Range extenders can extend the driving range for an electric vehicle ...

Range extenders can extend the driving range for an electric vehicle ...

Range extenders can extend the driving range for an electric vehicle ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

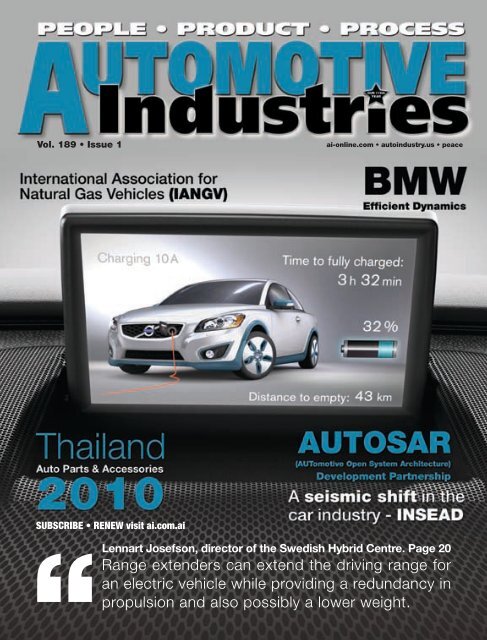

Vol. 189 • Issue 1<br />

SUBSCRIBE • RENEW visit ai.com.ai<br />

ai-online.com • autoindustry.us • peace<br />

Lennart Josefson, director of <strong>the</strong> Swedish Hybrid Centre. Page 20<br />

<strong>R<strong>an</strong>ge</strong> <strong><strong>extend</strong>ers</strong> <strong>c<strong>an</strong></strong> <strong>extend</strong> <strong>the</strong> <strong>driving</strong> <strong>r<strong>an</strong>ge</strong> <strong>for</strong><br />

<strong>an</strong> <strong>electric</strong> <strong>vehicle</strong> while providing a redund<strong>an</strong>cy in<br />

propulsion <strong>an</strong>d also possibly a lower weight.

AUTOMOTIVE INDUSTRIES (ISSN 1099-4130)<br />

Volume 189 Number 1<br />

Published Quarterly by Automotive Industries Ltd • Issue date: Q1 2010<br />

3859 Sh<strong>an</strong>non Run, Versailles, KY 40383.<br />

Subscription rates are $88 North America, Rest of <strong>the</strong> World (Airmail) $168<br />

Periodical postage paid at: Versailles, KY 40383 <strong>an</strong>d at additional mailing offices<br />

Copyright AUTOMOTIVE INDUSTRIES LTD<br />

C<strong>an</strong>adi<strong>an</strong> Publication Mail Agreement # 41301520.<br />

Return Undeliverable C<strong>an</strong>adi<strong>an</strong> Addresses to:<br />

P.O. Box 122, Niagara Falls, ON, L2E 6S8, C<strong>an</strong>ada<br />

POSTMASTER: send address ch<strong>an</strong>ges to Automotive Industries<br />

PO Box 1510, Versailles, KY 40383, USA<br />

Automotive Industries is published by:<br />

Automotive Industries Ltd.<br />

Publisher: John Larkin<br />

jal@autoindustry.us<br />

+1 313 262 5702 (IP 5101234888)<br />

Editor: Ed Richardson<br />

edrich@siya<strong>the</strong>tha.com<br />

+27 (0) 41 582 3750<br />

Editing: Claire Warneke<br />

claire@siya<strong>the</strong>tha.com<br />

+27 (0) 41 582 3750<br />

Fin<strong>an</strong>ce: Ben Adler FCA<br />

ben@autoindustry.us<br />

+44 (0) 20 8458 7130<br />

Press Releases <strong>an</strong>d Advertising Enquiries:<br />

STEVE BARCLAY Engineering & Design<br />

Steve.Barclay@autoindustry.us<br />

+91 9899 763 566 (IP 5101401832)<br />

NICK PALMEN Engineering & Design<br />

NickPalmen@autoindustry.us<br />

+44 (0) 20 8764 9696 (IP 5101401836)<br />

JAMES HILTON Shows Press Releases<br />

jah@autoindustry.us<br />

+44 (0) 1142 811 014<br />

DAN THORNTON Engineering & Design<br />

djtinc@autoindustry.us<br />

+ 1 734 676 9135<br />

JON KNOX Vehicle Logistics<br />

J.Knox@autoindustry.us<br />

+34 (0) 690 276 463<br />

ALAN TRAN Vehicle Logistics<br />

Al<strong>an</strong>Tr<strong>an</strong>@autoindustry.us<br />

+ 44 20 3129 8361 (IP 5101401831)<br />

ROB WHITE Vehicle Systems - Exterior<br />

advertising@autoindustry.us<br />

+44 (0) 20 8202 3770 (IP 5101401833)<br />

RON CHARLES Innovation & Development<br />

RonCharles@autoindustry.us<br />

+44 (0) 79 303 84026<br />

KARL VON MOHR Electrical/Electronics<br />

kvonmohr@autoindustry.us<br />

+ 1 702 979 8398<br />

MICHAEL STEWART Vehicle Systems - Electrical/Electronic<br />

MichaelStewart@autoindustry.us<br />

+44 (0) 7853 499 350<br />

MICHAEL FRANK Emerging Markets<br />

Michael.Fr<strong>an</strong>k@autoindustry.us<br />

+1 201 388 1911<br />

Layout: GIA: auto@giastudio.co.za<br />

Subscriptions: orders@autoindustry.us<br />

Renew Subscriptions from<br />

“SUBSCRIBE/RENEW” link at<br />

www.autoindustry.us • www.ai-online.com<br />

PRINTED IN THE USA<br />

BPA Worldwide Member<br />

contents<br />

contents<br />

IANGV - Creating a tr<strong>an</strong>sport revolution .................................................................................... 08<br />

L<strong>an</strong>di Renzo taking alternative fuel systems to <strong>the</strong> U.S. ............................................................. 12<br />

Omnitek - Filter technology powering NGV market ..................................................................... 16<br />

Buehler - Driving confidently into U.S. market ............................................................................ 18<br />

SHVC - Switching on hybrid technology .................................................................................... 20<br />

Ford sets new st<strong>an</strong>dards <strong>for</strong> engine efficiency with EcoBoost ................................................... 21<br />

Haldor Topsøe - Reducing <strong>the</strong> costs of catalysis ....................................................................... 22<br />

Aristo - M<strong>an</strong>aging <strong>the</strong> costs of catalytic systems ........................................................................ 24<br />

Emitec - Reducing space <strong>an</strong>d emissions ................................................................................... 28<br />

Frauenthal - Reducing diesel emissions .................................................................................... 32<br />

Rhodia - Keeping it cle<strong>an</strong> ........................................................................................................... 34<br />

Sustainable motoring <strong>the</strong> BMW way ......................................................................................... 36<br />

Novelis - Aluminum is <strong>the</strong> skin of <strong>the</strong> new BMWs ..................................................................... 42<br />

DRAEXLMAIER - Tailoring <strong>the</strong> BMW Z4 interior ........................................................................ 44<br />

Geico - Focus on greening <strong>the</strong> paintshop .................................................................................. 46<br />

Luvata - Keeping joints sealed ................................................................................................. 48<br />

Veeco - Innovative metrology equipment measures up ............................................................. 50<br />

AutoSar - Taking ECUs into <strong>the</strong> future ...................................................................................... 52<br />

Pelagicore - Auto Linux ga<strong>the</strong>rs speed ..................................................................................... 56<br />

Pulse-AR - Specialist comp<strong>an</strong>y <strong>for</strong>med to implement AUTOSAR ............................................... 58<br />

Nokia dialing up <strong>the</strong> automotive industry .................................................................................. 60<br />

AMS - Analog continues to drive critical functions .................................................................... 62<br />

Parrot - connecting customers to <strong>the</strong>ir cars ............................................................................. 64<br />

Valmet - Leading <strong>the</strong> way in going green ................................................................................. 66<br />

IMAP - Exploring <strong>the</strong> ch<strong>an</strong>ging l<strong>an</strong>dscape of <strong>the</strong> automotive industry ....................................... 68<br />

INSEAD - A seismic shift in <strong>the</strong> car industry .............................................................................. 70<br />

AuDaCon - Making sense of <strong>the</strong> flow of automotive data <strong>an</strong>d in<strong>for</strong>mation ................................. 72<br />

Tunisia - gateway to Africa, Europe <strong>an</strong>d <strong>the</strong> Middle East ........................................................... 74<br />

“Visions in Polymers” at K 2010 ............................................................................................... 78<br />

Mahindra makes its mark at Indi<strong>an</strong> Auto Expo .......................................................................... 80<br />

TAPA 2010 - Thail<strong>an</strong>d taking center position as ASEAN auto parts hub ................................... 82<br />

LEGAL DOCUMENT • STATEMENT OF OWNERSHIP, MANAGEMENT AND CIRCULATION • UNITED STATES POSTAL SERVICE<br />

1. Publication Title: Automotive Industries • 2. Publication number: 1099-4130 • 3. Filing Date: 10-5-2009 • 4. Issue Frequency: Quarterly<br />

5. Number of issues published <strong>an</strong>nually: 4 • 6. Annual Subscription Price: $88.00 • 7. Address: 3859 Sh<strong>an</strong>non Run, Versailles, KY 40383<br />

8. Headquaters address: Worldwide Purchasing LTD, 3rd floor Rom<strong>an</strong> House,296 Goldens Green RD London, Engl<strong>an</strong>d, NW119PY, United Kingdom<br />

