired a unit water storage tankin a drained condition during a scheduledmaintenance outage. This feat was eclipsedin February 2012 when the same teamsealed cracks on another tank – fullycharged with water, <strong>and</strong> the unit on fullgenerating mode. “The idea was to per<strong>for</strong>mthe work without impacting on Koeberg’spower generation capacity,” says the<strong>CSIR</strong>’s Herman Burger.According to Eskom’s engineeringprogrammes manager, Anton Kotze,the maintenance work was successfullycompleted by the <strong>CSIR</strong> in collaborationwith Eskom’s research, technology <strong>and</strong><strong>development</strong> team with the required leaksealing <strong>and</strong> overlays being applied in eightareas on the refuelling water storage tank.“This is probably the first time that laserbasedrefurbishment technology wasused <strong>for</strong> leak sealing in the nuclear power<strong>industry</strong>,” says Burger.“We would like to express our appreciation<strong>for</strong> the ef<strong>for</strong>ts made by <strong>CSIR</strong> engineers –Herman Rossouw <strong>and</strong> Corney van Rooyen– <strong>and</strong> their work ethic, professionalism<strong>and</strong> positive attitude,” says Kotze.Previously, the 18 m high stainlesssteel tank with its 15 m diameter wasrefurbished using arc-welding processes.“These caused undesirable effects suchas thermal distortion. The very low heatinput associated with the <strong>CSIR</strong>’s laserprocess eliminates these problems <strong>and</strong>in addition enables Eskom to use localsuppliers to conduct refurbishmentactivities of this nature,” explains Burger.He says that the success of therefurbishment work – during a scheduledmaintenance downtime – is a tellingexample of the strategic importanceof laser technology <strong>for</strong> <strong>industry</strong>. “In anenvironment with stringent requirementson quality <strong>and</strong> turnaround time, wesuccessfully per<strong>for</strong>med work that has notbeen done in South Africa be<strong>for</strong>e,” notesBurger.Eskom’s nuclear spokesperson, Tony Stott,commented on the excellent, safe <strong>and</strong>innovative approach used in conductingthis refurbishment work. “The success ofthe project is attributed to the continueddedication of the <strong>CSIR</strong> <strong>and</strong> the soundpartnership with Eskom,” states Stott.– Mzimasi GcukumanaEnquiries:Herman Burgerhburger@csir.co.zaThe water storage tank at Koeberg that has been repaired with anew laser process, while in use.The process as seen up close.| 65 |