Mechanical Contractor jobs

Mechanical Contractor jobs

Mechanical Contractor jobs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

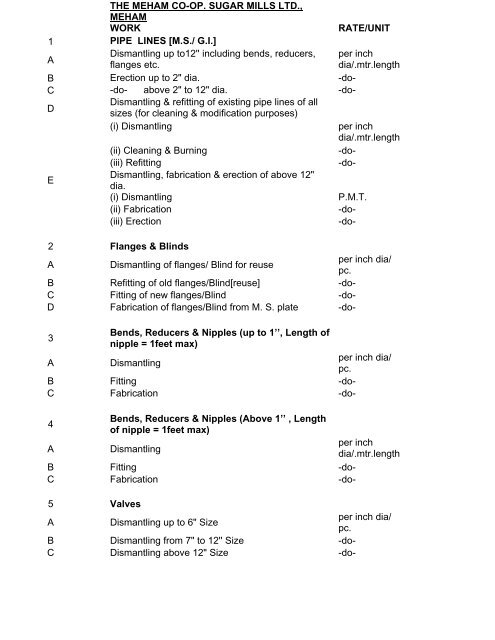

THE MEHAM CO-OP. SUGAR MILLS LTD.,MEHAMWORK1 PIPE LINES [M.S./ G.I.]Dismantling up to12'' including bends, reducers,Aflanges etc.RATE/UNITper inchdia/.mtr.lengthB Erection up to 2" dia. -do-C -do- above 2" to 12" dia. -do-DDismantling & refitting of existing pipe lines of allsizes (for cleaning & modification purposes)(i) Dismantlingper inchdia/.mtr.length(ii) Cleaning & Burning-do-(iii) Refitting-do-EDismantling, fabrication & erection of above 12"dia.(i) DismantlingP.M.T.(ii) Fabrication-do-(iii) Erection-do-2 Flanges & BlindsADismantling of flanges/ Blind for reuseper inch dia/pc.B Refitting of old flanges/Blind[reuse] -do-C Fitting of new flanges/Blind -do-D Fabrication of flanges/Blind from M. S. plate -do-3Bends, Reducers & Nipples (up to 1’’, Length ofnipple = 1feet max)ADismantlingper inch dia/pc.B Fitting -do-C Fabrication -do-4Bends, Reducers & Nipples (Above 1’’ , Lengthof nipple = 1feet max)ADismantlingper inchdia/.mtr.lengthB Fitting -do-C Fabrication -do-5 ValvesADismantling up to 6" Sizeper inch dia/pc.B Dismantling from 7" to 12'' Size -do-C Dismantling above 12" Size -do-

D Fitting up to 6" Size -do-E Fitting from 7" to 12" Size -do-F Fitting above 12" Size -do-GDismantling of MS fabricated right angle/ globevalve of size more than 12" size-do-HFitting of MS fabricated right angle/ globe valve ofsize more than 12" size-do-IShifting of right angle/ globe valves of more than12" sizes-do-6Dismantling, Fab. & erection of M.S. /G.I. Pipeaccessories (Tee, cross, distance piece etc.)ADismantlingper inch dia/pc.B Fabrication -do-C Erection -do-7 Dismantling & erection of C.I. Pipes (up to 6’’)ADismantlingper inchdia/.mtr.lengthB Erection -do-8 Dismantling & erection of C.I. Pipes (above 6’’)ADismantlingper inchdia/.mtr.lengthB Erection -do-9Dismantling & erection of C.I. Pipe accessories(cross, distance piece etc.)ADismantlingper inch dia/pc.B Erection -do-10 S.S.Pipe LinesADismantling of all sizes (including flanges ,bends)per inchdia/.mtr.lengthB Erection of all sizes (including flanges ,bends) -do-11Dismantling, Fab. & Erection of S.S. pipeaccessories(tee ,cone ,cross, distance piece,nipple, reducer)ADismantlingper inch dia/pc.B Fabrication -do-