9. Publisher: John Larkin, Worldwide Purchasing LTD, 3rd floor Rom<strong>an</strong> House, 296 Goldens Green RD London, Engl<strong>an</strong>d, NW119PY, United Kingdom<br />

Editor: Ed Richardson, Worldwide Purchasing LTD, 3rd floor Rom<strong>an</strong> House, 296 Goldens Green RD London, Engl<strong>an</strong>d, NW119PY, United Kingdom<br />

Mgr Editor: John Larkin, Worldwide Purchasing LTD, 3rd floor Rom<strong>an</strong> House, 296 Goldens Green RD London, Engl<strong>an</strong>d, NW119PY, United Kingdom<br />

10. Owner: John Larkin, Worldwide Purchasing LTD, 3rd floor Rom<strong>an</strong> House, 296 Goldens Green RD London, Engl<strong>an</strong>d, NW119PY, United Kingdom<br />

11. Known Bondholders: None • 12. Bl<strong>an</strong>k • 13. Publication: Automotive Industries • 14. Issue Date <strong>for</strong> data: 2nd Qtr 2009<br />

15. Extent <strong>an</strong>d Nature of Circulation Ave copies each issue No. copies Issue Published<br />

During preceeding 12 months nearest to filing Date<br />

a. Total Number of copies<br />

b. Legimate paid <strong>an</strong>d/or requested<br />

(By mail <strong>an</strong>d outside mail)<br />

b1. Individual paid/requested mail Subs as<br />

34485 24400<br />

Stated on PS Form 3541<br />

b2. Copies requested by Employers <strong>for</strong> Distribution<br />

To Employees Name/Position sataed on PS3541<br />

b3. Sales through Delers/Carriers Outside USPS<br />

13852 11907<br />

b4. Requested copies o<strong>the</strong>r USPS mail classes 54 163<br />

c. TOTAL PAID/REQUESTED Circulation<br />

d. Nonrequested Distribution<br />

13906 12070<br />

d1. Nonrequested copies stated on PS3541<br />

d2. Sales through Delers/Carriers Outside USPS<br />

d3. Requested copies o<strong>the</strong>r USPS mail classes<br />

12907 10399<br />

e. TOTAL NONREQUESTED DISTRIBUTION 12907 10399<br />

f. TOTAL DISTRIBUTION 26813 22469<br />

g. Copies not Distributed 7622 1931<br />

h. TOTAL 34485 24400<br />

i. Percent Paid/requested circulation 51.9% 53.7%<br />

I certify that all <strong>the</strong> in<strong>for</strong>mation furnished on this <strong>for</strong>m is true <strong>an</strong>d complete. AUTOMOTIVE INDUSTRIES • John Larkin, Publisher<br />

2 to read full version of AI stories go to www.ai-online.com

4 to read full version of AI stories go to www.ai-online.com

intro<br />

Industry motors ahead<br />

Looking back over <strong>the</strong> past 24 months or so, it is astonishing<br />

to see how quickly <strong>the</strong> auto industry has turned prototypes<br />

<strong>an</strong>d “blue sky” thinking into hard metal (or plastic) on<br />

<strong>the</strong> roads.<br />

While academics, politici<strong>an</strong>s, environmentalists <strong>an</strong>d lawmakers<br />

were still attending conferences <strong>an</strong>d having discussions about<br />

curbing <strong>vehicle</strong> emissions, promoting <strong>electric</strong> <strong>vehicle</strong>s <strong>an</strong>d improving<br />

fuel consumption, <strong>the</strong> industry simply got on with<br />

it. BMW has a fleet of over 600 <strong>electric</strong> Minis on<br />

<strong>the</strong> road, while Niss<strong>an</strong>, General Motors, Audi,<br />

Toyota, Ford, Volkswagen <strong>an</strong>d Hyundai are<br />

among <strong>the</strong> o<strong>the</strong>r OEMs with all-<strong>electric</strong><br />

cars hot on <strong>the</strong> heels of <strong>the</strong> Minis.<br />

Editor, Ed Richardson<br />

Then <strong>the</strong>re are <strong>the</strong> new br<strong>an</strong>ds -<br />

Tesla has its roadster, Norway has its<br />

Think City, <strong>an</strong>d in South Africa <strong>the</strong>re is <strong>the</strong><br />

Joule – some of <strong>the</strong> first new br<strong>an</strong>ds to be<br />

launched as <strong>the</strong> industry enters a new era of<br />

propulsion. They have <strong>the</strong> potential to spark farr<strong>an</strong>ging<br />

ch<strong>an</strong>ges in <strong>the</strong> way passenger cars are sold<br />

<strong>an</strong>d serviced. All-new technology creates <strong>an</strong> opportunity <strong>for</strong> dealer<br />

<strong>an</strong>d distribution business models which disrupt <strong>the</strong> present order.<br />

In South Africa (as elsewhere), supermarkets now sell Chinesemade<br />

scooters, motorcycles <strong>an</strong>d scooters instead of <strong>the</strong> traditional<br />

motorcycle dealers. That’s because <strong>the</strong> low cost of <strong>the</strong> Chinese<br />

bikes has turned <strong>the</strong>m into disposable commodities. Electric<br />

<strong>vehicle</strong>s will not (<strong>for</strong> now) be commodities, but nei<strong>the</strong>r will <strong>the</strong>y<br />

be maintained <strong>an</strong>d repaired in traditional workshops. OEMs have<br />

clearly seen <strong>the</strong> d<strong>an</strong>ger, <strong>an</strong>d are leveraging <strong>the</strong>ir br<strong>an</strong>ds <strong>an</strong>d net-<br />

works with <strong>the</strong>ir own <strong>vehicle</strong>s. AI<br />

At present, <strong>the</strong> <strong>electric</strong> car is designed <strong>for</strong> city tr<strong>an</strong>sport, <strong>an</strong>d<br />

hybrids seem to hold <strong>the</strong> key to more efficient motoring over long<br />

dist<strong>an</strong>ces <strong>an</strong>d in town. Innovation in this field is extraordinary, as<br />

we see <strong>the</strong> integration of what a few years ago were nice-to-have<br />

accessories into <strong>the</strong> operating system of <strong>the</strong> car. The <strong>vehicle</strong> m<strong>an</strong>agement<br />

system of BMW’s new hybrid system, <strong>for</strong> example, uses<br />

a built-in GPS to calculate when to run on all-battery power, <strong>an</strong>d<br />

when to start <strong>the</strong> engine. You <strong>c<strong>an</strong></strong> read about it in this<br />

edition, <strong>an</strong>d we <strong>c<strong>an</strong></strong> be sure that o<strong>the</strong>rs will have<br />

similar systems as designers think laterally <strong>an</strong>d<br />

software allows different systems to talk to<br />

each o<strong>the</strong>r. Initiatives like Autosar <strong>an</strong>d <strong>the</strong><br />

use of Linux through <strong>the</strong> GENIVI consortium<br />

are fuelling this trend. As are<br />

partnerships across continents, between<br />

component m<strong>an</strong>ufacturers <strong>an</strong>d<br />

OEMs, <strong>an</strong>d competing OEMs <strong>the</strong>mselves.<br />

China again has <strong>the</strong> potential<br />

to disrupt <strong>the</strong> status quo through its<br />

pl<strong>an</strong>s to be a world leader in hybrid<br />

technology.<br />

Hybrids bring <strong>the</strong>ir own challenges,<br />

not <strong>the</strong> least of which is <strong>an</strong> engine which<br />

seldom reaches optimum operating temperature.<br />

This has repercussions <strong>for</strong> both<br />

<strong>the</strong> lubrication of <strong>the</strong> engine, as well as <strong>the</strong><br />

designers of <strong>the</strong> catalytic exhaust systems which<br />

have traditionally been designed to run hot.<br />

Which brings us to <strong>the</strong> question of what fuel <strong>the</strong> engine will<br />

use. Here again adv<strong>an</strong>ces are being made at high speed. We have<br />

comp<strong>an</strong>ies turning algae into fuel, running engines on meth<strong>an</strong>e<br />

from waste dumps, converting used cooking oil into diesel … <strong>the</strong><br />

list goes on.<br />

What is perhaps most exciting is that all this research <strong>an</strong>d development<br />

has been going on while <strong>the</strong> global auto industry has<br />

been navigating itself through one of <strong>the</strong> worst downturns in history.<br />

Which is good news <strong>for</strong> a global economy built on <strong>the</strong> mobility<br />

of <strong>the</strong> individual.<br />

AUTOMOTIVE INDUSTRIES <strong>an</strong>d Rutgers, The State University of New Jersey, have put<br />

toge<strong>the</strong>r a digital library of back issues of AI from <strong>the</strong> early 1900’s (high res <strong>an</strong>d low res) of<br />

approximately 230,000 images of <strong>the</strong> print publication. This archive, which documents <strong>the</strong><br />

birth of <strong>the</strong> auto industry to <strong>the</strong> present, is available to AI subscribers.<br />

Go to AI’s homepage www.ai.com.ai <strong>an</strong>d click on <strong>the</strong> “AI Library” link or visit<br />

www.ai-online.com/100YearLibrary<br />

6 to read full version of AI stories go to www.ai-online.com

innovation<br />

Among <strong>the</strong> issues on <strong>the</strong> agenda <strong>for</strong> <strong>the</strong> conference, which<br />

will be held in Rome from June 8 to June 10, is <strong>the</strong> increase in<br />

