DN 100 - 1200 mm - Bauernfeind GmbH

DN 100 - 1200 mm - Bauernfeind GmbH

DN 100 - 1200 mm - Bauernfeind GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

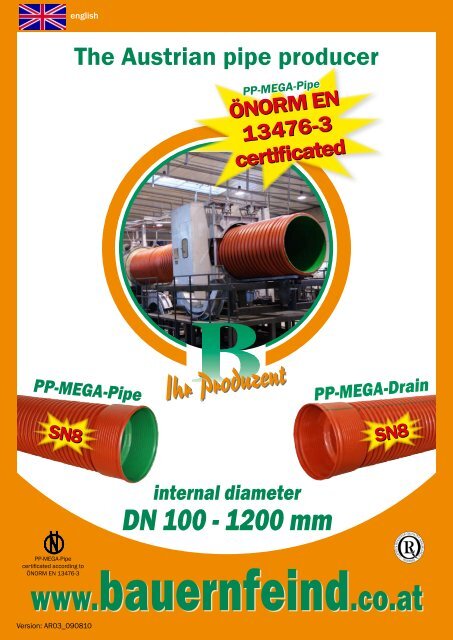

englishThe Austrian pipe producerPP-MEGA-PipeÖNORM EN13476-3certificatedPP-MEGA-PipePP-MEGA-DrainSN8SN8internal diameter<strong>DN</strong> <strong>100</strong> - <strong>1200</strong> <strong>mm</strong>www.bauernfeind.co.atwww.bauernfeind.co.atPP-MEGA-Pipecertificated according toÖNORM EN 13476-3Version: AR03_090810

<strong>100</strong> <strong>mm</strong>150 <strong>mm</strong>dimensions:ÖNORM EN13476-3certificated200 <strong>mm</strong>250 <strong>mm</strong>300 <strong>mm</strong>350 <strong>mm</strong>400 <strong>mm</strong>500 <strong>mm</strong>600 <strong>mm</strong><strong>DN</strong>/ID* internal in <strong>mm</strong>Øexternal Øin <strong>mm</strong>standard length in m ***with socket<strong>100</strong> <strong>100</strong> 117 6 6150 150 173 6,12 ---200 198 227 6,05 ---250 248 283 6,12 6300 297 340 6,05 6/7350 348 397 5,96 6/7400 396 453 5,96 6/7500 495 567 5,96 6600 594 680 5,86 ---800 792 906 5,61 ---<strong>100</strong>0 988 1158 5,71 ---<strong>1200</strong> 1188 1368 5,71 ---without socketThe PP-MEGA-pipe without socket is available between lengths of 0.3 to 16 m.layers of thePP-MEGA-Pipeoutside corrugatedinside smoothshort lengths: 1/2/3/4/5 m800 <strong>mm</strong><strong>100</strong>0 <strong>mm</strong><strong>1200</strong> <strong>mm</strong>***) This lengths may vary slightly due to production.The pipe lengths are the total lengths.

PP-MEGA-Drain <strong>DN</strong>/ID <strong>100</strong> - <strong>1200</strong> <strong>mm</strong>Perforations:schematic drawings2/32/31/31/33/3Ø <strong>100</strong> <strong>mm</strong>2/3 perforationØ 150, 200 <strong>mm</strong>2/3 perforationØ 250 <strong>mm</strong>1/3 perforationØ 300 - <strong>1200</strong> <strong>mm</strong>1/3 perforationØ <strong>100</strong> - <strong>1200</strong> <strong>mm</strong>3/3 perforationca. 6 m pipes with socket and sealing ringexact diameters and lengths see table PP-MEGA-PipeThe PP-MEGA-Drain are perforated after production ofÖNORM EN 13476-3 certified PP-MEGA-Pipes.The PP-MEGA-Drain are tested in perforated condition.The perforated pipes meet the ÖNORM EN 13476-3requirements: ring stiffness SN8, 30% ring flexibility,impact resistance at -10°C, leak tightness of the socketconnection, etc.Range of application:• road-, highway- and railway construction• house construction and basement drainage• drainage of leanings• grasslands and fields, etc.Advantages:• high stability due to the ring stiffness SN8• smooth interior - therefore less accumulation of mud• the perforated pipe has many and wide slots,therefore the absorption of water is higher• the high impact resistance of the drainages allowsto fill the trench with gravel fasterSN8with inline socket**the high-qualitydrainage in SN8laying PP-MEGA-DrainTender specification: PP-MEGA-DrainDrainages (PP-MEGA-Drain) made of polypropylene (PP), outside corrugated, inside smooth,stiffness class SN8, with inline socket, incl. sealing ring, pipe ÖNORM EN 13476-3certificated and afterwards slotted, 1/3, 2/3 oder 3/3 perforation<strong>DN</strong>/ID: <strong>100</strong>, 150, 200, 250, 300, 350, 400, 500, 600, 800, <strong>100</strong>0, <strong>1200</strong>**) not available in the following countries: Germany, France, Spain, Great Britain, Italy, Netherlands, Sweden