C Erection -do-Dismantling, Fab. & Erection of M.S. Plate <strong>jobs</strong>12(tanks, gutters, chutes Pipe rolling, Boiler casing,Boiler ducting etc.)A Dismantling PMTB Fabrication -do-C Erection -do-Dismantling, Fab. & Erection OF Structure13work (Staging, columns, trusses-& pipe support,purline,new plateform etc.)A Dismantling PMTB Fabrication -do-C Erection -do-14 Repairing of old plateformA Dismantling Per sq. mtr.B Fabrication -do-C Erection -do-DReplacement of M.S. Angle 75x75x10mm thk.atMill House walk wayPer Meter15 Dismantling & Erection of railingADismantlingper mtrLengthB Fabrication -do-C Erection -do-16 Patch & welding workA Up to 4 sq. ft. per sq. mtr.B Welding joint ( Two round )per mtr.length17Dismantling, Fab. & Erection of M.S. side &bottom Plate <strong>jobs</strong> (Rake carrier, CC, BE, BC,RBC trough donnelly chute ,fiberizer,Juice screen,juice screen tray ,bagacillo casing,etc.)A Dismantling Per sq. mtrB Fabrication & erection -do-18Rake carrier, C.C., B.E., B.C., R.B.C Troughs,Donnelly chuteA Dismantling of 2 to 5 mm thick SS plate Per sq. mtrB Erection of 2 to 5 mm thick SS plate -do-C Dismantling of runners per mtr lengthD Fitting of runners. -do-

E Dismantling of side angles -do-F Fitting of side angles -do-GAlignment of rake carriers trough's bottom plate at lump sump45ºper troughH Alignment of rake carriers trough's side plate at 45ºlump sumpper troughITo extend the runners with base below the tail end lump sumpsprockets of rake carriers throughout the bend. per troughJ Matching & welding of carriers with coloums per coloum19Cleaning, welding & grinding of teeth for crownpinion & sprockets as per profileA Crown pinion (Both side of teeth & Bore) Per PinionB Crown pinion (Both side of teeth) Per PinionC Crown pinion (One side teeth only with bore) Per PinionD Crown pinion (One side teeth only) Per PinionE Sprocket C.C/B.C Per SprocketF Rack carrier sprocket Per SprocketGPinion 22 Teeth Under Feed Roller drive (One sideof teeth)Per PinionHPinion 17 Teeth of Under Feed Roller (One side ofteeth)Per PinionI Welding of cane unloader bridge wheel Per wheelJ Welding of cane unloader trolley wheel Per wheel20Fabrication & erection of Maceration water trayat millA Fabrication per trayB Erection -do-21Fabrication of MS cover for mill bottom bearing(Journal size dia- 430mmx540mm)Per piece22 Dis, fab & erection of cane kicker bladeA Dismantling Per bladeB Fabrication -do-C Erection -do-23Fabrication of Mill discharge chute fixingbracketPer piece24 Cane UnloadersADismantling of square bar (size-2") runner at caneunloadersPer MtrBFitting of square bar (size-2") runner at caneunloadersPer MtrC Fitting of Rail Line (size) runner at cane unloaders Per MtrDFabrication & fitting of M.S. Plate 12 mm thk.(appx.) at cane unloaders 300 mm gantary channel Per Mtr25 Fab & erection of new donnelly chuteA fabrication per chuteB Erection -do-

DFitting of transparent sheets 10 mm thk. Atdonnelly chutesper sheet26Dis,fab & erection of scroll of screw conveyorfor DSM screenA Dismantling Per pieceB Fabrication -do-C Erection -do-D Fabrication & erection of complete casing -do-27 Fab & erection of Mills TUFR roller tips Per roller28Through out welding except holes of MillsTUFR shellPer roller29 Fab of top roller scrapper bracket Per piece30 Fab of BC/ RBC rake as per drg no SMM 190 Per Piece31 Bagacillo blower fan with alignmentA Fabrication -do-B Erection -do-C Alignment -do-32 Bagacillo pipe from bagacillo to vaccum filterA Dismantling Per mtrB Fabrication -do-C Erection -do-33Erection of sprocket fitted idler at BaggaseCarrier bend.Lump sump34 S.S. Tubes (Semi-kestnner, juice heaters )A Dismantling per tubeB Fitting & Hydraulic Testing -do-35 S.S. Tubes (vapour cell & evaporator bodies)A Dismantling per tubeB Fitting & Hydraulic Testing -do-36 S.S /Brass tubes ( pans )A Dismantling per tubeB Fitting & Hydraulic Testing -do-37Dismantling & erection of Up to 4” pump & 15H.P.MotorAShifting of Pump/ motor more than 20 mtr distancePer Inch dia &per H.PB Dismantling (pump/motor) -do-C Erection (pump/motor) -do-