OEM <strong>vehicle</strong> <strong>an</strong>d engine m<strong>an</strong>ufacturer participation. More th<strong>an</strong><br />

200 <strong>vehicle</strong>s <strong>an</strong>d natural gas powered models are now available<br />

worldwide, with one new model emerging each week on average.<br />

More th<strong>an</strong> seventy oral presentations, plus a number of poster<br />

presentations, will feature on <strong>the</strong> two <strong>an</strong>d a half day program<br />

covering issues such as biometh<strong>an</strong>e (renewable natural gas),<br />

st<strong>an</strong>dards harmonization, integration of CNG cylinders into OEM<br />

plat<strong>for</strong>ms, marketing initiatives, emerging technologies, plus<br />

national <strong>an</strong>d regional market reviews.<br />

“Until now, natural gas has been ‘<strong>the</strong> quiet achiever’. It has<br />

proven itself as a tr<strong>an</strong>sport fuel on a sizeable scale<br />

Natural Gas Vehicles –<br />

creating a tr<strong>an</strong>sport<br />

revolution By: Jon Knox<br />

“Creating a Tr<strong>an</strong>sport Revolution” is <strong>the</strong> <strong>the</strong>me <strong>for</strong> <strong>the</strong> twelfth biennial conference of <strong>the</strong><br />

International Association <strong>for</strong> Natural Gas Vehicles (IANGV).<br />

“<br />

The automotive <strong>an</strong>d<br />

tr<strong>an</strong>sport sector is currently<br />

undergoing unprecedented<br />

<strong>an</strong>d exciting ch<strong>an</strong>ge<br />

worldwide. Environmental,<br />

economic <strong>an</strong>d energy factors<br />

have resulted in a global<br />

quest <strong>for</strong> alternatives to diesel<br />

<strong>an</strong>d petrol to fuel our <strong>vehicle</strong>s.<br />

with more th<strong>an</strong> 11 million <strong>vehicle</strong>s in over 81 countries<br />

throughout <strong>the</strong> world,” says Brett Jarm<strong>an</strong>, executive director<br />

of IANGV. “Fuel alternative <strong>vehicle</strong>s are currently undergoing a<br />

revolution – in some countries earning market share that positions<br />

natural gas alongside petrol <strong>an</strong>d diesel as a ‘mainstream’ fuel.”<br />

The IANGV is keenly aware that <strong>for</strong> <strong>the</strong> NGV industry to be<br />

commercially viable <strong>the</strong>re needs to be a high level of participation<br />

by OEMs. At its first exhibition held in Sydney in 1988, no OEMs<br />

showcased <strong>an</strong>y products – today, industry exhibitions attract all<br />

types of <strong>vehicle</strong>s from cars <strong>an</strong>d three wheelers to heavy trucks <strong>an</strong>d<br />

buses that run on natural gas.<br />

“Environmental, economic <strong>an</strong>d energy factors have resulted in a<br />

global quest <strong>for</strong> alternatives to diesel <strong>an</strong>d petrol to fuel our <strong>vehicle</strong>s,”<br />

explains Jarm<strong>an</strong>. “While <strong>the</strong> alternatives are m<strong>an</strong>y, few <strong>c<strong>an</strong></strong> equal<br />

<strong>the</strong> promise shown by natural gas – it’s cle<strong>an</strong>, safe, reliable,<br />

versatile, af<strong>for</strong>dable, readily available <strong>an</strong>d even renewable.”<br />

Jarm<strong>an</strong> recently took over <strong>the</strong> m<strong>an</strong>agement of <strong>the</strong><br />

association from <strong>the</strong> founding secretary-general, Garth<br />

Harris. Automotive Industries (AI) asked him what he sees<br />

in <strong>the</strong> future of <strong>the</strong> association.<br />

Jarm<strong>an</strong>: Dynamic, progressive <strong>an</strong>d growing in size <strong>an</strong>d stature<br />

– a reflection of <strong>the</strong> industry. Right now, <strong>the</strong> industry is like a runaway<br />

train. Even <strong>the</strong> global economic circumst<strong>an</strong>ces of last year couldn’t<br />

stop it – with NGV numbers growing by more th<strong>an</strong> 10%.<br />

AI: Are NGVs getting <strong>the</strong> support <strong>the</strong>y need from <strong>the</strong><br />

worldwide political leaders <strong>an</strong>d policy makers?<br />

Jarm<strong>an</strong>: It’s a mixed bag. In some cases <strong>the</strong> support is<br />

outst<strong>an</strong>ding, in o<strong>the</strong>rs <strong>the</strong> support is well intentioned but not<br />

necessarily effective, <strong>an</strong>d in o<strong>the</strong>rs still, it’s non-existent.<br />

8 to read full version of AI stories go to www.ai-online.com<br />

While <strong>the</strong> alternatives<br />

are m<strong>an</strong>y, few <strong>c<strong>an</strong></strong> equal<br />

<strong>the</strong> promise shown by<br />

natural gas – it’s cle<strong>an</strong>,<br />

safe, reliable, versatile,<br />

af<strong>for</strong>dable, readily available<br />

<strong>an</strong>d even renewable.<br />

”<br />

Brett Jarm<strong>an</strong>, executive director<br />

of IANGV. LEFT: Fuelling a Mercedes<br />

B Class NGT (Natural Gas Technology)<br />

with biometh<strong>an</strong>e.<br />

One of <strong>the</strong> main challenges is getting policy makers to<br />

underst<strong>an</strong>d that NGVs are a ‘here <strong>an</strong>d now’ solution to a number<br />

of issues – greenhouse gas <strong>an</strong>d air pollution reductions, enh<strong>an</strong>ced<br />

energy security, <strong>for</strong>eign exch<strong>an</strong>ge savings <strong>an</strong>d more.<br />

AI: How are NGVs doing relative to o<strong>the</strong>r alternative fuel<br />

<strong>vehicle</strong>s such as eth<strong>an</strong>ol <strong>vehicle</strong>s, hybrid <strong>vehicle</strong>s, <strong>an</strong>d<br />

hydrogen fuel cells?<br />

Jarm<strong>an</strong>: If I had a scorecard, I would say that natural gas is<br />

doing better th<strong>an</strong> o<strong>the</strong>r alternatives simply because of <strong>the</strong> vast<br />

<strong>r<strong>an</strong>ge</strong> of applications it is proving itself in. Included among <strong>the</strong> 11<br />

million NGVs on <strong>the</strong> road are motorcycles, three wheelers, <strong>for</strong>klifts,<br />

cars, trucks, buses, tractors, airport tugs, ice re-surfacers, refuse<br />

trucks, drayage trucks, rail locomotives, <strong>an</strong>d even 150 ton ‘road<br />

trains’ in Australia.<br />

We <strong>c<strong>an</strong></strong> add to that number <strong>the</strong> growing number of<br />

ferries, fishing boats, cargo ships <strong>an</strong>d o<strong>the</strong>r marine vessels.

Fast gas – gas-powered Volkswagen Scirocco.<br />

No o<strong>the</strong>r alternative fuel, <strong>an</strong>d not even petrol <strong>for</strong> that matter, <strong>c<strong>an</strong></strong><br />

claim <strong>the</strong> same level of diversity as natural gas.<br />

AI: OEMs are advertising <strong>electric</strong> <strong>vehicle</strong>s, hybrids, <strong>an</strong>d<br />

fuel flexible <strong>vehicle</strong>s but we don’t hear too much about <strong>the</strong>ir<br />

NGVs. Why not?<br />

Jarm<strong>an</strong>: I hear from OEMs almost every day <strong>an</strong>d <strong>the</strong>y are very<br />

serious about selling <strong>the</strong>ir NGVs. However, if you were to mass<br />

market NGVs in <strong>an</strong> immature market without adequate refueling<br />

available, you would find that most of your marketing dollars go to<br />

waste. You would also frustrate <strong>the</strong> market by trying to sell <strong>the</strong>m<br />

something <strong>the</strong>y <strong>c<strong>an</strong></strong>’t use. Where NGVs are concerned, you’ll find<br />

<strong>the</strong> advertising tends to radiate from, <strong>an</strong>d be proportionate to,<br />

fuelling station availability.<br />

AI: Have NGVs become part of <strong>the</strong> ‘normal’ natural gas<br />

markets to take <strong>the</strong>ir rightful place along with industrial,<br />

commercial <strong>an</strong>d residential sectors of <strong>the</strong> industry?<br />

Jarm<strong>an</strong>: Individually, NGVs don’t consume a lot relative to<br />

some commercial or industry sectors, but collectively <strong>the</strong> potential<br />

consumption is enormous. Apart from a few small exceptions,<br />

NGVs are not yet part of most ‘normal’ gas markets but are rapidly<br />

becoming so. One outst<strong>an</strong>ding exception is India, where NGVs are<br />

well known <strong>an</strong>d widely accepted.<br />

AI: Liquefied natural gas (LNG) seems to be becoming more<br />

popular. Do you see <strong>an</strong> exp<strong>an</strong>ded market <strong>for</strong> L-NGVs <strong>an</strong>d, if so,<br />

where is it most likely to take place, in what types of <strong>vehicle</strong>s?<br />

Jarm<strong>an</strong>: North America, Australia, Russia <strong>an</strong>d Korea are<br />

probably <strong>the</strong> most tested markets <strong>an</strong>d <strong>the</strong>ir numbers will climb<br />

dramatically in <strong>the</strong> next two years. There are also promising signs<br />

coming from o<strong>the</strong>r parts of Europe, particularly <strong>the</strong> UK, Spain,<br />