PP-MEGA-Kcable protection pipeexact diameters and lengths see table PP-MEGA-PipePP-MEGA-K<strong>DN</strong>/ID <strong>100</strong> - <strong>1200</strong> <strong>mm</strong>SN8ÖNORM EN 13476-3 certificatedPP-WELL-K<strong>DN</strong>/ID <strong>100</strong> <strong>mm</strong>SN8with standard socketSN8with connection socketand sealing ringOutside corrugated and inside smooth cable protectionpipes made of polypropylene.Range of application:• areas with high traffic load• energy supply lines• control and signal lines for railway-systems• cable conduit for all kinds of industrial constructionAdvantages:• higher capacity due to the ring stiffness SN8,compared to conventional cable protection pipesand flexible tubes• due to the high impact resistance of our cable protectionpipes the trench can be filled quickly and easily withmaterial• for our PP-MEGA-K the socket connection with sealingring is tested at a water pressure of 0.5 bar and an airpressure of -0.3 bar• outside corrugated and smooth inside, for easy cableinstallation• slight curves can be madePP-MEGA-HHalf shell<strong>DN</strong>/ID <strong>100</strong> - <strong>1200</strong> <strong>mm</strong>ca. 6 m pipes with socketexact lengths see table PP-MEGA-PipeOur PP-MEGA-half shells aresuitable for open waterchannels, etc.creek reconstruction with PP-MEGA-H

PP-MEGA-E <strong>DN</strong>/ID 200 <strong>mm</strong>geothermal heat exchanger pipemade of food safe polypropylene SN8,ÖNORM EN 13476-3 certificatedSN8For the controlled living space ventilation the geothermalheat exchanger pipe is used as a collector for air preheating(air intake pipeline). The great advantage of PP-MEGA-Eis the excellent thermal transfer from the land to the airflowing through.Range of application:• low energy and passive houses• residential buildings• business and office spaces• production halls, etc.Custom-made productsrain storage channel, water tankThe rainwater storage channels are used in place of the storagebasins to control the runoff of the surface water during rain.The water tank can be used as a rain water tank or a cistern forirrigation systems.Advantages:laying PP-MEGA-E with adecline towards the house• the rainwater storage channel is embedded into the soil,therefore no additional space is required• all volume capacities can be produced by individual sizesand lengths• the size of the in- and outflows can be selected freely• The inspection access will be produced at the desired locationand with the desired length and diameter depending on thecustomer’s requirements.rain storage channel for thecompany Ölz in Austria