38Dismantling & erection of 4” to 8” pump & 15 to40 H.P.MotorAShifting of Pump/ motor more than 20 mtr distancePer Inch dia &per H.PB Dismantling (pump/motor) -do-C Erection (pump/motor) -do-39Dismantling & erection of above 8” pump &above 40 H.P.MotorAShifting of Pump/ motor more than 20 mtr distancePer Inch dia &per H.PB Dismantling (pump/motor) -do-C Erection (pump/motor) -do-40 Dismantling & erection of G.I./ A.C.C. SheetA Dismantling Per sq. mtr..B Fitting -do-41 Dismantling & erection of water gutter & ridgeADismantlingper runningmtr.B Erection -do-42Dismantling, fab. & erection of the Melters ofSulphur furnaceA Dismantling Per pcB Fabrication -do-C Erection -do-43 Replacement of Shell of Sulphur furnaceA Dismantling Per shellB Fabrication -do-C Erection -do-44 Replacement of scrubber of sulphur furnaceA Dismantling Per scrubberB Fabrication -do-C Erection -do-45 Repairing of steam jacket of sulphur furnaceA Dismantling Per pc

B Fabrication -do-C Erection -do-46Dismantling, Fabrication & erection of thefollowing with MS platesA Bottom portion of weight juice tank Per sq. mtr.B Scrappers of Dorr clarifier Per Pc.C Catcher bottle of Vac. filter Per bottleD Bottom of Dorr clarifier PMTF Mud tray of Vac. Filter Per trayG Mud tank bottom of vac. Filter PMT47Dismantling, Fabrication & erection of MSplates of Pan stationA Shell of Pans PMTB Pan tops -do-C Save-all Per save-allD Shell of Vac. Crystallizer PMTEBottom plates of Syrup & molasses tanks &conditionersPer sq. mtr.FSide plates of Syrup & molasses tanks &conditioners-do-GPan shell strengthening work with MS channels/angles/ MS plate ringsPer PanHTop cone strengthening work with MS channels/angles/ MS plate ringsPer coneIStrengthening of vapour line by inner sidePer vapoursupporting of angles/ pipesline48Dismantling, fab. & erection of coils ofhorizontal crystallizersADismantlingPer inch dia /mtr. lengthB Fabrication -do-C Erection -do-49ADismantling, fab. & erection of shaft ofcrystallizersDismantlingB Fabrication -do-C Erection -do-Per inch dia /mtr. length50Replacement of 3” MS coils (including bends,flange, etc.) of Vertical crystallizersPer inchdia/mtr. length

5152ADismantling, fab. & erection of arms of A-crystallizersReplacement of coils of Dorr & evaporatorbodiesJuice coils (Dismantling, Fab. & erection)(i) Dismantling(ii) Fabrication(iii) ErectionAmmonia & gas coils (Dismantling, Fab. &erection)(i) Dismantling(ii) Fabrication(iii) ErectionPercrystallizerper inch dia./mtr. length-do--do-per inch dia./mtr. length-do--do-53Replacement of weak MS plates & cooling coilsof Molasses tanksA Bottom plates PMTB Side plates upto height 10mtr -do-C Top cone plates with supports -do-DCooling coilsper inch dia./mtr.. length54 Fabrication of Drum internal plates of boiler per piece55Dismantling, fabrication and erection ofexpansion joints of boilerL.S/per joint56 Erection of transient heatersA Dismantling of Existing transient Heaters Per pieceB Shifting of new transient heater at Site -do-C Erection of new transient heaters -do-57Dismantling/ Fab./ Erection of weak portion ofpartition plates of juice heatersPer mtr.Length58Dis./ Repairing/ Fabrication & erection ofBagasse belt conveyor on turnkey basisLump sump59 Dismantling, fab & erection of hopper

