Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

Untitled - MetosExpo - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

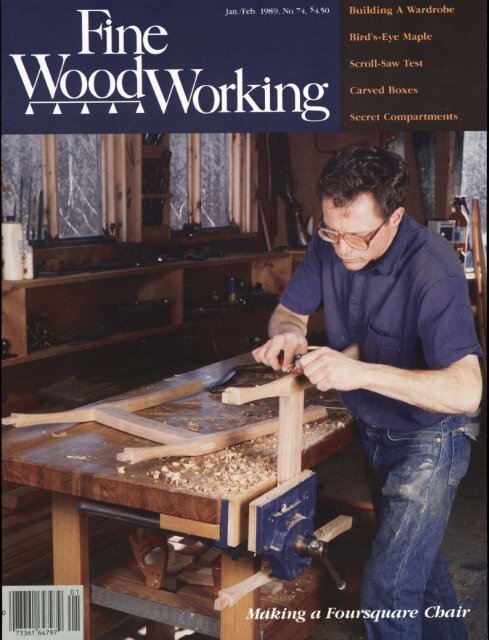

FineW> rktng'_' ______ ___ January/February 1989DEPARTMENTS4 Letters8 Methods of WorkFixed-louver shutters; spindle tapering jig; half-lap joints12 Questions & AnswersOil-bleeding problems; japan-finishing; northwest red alderModern scroll saws are precision machines capableof accurate work in thick hardwoods. Greg Bovertests eight current models on p. 50. Cover: Scott Dickersonshapes a leg on his foursquare chair, a chairbuilt without angled joinery (see article, p. 36).Managing EditorArt DirectorAssociate EditorAssistant EditorsCopy EditorDick BurrowsRoland WolfSandor NagyszalanczyJim Boesel, Alan PlattCathy McfannAssistant Art DirectorEditorial SecretaryContributing EditorsKathleen CrestonMary Ann ColbertTage Frid, R. Bruce Hoadley,Mi'chael S. Podmanjczky, Graham Blackburn, ChristianBcksvoort, Michael DresdnerCorJ.ulting EditorsNOrman VandalMethods of WorkIndexerHarriet HodgesAssociate PublisherGeorge Frank, Richard E. Preiss,Jim RicheyAdministrative SecretaryJohn LivelyLynn MeffertAdvertising Sales Manager James P. ChiavelliNational Accounts Managers Don Schroder,Dick WestAssistant Accounts Manager Ben WarnerSenior Sales Coordinator Carole WeckesserAssistant Advertising Coordinator Kathryn SimondsAdvertising Secretary Sherry DuhiggTel. (800) 243-7252 Fax. (203) 426-3434Fine Woodworking is a reader-written magazine. We welcomeproposals, manuscripts, photographs and ideas fromour reaciers, amateur or professional. We'll acknowledge allsubmissions and return within six weeks those we can'tpublish. Send your contributions to Fine \'(/oodworking, Box355, Newtown, Conn. 06470.Title to the copyrights in the contributions appearing inFine \Voodworking magazine remains in the authors, photographersand artists, unless otherwise indicated. They havegranted publication rights to Fine WoodworkingFine Woodworking (ISSN 0361-3453) is published bimonthly, January, March, May,July, September and November, by The Taunton Press, Inc.. Newtown, CT 06470.Telephone (203) 426-8171. Second-class postage paid at Newtown, CT 06470, andadditional mailing offices. Copyright 1989 by The Taunton Press, Inc. No rcproductionwithout permission of The Taunton Press, Inc. Fine Woodworking@ is a regiSteredtrademark of TIle Taunton Press, Inc. Subscription rates: United States andpossessions, S22 for one year, S40 for two years; Canada and other countries, S26 foronc year, S48 for rwo years (in U.S. dollars, please). Single copy, S4.50. Single copiesoutside U.s. and possessions, S5.50. Send to Subscription Dept., 111C Taunton Press,PO Box 355, Newtown, CT 06470. Address all correspondence 10 the appropriatedepartment (Subscription, EditoriaL or Advertising), TIle Taunton Press, 63 SouthMain Street, PO Box 355, Newtown, CT 06470. U.S. newsstand distribution by EasternNe .. vs Distributors, Inc., I 130 Cleveland Road, SandusJ...-y, OH 44870.14 Follow-upMore on tool reviews; radial-saw recall; safety and photography105 Index to Issues 66 through 73110 Events112 Books114 Notes and CommentWomen designers/makers; a bench for children; product reviewART ICLES36 Making a Foursquare Chair by Scott DickersonComfortable seating with right-angle joinery40 Wrapping a cane seat by Janet Redfield42 Secret Compartments by Christian BecksvoortA furnituremaker's cache box47 Sliding-Lid Boxes by John HeatwoleHand-carved, top to bottom50 Testing Scroll Saws by Greg BoverSmooth and precise cuts, even in thick stock55 Alabaster on the Lathe by Max KrimmelTurning stones into translucent vessels58 Building a Shaker-Style Wardrobe by Tom HagoodBeads and crown dress up a basic cabinet62 Souped-Up Scraper by Kelly MehlerOld-time hand tool challenges belt sander64 Pedestal Tables by Jim WallaceSculptural bases and veneered tops68 Joining Molding by Graham BlackburnCoping with COrners and complex miters70 Drawing and the Design Process by Peter KornTranslating ideas into furniture74 A Solar Kiln for Drying Wood by John WilsonDry, defect-free wood and a place to store it, too76 Wood-drying basics78 Bird's-Eye Maple by Bill KeenanNature flaunts her 'Midas' touch81 Woodworkers' Tour of Chinaby John Kriegshauser and Nancy LindquistAncients ways persist in the age of automation84 The International Turned Objects Showby Michael PodmaniczkyNew signs of the turning tidePostmaster: Send address changes to The Taunton Press, Inc., PO Box 355, Newtown, CT 06470. 3

LettersWoodworkers are not snobs -I'm upset by the letter in fWW#72 stating "woodworkers are egotistical, pompous snobs." Ifthe author had preceded his statement with the word "occasionally,"I might not have taken offense. But when he implied thatall woodworkers are in that category, he should be forced toswallow those words. I have met many woodworkers from allover the nited States and from a few foreign countries, andamong them all, I have found only one that fits his description,and he wasn't even a fair amateur. In my town, we have the ParsonsAmateur Woodworkers Society with 35 members. I mustsay I've never associated with a finer bunch of men, who arealways willing to help each other. When beginners feel they can'tcompete with the work being done by more experienced workers,we encourage them to keep trying and remind them ofthese lines that I once read, "Use your talents to the best of yourability. Remember, the woods would be very quiet if the onlybirds that sang were those that sang best."