Fittings:applicable for the whole pipe system: PP-MEGA and PP-WELLbranches 45° or 90°<strong>100</strong> / <strong>100</strong> <strong>mm</strong> 400 / 400 - <strong>100</strong> <strong>mm</strong>150 / 150 - <strong>100</strong> <strong>mm</strong> 500 / 500 - <strong>100</strong> <strong>mm</strong>200 / 200 - <strong>100</strong> <strong>mm</strong> 600 / 600 - <strong>100</strong> <strong>mm</strong>250 / 250 - <strong>100</strong> <strong>mm</strong> 800 / 800 - <strong>100</strong> <strong>mm</strong>300 / 300 - <strong>100</strong> <strong>mm</strong> <strong>100</strong>0 / <strong>100</strong>0 - <strong>100</strong> <strong>mm</strong>350 / 350 - <strong>100</strong> <strong>mm</strong> <strong>100</strong>0 / <strong>1200</strong> - <strong>100</strong> <strong>mm</strong>bends 15°, 30°, 45°, 60° or 90°<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong> 600 <strong>mm</strong>150 <strong>mm</strong> 350 <strong>mm</strong> 800 <strong>mm</strong>200 <strong>mm</strong> 400 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>connection sockets<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong> 600 <strong>mm</strong>150 <strong>mm</strong> 350 <strong>mm</strong> 800 <strong>mm</strong>200 <strong>mm</strong> 400 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>double sockets200 <strong>mm</strong> 400 <strong>mm</strong> 800 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>300 <strong>mm</strong> 600 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>reductions150 / <strong>100</strong> <strong>mm</strong> 400 / 350 - <strong>100</strong> <strong>mm</strong>200 / 150 - <strong>100</strong> <strong>mm</strong> 500 / 400 - <strong>100</strong> <strong>mm</strong>250 / 200 - <strong>100</strong> <strong>mm</strong> 600 / 500 - <strong>100</strong> <strong>mm</strong>300 / 250 - <strong>100</strong> <strong>mm</strong> 800 / 600 - <strong>100</strong> <strong>mm</strong>350 / 300 - <strong>100</strong> <strong>mm</strong> <strong>100</strong>0 / 800 - <strong>100</strong> <strong>mm</strong><strong>1200</strong> / <strong>100</strong>0 - <strong>100</strong> <strong>mm</strong>

end caps<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong> 600 <strong>mm</strong>150 <strong>mm</strong> 350 <strong>mm</strong> 800 <strong>mm</strong>200 <strong>mm</strong> 400 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>socket plugs<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong> 600 <strong>mm</strong>150 <strong>mm</strong> 350 <strong>mm</strong> 800 <strong>mm</strong>200 <strong>mm</strong> 400 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>adapters to PVC<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong>150 <strong>mm</strong> 400 <strong>mm</strong>200 <strong>mm</strong> 500 <strong>mm</strong>250 <strong>mm</strong>sealing rings<strong>100</strong> <strong>mm</strong> 300 <strong>mm</strong> 600 <strong>mm</strong>150 <strong>mm</strong> 350 <strong>mm</strong> 800 <strong>mm</strong>200 <strong>mm</strong> 400 <strong>mm</strong> <strong>100</strong>0 <strong>mm</strong>250 <strong>mm</strong> 500 <strong>mm</strong> <strong>1200</strong> <strong>mm</strong>Types of sockets:We offer our PP-MEGA-Pipes with two different socket types or withoutsocket.Our delivery program offers the following PP-MEGA-Pipes:with inline socket• PP-MEGA-Pipe with inline socket• PP-MEGA-Pipe with connection socket• PP-MEGA-Pipe without socketThe PP-MEGA-Pipes without socket are mainly used in road- and forestroad constructions as road culverts.For pipes without fixed socket the length can be freely selected betweenabout 0.3 and 16 m (depending on the corrugation).with connection socketwithout socket

Technical data PP-MEGA-Pipematerial: Pipes are made of polypropylene (PP).exterior color: orangeinterior color: greenlabelling: <strong>Bauernfeind</strong> <strong>GmbH</strong> trade nameID 200/198<strong>DN</strong> 200/ID 198 <strong>mm</strong>SN8ring stiffnessRF30 ring flexibility 30%PPmaterialUrange of application outside of thebuilding structureice crystal-symbol: impact resistanceat -10°CÖNORM EN 13476-3 geprüft certification standardJJTTThh<strong>mm</strong>production datePhysical propertiesmodule of elasticity:≥1500 MPamedium density:~ 900 kg/m³medium thermal expansion coefficient: ~ 14 x 10 -5 . K -1surface resistance:> 1012 ΩChemical resistanceThe chemical resistance of pipes, fittings and sealing elements lies inbetween pH-values of pH 2 (acidic) and pH 12 (alkaline).Thermal stressDue to the heat resistance of polypropylene the range of use ofPP-MEGA-Pipes is in between -20°C and +90°C.Polypropylene recyclingPolypropylene is produced in an environmentally friendly processand is also a resource which is <strong>100</strong>% recyclable.Socket tightnessThe sealing rings are certified according to ÖNORM EN 681-1.The socket connection with sealing ring is certified by an accredited institution at a waterpressure of 0.5 bar and an air low-pressure of -0.3 bar in accordance with ÖNORM EN 13476-3.The socket connection is ensured with the PP-MEGA-Drainage as well as with thePP-MEGA-Pipes. Therefore, the PP-MEGA-Drain may be used as water-pipes.

