You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

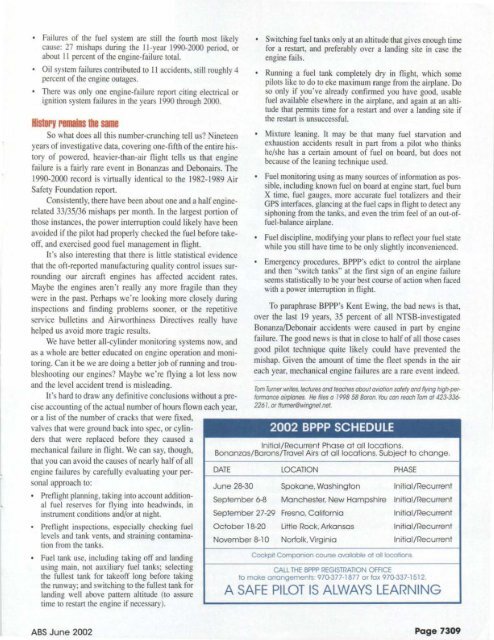

Failures of the fuel system are still the founh most likelycause: 27 mishaps during the II-year 1990-2000 period. orabout II percent of the engine-failure tOlal.Oil system fa ilures contributed to II accidents, still roughly 4percent of the engine outages.There was on ly one engine· failure repon citing electrical orignition system failures in the years 1990 through 2000.Switching fuel tanks only al an altitude Ihal gives enough timefor a restan, and preferably over a landing site in case theengine fails.Running a fuel tank completely dry in night, which somepilOls like to do to eke maximum range from Ihe airplane. Doso only if you've already confirmed you have good, usablefuel available elsewhere in the airplane. and again at an altitudethat permits time for a restan and over a landing site ifthe restart is unsuccessful.Mixture leaning. It may be that many fuel starvation andexhaustion accidents result in pan from a pilot who Ihinkshe/she has a cenain amount of fuel on board, but does notbecause of the leaning technique used.Fuel monitoring using as many sources of information as pos·sible, including known fue l on board at engine stan, fuel bumX time, fuel gauges, more accurale fuel totalizers and theirGPS interfaces, glancing at the fuel caps in Ilight to detect anysiphoning from the tanks, and even the trim feel of an out·offuel·balanceairplane.Fuel discipline, modifying your plans to reflect your fuel statewhile you still have time to be only slightly inconvenienced.Emergency procedures. BPPP's edict to control the airplaneand then "switch tanks" at the first sign of an engine failureseems statistically to be your best course of action when facedwith a power interruption in night.To paraphrase BPPP's Kent Ewing, the bad news is that,over the last 19 years, 35 percent of all NTSB-investigated<strong>Bonanza</strong>/Debonair accidents were caused in pan by enginefailure. The good news is that in close to half of all those casesgood pilot technique quite likely could have prevented themishap. Given the amount of time the neet spends in the aireach year, mechanical engine failu res are a rare eve nt indeed.Tom Turner writes, Jectures and teaches obout aviation safety and flying high-performanceairpfanes. He flies a 199858 Boron. You con reach fom at 423-336-2261, or tturner@wingnef.net.History remains the sameSo what does all this number-crunch ing tell us? Nineteenyears of investigative data, covering one-fi fth of the entire historyof powered. heavier-than-air flight tells us that enginefailure is a fairly rare event in <strong>Bonanza</strong>s and Debonairs. The1990-2000 record is virtually identical to the 1982-1989 AirSafety Foundation repon.ConSistently, there have been about one and a half enginerelated33/35/36 mishaps per month. In the largest ponion ofthose instances, the power interruption could likely have beenavoided if the pilot had properly checked the fuel before takeoff,and exercised good fuel management in flight.It's also interesting that there is lillie statistical evidenceth at the oft·reponed manufacturing quality control issues surroundingour aircraft engi nes has affected accident rates.Maybe the engines aren't really any more fragile than theywere in the past. Perhaps we're looking more closely duringinspections and finding problems sooner, or the repetitiveservice bulletins and Airwonhiness Directives really havehelped us avoid more tragic results.We have better all-cylinder monitoring systems now, andas a whole are better educated on engine operation and monitoring.Can it be we are doing a better job of running and troubleshootingour engines? Maybe we' re flying a lot less nowand the level accident trend is misleading.It 's hard to draw any definitive conclusions without a preciseaccounting of the actual number of hours flown each year,or a list of the number of cracks that were fixed,valves that were ground back into spec, or cylinders<strong>2002</strong> BPPP SCHEDULEthat were replaced before they caused aInitial/Recurrent Phase at all tocations.mechanical failure in flight. We can say, though, <strong>Bonanza</strong>s/Barons/Travel Airs at all locations. Subject to change.that you can avoid the causes of nearly half of allengine failures by carefully evaluating your personalDATE LOCATION PHASEapproach to:<strong>June</strong> 28-30 Spokane. Washington Initial/RecurrentPrellight planning, taking into account additionalfuel reserves for flying into headwinds, inSeptember &8 Manchester, New Hampshire Initial/Recurrentinstrument conditions and/or at night.September 27-29 Fresno. CaliforniaInitial/RecurrentPreflight inspections, especialty checking fuel Oelober 18·20 Little Rock. Arkansas Initial/Recurrentlevels and tank ve nts, and straining contaminationfrom the tanks.November 8-10 Norfolk. Virginia Initial/RecurrentFuel tank use, including taking off and landingCoclcplt Companion course ovailob4e at all Iocahons.using main, not auxiliary fuel tanks; selectingCALL THE BPPP REGISTRAnON OFFICEthe fullest tank for takeoff long before takingto make arrangements 970-377·1877 or fox 970-337-1512.the runway; and switChing to the fullest tank forlanding well above pattern altitude (to assure A SAFE PILOT IS ALWAYS LEARNINGtime to restan the engine if necessary).ABS <strong>June</strong> <strong>2002</strong>Page 7309