-Myer S. Freshman, Parsons, Kans.Praise for authentic Chinese joinery-Allan Smith's article infWW #73 on Chinese furniture was not only good reading, but adelightful change of pace. For many years, I've been excited bythe Chinese style and curious about the joinery. I've made twocoffee tables similar to Smith's horsefoot deSign, to showcasesome antique tiles my wife inherited. The results were spectacular.But, I used classical European joinery methods, because Ididn't know any better. It wasn't untill read Gustav Ecke's bookChinese Domestic Furniture that I discovered the authentic Chinesejoinery. (Smith recommended this book, and it is available fromCharles E. Tuttle Co. Inc., Box 410, Rutland, vr 05701-0410.) I'vemade a third table following Ecke's faultless drawings. All thecomponents interlock, and the structure would be perfectly stablewithout glue. However, I'm not a total purist and did gluethings together at final assembly. This table will last forever andneed never be taken apart. -Thomas A. Sharp, Sanibel, Fla.The old resaw joke -A man came to our store and boughtseveral thousand dollars of woodworking equipment. After athree-day class in the fundamentals of woodworking, he put anad in the paper that claimed his shop could do any kind ofwoodworking. His first caller asked if they resawed wood, towhich this entrepreneur answered, "We don't have to; we saw itright the first time." He later came back to the store and prefacedhis story with the question, "Hey, what does resaw mean ?"-Jimmy Reina, Indianapolis, Ind.More hints on rubbing out finishes-Many thanks to MichaelDresdner for his fine article on rubbing out fi nishes ( fWW #72).But I would like to make a few suggestions that might be helpful,especially to those who do a lot of commercial refinishingand finish restoration.When spraying lacquer, add fish-eye remover rather than retarderto increase flow-out and gloss. Add the fish-eye removeranyway when working with previously finished furniture thatmight be contaminated by silicone. The fish-eye remover won'tUNTON PUBLICATIONS... hy Icllo",' ('H(hll:;;:J."I'The Taunton Press: PaulRoman, publisher; janice A. Roman,associate publisher; Roger Barnes, design director, Carol Gee, e.'-eculive secretary. Accounting: Wayne Reynolds, controller; PatrickLamontagne, manager; Carol Diehm. Rosemary McCulloch, JudithSmith, Rachel Yahwak, Elaine Yamin. BooksIVideos: john Kelsey,associate publisber, Eileen Hanson, administrative secretary, DeborahCannarella, managing editor, Paul Bcrtorelli, senior editor, ChristineTimmons, associate editor, Maria Angione. secretary; Videos: RickMastclli, producer/director; James Hall, assistant producer; Art:Deborah Fillion, manager; Gary Williamson, assistant art director;Cathy Cassidy, art assistant; CopylProduction: Ruth Dobsevage.manager; Pamela Purrone, COPY/production editor; Marketing: JonMiller, manager, Philip Allard,promotion writer. Corporate Market·lng: Dale Brown, director, Andrea Ondak, manager, Donna Pierpont,publiC relations manager; Barbara Buckalew, e:t:ecutive secretary;Christine Cosacchi. customer service coordinator. Data Process·ing: Drew Salisbury, manager; Brendan Bowe, senior programmer/tmalyst; Susan Partis, programmer trainee; Ellen Wolf, PC coortlillator.Fulflliment & Operations: Tom luxeder, director; janeTorrence, secretary; Circulation: Karen Cheh, coordinator .. Barbaral'less, fulfillment assistant; Customer Service: Terryl n,omas, supervisor,Anette Hamerski, Patricia Malouff, Nancy Schoch, ClaireWarner; Distribution: Danny D'Antonio, supervisor, Grace Aumuller,David Blasko, TimodlY Harrington, linnea Ingram, Mary Ann Costagliola,Alice Saxton, Robert Weinstein; Purchasing & Facilities: Williamslow the (hying/curing process as it improves flow-out and gloss.Also, here's how to rub out a dining table to a beautiful glossin an hour or less: First, level the surface with 600-grit stearatedpaper. Remove any sanding scratches and remaining orange peelwith a power buffer and Ditzler #16 rubbing compound, whichis available from auto-body supply stores. If you've never used apower buffer, practice on something expendable fi rst-bufferscan be tricky. Finally, remove t11e residue with naptha and a softrag, then buff to a diamond gloss with a clean lamb's wool padon your power buffer. -Scott Lawrence, Redmond, Wash.Clean water for eye safety-Dr. Paul Yinger's eye-safety article(fWW #72) is fi ne as far as it goes, but I have some concernsabout his recommendations on using water as eye wash. Thewater in Lexington, Mass., must be better than here in centralOhio. Tap water here is so hard it's an irritant. For this reason, Ikeep sterile solution close to my first-aid kits. Sterile saline isconunonly available at drug and grocely stores in t11e contact-lenscare sections. I reconunend the types labeled "for sensitive eyes."-Douglas Campbell, Clintonville, OhioMore warnings on eye injuries -In addition to Dr. Yinger'swarnings (fWW #72), I'd like to mention two other specific injuriesI've seen as an ophthalmologist. Catastrophic eye injury canoccur when someone is reaching under a surface to drive in ascrew and looking from above. A slipped screwdriver can be adangerous stabbing tool. I've seen three such injuries in t11e pasttwo years, and each one resulted in an eye lost.All forms of hammering can be dangerous, but hitting steel onsteel is by far t11e most dangerous, as tiny particles can fly off theface of the tool at tremendous speed. These tiny particles canpuncture the eye quite easily, and they are very difficult to locateand remove. Observers are just as vulnerable as the tool operatorto injuly, too. Unfortunately, many times t11e injUly may noteven be recognized as serious, and the person may not seek adoctor. This could lead to potentially disastrous complications.Dr. Nick Strong, Cambridge, EnglandLye for apple - Some time back, Fine Woodworking had an articleon using lye to enhance the color of cherty. I tried the ideaand was totally satisfied. Perhaps the finest piece of furniture Ihave yet made is a cherty side table colored with lye and fi nished with an oil finish. I've since used lye to enhance the colorof apple and have had equally impressive results. Appleheartwood takes a rich, deep color, whereas sapwood is affectedonly slightly. The results can be quite dramatic.-Keith Hacker, Scandia, Minn.Kids do have a place in the shop-I don't agree with recentletters (fWW #71 and #73) that say kids don't belong in theworkshop. The first reason being that my father was a carpenter,and if he hadn't allowed me in the shop, I would never havebecome so involved with woodworking. Secondly, my 8-year-oldson now works with me in my shop. He knows how to safelyoperate the bandsaw, drill press, jigsaw, sander and lathe. He hasSchappert, purchasing agent; Lois Beck, office-services coordinator;Donald Hammond, mail-services clerk; Chuck Hollis, Office maintenance;Christopher Myers, Office-operations clerk; Debra Brown,chef/manager, Yang Rogers, cafeteria (lsslstant; Subscription:Carole Ando, manager, Patricia Aziere, Connie Bar