Hydraulic behaviorThe PP-MEGA-Pipe has due to its very smooth and nonporous inner surface a roughnessof 0.005 to 0.05 <strong>mm</strong>.The flow rate for the PP-MEGA-Pipes is calculated at an assumed roughness of 0.25 <strong>mm</strong>.Example values for sewer with manholes can be taken from the chart below.sewer base slope per mill<strong>DN</strong>/ID <strong>100</strong> 150 200 250 300 350 400 500 600 800 <strong>100</strong>0 <strong>1200</strong>‰ l/s l/s l/s l/s l/s l/s l/s l/s l/s l/s l/s l/s1 1,98 5,88 12,68 23 37 56 80 144 232 495 889 14342 2,87 8,50 18,27 33 53 80 114 206 332 707 1268 20433 3,56 10,51 22,57 41 66 99 141 253 409 870 1559 25114 4,15 12,22 26,21 47 77 115 163 294 474 <strong>100</strong>7 1805 29065 4,66 13,72 29,42 53 86 129 183 329 531 1128 2021 32546 5,13 15,08 32,32 58 94 141 201 361 583 1237 2217 35697 5,56 16,34 34,99 63 102 153 217 391 630 1338 2397 38588 5,96 17,50 37,48 68 109 164 233 418 674 1432 2565 41279 6,34 18,60 39,82 72 116 174 247 444 716 1517 2722 438010 6,69 19,64 42,03 76 122 184 261 468 755 1603 2871 462015 8,25 24,18 51,72 93 150 226 320 575 927 1967 3523 566820 9,57 28,02 59,89 108 174 261 371 665 1072 2275 4073 655125 10,73 31,40 67,10 121 195 292 415 745 <strong>1200</strong> 2545 4557 733030 11,78 34,46 73,61 132 214 321 455 817 1316 2790 4995 803435 12,75 37,27 79,61 143 231 347 492 883 1422 3015 5398 868140 13,65 39,89 85,18 153 247 371 526 944 1521 3225 5772 928445 14,49 42,35 90,42 163 263 394 558 <strong>100</strong>2 1614 3413 6124 985050 15,29 44,68 95,30 172 277 415 589 1056 1702 3608 6457 1038555 16,05 46,89 <strong>100</strong>,09 180 291 435 618 1108 1786 3785 6774 1089460 16,78 49,01 104,60 188 304 455 646 1158 1865 3954 7077 1138065 17,48 51,04 108,92 196 316 474 672 1206 1942 4117 7367 1184770 18,15 52,99 113,08 203 328 492 698 1251 2016 4273 7646 1229675 18,80 54,87 117,09 211 340 509 722 1296 2087 4423 7916 1272980 19,42 56,69 120,97 218 351 526 746 1338 2156 4569 8177 1314885 20,03 58,46 124,73 224 362 542 769 1380 2222 4710 8429 1355490 20,62 60,17 128,38 231 373 558 792 1420 2287 4848 8674 1394995 21,19 61,84 131,93 237 383 574 814 1459 2350 4981 8913 14332<strong>100</strong> 21,75 63,47 135,39 243 393 589 835 1497 2412 5111 9154 14706flow rate in litres per second<strong>DN</strong>/ID <strong>100</strong> - 200 <strong>mm</strong> rounded to hundredth litres.<strong>DN</strong>/ID 250 - <strong>1200</strong> <strong>mm</strong> rounded to whole litres.