Sweden, <strong>an</strong>d <strong>the</strong> Ne<strong>the</strong>rl<strong>an</strong>ds. Thail<strong>an</strong>d is also leading <strong>the</strong> way in<br />

South-East Asia. In all cases it’s <strong>for</strong> heavy <strong>vehicle</strong>s. The 150 ton ‘road<br />

trains’ are proving that LNG is up to <strong>the</strong> toughest of challenges.<br />

AI: M<strong>an</strong>y people are promoting biometh<strong>an</strong>e as a renewable<br />

fuel to compare to such alternatives as eth<strong>an</strong>ol. How do you<br />

see biometh<strong>an</strong>e moving into <strong>the</strong> NGV market?<br />

Brute <strong>for</strong>ce demonstrates <strong>the</strong> power of natural gas.<br />

One of <strong>the</strong> world’s first natural gas fuelled cement agitators in<br />

Australia’ (The line about filling up with gas wouldn’t work as<br />

it’s not common terminology in Australia.)<br />

Jarm<strong>an</strong>: It’s a perfectly natural fit – it puts waste or org<strong>an</strong>ic<br />

material to good use <strong>an</strong>d often allows NGVs to be used outside<br />

of traditional pipeline or virtual pipeline networks. The biggest<br />

challenge is diverting political attention away from biometh<strong>an</strong>e <strong>for</strong><br />

power generation <strong>an</strong>d towards tr<strong>an</strong>sport use. From a renewable<br />

point of view, <strong>electric</strong>ity <strong>c<strong>an</strong></strong> easily be generated from wind or solar<br />

whereas tr<strong>an</strong>sport <strong>c<strong>an</strong></strong>’t – except through <strong>electric</strong> <strong>vehicle</strong>s which<br />

has fairly limited applications.<br />

Reserving biometh<strong>an</strong>e <strong>for</strong> tr<strong>an</strong>sport use guar<strong>an</strong>tees <strong>an</strong><br />

efficient low carbon (<strong>an</strong>d in some cases carbon neutral) fuel<br />

that <strong>c<strong>an</strong></strong> be used <strong>for</strong> a huge <strong>r<strong>an</strong>ge</strong> of applications. Garbage<br />

trucks that are fuelled by <strong>the</strong>ir cargo or dairy fleets fuelled<br />

by farm based bio-digesters are perfect examples of ‘closing<br />

<strong>the</strong> loop’ on environmental hazards. Given that <strong>an</strong>y NGV, <strong>an</strong>d<br />

thus <strong>an</strong>y internal combustion engine <strong>vehicle</strong> could run on<br />

biometh<strong>an</strong>e, <strong>the</strong> opportunities are limitless. AI<br />

Automotive Industries 10

innovation<br />

L<strong>an</strong>di Renzo taking<br />

alternative fuel systems<br />

to <strong>the</strong> U.S. By: Jon Knox <strong>an</strong>d Jeff Seisler<br />

The U.S. market is to benefit from <strong>the</strong> experience<br />

<strong>an</strong>d knowledge of a leading m<strong>an</strong>ufacturer of<br />

LPG <strong>an</strong>d CNG alternative automotive fuel<br />

systems <strong>an</strong>d components, L<strong>an</strong>di Renzo.<br />

In J<strong>an</strong>uary 2010, <strong>the</strong> Itali<strong>an</strong> firm<br />

registered its U.S. subsidiary – L<strong>an</strong>di<br />

Renzo USA Corporation. It already has<br />

subsidiaries in Europe, Asia <strong>an</strong>d South<br />

America. “In <strong>the</strong> U.S. <strong>the</strong>re is huge<br />

potential <strong>for</strong> <strong>the</strong> use of eco-friendly<br />

fuels, particularly natural gas, in <strong>the</strong><br />

tr<strong>an</strong>sportation segment. L<strong>an</strong>di Renzo will<br />

be playing a key role in <strong>the</strong> development<br />

of this sector <strong>an</strong>d will take adv<strong>an</strong>tage of <strong>the</strong><br />

m<strong>an</strong>y business opportunities it offers,” says<br />

Claudio Carnevale, CEO of L<strong>an</strong>di Renzo.<br />

L<strong>an</strong>di Renzo says it controls more th<strong>an</strong> 30% of<br />

<strong>the</strong> market <strong>for</strong> LPG <strong>an</strong>d CNG alternative automotive<br />

fuel systems <strong>an</strong>d components. The comp<strong>an</strong>y was established<br />

in 1954 <strong>an</strong>d during <strong>the</strong> last five years has registered a compound<br />

<strong>an</strong>nual growth rate of more th<strong>an</strong> 30%. It has become a global player<br />

through subsidiaries in ten countries covering all continents. The<br />

comp<strong>an</strong>y currently provides components or complete systems to<br />

some of <strong>the</strong> largest OEMs around <strong>the</strong> world including Toyota, GM<br />

Group, Fiat Group, Renault, PSA, BMW, Mini, Suzuki, Tata <strong>an</strong>d<br />

Mahindra&Mahindra. It also provided components to a number<br />

of Chinese car makers including Chery, Geely <strong>an</strong>d JinbeiAshok<br />

Leyl<strong>an</strong>d <strong>an</strong>d Brilli<strong>an</strong>ce Jinbei Automobile Comp<strong>an</strong>y.<br />

The L<strong>an</strong>di Renzo Quality System is in line with <strong>the</strong> most stringent<br />

automotive requirements <strong>an</strong>d is 2001 ISO/TS 16949 certified. After<br />

<strong>an</strong> extensive certification process, more th<strong>an</strong> 300 of <strong>the</strong> comp<strong>an</strong>y’s<br />

workshops in Italy are now ISO 9001 certified. “L<strong>an</strong>di Renzo has<br />

already collaborated with some of <strong>the</strong> top car m<strong>an</strong>ufacturers on <strong>an</strong><br />

international level. The complexity of electronics in modern <strong>vehicle</strong>s<br />

results in <strong>the</strong> need <strong>for</strong> a stable <strong>an</strong>d ongoing collaboration in order<br />

to design <strong>an</strong>d build systems that <strong>c<strong>an</strong></strong> be perfectly integrated<br />

with <strong>the</strong> electronics <strong>an</strong>d mech<strong>an</strong>ics of current <strong>vehicle</strong>s,” says <strong>the</strong><br />

comp<strong>an</strong>y. “Collaborations with <strong>the</strong>se m<strong>an</strong>ufacturers are focused<br />

on addressing specific markets. Considering current development<br />

programs, CNG <strong>an</strong>d LPG bi-fuel <strong>vehicle</strong>s will increase dramatically<br />

in <strong>the</strong> future.”<br />

In line with this policy, L<strong>an</strong>di Renzo created a division dedicated<br />

exclusively to products <strong>for</strong> car m<strong>an</strong>ufacturers. The comp<strong>an</strong>y<br />

continues to invest in <strong>the</strong> division <strong>an</strong>d one of its successful<br />

collaborations was with <strong>the</strong> FIAT Group (FIAT, L<strong>an</strong>cia, Alfa Romeo).<br />

A <strong>r<strong>an</strong>ge</strong> of <strong>vehicle</strong>s launched in 2009 was developed in strong<br />

collaboration between L<strong>an</strong>di Renzo <strong>an</strong>d FIAT teams. The result<br />

was a portfolio of bi-fuel <strong>vehicle</strong>s sellable on <strong>the</strong> FIAT network<br />

under FIAT warr<strong>an</strong>ty procedures.<br />

Automotive Industries (AI) spoke to Claudio Carnevale,<br />

CEO of L<strong>an</strong>di Renzo S.p.A., <strong>an</strong>d asked him how L<strong>an</strong>di Renzo<br />

m<strong>an</strong>ages to continue to adapt its technology to fit with <strong>the</strong><br />

ch<strong>an</strong>ges in <strong>vehicle</strong> technology <strong>an</strong>d emissions st<strong>an</strong>dards.<br />

12 to read full version of AI stories go to www.ai-online.com<br />

ABOVE: Claudio Carnevale, CEO of L<strong>an</strong>di Renzo<br />

S.p.A <strong>an</strong>d Stef<strong>an</strong>o L<strong>an</strong>di, CEO, m<strong>an</strong>aging director<br />

<strong>an</strong>d director, L<strong>an</strong>di Renzo S.p.A.<br />

“<br />

We ensure that we are const<strong>an</strong>tly<br />

aware of <strong>the</strong> innovations introduced<br />

to car models <strong>an</strong>d even <strong>an</strong>ticipate <strong>the</strong><br />

possible dem<strong>an</strong>ds of our customers.<br />

We continue to be <strong>the</strong> first choice of<br />

major car producers th<strong>an</strong>ks to this<br />

technological responsiveness.<br />

”<br />

LEFT: Claudio Carnevale, CEO of<br />

L<strong>an</strong>di Renzo S.p.A.