Letters (contillued)never hurt himself, except for a bruised thumb from his hammer.I believe that if kids aren't allowed in the shop, they willnever learn, and 1 don't want my son to be afraid of the equipment.Children need to participate in, as well as watch, what isgoing on. Telling children they're not allowed in the shop onlyarouses their curiosity; then, you have problems.-Scott j. Cornelius Sr., Amberst, ObioSubstituting catalpa for butternut- I was pleased to read JonArno's article on catalpa (FWW' #72). Like Arno, 1 find catalpahas properties quite similar to butternut, which is my favoriteand most-used carving wood. But as far as I can determine, buttermltis disappearing from the commercial market in manyparts of the country, as existing stands are wiped out by disease.In the future, many carvers and other woodworkers will probablybe looking for catalpa as a substitute for butternut.-Wa lter F Gretber, Dayton, ObioPEG and refractory wood-Regarding comments on usingpolyethylene glycol (PEG) for drying almond wood, PEG doesnot work well with almond or any other wood that has a lowpermeability to liquids (including PEG solutions). Low permeabilitycan result naturally, as in Douglas-fir heartwood, or it canresult from a tree injury. Orchard trees, such as almond, wouldbe full of impermeable wood due to frequent pruning of the trees.Air drying is also not suitable for this wood or any other refractory(prone to splitting, cracking) wood. The uncontrolledexposure to hot, dry weather and then rainy weather will damageall but the most tolerant species. The best drying method forrefractory woods is a partially closed shed, which will protectthe wood from rain and sun and help control drying. Duringespecially dry weather, the shed's walls may have to be closedfully with burlap to retard airflow. Also, when sawing refractorywood, always leave the bark edge on to minimized warpage. Edgethe lumber after drying. -Eugene M. Wengert, Blacksburg, VirgHardness not the only factor in tool quality-A recent itemin "Question and Answer" (FWW' #71) stated that a high-qualitychisel blade might have a Rockwell hardness of 60, while a poorqualitytool might be around 52. These words echo an apparentlywidespread assumption that regardless of other factors, the harderthe steel, the higher its quality. The fact is that whatever itsquality, the steel in a wood chisel or plane iron is not made ashard as it could be. The reason is based on the nature of steeland the process by which it is hardened.At the risk of oversimplifying things, most woodworking cuttingtools are made from "high carbon" or "tool steel," which containsfrom 5% up to l.5% carbon. The deliberate, as well as unwelcomepresence of other elements, in quite small amounts, gives the steelother qualities, but the presence of carbon permits hardening.Hardening is done by heating the steel between 1,350or- and1,480or-, which changes tlle crystalline structure of the metal tomake it hardenable. If the steel is allowed to cool slowly, it revertspretty much to its former state. If the steel cools quickly,the new structure is "frozen," and the steel hardens dead hard.In this dead-hard state, the steel is brittle. If you made a chiselout of it, it would be tough to shape and sharpen, and the edgewould chip and crack. To achieve a better balance betweenhardness and utility, the steel is softened. This is done by reheatingit, but to a lower temperature than before, to change thecrystalline structure. This is called tempering. At about 430"F,quite hard steel will result, suitable for machinist's scrapers,scribers and burnishers. At 600or-, the steel is too soft for muchexcept wood saws, screwdrivers and springs. Wood chisels andplane irons come in at or near 500or-.There is, of course, a lot more to say, but the point is thatthere is a good deal more than hardness to deal witll if a high-quality tool is to be made. These factors include toughness, malleability,heat resistance, stability and grain size. The right mixbegins with tile right steel alloy and runs through the whole heattreatingprocess. Steel doesn't lend itself cheerfully to all this.Given half a chance, it oxidizes, cracks, distorts, pits, scales, heatsunevenly, carburizes or decarburizes. And in other ways, it justdoesn't go along with your plans. High-quality steel is the resultof dealing successfully with all of these factors, and there is noone nonsubjective criterion that can be applied to gauge quality. Intile end, as a steel user, you have to accept what tile man says andfind out if he's right later. -Henry T. Kramer, Somerville, Nj.More on myrtle wood-It is high time to put the old myth ofmyrtle wood only growing in Southern Oregon and in the HolyLand aside for good. In the first place, the tree is not a myrtletree, but it is in the bay or laurel family. The scientific name isUmbellularia cali/arnica. 