CylindersBY LEW GAGESa l finally broke down and used the new Continentalcylinder set I've had on the shelf for about 10 years.I bought these to use on my reserve engine that I'vehad ready to assemble. The currently installed engine inmy 035 had 1200 hours since major with cermi-chromecylinders, four-ring pistons, new valves, etc. It has performedwell and at 1200 hours was consuming only onequart between 50-hour oil changes.The old onesAt the time 1 had these cylinders overhauled andcermi-chromed at ECI, they were not doing the "freedom"process on the heads. That process calls for removing thehead from the barrel, making any repairs to the aluminum(after removing all steel components from the head) andthen doing a heat treatment procedure to the repairedhead. ECI claims the result is as good as a new head .Maybe, but new is hard to beat.Cracking of aluminum heads is a common problem,even with new ones. The old procedure of welding upcracks and dress ing and machining the weld area asnecessary left the head vulnerable to further cracking afterthe repaired head was put back in service. Some of thesewelded heads would have no problem, but the odds werethat additional cracks would appear.The ECI "freedom" process probably reduces thatproblem. If I were to use other than new cylinders, itwould be the "cermi-nil " barrels with "freedom " processheads.A short time ago, I noticed a hairline crack emanatingfrom the top spark plug on the #1 cylinder. By pressuri zing the cylinder and a soap/water solution applied to thecrack area, it was obvious the crack was through the head.Checking the other cylinders, I found #4 leak ing at thebarrel to head joint and a slight leak on #2 around thespark plug. It was either repair the old ones again or bitethe bullet and install my new cylinders.The new onesThese are plain steel barrels that present a new set ofproblems. The possibility of rust is present in a plain steelbarrel whereas chrome- or nickel-plated does not rust. Ofcourse. the piston rings used in a plated cylinder arcsubject to rust, but that is not quite the same degree ofproblem the plain steel barrels present.Frequent use of the engine will assure the best possibleservice life of the plain steel barrels. However, that issometimes difficult to accomplish due to our schedule.Being away for a month's vacation, a long stretch of badweather or just plain neglect leads to rust and other corrosioninside the idled engine.Although atmospheric conditions will contribute tomoisture in the engine, the worst condition exists atengine shutdown. Although we run the engines to let theoil do its job of cleaning, lubricating and coating everythingwith a protective cover of oil, there is a great deal ofmoisture generated by the engine that winds up in thecrankcase.The products of combustion of gasoline includewater. We've all seen water streaming from the tailpipe ofan automobile operated in cold climates. Or after theexhaust system warms up and the water vapor is not condensedby the cold exhaust system, the auto may be emittingsteam from the exhaust.That water or water vapor is produced during theprocess of oxidizing (burning) the gasoline. Since theengines in our airplanes have no provision for positivecrankcase ventilation as automobiles do, all the gas in theinterior of the crankcase got in there from the combustionchamber-some during the compress ion stroke, somefrom the exhaust stroke, but most from the power stroke.So we leave the engine in a state of being full ofverymoi st gases. If the engine is run regularly, maybe once aweek more or less, the remaining oil film on the bare steelsurfaces will fend off the anacking moisture. But let it sitfor long periods of time and the oil film will lose the figh t.One way to help alleviate the situation is to ventilatethe crankcase if the engine will not be operated on areg ular basis. The "E" engine lends itself nicely to thisprocedure by virtue of the arrangement of the crankcasevent system. Some engines that have the oil filler cap at thesame location as the breather line attach point need a fittingfabricated to draw the gases from the crankcase interior.What I've done on my 035 to charge the crankcasewith the relatively dry ambient air is si mply insert the endof my shop vacuum hose into the end of the crankcasevent line (scat hose from the air/oil separator) and removethe cap from the oil tank. Turning on the vacuum for fiveminutes or so evacuates all or most all the moistureladenedgases.You can check the ventilation rate by holding alighted match or candle at the oil tank cap opening. Thesmoke or name wi ll show a very strong draft into the tank.The air nows into the tank and then through the equalizerline (I /2-inch hose/tube) to the upper left side of theaccessory case. From there it is drawn to the front of theengine and out th rough the vent line at the top right sideof the crankcase, a fairly perfect routing to scavenge all ofthe engine interior. I do the same routine on the Lycomingengine in my 8E Luscombe.Exactly how much benefit is derived from this exer-Page 7320ASS <strong>June</strong> <strong>2002</strong>