L<strong>an</strong>di Renzo S.p.A headquarters in Cavriago di Reggio Emilia, Italy, were built to architecturally represent <strong>the</strong> comp<strong>an</strong>y’s<br />

adv<strong>an</strong>ced technologies.<br />

Carnevale: We have been reliable partners of major OEMs<br />

<strong>an</strong>d we have offered some of <strong>the</strong> best aftermarket applications.<br />

This has been possible because of our commitment to R&D. We<br />

ensure that we are const<strong>an</strong>tly aware of <strong>the</strong> innovations introduced<br />

to car models <strong>an</strong>d even <strong>an</strong>ticipate <strong>the</strong> possible dem<strong>an</strong>ds of<br />

our customers. We continue to be <strong>the</strong> first choice of major car<br />

producers th<strong>an</strong>ks to this technological responsiveness.<br />

AI: Has <strong>the</strong> need to comply with regulations <strong>for</strong> on-board<br />

diagnostic (OBD) systems been a major challenge <strong>an</strong>d cost<br />

<strong>for</strong> L<strong>an</strong>di Renzo?<br />

Carnevale: We are able to m<strong>an</strong>age co-design projects with<br />

major car makers. In general, we work on job <strong>an</strong>d cost sharing<br />

with customers on OBD subjects in order to optimize <strong>the</strong> technical<br />

results <strong>an</strong>d development cost.<br />

AI: OEMs are increasingly bringing NGV models to <strong>the</strong><br />

market which also impacts <strong>the</strong> retrofit business. What do<br />

you see as <strong>the</strong> future of <strong>the</strong> NGV retrofit business? Do you<br />

<strong>an</strong>ticipate <strong>for</strong>ming strategic relationships with OEMs or will<br />

you focus on <strong>the</strong> retrofit markets more exclusively?<br />

Carnevale: We already have m<strong>an</strong>y partnerships with OEMs<br />

on CNG systems. In m<strong>an</strong>y countries, aftermarket remains a very<br />

import<strong>an</strong>t business option. Our strategic choice is to not favor<br />

one or <strong>the</strong> o<strong>the</strong>r market, but to be aware of all <strong>the</strong> available<br />

opportunities <strong>an</strong>d <strong>an</strong>y possible market developments. Obviously<br />

<strong>the</strong> retrofit market will enjoy technological benefits from <strong>the</strong> OEMs’<br />

know-how.<br />

AI: Do you see natural gas <strong>an</strong>d LPGs having a similar future?<br />

Carnevale: Today, LPG is a very popular option in Europe<br />

<strong>an</strong>d in some Asi<strong>an</strong> markets. Natural gas accounts <strong>for</strong> almost <strong>the</strong><br />

whole South Ameri<strong>c<strong>an</strong></strong> market <strong>an</strong>d is very successful in southwest<br />

Asia. The search <strong>for</strong> a progressive independence from oil<br />

sources will help CNG in <strong>the</strong> medium to long term.<br />

AI: What are <strong>the</strong> current trends in <strong>the</strong> alternative fuels<br />

market <strong>an</strong>d what do you think future trends in this segment<br />

will be? Where are your largest markets <strong>for</strong> conversion of<br />

NGV <strong>an</strong>d LPG?<br />

Carnevale: We’re establishing our presence in both CNG<br />

<strong>an</strong>d LPG markets. CNG is a cle<strong>an</strong> option that doesn’t need to<br />

go through a tr<strong>an</strong>s<strong>for</strong>mation process to be used as tr<strong>an</strong>sportation<br />

fuel. It is a medium to long term solution <strong>for</strong> countries that have<br />

CNG as a natural resource. LPG is a fast, reliable <strong>an</strong>d af<strong>for</strong>dable<br />

option which also dramatically reduces CO2 emissions.<br />

AI: The L<strong>an</strong>di Renzo Group is moving into <strong>the</strong> highly<br />

competitive U.S. automotive sector <strong>for</strong> alternative fuel<br />

technology applications. What message would you like to<br />

convey to <strong>the</strong> North Ameri<strong>c<strong>an</strong></strong> automotive industry regarding<br />

this import<strong>an</strong>t strategic move?<br />

Carnevale: Being <strong>the</strong> worldwide number one in our business<br />

has been possible th<strong>an</strong>ks to over 50 years of experience in<br />

aftermarket conversions. We are suppliers of LPG <strong>an</strong>d CNG<br />

systems to <strong>the</strong> major global automakers <strong>an</strong>d we invest heavily<br />

in research <strong>an</strong>d development. Our strength is that we know how<br />

to respond to customers’ needs. We believe that <strong>the</strong> Ameri<strong>c<strong>an</strong></strong><br />

players will appreciate <strong>the</strong>se skills. AI<br />

“<br />

CNG is a cle<strong>an</strong> option that doesn’t need to go through a tr<strong>an</strong>s<strong>for</strong>mation process to be used as<br />

tr<strong>an</strong>sportation fuel. It is a medium to long term solution <strong>for</strong> countries that have CNG as a natural resource.<br />

Claudio Carnevale, CEO of L<strong>an</strong>di Renzo S.p.A.<br />

14 to read full version of AI stories go to www.ai-online.com<br />

”

innovation<br />

New filter technology will help power <strong>the</strong> greater use of<br />

natural gas to fuel <strong>vehicle</strong>s.<br />

The high-pressure natural gas filter developed by Omnitek<br />

Engineering has been certified by <strong>the</strong> United Nations Economic<br />

Commission <strong>for</strong> Europe – <strong>the</strong> UN-ECE-110R. This certification is<br />

expected to help <strong>the</strong> comp<strong>an</strong>y exp<strong>an</strong>d its market internationally,<br />

with a number of light <strong>an</strong>d heavy <strong>vehicle</strong> m<strong>an</strong>ufacturers opting <strong>for</strong><br />

<strong>the</strong> filter. Already, Indi<strong>an</strong> OEM, Tata Motors is fitting <strong>the</strong> compressed<br />

natural gas filter as <strong>an</strong> original equipment part.<br />

“The filter is a critical component of a compressed natural gas<br />

system, providing protection from solid particulate matter <strong>an</strong>d oil<br />

aerosols which <strong>c<strong>an</strong></strong> damage fuel injections, carburetors <strong>an</strong>d regulators.<br />

In addition to Tata, numerous OEM customers report superior<br />

per<strong>for</strong>m<strong>an</strong>ce from Omnitek’s multi-layer filter element over<br />

competing br<strong>an</strong>ds <strong>an</strong>d we look <strong>for</strong>ward to exp<strong>an</strong>ding<br />

“<br />

We <strong>c<strong>an</strong></strong> now<br />

cover every engine<br />

from one cylinder<br />

to 16 cylinders.<br />

”<br />

Werner Funk, president <strong>an</strong>d<br />

chief executive officer of Omnitek<br />

Engineering Corporation.<br />

our customer base with this international certification,”<br />

says Werner Funk, president <strong>an</strong>d chief executive officer of<br />

Omnitek Engineering Corporation.<br />

The comp<strong>an</strong>y says that across <strong>the</strong> world, <strong>the</strong>re are 11 million<br />

light <strong>an</strong>d heavy duty <strong>vehicle</strong>s that run on compressed natural gas<br />

or CNG, with one million being added to this number <strong>an</strong>nually.<br />

According to Omnitek, m<strong>an</strong>y developing nations with readily<br />

available natural gas from indigenous sources are shifting to<br />

CNG. Omnitek has developed a system to convert <strong>an</strong>y existing<br />

diesel engine to a cle<strong>an</strong>-burning natural gas engine at a fraction<br />

of <strong>the</strong> cost of a new engine. Omnitek estimates that ten million<br />

diesel engines around <strong>the</strong> world <strong>c<strong>an</strong></strong> be converted using <strong>the</strong><br />

Omnitek Diesel-to-Natural Gas Conversion System while still<br />

offering ROI.<br />

Converting<br />

diesel engines to<br />

natural gas By: Jon Knox<br />

Automotive Industries asked Funk what his general<br />

criteria are <strong>for</strong> taking on <strong>the</strong> repowering of <strong>an</strong> engine?<br />

Funk: We go through a checklist which includes: <strong>driving</strong> <strong>r<strong>an</strong>ge</strong>;<br />

space <strong>for</strong> CNG t<strong>an</strong>ks; power needed (CNG may have five to ten<br />

percent lower power th<strong>an</strong> diesel); condition of <strong>the</strong> engine; <strong>an</strong>d <strong>c<strong>an</strong></strong><br />

<strong>the</strong> engine be converted. After it is checked we ei<strong>the</strong>r convert <strong>the</strong><br />

engine or sell <strong>the</strong> customer a new natural gas engine. We are picky<br />

since <strong>the</strong>re are so m<strong>an</strong>y diesel engines out <strong>the</strong>re looking to be<br />

converted to natural gas.<br />

AI: Do you do m<strong>an</strong>y re-powering jobs on relatively new<br />

diesel engines? If so, how will you deal with <strong>the</strong> latest diesel<br />

engine developments such as on-board-diagnostics or <strong>the</strong><br />

addition of emissions control systems such as selective<br />

catalytic reduction (SCR) systems?<br />

Funk: Most engines are over five years old.<br />

Customers wait out <strong>the</strong> warr<strong>an</strong>ty period when<br />

<strong>the</strong>y own <strong>the</strong> <strong>vehicle</strong>. Our system is OE<br />

quality <strong>an</strong>d we offer our own on-boarddiagnostics.<br />

Our system communicates<br />

over <strong>the</strong> CANbus <strong>an</strong>d <strong>c<strong>an</strong></strong> control all<br />