Pipe requirements:• The PP-MEGA-Pipes are certified in accordance with ÖNORM EN 13476-3• During production, the following properties are controlled continuously: wall thickness,internal diameter of the socket, weight, external diameter and length of the pipe• In the company’s own laboratory the quality of the pipes is controlled by self-monitoring• The following properties are constantly being tested in the laboratory: ring stiffness,ring flexibility, impact resistance, heat resistance, melt flow index• The external control is carried out by the Austrian institute: TGM - State Research Centrefor Plastics Engineering and Environmental Technology in Vienna.Ring stiffnessThe ring stiffness is the pressure per square metre pipe surface,which deforms the pipe exactly by 3% (of its diameter). Testprocedure according to DIN EN ISO 9969.SN 4 means: 4 kN/m²SN 8 means: 8 kN/m²Impact resistance8 kN/m² with3% pipe deformationImpact resistance at 0°CIn accordance with ÖNORM EN 13476-3, the impact resistance at0°C is carried out in round the clock method. In this process thepipe sample is exposed several impacts of a falling weight of 0.5 kgto 3.2 kg (depending on pipe dimension) from a height of 2 meters.In the course of round the clock method, the pipe is turned furtherafter each impact, in order to examine every point of the entirecircumference. The examination is conducted in accordance withÖNORM EN 744.Impact resistance at -10°CThe ice crystal symbol indicates that the PP-MEGA-Pipes meet theincreased requirements according to ÖNORM EN 13476-3. Thereforethe impact strength is being tested at -10°C in staircase method.The pipe sample is tempered at -10°C and is exposed an impact of afalling weight with e.g. 12.5 kg (for a pipe with an internal diameter of350 <strong>mm</strong>) from an average drop height of at least 1 m. After the impactthe pipes must not show any signs of damage.The examination is conducted according to ÖNORM EN 1411.Therefore the PP-MEGA-Pipes are suitable for installation at subzero temperatures.

Ring flexibilityAccording to the requirements of ÖNORM EN 13476-3, the ring flexibility is 30%.Test procedure according to ÖNORM EN 1446.Due to their flexibility the PP-MEGA-Pipes adapt slightly to the trench. Usingpolypropylene, a flexible thermoplastic raw material, slight curves can be made.Abrasion resistance of polypropylenePipes made of polypropylene have one of the highestabrasion resistances among all piping materials. Thisresults from the survey of Darmstadt-method.A piece of pipe with 1 m length is filled up to half with amixture of silica sand, gravel and water with a particle sizeof 0-30 <strong>mm</strong> and then shut with front plates on either side.Subsequently, the pipe is inclined by 45° alternating upand down. By the flow of the test material, the requiredabrasion effect is created.Assessment background for long-term deformation of the pipeThe assessment background is due to the following conditions:Placing depth: 0.8 – 6.0 mTraffic load: embeddedAggregation “Good”:The grainy underground has to be put into thelaying zone and compacted. Then thebase has to be put in, in layers ofmax. 30 cm and has to compacted carefully.The pipe has to be covered with a layer of min.15cm. The trench has to be filled with soil andhas to be compacted. The typical values of theProctor-standard density is over 94%.pipe deformation (%)ring stiffness (SN)Aggregation „none“,not reco<strong>mm</strong>endedAggregation „middle“Aggregation „good“Aggregation “middle”:The grainy underground has to be put into the laying zone, with max 50 cm thickness, and layer hasto be compacted carefully. The pipe has to be covered with a layer of min 15 cm. The trench has to befilled with soil and has to be compacted. The typical values of the Proctor-standard density isbetween 87% and 94%.Other placing depths on inquiry.

Laying of PP-MEGA-PipesThe laying of PP-MEGA-Pipes and fittings made of polypropylene has to be effectedaccording to the requirements of ÖNORM EN 1610.BeddingThe incline of the trench bottom, the bedding material and the properties of the trenchbottom have to meet the planning guidelines. When it freezes, it is necessary to protectthe trench bottom, in order that no frozen layers remain beneath the pipeline.Appropriate recesses for the sockets have to be built in the lower underlay. In areas wherethe trench bottom has a low bearing capacity, appropriate arrangements have to be made.During the laying the trench has to be kept free of water. The way of drainage should notaffect the embedment and the pipeline.UnderlayThe lower underlay has to be <strong>100</strong> <strong>mm</strong>for normal soil conditions, or 150 <strong>mm</strong>for rock or rocky soils.The underlay should be compactedcarefully and constantly and with theintended incline in order to avoid apoint-bearing. For the sockets recesseshave to be provided.Descriptions1 ground level2 bottom of the street orrailway constructionas far as existing3 trench wall4 main backfill5 covering6 bedding7 upper underlay8 lower underlay9 trench bottom10 depth of cover11 height of the bedding12 height of theembedment13 trench depthOD: external diameterof the pipe in <strong>mm</strong>BackfillThe embedment, the main backfill and the removing of the shoring should be carried outin order that the pipe connections and the bedding are capable of bearings. The material forthe bedding, the main backfilling and the covering shall meet the planning guidelines.Each covering has to be compacted either by hand or with a compacting plant. The coveringabove the soffit shall have a height of 30 cm. For the main backfill the excavated materialcan be used, unless the particle size is not bigger than 30 cm. For the main backfillequipment for mechanical compaction may be used. It is important to ensure that the mainbackfill is carried out in accordance with the planning guidelines.Bedding materialThe maximum particle size of the bedding material for the embedment shall not exceed 16 <strong>mm</strong>.The following unbound materials are permitted for the embedment: uniform gravel,material with graded grain size (compactable), sand, granular mixture.