1 have used tlle leaves in cooking foryears, collecting only the new tender leaves and drying them.The tree grows all the way from Southern Oregon to thesouthern border of California, and tile largest tree is to be foundin San Leandro, Calif. It is a monster and should be seen byanyone interested in that species. Contrary to belief, myrtlewood does not grow in the Holy Land.Anyone who ever works myrtle wood will fall in love with it.I put myrtle wood up there with black walnut and mahogany interms of bOtil its beauty and working qualities.-Fran Hall, Boulder, Colo ... . Myrtus communis, tlle myrtle found in the Holy Land andcited in the Bible (Isaiah 55:13) belongs to a different family(Myrtaceae). It is not related to Oregon myrtle, aka Californialaurel (Umbellularia cali/arnica, family Lauraceae).-Robert Pinney, Rutbeliord, Calif.... The talk about Oregon myrtle wood growing only in Oregonand the Holy Land is a myth perpetrated by the companies thatmake and sell "myrtle wood" souvenirs.-Cbarles Slay, Belmont, Calif.Twig-whistle poetry-In reference to Denis Foster's search forthe poem his grandfather used to recite as he made twig whistles(FWW #73), here is one I learned from my mother. I don'tknow if it's the poem Denis remembers, but it comes to mindnow and tllen, and gives me a chuckle: I've always been a suckerfor sophisticated humor. -Roy Deppa, Brookeville, Md.(We also received a copy of the same poem from Richard A.Fisher of Cleves, Ohio, who points out that tlle "tin" in the lastline was interpreted a a toddler'S word for "can.")I made a wooden whistle,But it wooden whistle.So 1 bought a steel whistle,Bit it steel wooden whistle.Then 1 bought a lead whistle,But it steel wooden lead me whistle.Then I got a tin whistle.Now I tin whistle.About your safety:Working wood is inherently dangerous. Using hand or powertools improperly or neglecting standard safety practices canlead to permanent injury or death. So don't try to performoperations you learn about here (or elsewhere) until you'recertain tbat tbey are safe for you and your sbop situation.We want you to enjoy your craft and to find satisfaction inthe doing, as well as in the finished work. So please keepsafety foremost in your mind whenever you're in the shop.-Jobn Lively, associate publisber6 Fine Woodworking

• •DOWEL IT!For tough joints that are perfectly aligned, The Dowel Mateis the answer. A single step on the foot pedal firstclamps the wood and then shoots in two dowel holes.Air clamp and air feed. • Shipped ready for• Double spindles on 1"production.centers.• USA High quality at• 3/4 hp 115/220 V withLow price.switch & cord.See your woodworking machinery dealer or calltoll free for an informative brochure.• • • • •PORTA-NAILS, INC. PO BOX 1257 WILMINGTON, NC 28402PHONE (919) 762-6334, OUT OF NC 1-800-634-9281Porta-Nailer Router Mate Panel Template Ring MasterTHE "DOOR-STICK"NEVER THROW OUT ANOTHER DOOROR DRAWER FRONT AGAIN !MODEL NO. DS-48PRICE $49.95+4.05 postage & handlingTHE FAST, EASY WAY TOMEASURE EUROPEANSTYLE CABINETRY*Cuts Measuring Time Up To 60%Designed Primarily For Use WithFrameless Box ConstructionEliminates Erratic Spacing of Doorand Drawer Fronts Both Verticallyand Horizontally* Compensates For Overlays, Inlays,Door Gaps and Edging Material ___ ":':":"":==':'_-'--- ...." * Calculates Drawer Fronts - 1 to 5 PanelsINDUSTRIES,INC.45 HALLADAY ST. 175 LAFAYETTE ST.* Calculates Doors - Singles and PairsCalculatesActual Drawer DimensionsWithin a Cabinet Compensating ForDrawer SlidesCALL 1-800-526-30033660 GENESEE ST 7215 N. WEST 31ST LANEJERSEY CITY, NJ NY,NY BUFFALO,NY MIAMI, FL(201) 433·3800 (212) 226-4000 (716) 634·8930 (305) 691·2277VISA - MASTERCARD ACCEPTEDBEGINNING·OF· THE· YEAR SPECIAl.S!G11822601bs.!WeighsOur Best Selling10" Tablesaw!Precision ground cast-iron tableand wings, powerful 1 V2 HPmotor, heavy-duty rip fence withmicro adjustment and T-slo15 intable are only some of its excellentfeatures. Weighs 235 Ibs.Regularly $365.SALE PRICE 53256 X 47" JointerAll ball bearing, 3-bladecutterhead, 1 HP single phasemotor, precision ground bedswith an exclusive 47" bed length.This is the nicest 6" Jointer onthe market.8 X 65" JointerAnother winner! Ali bali bearing,3-blade cutterhead, magneticswitch 1 V2 HP single phasemotor and precision groundcast-iron beds.Regularly $335Regularly $665SALE PRICE 5310SALE PRICE 5625-+ -+(For Orders & Catalogs Only)WEST+-(For Inquiries & Customer Service)All above prices are F.O.B. Williamsport, PA or Bellingham, WANEW TOLL FREE LINESEAST OF THEMISSISSIPPI:1-800-523-GRRR(717) 326-380620" Planer20" x 8" capacity, 2 automaticfeed rates, 3 HP single phasemotor, 4-blade ali bali-bearingcutterhead, built in stand,extension roliers and dust chute.Weighs 950 Ibs.Regularly $1295SALE PRICE 51175(FOR ORDERS AND CATALOG REQUES TS ONLY)OF THEMISSISSIPPI:1-800-541-5537 §(206) 647-0801 January/February 1989 7

MetiJods of Wo rkedited and drawn by Jim RicheyMaking fixed-louver shuttersto lock the arms at this distance. With dle sawblade set as high asdle cove will be deep, place the device over the blade and rotateit until the arms contact the tips of the teeth at front and back.The device is now at dle correct fence angle. All that remains isto clamp a fence to the saw at the same angle, and taking about!i16 in. at a pass, begin making incremental cove cuts untildle final depth is reached.