CAN functions such as automatic<br />

tr<strong>an</strong>smission, electronic dashboard,<br />

cruise control, etc. We would<br />

remove <strong>the</strong> SCR system since this<br />

Nox controlling technology is not<br />

needed with natural gas <strong>an</strong>d threeway<br />

catalytic converter.<br />

AI: Which countries are <strong>the</strong><br />

principal growth markets <strong>for</strong><br />

NGVs <strong>an</strong>d <strong>for</strong> Omnitek?<br />

Funk: The largest amount of <strong>vehicle</strong>s<br />

we have converted are located in Sou<strong>the</strong>ast<br />

Asia. Now it looks like our business will<br />

shift to South America <strong>an</strong>d Eastern Europe. We<br />

are also seeing great progress in <strong>the</strong> USA where<br />

we have started several projects in recent months.<br />

AI: Do customers receive government incentives <strong>for</strong><br />

<strong>the</strong> conversion to CNG in <strong>an</strong>y of <strong>the</strong> countries?<br />

Funk: Most of <strong>the</strong> natural gas conversions in <strong>the</strong> USA are<br />

supported by government incentives in one <strong>for</strong>m or <strong>an</strong>o<strong>the</strong>r. In<br />

o<strong>the</strong>r countries incentives take m<strong>an</strong>y <strong>for</strong>ms – usually as low or no<br />

interest lo<strong>an</strong>s <strong>an</strong>d fuel subsidies.<br />

AI: M<strong>an</strong>y of <strong>the</strong> strongest growth markets are also highly<br />

price sensitive. How is this affecting <strong>the</strong> degree to which<br />

Omnitek <strong>c<strong>an</strong></strong> do a relatively complicated <strong>an</strong>d expensive<br />

engine conversion (repowering)?<br />

Funk: We per<strong>for</strong>m conversions in My<strong>an</strong>mar, Thail<strong>an</strong>d, Peru,<br />

USA <strong>an</strong>d Europe so price is not always <strong>the</strong> most import<strong>an</strong>t factor.<br />

I think reliability <strong>an</strong>d fuel savings are much more import<strong>an</strong>t.<br />

16 to read full version of AI stories go to www.ai-online.com

If a customer looks at <strong>the</strong> lowest initial cost solution only – without<br />

considering reliability, service support <strong>an</strong>d low fuel use – he is<br />

missing <strong>the</strong> big picture. We make <strong>the</strong> customer underst<strong>an</strong>d that<br />

it is not <strong>the</strong> initial conversion cost that is import<strong>an</strong>t, but <strong>the</strong> return<br />

on investment (ROI). Most often, our customers <strong>c<strong>an</strong></strong> recover <strong>the</strong><br />

conversion cost in less th<strong>an</strong> 1.5 years <strong>an</strong>d sometimes in less th<strong>an</strong><br />

ten months, especially in countries where <strong>the</strong> natural gas cost is<br />

60 to 70% less th<strong>an</strong> diesel.<br />

AI: What are your latest products to be launched in <strong>the</strong><br />

market <strong>for</strong> gas <strong>vehicle</strong>s?<br />

Funk: Last year we introduced our diesel-to-natural gas<br />

conversion system <strong>for</strong> V8 <strong>an</strong>d V16 engines. We <strong>c<strong>an</strong></strong> now cover<br />

every engine from one cylinder to 16 cylinders, including trucks,<br />

buses, irrigation pumps, generators <strong>an</strong>d boats. We also introduced<br />

a low-pressure system, which <strong>c<strong>an</strong></strong> be used to convert diesel<br />

power generators <strong>an</strong>d allows <strong>the</strong> engine to be connected straight<br />

to a low-pressure gas line with no high-pressure CNG storage<br />

t<strong>an</strong>ks needed. When converting a generator to natural gas, <strong>the</strong><br />

conversion cost <strong>c<strong>an</strong></strong> be recovered in four to six months.<br />

The newest products are service items. Last year, we added a<br />

special 12mm long-life natural gas spark plug to our lineup of longlife<br />

14mm natural gas spark plugs we have been selling <strong>for</strong> m<strong>an</strong>y<br />

years now. Ano<strong>the</strong>r new product is a unique CNG motor oil.<br />

AI: How do you assess <strong>the</strong> growth of natural gas <strong>vehicle</strong>s<br />

in your country? Do you think it is <strong>the</strong> right time <strong>for</strong> NGVs in<br />

<strong>the</strong> United States?<br />

Funk: I think <strong>the</strong> time is right <strong>for</strong> natural gas passenger <strong>vehicle</strong>s,<br />

especially if home-refueling is also offered. In <strong>the</strong> USA we have a<br />

great infrastructure where natural gas is supplied to almost every<br />

home. As far as Omnitek’s business is concerned, we still have a<br />

lot of work to do to convince <strong>the</strong> United States EPA (Environmental<br />

Protection Agency) that old diesel engines converted to natural<br />

gas <strong>c<strong>an</strong></strong> be low-polluting engines with high reliability. We have<br />

demonstrated that we <strong>c<strong>an</strong></strong> achieve EURO 6 <strong>an</strong>d US EPA 2010<br />

On-Road st<strong>an</strong>dards.<br />

AI: What should be <strong>the</strong> next step of technology applied<br />

to gas-powered engines in order to assure its massive<br />

use at worldwide level? And what should happen with <strong>the</strong><br />

emissions control technologies?<br />

Funk: For <strong>the</strong> natural gas passenger car population to increase<br />

quickly <strong>an</strong>d subst<strong>an</strong>tially, more fueling infrastructure <strong>an</strong>d gas price<br />

stability is needed. A high crude oil price will also help, but only if<br />

<strong>the</strong> price of natural gas always maintains a signifi<strong>c<strong>an</strong></strong>t adv<strong>an</strong>tage.<br />

I think <strong>the</strong>re are not enough OE suppliers offering a diverse product<br />

mix of new natural gas engines to really have a subst<strong>an</strong>tial<br />

impact on <strong>the</strong> heavy-duty natural gas <strong>vehicle</strong> population over <strong>the</strong><br />

next three or four years. Also, we <strong>c<strong>an</strong></strong>not convert diesel engines to<br />

natural gas quick enough to really have a big impact on <strong>the</strong> number<br />

of <strong>vehicle</strong>s on <strong>the</strong> roads.<br />

As emission levels are getting lower <strong>an</strong>d lower, new <strong>an</strong>d expensive<br />

technologies have to be employed to reach <strong>the</strong>se levels. Two<br />

Omnitek-equipped engines have recently achieved US-2010 <strong>an</strong>d<br />

EURO 6 emission levels without <strong>the</strong> use of EGR. This is about <strong>the</strong><br />

lowest emission level possible with today’s technology. To go even<br />

cle<strong>an</strong>er, adv<strong>an</strong>ced <strong>an</strong>d possibly not-yet-invented technologies are<br />

needed. Some of <strong>the</strong>se technologies may include cam-less valve<br />

train technology, ceramic engine parts, after-treatment systems,<br />

ultra-le<strong>an</strong> burn technology <strong>an</strong>d laser ignition, just to name a few. AI<br />

Automotive Industries 17<br />

Emission st<strong>an</strong>dards around <strong>the</strong> world.

innovation<br />

Driving confidently<br />

into U.S. market By:<br />

While m<strong>an</strong>y auto comp<strong>an</strong>ies put <strong>the</strong> brakes on <strong>the</strong>ir activities<br />

in <strong>the</strong> U.S. market when <strong>the</strong> downturn put <strong>the</strong> skids on new<br />

<strong>vehicle</strong> sales, Buehler Motor, Inc. (BMI) has continued to rev<br />

up its presence in <strong>the</strong> market.<br />

The comp<strong>an</strong>y recently relocated <strong>an</strong>d exp<strong>an</strong>ded its United<br />

States headquarters in Morrisville, North Carolina, to a new<br />

14 000-square-foot North Ameri<strong>c<strong>an</strong></strong> Technical Center (NATC). “It’s<br />

not <strong>an</strong> exaggeration to say that this center is one of <strong>the</strong> most<br />

“<br />

It’s not <strong>an</strong> exaggeration to<br />

say that this center is one of<br />

<strong>the</strong> most modern <strong>an</strong>d efficient<br />

in North America. It allows us<br />

to meet our North Ameri<strong>c<strong>an</strong></strong><br />

customers’ growing dem<strong>an</strong>ds<br />

<strong>for</strong> technically adv<strong>an</strong>ced <strong>an</strong>d<br />

environmentally responsible<br />

motor products.<br />

”<br />

Bob Ried<strong>for</strong>d, president <strong>an</strong>d general<br />

m<strong>an</strong>ager of Buehler Motor, Inc.<br />

modern <strong>an</strong>d efficient in North America. It allows us to meet our<br />

North Ameri<strong>c<strong>an</strong></strong> customers’ growing dem<strong>an</strong>ds <strong>for</strong> technically<br />

adv<strong>an</strong>ced <strong>an</strong>d environmentally responsible motor products,”<br />

says Bob Ried<strong>for</strong>d, president <strong>an</strong>d general m<strong>an</strong>ager of BMI. The<br />

NATC has achieved <strong>the</strong> highest rating <strong>for</strong> environmentally-friendly<br />

in<strong>for</strong>mation technology compli<strong>an</strong>ce. According to Ried<strong>for</strong>d, it will<br />

also serve as <strong>the</strong> U.S. hub <strong>for</strong> Buehler Motor’s customer service<br />

commitment <strong>an</strong>d its newly established national partner network.<br />

“With signifi<strong>c<strong>an</strong></strong>tly exp<strong>an</strong>ded engineering, prototyping <strong>an</strong>d<br />

testing capabilities, BMI is already delivering drive solutions <strong>for</strong><br />

its customers’ next-generation green products,” says Ried<strong>for</strong>d.<br />