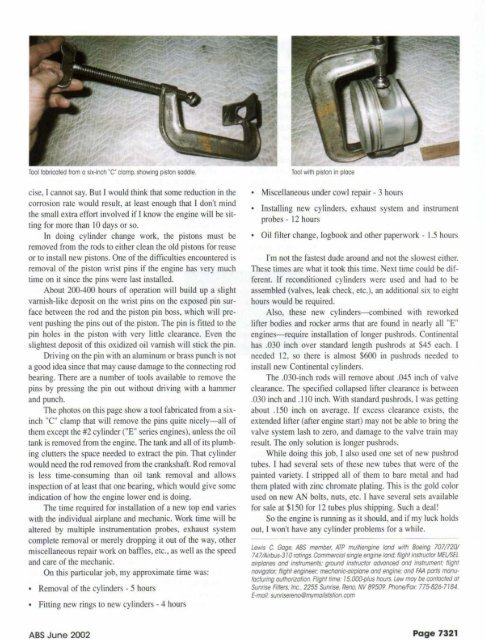

Tool fabricated from a six-inch ·C· clomp, showing piston saddle.cise, I cannot say. But I would think that some reduction in thecorrosion rate would result, at least enough that I don't mindthe small extra effort involved if I know the engine will be sittingfor more than 10 days or so.In doing cylinder change work, the pistons must beremoved from the rods to either clean the old pi stons for reuseor to install new pistons. One of the difficulties encountered isremoval of the piston wrist pins if the engine has very muchtime on it since the pins were last installed.About 200-400 hours of operation will build up a slightvarnish-like deposit on the wrist pins on the exposed pin surfacebetween the rod and the piston pin boss, which will preventpushing the pins out of the piston. The pin is fitted to thepin holes in the piston with very little clearance. Even theslightest deposit of this oxidized oil varnish will stick the pin.Driving on the pin with an aluminum or brass punch is nota good idea since that may cause damage to the connecting rodbearing. There are a number of tools available to remove thepins by pressing the pin out without driving with a hammerand punch.The photos on this page show a tool fabricated from a sixinch"C OO clamp that will remove the pins quite nicely-all ofthem except the #2 cylinder ("E" series engines), unless the oiltank is removed from the engine. The tank and all of its plumbingclutters the space needed to extract the pin. That cylinderwould need the rod removed from the crankshaft. Rod removalis less time-consuming than oil tank removal and allowsinspection of at least that one bearing, which would give someindication of how the engine lower end is doing.The time required for installation of a new top end varieswith the individual airplane and mechanic. Work time will bealtered by multiple instrumentation probes, exhaust systemcomplete removal or merely dropping it out of the way, othermiscellaneous repair work on barnes, etc., as we ll as the speedand care of the mechanic.On this panicular job, my approximate time was:Removal of the cylinders - 5 hoursFitting new rings to new cylinders - 4 hoursTool with piston in placeMisce llaneous under cowl repair - 3 hoursInstalling new cylinders, exhaust system and instrumentprobes - 12 hoursOil filter change, logbook and other paperwo rk - 1.5 hoursI'm not the fastest dude around and not the slowest either.These times are what it took this time. Next time could be different.If reconditioned cyl inders were used and had to beassembled (valves, leak check, etc.), an additional six to eighthours wo uld be required.Also, these new c y linders~ombin ed with reworkedlifter bodies and rocker arms that are found in nearly all "E"engines-require installation of longer pushrods. Continentalhas .030 inch over standard length push rods at $45 each. Ineeded 12, so there is almost $600 in pushrods needed toinstall new Continental cylinders.The .030-inch rods will remove about .045 inch of valveclearance. The specified collapsed lifter clearance is between.030 inch and .110 inch. With standard pushrods, I was gettingabout .150 inch on average. If excess clearance ex ists, theextended lifter (after engine start) may not be able to bring thevalve system lash to zero, and damage to the valve train mayresult. The only solution is longer pushrods.While doing this job, I also used one set of new push rodtubes. I had several sets of these new tubes that were of thepainted variety. 1 stripped all of them to bare metal and hadthem plated with zinc chromate plating. This is the gold colorused on new AN bolts, nuts, etc. I have several sets availablefor sale at $150 for 12 tubes plus Shipping. Such a deal!So the engine is running as it should, and if my luck holdsout, I won't have any cylinder problems for a while.Lewis C. Gage. ABS member. ATP mulfiengine fand with Boeing 707172017471Airbus·310 ratings. Commerciaf single engine land; flight instructor MEI.JSELO/rpfanes and instruments; ground instructor advanced and instrument; flightnowgator; flight engineer; mechanic-airpfane and engine; and FAA parts manufacturingauthoazation. Flight time: 15,OOO-plus hours. Lew may be contacted atSunnse Fillers. Inc .. 2255 Sunrise. Reno. NY 89509. Phone/Fox: 775-826-7184.E·mail: sunrisereno@mymaifststion.comABS <strong>June</strong> <strong>2002</strong>Page 7321