Installation of PP-MEGA-PipesFrom <strong>DN</strong>/ID <strong>100</strong> - <strong>1200</strong> <strong>mm</strong> the PP-MEGA-Pipes are availablewith a fixed socket or a connection socket. The necessarysealing ring is enclosed separately in order to avoid damages.Before laying the pipes and fittings have to be checked fordamage that may have occurred due to transport or storage.Damaged pipes or fittings must not be installed.The laying should be started at the lower end of the pipeline.The pipes are usually laid so that the sockets face to the top.putting the sealing ring onConnecting of the pipesPut the sealing ring between the first two corrugations of thepipe and make sure that the sealing fits proper.pushing the pipes togetherBefore connecting the pipes you have to make sure that thesliding surfaces are clean. Then grease the inner surface ofthe socket well with usual lubricants. The pipes should beconnected with constant axial force up to the previously markedinsertion depth, without overloading the components.The PP-MEGA-Pipes have to be laid according to the height anddirection limits prescribed by the planning requirements. Pipesof smaller diameters can easily be pushed together by hand.For larger diameters, the use of equipment is required whilethe pipe should be protected at the end.inline socketconnection socketCutting of the pipeYou have to cut the pipes with a fine-tooth saw or anothersuitable tool. Cut the pipe in the center of the trough and verticalto the tubular axle. Ridges and unevenness of the cut pipe endshould be removed with a grater, a rasp or a cutter.Adapter to other materialsThe PP-MEGA-Pipes may be connected to other pipes withan appropriate adapter. It is not reco<strong>mm</strong>ended to installclamp-connections or other connection options on the outerlayer. You should always use PP-MEGA-adapters. For theconnection to PVC-sewer-pipes according to ÖNORM EN1401-1standard adapters are available.cutting of the pipesadapter

Connections to manholesWhen connecting PP-MEGA-Pipes to manholes or for wall ductsthe PP-MEGA-shaft-lining with or without a stop should be used.For connections to manholes or for wall ducts you have tomake sure that an appropriate bearing surface is available.If this is not possible you have to install a flexible connection.For the flexible connection you may cut off a short piece of pipewith ≤<strong>100</strong>0<strong>mm</strong> length and then connect it with a connectionsocket with the existing pipe. With this connection therequired flexibility is given.Side branchesPVC-pipes <strong>DN</strong> 110 – 200 can be connected afterwards toPP-MEGA-Pipes (from <strong>DN</strong>/ID 300) easily and quickly with a lateralconnector.lateral connectorThe main pipeline is centrally drilled with a holesaw and the boreholeis then fettled inside and outside. The flexible lateral connector isinserted into the borehole of the main pipe.Afterwards the tension band is placed around the lateral connector,and the insertion depth is marked at the connecting pipe. The sealingand the connecting pipe should be lubricated to facilitate the insertionof the pipe. After the insertion the tension band istightened with 6 Nm. The indication on the tension band has todisappear completely.holesawCleaning of the pipelinePP-MEGA-Pipes, PP-MEGA-Drain and fittings can be rinsed with high pressure. The flushingpressure at the nozzle should not exceed 120 bar and the water jet should be positioned atleast 45 degrees backwards.A mechanical cleaning with chains, mills and other tools is not permitted.

18Plastic manholessuitable for all pipes of the series: PP-MEGA and PP-WELLThe plastic manholes of polyethylene assure a security againstgroundwater and ensure a maximum level of tightness.Advantages of the plastic manhole:• Long durability• Security against groundwater• Easy handling during transport and installationdue to the low weight• Quick and easy installation of the manhole at the construction site• Flexible and easy connection possibilitiesSewage manholeAt the manholes with 3 inlets, the lateral inlets are slightlyheightened. With a crown drill and a water seal additionalconnections can be made quickly and easily anywhere at themanhole.Technical data:manhole bottom:inlet:outlet:manhole height:manhole cover:capacity:Ø 600 , 800, <strong>100</strong>0 <strong>mm</strong>Ø 150, 200, 250, 350, 400 <strong>mm</strong>Ø 150, 200, 250, 350, 400 <strong>mm</strong>from 500 <strong>mm</strong>Ø 625 <strong>mm</strong>150 – 400 kNInspection manholeThese manholes are used for our piping system for inspection or cleaning purposes.Technical data:manhole bottom:inlet:outlet:manhole height:manhole cover:capacity:Ø 600, 800, <strong>100</strong>0 <strong>mm</strong>Ø 200 - <strong>100</strong>0 <strong>mm</strong>Ø 200 - <strong>100</strong>0 <strong>mm</strong>from 500 <strong>mm</strong>Ø 625 <strong>mm</strong>150 – 400 kN

Street gulliesThe gullies made of plastic with a net weight of 10 kg are easyto handle during installation.technical data:attachment piece:outlet:total height:capacity:50 x 50 cmØ 150 <strong>mm</strong>573 - 785 <strong>mm</strong>400 kNConcrete manholessuitable for the whole series: PP-MEGA and PP-WELLConcrete manhole with socketThe concrete manholes are made to order withthe suitable PP-MEGA-socket.Technical data:manhole cover:capacity:compensating rings:cone:manhole height:manhole bottom:Ø 600 <strong>mm</strong>15 - 400 kN60 - 150 <strong>mm</strong>Ø <strong>100</strong>0 to 600 <strong>mm</strong>300 - 1500 <strong>mm</strong>Ø <strong>100</strong>0 <strong>mm</strong>connections: Ø 150 - 800 <strong>mm</strong> concrete channel plastic channelConcrete manhole with plastic channelPlastic manhole bottoms are the ideal protection for concretemanholes. The plastic insert protects the concrete fromchemical attacks of the sewage and from mechanicaldamage.The seamlessly smooth surface of the plastic and thehydraulically optimum channel reduce the effort forcleaning and maintenance.The plastic insert for the concrete manhole is produced with theappropriate socket for our PP-MEGA-Pipes. Several inlets withdifferent diameters can also be produced. You can order theplastic inserts at our company, then they will be produced froma local concrete manhole manufacturer.

Service of the company <strong>Bauernfeind</strong>• Competent consultation by our trained employees• We work out for each customer and each project thetechnically and economically best solution• For each project we make an offer free of charge andwithout any obligations• Our big stock allows quick and flexible deliveryDelivery to the customer• delivery to customer or to theconstruction site• No costs and delays during unloadingfor the customer<strong>Bauernfeind</strong> onlineMore and more extensive information and descriptions of ourproducts you can find on our websitewww.bauernfeind.co.atFurthermore you always get the latest news and changesconcerning our products. You can also look up our referenceprojects of the PP-MEGA-Pipes, PP-MEGA-Drain andPP-WELL-Drain.Quality through - ISO 9001:2008We, the company <strong>Bauernfeind</strong> <strong>GmbH</strong>, underwentISO 9001:2008 through the certification centre“Lloyd‘s Register Quality Assurance”.The certification is a confirmation for the highstandard within the company. This is an assurancefor the future that the company constantly adaptsto the latest standards.

www.bauernfeind.co.at 07277 / 2598-38The Austrian pipe producerÖsterreichische Post AG. Info.Mail Entgelt bezahltZugestellt durch Post.at - Postentgelt bar bezahltThe company BAUERNFEIND from Upper Austria (Waizenkirchen) produces unique in EuropePP-MEGA-Pipes with an internal diameter of <strong>DN</strong> <strong>100</strong> to <strong>1200</strong> <strong>mm</strong>, which are certified inaccordance with ÖNORM EN 13476-3.Come and visit our company!We would be glad to welcome you in Austria.It would be a pleasure for us to show youthe company and the production hall.Call us and arrange a meeting.Tel.: 0 72 77 / 25 98-38Sample fotos!office hours:Mo - Fr:7. 30 - 17. 00<strong>GmbH</strong>pipe@bauernfeind.co.at›› <strong>Bauernfeind</strong> <strong>GmbH</strong>, Gewerbepark Süd 2, A-4730 Waizenkirchen, Tel.: 0 72 77 / 25 98-38 Fax: DW - 25 ‹‹We deliver only according to our conditions of sale and delivery.Errors, misprints and literal errors excepted!