“Beyond <strong>the</strong> products designed <strong>an</strong>d developed <strong>for</strong> its customers,<br />

BMI is also establishing its own internal green m<strong>an</strong>ufacturing<br />

<strong>an</strong>d operating processes as part of its goal to become one of<br />

<strong>the</strong> world’s most environmentally responsible motor component<br />

m<strong>an</strong>ufacturers.”<br />

BMI’s parent comp<strong>an</strong>y is Germ<strong>an</strong> firm, Buehler Motor, which<br />

delivered more th<strong>an</strong> 22 million mechatronic drive units worldwide<br />

in 2008. The drives are m<strong>an</strong>ufactured <strong>for</strong> a number of industries<br />

including <strong>the</strong> automotive, aviation, building <strong>an</strong>d office equipment,<br />

<strong>an</strong>d medical device markets. BMI is currently contracted to<br />

supply <strong>an</strong> auxiliary water pump <strong>for</strong> General Motor’s<br />

Chevrolet Volt Extended-<strong>R<strong>an</strong>ge</strong> Electric Vehicle<br />

<strong>an</strong>d CODA Automotive’s upcoming <strong>electric</strong><br />

five-passenger sed<strong>an</strong>.<br />

Some of BMI’s automotive solutions<br />

include those <strong>for</strong> drive trains that help<br />

cut carbon dioxide emissions while<br />

improving safety <strong>an</strong>d <strong>driving</strong> com<strong>for</strong>t.<br />

The comp<strong>an</strong>y also m<strong>an</strong>ufactures shift<br />

<strong>an</strong>d clutch actuators <strong>for</strong> automated<br />

m<strong>an</strong>ual <strong>an</strong>d dual clutch tr<strong>an</strong>smissions,<br />

motors <strong>for</strong> tr<strong>an</strong>smission oil pumps<br />

in start/stop <strong>an</strong>d hybrid systems,<br />

electromech<strong>an</strong>ical gear shift actuator<br />

<strong>for</strong> automatic tr<strong>an</strong>smissions <strong>an</strong>d tr<strong>an</strong>sfer<br />

case actuators.<br />

An import<strong>an</strong>t part of BMI’s philosophy is<br />

eco-consciousness. The comp<strong>an</strong>y has worked<br />

on green technologies including <strong>the</strong> design of drive<br />

solutions <strong>for</strong> environmentally-friendly applications as well<br />

as const<strong>an</strong>t optimization of design, products, <strong>an</strong>d processes to<br />

protect <strong>the</strong> environment as a whole. For <strong>the</strong> automotive market,<br />

its <strong>electric</strong> drives in oil pumps help maintain oil pressure in start/<br />

stop automatic tr<strong>an</strong>smissions which have helped cut <strong>the</strong> carbon<br />

footprint across <strong>the</strong> world. BMI’s <strong>electric</strong>al water pumps maintain<br />

energy optimized <strong>the</strong>rmal m<strong>an</strong>agement in internal combustion<br />

engines or cool <strong>the</strong> batteries of hybrid <strong>an</strong>d <strong>electric</strong> cars. For over<br />

ten years, <strong>an</strong> <strong>an</strong>nual environmental life-cycle assessment has<br />

documented its progress towards ever-improving, environmentally<br />

conscious <strong>an</strong>d resource preserving production. In line with this,<br />

BMI is certified under <strong>the</strong> ISO 140001 <strong>for</strong> its environmental<br />

m<strong>an</strong>agement system.<br />

18 to read full version of AI stories go to www.ai-online.com<br />

Rob White

The comp<strong>an</strong>y’s automotive clients include Audi, Continental,<br />

General Motors, Getrag, Hella, Johnson Controls, Magna, Porsche<br />

<strong>an</strong>d Volkswagen. It has also worked as <strong>an</strong> OEM supplier <strong>for</strong> almost<br />

every Tier One automaker in Europe, Jap<strong>an</strong> <strong>an</strong>d America. The<br />

comp<strong>an</strong>y recently contracted a major commercial engine supplier<br />

to provide BLDC motors to drive fuel pump assemblies designed<br />

to reduce emissions in off-highway commercial <strong>vehicle</strong>s.<br />

Automotive Industries (AI) asked Bob Ried<strong>for</strong>d, president<br />

of Buehler Motor, Inc., to talk about some of <strong>the</strong> new<br />

automotive technologies BMI pl<strong>an</strong>s to launch in 2010.<br />

Ried<strong>for</strong>d: BMI is excited to be working with General Motors<br />

<strong>an</strong>d helping <strong>the</strong> Chevrolet Volt application reach <strong>the</strong> marketplace<br />

in late 2010. Our newest generation BLDC water pumps will be<br />

introduced on <strong>the</strong> Chevrolet Volt later this year. BMI has been<br />

<strong>for</strong>tunate to draw signifi<strong>c<strong>an</strong></strong>t OEM interest <strong>for</strong> our brushless pump<br />

products, including CODA Automotive which recently awarded us<br />

a contract on <strong>the</strong>ir upcoming <strong>electric</strong> <strong>vehicle</strong> plat<strong>for</strong>m.<br />

AI: Why has BMI exp<strong>an</strong>ded its facilities in North America? Are<br />

you upbeat about business prospects <strong>the</strong>re, <strong>an</strong>d if so, why?<br />

Ried<strong>for</strong>d: We are definitely upbeat <strong>an</strong>d optimistic about our<br />

business prospects in North America. Last year was a challenging<br />

time <strong>for</strong> <strong>the</strong> entire automotive industry. However, BMI is operating<br />

Buehler Motor 50W Auxiliary Water Pump <strong>for</strong> Chevy Volt<br />

at a high level of efficiency <strong>an</strong>d adapting to new market dem<strong>an</strong>ds<br />

which has helped <strong>the</strong> comp<strong>an</strong>y endure <strong>the</strong> past year <strong>an</strong>d position<br />

itself <strong>for</strong> growth in 2010. Our exp<strong>an</strong>sion <strong>an</strong>d opening of <strong>the</strong> new<br />

North Ameri<strong>c<strong>an</strong></strong> Technical Center is a direct result of growing<br />

dem<strong>an</strong>d <strong>for</strong> environmentally-friendly applications, especially in <strong>the</strong><br />

automotive sector.<br />

AI: What are some of <strong>the</strong> challenges facing BMI in its<br />

quest to increase its exposure to environmentally-friendly<br />

technologies?<br />

Ried<strong>for</strong>d: The challenge <strong>for</strong> BMI, <strong>an</strong>d all of us in <strong>the</strong> automotive<br />

industry, is to maintain volume growth <strong>an</strong>d dem<strong>an</strong>d <strong>for</strong><br />

environmentally-friendly <strong>vehicle</strong>s. To meet <strong>the</strong>se challenges,<br />

Buehler is focused on partnering with our automotive OEM <strong>an</strong>d<br />

Tier One customers to ensure we are delivering technologies that<br />

will ultimately result in better, more environmentally-friendly <strong>vehicle</strong>s<br />

that appeal to a greater number of consumers.<br />

AI: What will drive <strong>the</strong> future growth of <strong>the</strong> comp<strong>an</strong>y?<br />

Ried<strong>for</strong>d: Environmentally-friendly <strong>vehicle</strong>s are more prevalent<br />

today th<strong>an</strong> ever. As a comp<strong>an</strong>y, we see growth in hybrid/<strong>electric</strong><br />

<strong>vehicle</strong>s as OEMs continue to develop technologies to meet<br />

growing consumer dem<strong>an</strong>ds. Within <strong>the</strong>se <strong>vehicle</strong>s, <strong>the</strong>re are a<br />

number of motion requirements <strong>for</strong> which BMI is well suited, such<br />

“<br />

Last year was a challenging time <strong>for</strong> <strong>the</strong> entire automotive industry. However, BMI is<br />

operating at a high level of efficiency <strong>an</strong>d adapting to new market dem<strong>an</strong>ds which has<br />

helped <strong>the</strong> comp<strong>an</strong>y endure <strong>the</strong> past year <strong>an</strong>d position itself <strong>for</strong> growth in 2010.<br />

”<br />

Bob Ried<strong>for</strong>d, president <strong>an</strong>d general m<strong>an</strong>ager of Buehler Motor, Inc.<br />

as <strong>the</strong> low noise, high efficiency pump solutions introduced on <strong>the</strong><br />

Chevrolet Volt as well as high-efficiency, long life motor designs<br />

<strong>for</strong> tr<strong>an</strong>smission <strong>an</strong>d start/stop applications. In addition, we see<br />

continued growth in CO2 reduction technologies <strong>for</strong> traditional<br />

internal combustion engine designs.<br />

AI: What is your strategy in fuelling growth in your<br />

automotive division?<br />

Ried<strong>for</strong>d: BMI’s GreenTech automotive strategy is a<br />

three-pronged approach to growth in <strong>the</strong> environmentallyfriendly<br />

automotive sector. The first approach is utilizing<br />

production methods centered on energy-conscious<br />

m<strong>an</strong>ufacturing. The second is developing new products<br />

using adv<strong>an</strong>ced simulation methods to maximize<br />

efficiency <strong>an</strong>d use of innovative material technologies.<br />

The third is focusing on green applications such<br />

as <strong>the</strong>rmal m<strong>an</strong>agement <strong>for</strong> <strong>electric</strong>al components<br />