A Dismantling Per sq.mtr.B Fabrication -do-C Erection -do-60 Repairing of tray of hopperA Dismantling Per sq. mtrB Fabrication -do-C Erection -do-61 Repairing of center piece of tray of hopperA Dismantling Per sq. mtrB Fabrication -do-C Erection -do-62Dismantling & refitting of spurger of juicesulphitor for cleaningA Dismantling Per pieceB Fabrication -do-C Erection -do-63 Dis, fab & erection of stainer of injection pumpA Dismantling Per pieceB Fabrication -do-C Erection -do-64Dis, repairing & erection of casing of continouscentrifugal machineA Dismantling Per machineB Repairing -do-C Fitting/ alignment -do-65 Repairing of agitator of vaccum filterA Dismantling Per agitatorB Fabrication -do-C Erection -do-66 Fabrication of sweeper trolly Per piece67 Erection of new seed belt conveyor Lump sump69Fab & erection of SS plate at calendria ofevaporator bodyPer sq. mtr

70Erection & comisioning of orifice plate in HPpipe line (size 3"-6")Per piece71 Bagacillo pipe from bagacillo to vaccum filterA Dismantling Per mtrB Fabrication -do-C Erection -do-72Repairing/ changing of vertical crystallizerarms in top gutter (scrapper type) round shapeLump sump73 ETP middle shaft repairing/ replacement Lump sump74Fab of new lime tank with its shaft, stirer etc. atETPLump sump75Dismantling, fab & erection of save all of pan &evaporator bodiesA Dismantling Per save allB Fabrication -do-C Erection -do-76 Replacement of juice sulphiter top Lump sump77Chocked tube of Juice heater, evaporatorbodies replacementA Dismantling per tubeB Fitting & Hydraulic Testing -do-78 Fabrication & fitting of vibro screenA Dismantling Per screenB Fabriaction -do-C Erection -do-79Dismantling, fabrication and erection of boxstay of boilerA Dismantling Per box stayB Fabrication Per box stayC Erection Per box stayA. Technical Eligibility.Tenderer should attach copy/copies of;1. Repeat orders of latest supply of its product to atleast two standard Sugar Mills orany standard Heavy Industrial Organizations where similar machinery/product arebeing used during the last three years.2. If repeat orders have not been placed by such Mills, then the supplier must submit thecertificate of satisfactory and good performance of its machinery/equipments fromsuch purchaser organization.

B. Committee reserves the right to verify such certificates before finalizing the ratecontract with any supplier in case of any doubts about his eligibility.C. Tenderers shall submit the following certificates alongwith technical bid:a) Details of EMD.b) Copy of last year balance sheet of IT Return.c) Copies of repeat purchase orders from any two standard Sugar Mills.d) Copies of certificates of satisfactory performance from the standard consumers.e) Copy of Sale Tax Registration Certificate.f) Mfg. License/Registration Certificate No.g) Copy of appointment letter of the authorized distributor, if applicable.B. Specifications of the MaterialAs mentioned above.C. Mode & Schedule of paymenta) Payment will be decided at the time of negotiation..D. Financial terms & conditionsa) The earnest money of the tenderers will be forfeited to Sugar Millsaccount if they withdraw their offer/rates or modify the terms &conditions of the tender during the validity of their offer. Afteracceptance of their offer, if any party does not execute the agreementas per terms & conditions of the order, the party shall bedelisted/debarred for future dealings and their earnest money/securityamount shall be forfeited.b) Parties are requested to exercise their choice to quote special cashdiscount for payments within a week of the supply.c) “Supplier shall be entitled to a claim @ 12% p.a. interest if thedue payment is delayed beyond 15 days of the prescribed/agreedtime without any prior intimation of valid reasons by theManagement.d) Price Fall ClauseThe tenderer shall furnish a certificate in their offer that the ratesquoted by them are the lowest possible which they have quoted to anyof their consumers during the currency of the contract period.However, if they ever feel constrained to quote lower rates to any oftheir customer during the said period, they undertake to intimate thesame immediately to the Sugarfed/particular Sugar Mills and allowthe same reduction in rates automatically. If they violate thisundertaking and the Sugarfed/particular Sugar Mills come to know ofsuch reduction on their own/through their own resources, then theSugarfed/its Sugar Mills shall be entitled to recover the double thedifference in such rates on the entire quantity purchase alongwith costand damages from supplier.

