Smart textiles and advanced composites TENCATE MATERIALIZED

Smart textiles and advanced composites TENCATE MATERIALIZED

Smart textiles and advanced composites TENCATE MATERIALIZED

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

tencate materialized<br />

<strong>Smart</strong> <strong>textiles</strong> <strong>and</strong> <strong>advanced</strong> <strong>composites</strong><br />

Protective Fabrics<br />

Space Composites<br />

Aerospace Composites<br />

Advanced Armour<br />

Geosynthetics<br />

Industrial Fabrics<br />

Grass

<strong>Smart</strong> teXtileS <strong>and</strong> adVanced cOmPOSiteS<br />

intrOductiOn<br />

rOYal ten cate<br />

The multinational company Royal Ten Cate (TenCate) combines<br />

textile technology with related chemical processes <strong>and</strong> material<br />

technology in the development <strong>and</strong> production of functional<br />

materials with distinctive characteristics. Products of TenCate are<br />

sold worldwide.<br />

Systems <strong>and</strong> materials from TenCate come in four areas of<br />

application: safety <strong>and</strong> protection, space <strong>and</strong> aerospace,<br />

infrastructure <strong>and</strong> the environment, <strong>and</strong> sport <strong>and</strong> recreation. TenCate<br />

occupies leading positions in protective fabrics, <strong>composites</strong> for<br />

space <strong>and</strong> aerospace, antiballistics, geosynthetics <strong>and</strong> synthetic turf.<br />

Since 2005 TenCate is sponsoring the Solar Team Twente of the<br />

University of Twente with a series of functional materials, which may<br />

be decisive for their successes during the World Solar Challenges in<br />

Australia. Every two years, in one week time the team drives a<br />

distance of 3,010 km from Darwin to Adelaide, straight through the<br />

outback.<br />

c h a l l e n g i n g fu t u r e te c h n o l o g y<br />

adVanced cOmPOSiteS<br />

TenCate Advanced Composites develops <strong>and</strong> produces <strong>composites</strong><br />

for space <strong>and</strong> aerospace <strong>and</strong> industrial applications. TenCate<br />

Advanced Composites has plants in Europe <strong>and</strong> North-America.<br />

PrOtectiVe FaBricS<br />

TenCate Protective Fabrics develops <strong>and</strong> produces protective <strong>and</strong><br />

safety fabrics for industry, services, firefighting <strong>and</strong> defence.<br />

TenCate Protective Fabrics has plants in Europe, Asia <strong>and</strong> North-<br />

America.<br />

OutdOOr FaBricS<br />

TenCate Outdoor Fabrics develops <strong>and</strong> produces protective fabrics<br />

for outdoor applications. TenCate Outdoor Fabrics has a plant in<br />

Europe.<br />

© visuals frontpage <strong>and</strong> pages 2 <strong>and</strong> 3<br />

2 SMART TEXTILES AND ADVANCED COMPOSITES<br />

SMART TEXTILES AND ADVANCED COMPOSITES 3

adVanced cOmPOSiteS<br />

SOlar team twente 2009<br />

liGHtweiGHt Structure<br />

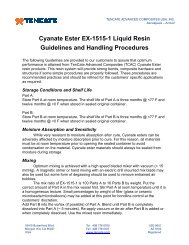

For the solar car 2009, TenCate has offered the team a wide range<br />

of space <strong>and</strong> aerospace <strong>composites</strong>. These are produced by<br />

TenCate Advanced Composites in Nijverdal, The Netherl<strong>and</strong>s.<br />

TenCate supplied both TenCate Cetex ® RTL thermoplastic glass<br />

reinforced carbon laminates, as high-end core thermoplastic<br />

materials – as used in TenCate Cetex ® System3 - for the production<br />

of lightweight structural parts of the solar car.<br />

In addition, carbon, glass <strong>and</strong> aramide texture is supplied for both<br />

the curves of the solar car <strong>and</strong> for its structure. With its<br />

sponsorship material TenCate strives for a substantial reduction of<br />

the weight of the solar car of Solar Team Twente without affecting<br />

the overall strength of the vehicle.<br />

The frame of this solar car is 5 kilograms lighter. This is a weight<br />

savings of 29.4 percent. The frame now only weighs 12 kilograms.<br />

Another advantage of composite material is that it’s easy to finish,<br />

making the surface of the vehicle smoother <strong>and</strong> more aerodynamic.<br />

The total air-resistance of the solar car is 25 percent lower due to<br />

the new design, the good finished surface <strong>and</strong> thanks to the flexible<br />

body structure.<br />

The main innovation in the solar car 2009 is the flexible, pivoting<br />

body structure which connects the wing of the car to the frame.<br />

This body structure is made of a thermoplastic elastomer which the<br />

team uses to optimize the aerodynamic properties.<br />

The solar car of Solar Team Twente distinguishes itself thanks to<br />

the large amount of energy that is achieved by the tilting wing. The<br />

wing moves with the sun, so that sunrays fall directly onto the solar<br />

cells. This, together with the patented lens system, focuses solar<br />

energy onto the underlying solar cells. Thus enabling the team to<br />

generate 7.5 m2 of sunlight from 6 m2 of solar cells. This approach in<br />

fact works like a magnifying glass.<br />

4 SMART TEXTILES AND ADVANCED COMPOSITES<br />

SMART TEXTILES AND ADVANCED COMPOSITES 5

<strong>Smart</strong> teXtileS<br />

SOlar team twente 2009<br />

liGHtweiGHt teXture<br />

Solar Team Twente 2009 will be wearing red overalls made of<br />

inherently heat <strong>and</strong> flame resistant fabric that is produced by<br />