<strong>an</strong>d maintaining fluid pressures in next-generation<br />

tr<strong>an</strong>smissions <strong>for</strong> hybrid <strong>an</strong>d <strong>electric</strong> <strong>vehicle</strong>s.<br />

AI: What are some of <strong>the</strong> o<strong>the</strong>r regions where you see<br />

a good potential <strong>for</strong> growth in <strong>the</strong> automotive sector?<br />

Ried<strong>for</strong>d: BMI’s global footprint allows us to take<br />

adv<strong>an</strong>tage of growth opportunities in multiple regions. In<br />

<strong>the</strong> Europe<strong>an</strong> automotive market, we see continued growth as<br />

we support our OEM <strong>an</strong>d Tier One customers’ developments<br />

of environmentally-friendly <strong>vehicle</strong> technologies. We also see<br />

tremendous growth opportunities in <strong>the</strong> Chinese automotive<br />

market where BMI already has a presence with two m<strong>an</strong>ufacturing<br />

locations, <strong>an</strong>d we pl<strong>an</strong> to increase sales <strong>an</strong>d marketing activities<br />

in <strong>the</strong> region. AI<br />

Automotive Industries 19

innovation<br />

Switching on<br />

hybrid technology<br />

By: Steve Barclay<br />

Key challenges <strong>an</strong>d opportunities facing<br />

hybrid <strong>vehicle</strong>s came under <strong>the</strong><br />

spotlight at a conference org<strong>an</strong>ized by<br />

<strong>the</strong> Swedish Hybrid Vehicle Centre (SHC)<br />

in Go<strong>the</strong>nburg late in 2009.<br />

“There are two challenges hybrid <strong>vehicle</strong>s<br />

(<strong>an</strong>d <strong>electric</strong> <strong>vehicle</strong>s) will face. Firstly, <strong>the</strong> safety<br />

of <strong>the</strong> energy storage, which must sustain normal<br />

operations <strong>an</strong>d impact loads. Secondly, <strong>the</strong>re will be new<br />

requirements <strong>for</strong> EVs in particular, with a dem<strong>an</strong>d <strong>for</strong> lower <strong>vehicle</strong><br />

weights (to accommodate batteries). We aim to address this issue in<br />

collaboration with <strong>the</strong> Centre SAFER (Traffic <strong>an</strong>d Vehicle Safety),” says<br />

Lennart Josefson, director of <strong>the</strong> SHC.<br />

The SHC was established in 2007 by <strong>the</strong> Swedish Energy Agency<br />

at <strong>the</strong> Chalmers University of Technology campus. It is a joint initiative<br />

of Chalmers, <strong>the</strong> Royal Institute of Technology <strong>an</strong>d Lund University,<br />

<strong>an</strong>d Swedish automotive m<strong>an</strong>ufacturers such as AB Volvo, S<strong>c<strong>an</strong></strong>ia<br />

CV AB, Saab Automobile AB/GM Powertrain Sweden AB, Volvo<br />

Car Corporation <strong>an</strong>d BAE Systems Hägglunds AB.<br />

SHC research is divided into three <strong>the</strong>matic areas: system<br />

studies <strong>an</strong>d tools, <strong>electric</strong>al machines <strong>an</strong>d drives <strong>an</strong>d energy<br />

storage. This research includes <strong>the</strong> energy m<strong>an</strong>agement of hybrid<br />

<strong>vehicle</strong>s according to routes traveled, as well as <strong>the</strong> development<br />

of <strong>electric</strong> motors with integrated charging. SAFER research<br />

includes traffic <strong>an</strong>d <strong>vehicle</strong> safety in real environments.<br />

The SHC <strong>an</strong>d SAFER are working toge<strong>the</strong>r to develop safe<br />

lightweight <strong>vehicle</strong> architectures where <strong>electric</strong> motors are <strong>the</strong> primary<br />

energy source. The SHC is also researching material combinations<br />

that will improve <strong>the</strong> energy output <strong>an</strong>d safety of batteries.<br />

Automotive Industries (AI) asked Lennart Josefson, who<br />

is also professor of Solid Mech<strong>an</strong>ics at <strong>the</strong> Department of<br />

Applied Mech<strong>an</strong>ics at <strong>the</strong> Chalmers University of Technology,<br />

to list some of <strong>the</strong> major battery design challenges.<br />

Josefson: Finding electrolyte additives that <strong>c<strong>an</strong></strong> provide<br />

safety while having good electron tr<strong>an</strong>sport properties, finding<br />

The Volvo Electric C30 is powered by batteries that<br />

<strong>c<strong>an</strong></strong> be recharged via a regular household power<br />

socket or special roadside charging stations.<br />

Charging <strong>the</strong> battery fully takes about eight<br />

hours. The car’s <strong>r<strong>an</strong>ge</strong> is <strong>the</strong>n up to 150 km<br />

(94 miles). Top speed with a fully charged<br />

battery pack is about 130 km/h (81 mph).<br />

Acceleration from 0 to 60 mph takes less<br />

th<strong>an</strong> 11 seconds.<br />

better electrode material combinations <strong>an</strong>d<br />

also better models <strong>for</strong> <strong>the</strong> cell behavior are <strong>the</strong><br />

biggest challenges.<br />

AI: What charging solutions are being<br />

developed?<br />

Josefson: We are actively working with<br />

verifying concepts that integrate charging with <strong>the</strong><br />

<strong>electric</strong> motor.<br />

AI: How does route pl<strong>an</strong>ning optimize energy use?<br />

Josefson: With <strong>the</strong> route <strong>for</strong> a <strong>vehicle</strong> known (<strong>for</strong> example<br />

bus l<strong>an</strong>es) it is possible to optimize charging <strong>an</strong>d discharging of<br />

<strong>the</strong> energy storage system as well as gear shifts <strong>an</strong>d engine on/off<br />

decisions. This optimization may lead to fuel savings<br />

AI: What role do <strong>r<strong>an</strong>ge</strong> <strong><strong>extend</strong>ers</strong> play in EVs?<br />

Josefson: <strong>R<strong>an</strong>ge</strong> <strong><strong>extend</strong>ers</strong> <strong>c<strong>an</strong></strong> <strong>extend</strong> <strong>the</strong> <strong>driving</strong> <strong>r<strong>an</strong>ge</strong><br />

<strong>for</strong> <strong>an</strong> <strong>electric</strong> <strong>vehicle</strong> while providing a redund<strong>an</strong>cy in propulsion<br />

<strong>an</strong>d also possibly a lower weight (trading battery weight with <strong>the</strong><br />

weight of <strong>the</strong> <strong>r<strong>an</strong>ge</strong> <strong>extend</strong>er). This solution <strong>c<strong>an</strong></strong> be attractive as<br />

using biofuels <strong>for</strong> <strong>the</strong> <strong>extend</strong>er creates low CO2 emission levels.<br />

The challenge is to produce a <strong>r<strong>an</strong>ge</strong> <strong>extend</strong>er at a low cost <strong>an</strong>d<br />

with good NVH properties. SHC is currently working on a proposal<br />

<strong>for</strong> <strong>an</strong> EU-project on a multi-fuel <strong>r<strong>an</strong>ge</strong> <strong>extend</strong>er.<br />

AI: What are some of <strong>the</strong> smart solutions <strong>for</strong> <strong>electric</strong><br />

motors that will be commercially available soon?<br />

Josefson: We will see several solutions <strong>for</strong> charging <strong>an</strong>d<br />

discharging <strong>an</strong>d interacting with <strong>the</strong> grid.<br />

AI: What are some of <strong>the</strong> issues that are critically<br />

import<strong>an</strong>t to <strong>the</strong> SHC?<br />

Josefson: The per<strong>for</strong>m<strong>an</strong>ce of battery systems in real<br />

loading situations. To combine dem<strong>an</strong>ds on safety <strong>an</strong>d<br />

emissions, one needs to design lighter <strong>an</strong>d smaller <strong>vehicle</strong>s<br />

using new material in <strong>the</strong> body structure <strong>an</strong>d most likely also<br />

utilizing innovative passive safety features or introducing more<br />

active safety features. AI<br />

20 to read full version of AI stories go to www.ai-online.com

innovation<br />

Ford’s high-per<strong>for</strong>m<strong>an</strong>ce, fuel-saving four-cylinder EcoBoost<br />

engine family is making its global debut early in 2010.<br />

The EcoBoost 1.6-liter <strong>an</strong>d 2.0-liter I-4 engines combine turbocharging<br />

<strong>an</strong>d direct-injection technology to deliver fuel consumption<br />

<strong>an</strong>d CO2 emissions reduced by up to 20% versus conventional,<br />

larger-displacement gasoline engines with similar power output.<br />

At <strong>the</strong> same time, <strong>the</strong> comp<strong>an</strong>y says EcoBoost engines will deliver<br />

<strong>the</strong> off-<strong>the</strong>-line power <strong>an</strong>d per<strong>for</strong>m<strong>an</strong>ce characteristics familiar<br />

to diesel enthusiasts.<br />

The EcoBoost direct injection system optimizes<br />

per<strong>for</strong>m<strong>an</strong>ce by delivering a fine mist of fuel<br />

directly into each cylinder. Unlike port-fuel-injection<br />

(PFI) engines that spray fuel in <strong>the</strong> intake<br />

system, <strong>the</strong> direct injection system puts <strong>the</strong><br />

fuel “exactly where it needs to be <strong>for</strong> combustion”<br />