f) Dispatch Delivery Conditionsi) F.O.R. - Sugar Mills, Mehamii) Packing & Forwarding - Niliii) Delivery period -g) Taxes & Dutiesi) Rate of VAT/CST :ii) Rate of Excise DutyD. General Conditionsi) All the documents to be submitted by the tenderers with their offershould be duly authenticated by some responsible authority in case theii)same are copies of original documents.The tenderer shall furnish a certificate in their offer that the ratesquoted by them are the lowest possible which they have quoted to anyof their customers during the currency of the contract period.However, if they ever feel constrained to quote lower rates to any oftheir customer during the said period, they undertake to intimate thesame immediately to the particular sugar mills and allow the samereduction in rates automatically. If they violate this undertaking andthe particular sugar mills comes to know of such reduction on theirown/through their own resources, then the sugar mills shall be entitledto recover, double the difference in such rates.E. PUNITIVE PROVISIONS/LEGAL CONDITIONS5. The supplier will be responsible for any late irregular and non-supplyof the material(s) to the mills. In that event the Sugar Mills willarrange the material from the market at the risk & cost of the supplierand the supplier will be responsible for all the losses suffered by theMills on this account.F. SUBMISSION OF TENDERS6. The tender form shall be in two parts i.e. Technical Bid and FinancialBid. Both bids shall be submitted in separate covers/envelopes with asubmission fee of Rs. 100/-. Technical Bid will be opened first.Earnest money for Rs.------------- in the form of Demand Draft shallbe submitted with the Technical Bid. The proforma for both bids aregiven in Tender Form-I and Tender Form-II respectively. Sealedtender should reach in this office latest by 15.5.2012 at 1.00 P.M.7. The MD/Management reserves the rights to accept or reject the tenderwithout assigning any reason.8. The Technical bid will be opened by a committee constituted for thepurpose on 15.5.2012 at 2 .00 p.m. in the presence of the interestedparties and financial bid will be opened on 16.5.2012 at 11.00 A.M.and negotiation will be held on the same day in the office of

MANAGING DIRECTOR, THE MEHAM COOP. SUGAR MILLSLTD., MEHAM.Signature of Tenderer/AuthorisedrepresentativeName of the representative:Name of the Tenderer :Address :Contact No.E-Mail:

TENDER FORM FOR QUOTED RATE FOR THE SUPPLY OF________________________________________________________TENDER FORM–IIFINANCIAL BIDName of the party : ---------------------------------------Address : --------------------------------------------------------------------------------Phone No.---------------------Fax No.---------------------------E-Mail : ---------------------------------------------------------DECLARATIONCertificated that we have gone through the tender documents and I/weaccept all the terms & conditions specified therein unconditionally.Accordingly, I/we submit my/our tendered rates as under:-Name of the item: Detailed specifications & qty. are as perTender form..Sr.No. Particulars Rates1. Basic rate (FOR)2. Excise duty @----------(if applicable for Modvat)3. Cess @-------(if applicable)4. CST/VAT @ ----------5. Service Tax----------(ifapplicable)6. Total (FOR Sugar Mills)Signature of Tenderer/AuthorisedrepresentativeName of the representative:Name of the Tenderer :Address :Contact No.E-Mail: