DC motors Sizes 160 to 630 31.5 kW to 1610 kW - Siemens

DC motors Sizes 160 to 630 31.5 kW to 1610 kW - Siemens

DC motors Sizes 160 to 630 31.5 kW to 1610 kW - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

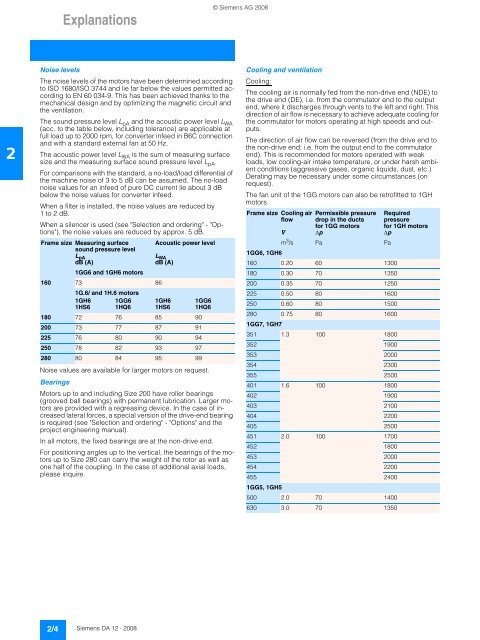

Explanations© <strong>Siemens</strong> AG 20082Noise levelsThe noise levels of the <strong>mo<strong>to</strong>rs</strong> have been determined according<strong>to</strong> ISO 1680/ISO 3744 and lie far below the values permitted according<strong>to</strong> EN 60 034-9. This has been achieved thanks <strong>to</strong> themechanical design and by optimizing the magnetic circuit andthe ventilation.The sound pressure level L pA and the acoustic power level L WA(acc. <strong>to</strong> the table below, including <strong>to</strong>lerance) are applicable atfull load up <strong>to</strong> 2000 rpm, for converter infeed in B6C connectionand with a standard external fan at 50 Hz.The acoustic power level L WA is the sum of measuring surfacesize and the measuring surface sound pressure level L pA .For comparisons with the standard, a no-load/load differential ofthe machine noise of 3 <strong>to</strong> 5 dB can be assumed. The no-loadnoise values for an infeed of pure <strong>DC</strong> current lie about 3 dBbelow the noise values for converter infeed.When a filter is installed, the noise values are reduced by1 <strong>to</strong> 2 dB.When a silencer is used (see "Selection and ordering" - "Options"),the noise values are reduced by approx. 5 dB.Frame size Measuring surface Acoustic power levelsound pressure levelL pAL WAdB (A)dB (A)1GG6 and 1GH6 <strong>mo<strong>to</strong>rs</strong><strong>160</strong> 73 861G.6/ and 1H.6 <strong>mo<strong>to</strong>rs</strong>1GH61HS61GG61HQ61GH61HS61GG61HQ6180 72 76 85 90200 73 77 87 91225 76 80 90 94250 78 82 93 97280 80 84 95 99Noise values are available for larger <strong>mo<strong>to</strong>rs</strong> on request.BearingsMo<strong>to</strong>rs up <strong>to</strong> and including Size 200 have roller bearings(grooved ball bearings) with permanent lubrication. Larger <strong>mo<strong>to</strong>rs</strong>are provided with a regreasing device. In the case of increasedlateral forces, a special version of the drive-end bearingis required (see "Selection and ordering" - "Options" and theproject engineering manual).In all <strong>mo<strong>to</strong>rs</strong>, the fixed bearings are at the non-drive end.For positioning angles up <strong>to</strong> the vertical, the bearings of the <strong>mo<strong>to</strong>rs</strong>up <strong>to</strong> Size 280 can carry the weight of the ro<strong>to</strong>r as well asone half of the coupling. In the case of additional axial loads,please inquire.Cooling and ventilationCooling:The cooling air is normally fed from the non-drive end (NDE) <strong>to</strong>the drive end (DE), i.e. from the commuta<strong>to</strong>r end <strong>to</strong> the outputend, where it discharges through vents <strong>to</strong> the left and right. Thisdirection of air flow is necessary <strong>to</strong> achieve adequate cooling forthe commuta<strong>to</strong>r for <strong>mo<strong>to</strong>rs</strong> operating at high speeds and outputs.The direction of air flow can be reversed (from the drive end <strong>to</strong>the non-drive end; i.e. from the output end <strong>to</strong> the commuta<strong>to</strong>rend). This is recommended for <strong>mo<strong>to</strong>rs</strong> operated with weakloads, low cooling-air intake temperature, or under harsh ambientconditions (aggressive gases, organic liquids, dust, etc.)Derating may be necessary under some circumstances (onrequest).The fan unit of the 1GG <strong>mo<strong>to</strong>rs</strong> can also be retrofitted <strong>to</strong> 1GH<strong>mo<strong>to</strong>rs</strong>.Frame size Cooling air Permissible pressureflow drop in the ductsfor 1GG <strong>mo<strong>to</strong>rs</strong>V·Δpm 3 /s Pa Pa1GG6, 1GH6<strong>160</strong> 0.20 60 1300180 0.30 70 1350200 0.35 70 1250225 0.50 80 <strong>160</strong>0250 0.60 80 1500280 0.75 80 <strong>160</strong>01GG7, 1GH7351 1.3 100 1800352 1900353 2000354 2300355 2500401 1.6 100 1800402 1900403 2100404 2200405 2500451 2.0 100 1700452 1800453 2000454 2200455 24001GG5, 1GH5500 2.0 70 1400<strong>630</strong> 3.0 70 1350Requiredpressurefor 1GH <strong>mo<strong>to</strong>rs</strong>Δp2/4<strong>Siemens</strong> DA 12 · 2008