TenCate Protective Fabrics in Nijverdal, The Netherl<strong>and</strong>s. This<br />

lightweight TenCate Tecashield ® material is highly durable but also<br />

stable through the use of meta-<strong>and</strong> para-aramid fibres.<br />

TenCate Outdoor Fabrics will be supplying an inherently flame<br />

retardant red garage tent for the solar car with<br />

accompanying inherently flame retardant red<br />

groundsheet for small repairs on the side of<br />

the road. The team sleeps in inherently flame<br />

retardant red tents made of TenCate fabric. Because all tents have<br />

a pump up frame they can be set up fast <strong>and</strong> easy. The canvas of<br />

TenCate Outdoor Fabrics is composed of a blend of four different<br />

fibres, offering the canvas its inherently flame retardant qualities.<br />

The material is strong, has great breathability properties, has<br />

moisture-regulating capacity <strong>and</strong> is resistant to all weather<br />

conditions. This is important because in Australia the temperature<br />

can differ enormously between day <strong>and</strong> night.<br />

6 SMART TEXTILES AND ADVANCED COMPOSITES<br />

SMART TEXTILES AND ADVANCED COMPOSITES 7

adVanced cOmPOSiteS<br />

SOlar team twente 2007<br />

FiniSHed aS numBer 6<br />

Like the aviation sector, the auto industry too has a great deal to<br />

gain from the use of more composite materials. After all, these<br />

materials are lighter than aluminium, stronger than steel <strong>and</strong> in<br />

theory recyclable. The Twente One 2007, the solar car of the Solar<br />

Team Twente 2007 is light thanks to aerospace composite materials<br />

from TenCate. This sustainable vehicle achieved speeds as high as<br />

126 kilometers per hour during the 2007 World Solar Challenge<br />

through Australia <strong>and</strong> finished as number 6.<br />

SOLAR TEAM TWENTE<br />

cOmPOSite materialS<br />

Thermoplastic <strong>and</strong> thermosetting materials of TenCate contribute to<br />

more sustainable transport. The car racing industry is already<br />

making considerable use of these innovative materials, which are<br />

widely used in the aircraft <strong>and</strong> space industry. Solar Team Twente<br />

2007 finished the more than 3,000 kilometers journey <strong>and</strong> won on<br />

technology <strong>and</strong> innovation, thanks to the integrated pivoting wing,<br />

made of aerospace composite: a novelty in the world of mobility.<br />

Made with composite material, consisting of carbon fabric.<br />

mOBile SOlar Panel<br />

During the outback journey down under, the Twente One 2007 was<br />

equipped with a solar panel that could be pivoted. This allowed the<br />

most ideal angle of the sun – focused directly onto the solar cells –<br />

to be achieved for the greater part of the day. In addition, a<br />

patented lens system was used, in which the solar cells could<br />

move under the lenses so that they always remained in focus. This<br />

also produced extra solar energy.<br />

Integrated pivoting solar panels Patented lens system Horizontal shock dampers<br />

8 SMART TEXTILES AND ADVANCED COMPOSITES<br />

SMART TEXTILES AND ADVANCED COMPOSITES 9

<strong>Smart</strong> teXtileS <strong>and</strong> adVanced cOmPOSiteS<br />

SOlar team twente 2005<br />

FiniSHed aS numBer 9<br />

In 2005 TenCate for the first time sponsored the solar car of Solar<br />

Team Twente, then called SolUTra. As best newcomer in the 2005<br />

World Solar Challenge this car finished in ninth place. According to<br />

participants in this race, the SolUTra was one of the best solar cars<br />

in the field of aerodynamics. This car has been the basis for<br />

subsequent teams from the University of Twente. Solar Team<br />

Twente 2005 was also provided with overalls of TenCate Protective<br />

Fabrics <strong>and</strong> tents of TenCate Outdoor Fabrics for both the teams<br />

<strong>and</strong> the solar car.<br />

Solar Team University of Twente<br />

inteGratiOn OF cHaSSiS <strong>and</strong> BOdY<br />

An important feature of the SolUTra is the integration of the chassis<br />

<strong>and</strong> the body in the form of a monocoque construction with an<br />

aerodynamic top. Simply put this means that the frame <strong>and</strong> the<br />

outer shell of the solar car are combined as a whole using plastic<br />

material reinforced with fibre tissue. This made it possible to<br />

design <strong>and</strong> develop a chassis that is strong but also light.<br />

FrOnt wHeel SuSPenSiOn<br />

The front wheel suspension is designed according to the double<br />

wishbone principle. In fact, these are two superimposed triangular<br />

structures in which the wheel is stuck. The damper is directly fixed<br />

to the ball joints, the connection between the two triangles lying on<br />

top of each other. Besides a normal h<strong>and</strong>lebar to turn the wheels,<br />

the SolUTra has an extra h<strong>and</strong>lebar to turn the wheel covers as<br />

well.<br />

rear wHeel SuSPenSiOn<br />

Another nice detail of the SolUTra is the rear wheel suspension.<br />

This one is made of thin aluminium sheet combined with aluminium<br />

milled parts. The applied box principle <strong>and</strong> the finishing with rows<br />

of pop nails make the rear wheel suspension complete.<br />

Front wheel suspension Rear wheel suspension<br />

10 SMART TEXTILES AND ADVANCED COMPOSITES<br />

SMART TEXTILES AND ADVANCED COMPOSITES 11

tencate materialized<br />

<strong>Smart</strong> <strong>textiles</strong> <strong>and</strong> <strong>advanced</strong> <strong>composites</strong><br />

North America<br />

South America<br />

www.tencate.com<br />

Europe<br />

Middle East<br />

Africa<br />

Asia<br />

Australia