-joe Hardy, Des Moines, Iowa--",jlll"- Dowel in stop blockfits holes in channel.Exterior wood really takes a beating in the subtropical climate ofKey West, Fla., where I work. So when a client hired our companyto replace his deteriorated pine shutters with longer-lastingredwood, we developed dlis quick, easy and inexpensive medlodfor building the shutters right on the job site.A 'tedious but critical part of shutter construction is routingslots in dle stiles for louvers. For this operation, we devised a jig,as shown in the sketch above, dut holds the stile in a channeland allows it to be moved in steps as each louver slot is routed.Accurate spacing is ensured by using a stop block and a series ofholes 1318 in. apart in me channel. A dowel in the bottom ofme stop block fits the holes. The jig is also fitted with a bridgemat holds the router above and at ISO to the stile. The bridgemay be unfastened and repositioned to cut mirror-image slots inme mating stile. A recess in dle top of me bridge allows merouter to travel back and forth the precise distance needed tocut each slot.To rout louver slots in a stile, we first mark off 6 in. at the topand bottom to allow enough room for the rails and waste. Wealso mark off me center of the stile where we skip two slots toleave room for the middle rail. Then, with the stile located in thejig's channel, we begin routing slots, tipping back the router tostart me cut (a plunge router would be great for this job). Afterrepositioning the bridge, we rout slots in me opposite stile. Tocomplete the shutters, we mortise the stiles, cut tenons on merails and glue up with epoxy and pipe clamps.-Barb M. Kamm, Key West, Fla.Angle finder for cutting covesSet parallelogram jig to desired covewidth; place astride blade todetermine fence angle.Quick tip: Recently I was assembling some sliding dovetailjoints. As might be expected, they stuck. To find the tight spots, Irubbed the dovetail wim chalk. Where me joint was binding, thechalk was rubbed off, indicating high spots mat needed to bepared down. -Dennis Sweeney, Upper St. Clair, Penn.Wooden spring for outfeed supportI tried using a roller work-support while joining the edges oflong, heavy boards, but no matter how carefully I adjusted theheight, invariably the work would be marked when the end ofme board bumped me roller. What I really needed was a moreflexible support that simply helped hold up me front of mePlywood springsupports work.board. The arrangement I came up with consists of a 2-ft.-long,!i4-in. plywood spring screwed to a 6-in.-long 2x4 clampingspline. 1 clamp me spring in a portable vise an I adjust it so itbalances the weight of the work and requires only a slight downwardpressure to keep the work flat on the outfeed table.-jack jerome, Nokomis, Fla.Glue injectorOverall lengthis about 3 in.To accurately cut coves on the tablesaw, you must clamp thefence to the table at dle correct angle, because dle angle determinesme shape of me cove. This simple parallelogram devicemakes finding me correct fence angle easy.To use the device, simply move the arms apart a distanceequal to me desired widm of the cove and tighten the wing nutsAsk your veterinarian to save you a few of these little accordionsqueeze bottles mat come filled wim an antiseptic used to irrigatepuncture wounds. The bottles make great glue or oil applicatorsin tight places.-Steve Altal-d, Carbondale, Ill.Quick tip: It's long been dle rule to buy two rechargeablebatteries for a portable electric tool: One battelY can sit chargingwhile me other one works. A neighbor recently shared another8 Fine Woodworking

JIG SAWS158ZVS Orbit. Action 1I0b Hdlo Jig So .. .118.003Z38VS Un •. Shonk Muh. Orbit. Jig So .. 99.001651 7 1/4" Cir. So .. , 13 Imp 99.001654 7 1/4" Pi.oting Cire. SI .. 105.00163Z VSK Plntlllr Rlep. SI ..lZ9.00DRILLS DRILLS DRILLS9Z0VSRK 3/8" 9.6 V Cordlo .. Drill I I 5.009Z0VS 3/8" 9.6 V Cordl.ss Drill ../0 elso lZZ.0019Z0VSRK 3/8" Cordlo .. R .. orsing Drill 95.00II 58VSR 3/8" Vir. Spd. Rev. Drill 69.0091066 liZ" VSR Mighty Midget Drill 109.001196VSR 3/8" VSR Hornet Hlmmor Drill 109.00II 98VSR 112" VSR Z spd. Hlmmor Drill 129.009Z1VSRK 3/8" Cordl .. s 9.6 Drill ../eluteh139.00ROUTERS ROUTERS ROUTERS1601 I hp Routor 9Z.00160Z I 112 hp Routor 109.001604 I 3/4hp Router 118.001606 D-Hlndle, I 3/4 hp Routor 138.0090300 FilOd Blso Router. 3 3/4 hp 309.0090303 Plungo Blso Routor, 3 112 hp 449.501608 Trim Router 79.001608M Motor for 1608/1609 Series 85.00160BL Laminite Trimmer 85.001608T Tih Blse Trimmer 89.001609 Offset B,se Trimmer 119.001609K Installers Kit 159.001611 Plunge Routor. 3 hp 198.001611 Plunge Router. 3 hp. 220 Volt 261 .00SANDERSSANDERS SANDERS32700 3.21 Dustlo .. Bolt Sindor 125.001272 3".24" Bolt Sindor 149.0012720 3".24" Bolt Slndor .. I Dust Colloetor 169.001273 4".24" Bolt Sandor 168.0012730 4".24" Belt Sindor 101 Dust Collector 175.001290 Finishing Sandor, 1/2 shoet12900 Finishing Slndor, 1/2 sheot dustloss1273 DVS 4".24" B.lt Sindor3268 H.lt GunOTHER TOOLS1700 10 Gil. WetlDry Vleuum3221 18" Professionll Hid •• Trimmer3221l26" Professional Hedge Trimmer1347 4 1/2" Mini Grindor1323 9" Grinder11210 5/8 Rotary Hammer11212 3/4 Rotlry Hlmmor3258 3 1/4" Powor PllnlrC15FBFl000A001 .. 0 IS" Mitor SIlOHITACHI12" Pllnor/6" Joinor Comb.129.00139.00198.0069.00227.5094.50105.0075.00119.00169.00189.00119.00380.001440.00CB75A Bind Sa.. 1589.00C8FB Compound Mit .. Saw 480.00FREE FREIGHTColo. Watts 1-800-523-6285CALL TOLL FREE1-800-525-0750VISA and MASTERCARD ACCEPTEDAVIATION/INDUSTRIAL SUPPLYP,O. Box38159 . Denver. CO 8023871'1.aKilafreight prepaid6012 HDW.,,-&3/8 Cess Clutch Drill2708 W 8" Table Saw wlc blade 266.00'"3601 B I 318 hp. Router121.00 .9820-2 Blade Sharpener199.00 . ,... "5402 A 16" Circular Saw 330.001900 BW 3 1/4 Planer115.00 4302 C Var. spd. Jig Saw 152.00LS10209900 B 3x21 Belt Sander 143.0010" Mitre9401 4x24 Belt Sander170.005007NBA 7 1/4" Circular Saw 136.00JR3000V Recpro Saw3705 Offset Lam. TrimDP 4700i .130.00134.00112" Drill1 ... 00410 Oust Collector272.003620 1 1/4 hp. Plunge Router 97.003612B 3 hp. Plunge Sq. Base 199.005077B Hypoid Circular Saw 149.006093DW Clless Clutch drill, V.S. 121.00 3612 BR9030 I 1/8" x 21" Belt Sander 132.00BO 45503 hp. RouterDustless Pad Sander 49.00 $199Batteries for Cordless7.2 Volt $32.009.6 Volt $34.00Orders only Call:1-800-533-9282608-273-01482833 Perry St.Madison, WI 53713MasterCard and Visa Welcomelr ROBLANDThein te11 igen tone-manshop.-DEALERS WELCOMECANADAGeneral Mfg. Co. Ltd.835 CherrierDrummondville, QUE J2B 5A8(819) 472-1161LAGU\IA TOOLS1-(800) 234-19762081 Llguna Canyon RoadLlguna Beach, California 92651TheseTwo ToolsMayBeThe finestThat YouWm r:verOwn.A wonder to look at, a loy to hold and apleasure to use.Craftsmanship demands accuracy.The TS-2 MASTER TRY SQUAREis the most beautiful and accuratesquare made today. Solid hardenedbrass and rosewood, it is the perfectmarriage between craftsmanship andmaterials. The TS-2 is guaranteedsquare to ± .002:' inside and out,over the length of the 8" blade!Designed as a companion tool withthe TS-2, we proudly offer the SA-2SCRATCH AW L. This 8" tool is acraftsman's dream. The two degreetapered blade is long and sharpenough to get into those tight dovetaillayout situations. The hardened toolsteel blade is capped with a fla'blesSlyhand-turned rosewood handle ymaster turner, Mark Stevens.Craftspeople deserve and shoulddemand quality. Our tools are forpeople who care, those that know thespecial joy of working with distinctiveproducts, those that know quality iscontagiOUS.----1·800·253·3332r Bridge City Tool Works - 1IIII__1104 N.E. 28thSuite 200APortland, OR 97232Please send me.TS-2--SA-2 Scratch Awl @$28.00 + 4.50 P&H__ OneIIMaster Try Square @ $50.00 + 5.50 P&H______________ Iof each @ $82.00. SAVE $6.001 II--Catalog $1.00 (<strong>Free</strong> with purchase)IEnclosed is $ 0 CK 0 Money OrderI 0 Visa 0 --MC 0--- _ __AE Exp. Date II Card # INameI IAddressState ---ZipJ-----------L CityJanuary/February 1989 9

Methods of Wo rk (contillued)example of the "buy two" rule with me. If you have two filtersfor your shop vacuum, you can use the fresh one to clean theembedded dust out of the old one, thus avoiding a typically miserablejob.-Dan Miller, Elgin, Ill.Detachable vise padsSpindle tapering jigDowel to be taperedMasoniteTapered V-grooveRecently 1 needed a quantity of tapered wood rods to make dropspindles for spinning wool. The spindles' diameter had to taperfrom Y2 in. to Ijj in. evenly along their 12-in. length. Rather thanattempt to turn these tiny spindles on the lathe, 1 designed thejig shown above, which worked perfectly.First 1 selected a 12-in.-long chunk of 1 1/2-in.-thick hardwoodfor the sanding guide and sawed a Y2-in.-deep V-grooveinto one edge. After cutting the groove, I ripped the guide at aslight taper so the groove was only Y4 in. deep at one end. Touse the guide, 1 clamped it to the worktable of a disc sander,with the grooved edge almost flush against the disc. Then Ichucked a length of dowel in an electric drill, and with the drillat slow speed, guided the dowel into the V-groove. After a littlepractice and some trial-and-error setting of the guide, I was ableto make perfect tapers every time.-Bert. G. Whitchurch, Hemet, Calif.Quick tip: 1 have finally found the perfect spot to keep mysteel carpenter's square: It hangs on the molding around thedoor to my shop.-A.E. Waterhouse, Redding, Conn.Carcase dadoing jigDadoingjigscrewWorkpiece --"-- ___The homemade dad01l1g jig illustrated in Christian Becksvoort'sarticle "Building a Chest of Drawers" (FW\V #68) is similar tothe one 1 made several years ago. Mine differs in one respectthat I think improves the jig. I purchased an Acme screw, whichis often used in constructing book, cheese or juice presses and isavailable through many tool catalogs. I installed the screw asshown to make the positioning and clamping of the jig quickand accurate-certainly better than using C-clamps.-Cha1'les Leik, Great Falls, Va.These easy-to-make jaw pads enable me to adapt my machinist'svise for woodworking, and just as quickly, to switch it back tometalworking. To make the pads, cut two Ijj-in.-thick Masoniteor hardwood blocks as wide as the vise jaws and as tall as thedistance from the top of the jaws to the vise screw housing.Thread a short length of Y16-in. elastic cord through twoscrew eyes on the back of the pads to hold them to the jaws.Secure the ends of the elastic cord by wrapping them with 20-gauge steel wire.-George A. Ferrell, Huntsville, Ala.Quick tip: If you do not have a round slipstone to fit the fluteof a gouge, wrap some 600-grit wet-or-dry sandpaper around adowel of the correct diameter. This makes a very handy hone.-William E. Richie, Mechanicsburg, Penn.Sliding measuring sticksAdjust to inside dimensionsand clamp together ormark with pencil.The next time you're running tongue-and-groove glue joints, ripoff some sticks about % in. thick, with the joint profile onone side. Put the two sticks together to make a sliding measuringstick that can take inside measurements accurately. The measurementscan be registered by marking across both sticks with apencil or by clamping the two sticks together with a small Cclamp. The measuring stick is especially useful for checking adoor opening for consistent width from top to bottom.-Robert M. Vaughan, Roanoke, Va.Perfect half-lap jointsThe half-lap joint is a strong, useful joint for cabinet frames, butsetting up the saw so it cuts away exactly half from each piececan be frustrating. Here's a method for setting the blade heightthat's fast and foolproof, and it doesn't require jigs or measuring.Grab a waste piece of the frame stock, and with your tablesaw'sblade height elevated to less than half the stock thickness, passthe stock over the saw on both sides to leave a d1in center section.Raise the blade a little and make a second pass. Continueraising the blade, taking cuts on both sides, until only the slightestmembrane of wood remains in the center. You have nowachieved the perfect blade-elevation setting. I waste the lap areawith repeated passes, then clean up any small ridges and sawmarks with a rasp. -Duane Waskow, Cedar Rapids, Iowa.Methods of Work buys readers' tips, jigs and tricks. Senddetails, sketches (we'll redraw tbem) and pbotos to Metbods, FineWoodworking, Box 355, Newtown, Conn. 06470. We 'll returnonly those contributions tbat include an SASE.10 Fine Woodworking

R · I · TA.O. S: ASSOCIATE OF OCCUPATIONAL STUDIES• • •A• •New Two-Year• •Degree in• • •Wood'Formerly offered at the Wendell Castle SchoolA two-year program leading to excellence in woodworking and furniture design.Wood Studio I 3-D Design Crafts Drawing Creative SolUtes Technical DrawingWood Studio n 2-D Design Professional Practices Furniture HistoryRochester Institute of Te chnology(716) 475-2646COLLEGE OF THE REDWOODSFine Cabinetmaking• with James Krenovand Michael Burnsaccepting applications to theAugust '89· May '90 programfrom April 1 to May 1, 1989.College of the Redwoods440 Alger StreetFort Bragg, CA 95437(707) 964·7056LEEDS DESIGNWORKSHOPSTraining ProgramUncompromising attentionto fine workmanship in contemporaryfurniture design.• • •Onetotwoyear internships infinewoodworking, hand•.• and machine• •instruction Drawing DraftingProfessional developmentamidst design-maker businessesLoan financing available.ONE EASTHAMPTON COTTAGE ST MA BOX 348 01027DO YOU WISH YOU HAD MORE TIMEFOR YOUR SHOP?THEN PROJECTS N METAL IS FOR YOU•Projects in Metal is the new magazine for busy home shopworkers. It's filled with all kinds of small yet challengingprojects- each complete in one issue. You can relax foran evening or weekend, and finish a job you can show offwith pride.Projects in Metal is 100% editorial. Not one word ofadvertising limits the space devoted to helpful details onprojects, special workshop features, and tips on savingtime, money, and headaches.$15.50 a yearMaslerCard orders (6 issues,. call toIllree Visa or1-800-447-7367, or write P.O.1810-02, BoxTraverse City, Ml49685How to Design, Build, and InstallJapanese ScreensBy Jay van ArsdaleThe first practical guide to designing and makingJapanese shoji screens, this new book covers allthe basics of materials, assembly, installation, anda wealth of creative design suggestions. Traditionallyused to partition rooms without sacrificinglight or airiness, shoji can open up a world of possibilitiesas doors, transoms, windows, and evenskylights. Jay van Arsdale also includes a specialsection on how to restore antique shoji.$15.95pb 96 pages 40 black-and-white photos, ZOO line drawingsTHE SOUL OF A TREEA Woodworker's ReflectionsBy George NakashimaThis new, lavishly-illustrated paperback revealsan intimate portrait of the Americanmaster woodworker George Nakashima.Woodworkers everywhere will enjoy the visionof this artist as he shares his experience,techniques, and above all, his devotionto preserving the vitality of wood in his exquisitefurniture.$34.95pb 224 pages 48 full-color pages,250 sketches, drawings, and photosSAM MALOOF: WOODWORKERBy Sam MaloojThis long-awaited paperback tells the personaland professional story of Sam Maloof,winner of the 1988 Craft Council Gold Medal. Award. Mr. Maloof relates his artistic aims tohis philosophical concerns, revealing thelove for his medium that has infused his furniturewith simplicity, warmth, and beauty."This master furniture maker handlesprose with the same clear, natural mannerwith which he applies a chisel to awalnut board."-The New York Times"Magnificently made ..."-Fine Woodworking'l\n important contribution toward documenting the American craftrevival."-Washington Post$39.95pb 224 pages 70 color plates, 236 black-and-white photosCOMING IN APRILTHE GENIUS OFJAPANESE CARPENTRYAn Account of a Temple's ReconstructionBy S. Azby Brown1-800-638-3030

Making a door sandwichI intend to make a heavy front door, 2% in. thick, 36 in.wide and 77 in. tall, with two glass panels. Rather than constructit of solid stock, with conventional mortise-and-tenonjoints, could I make it a three-layer sandwich of %-in. plywood,as shown below, glued together with epoxy?-Paul Carson, Minneapolis, Minn.---=-=77:----- ILayers are glued togetherwith epoxy glue.John Birchard replies: Making anone you describe by laminating three layers of %-in. material isa viable approach, as long as you are careful to use good-qualityplywood that is very dry and of a uniform thickness. You aresmart to use an epoxy glue for this type of lamination, because itwill hold well even if your joints are not perfectly tight. I recommendSystem Three Quick-Cure epm.)', available from SystemThree Resins, Box 70436, Seattle, Wash., 98107; (206) 782-7976.Your main problem will probably be finding enough C-clampsfor dle glue-up. You might want to use as many as 100-two evely6 in. all dle way around. if you can't get dlat many clamps togedler,you could use finish nails, which can be set and puttied. Youmight also consider doweling dle frames togedler before youlaminate them so you don't have to worry about getting the railto-stilebutt joints tight while you're laminating. You could evenmake the window holes a little bigger on one of the frames soyou won't have to rout out a rabbet for the glass after the laminationis together.Uohn Birchard is a professional woodworker in MendOCino, Calif.]Oil bleeding problemsI was oiling several raised-panel mahogany doors with clearWatco oil. After the oil dried overnight, there was a thicksludge of oil that couldn't be removed from the surface. Themanufacture,-'s instructions say to reoil and wipe immediately,but this didn't help. I called Watco and was told the oilworks its way out of the pores and that lacquer thinner willclean it up. This does work, but very slowly. Is there anythingelse I can do?-Tim Tomaselli, Salt Point, NYBob Flexner replies: Varnishes and sealing oils, such as linseed,tung and Watco Danish oil, cure and harden mrough aprocess of solvent release and polymerization. As the turpentine,mineral spirits or other solvents evaporate, the resin moleculeslink up and form a hard film that can no longer be dissolved bythese solvents. When you spread one of these oils onto a porouswood, such as oak, walnut or mahogany, the oil penetrates fairlydeeply into the pores and remains mere even after me surfaceexcess is wiped off. Even dl0Ugh the oil immediately begins topolymerize over any surface exposed to air, the resins will havetrouble linking-up over the pores, because the solvents continueto break through as they evaporate. As the solvents come to thesurface, they carry along resins that spread out around me pores.If these resins are not wiped off in time, they polymerize on thesurface, forming hard shiny spots, much like scabs over wounds.The problem is worse on warm days or when the wood ismoved to a warmer atmosphere, which excites the molecules ofthe trapped solvents. But, as you have probably experienced, itoccurs even on cold days.I don't know of any way to prevent oil from bleeding, but Ihave found dlat I can avoid the problem if I apply the oil early inthe day and wipe the surface every hour or two before me resinshave a chance to harden. The bleeding usually stops by the endof the day. The next coat causes fewer problems, because thepores are now partially or fully sealed. You are correct dut neitherthe application of more oil nor lacquer thinner will removefully cured spots. These spots should be abraded off wim finesteel wool or sandpaper, possibly using some more oil as a lubricant.As a last resort, dle finish should be removed with paintand varnish remover, and you should start over.[Bob Flexner is a professional finisher and restorer in Norman,Okla. His videos "Repairing Furniture" and "Refinishing Furniture"are available from The Taunton Press, Box 355, Newtown,Conn. 06470.]Two glue problemsFor some time I have been having problems with yellow glue.The glue seems to grow out of the joint after the project hasbeen finished, so I have to resand and refinish the piece. I usuallyfinish with Watco oil. How can I solve the prOblem?-Ray Allen, Yuma, Ariz.I've been using epoxy for gluing furniture for some timenow. It works very well for restoring old splintered joints,but I hesitate to use it too much, because I've heard epoxy istoo rigid to accommodate normal wood movement. I'vealso heard that you should not use it, because it is impossibleto disassemble to make repairs.- Colin Conolly, Corvallis, Oreg.George Mustoe replies: After years of listening to woodworkerswony about "which glue is the strongest," it's refreshing toreceive two letters that illustrate that strengm alone doesn'talways determine whemer an adhesive performs adequately. Theexperiences of Allen and Conolly can both be traced to the greatrange of rigidity among various types of adhesives. Soft-settingglues include contact cement, hot-melt thermoplastic sticks andboth the white and yellow varieties of polyvinyl acetate (PVA)glue. These adhesives produce a rubber-like glue film that cancreep under load. For dlis reason, they are not recommendedfor heavy-duty applications, such as laminated structural beams,where intense stress may cause dle joints to deform or rupture.As Allen discovered, soft-body glues may bulge or shrink as dlesurrounding wood undergoes changes in its moisture content.This is particularly common when a thick glue layer is present.Yellow glue sets to a harder consistency than white glue, and itshouldn't cause problems if it's used on well-mated surfaces.Make sure to use just enough adhesive to coat the surfaces;applying a thick layer is asking for trouble.At me omer end of dle spectrum, Conolly is worried about epoxybeing too rigid an adhesive. ExceSSive rigidity is not a problemwim epoxy. In fact, epoxy's hard, but not brittle, durability is oneof its best features. In contrast, hide glue and urea-formaldehydeplastic resin glue bodl form brittle films that sometimes fail dueto internal fracturing wimin the glass-hard layer of cured adhesive.The inherent brittleness of these adheSives usually causesno difficulties, as long as the glue film is kept min. AlthoughConolly is correct in his statement that epoxied wood joints arevirtually impossible to disassemble, me same can be said of mostodler adhesives. Synmetic mermoplastic resins can be softenedusing heat, but even wim these glues, taking apart a joint isalways a tricky procedure.With any type of woodworking adhesive, maximum performancecharacteristics are obtained when the glue line is kept asthin as possible. This means close-fitting surfaces; uniform adhesiveapplication using a brush, roller or spreading stick; andfirm, evenly-distributed pressure during curing. If you have touse glue to fill up the voids of a poorly fit joint, make me best12 Fine Woodworking

The Fjrst ECONOMICALScroll saw That Works LikeTHE REAL THINGSave with Our Package DealA $204.85 Value, roN just$149.95plus $6.00 shipping(within 48 states)SCAOLLSAW lEQflOLOOy klok a giantthe late 1970's when a Gennan manufOClUrerintroduced firstthe rod

Q & A (colltillued)of a bad situation by using epoxy. It's about the only glue thatdisplays an acceptable degree of gap-filling ability without sacrificingother physical properties.[George Mustoe is a geochemistry research technician at WesternWashington University in Bellingham, Wash.]Japan-finishing a planeI have several old Stanley planes that I would like to refurbish.I have no difficulty cleaning and tuning the planes,but I don't know how to japan the parts that are in badshape. Is there some home process available that will allowme to duplicate the original finish?-Harold Shipley, Memphis, Tenn.Graham Blackburn replies: The japan finish used on oldStanley planes was a tough, durable coating composed of pigmentsand synthetic resin varnish, dipped or sprayed on, then baked attemperatures ranging from 250°F to 350°F. In short, japanning isbaking on enamel. Duplicating this process isn't practical athome and can be extremely dangerous. An alternative is to use amodern air-drying enamel. These enamels are less resistant towear, but they are easy to apply and capable of producing resultsthat look just like the plane's original finish. The air-dryingenamels formulated for household use are sometimes called"liquid enamels," because they closely resemble porcelain orvitreous enamels-like japan. Avoid using lacquer-base enamelson your planes: They are cheap and fast drying, but less durablethan the air-dtying enamels.[Graham Blackburn is a conu'ibuting editor to Fine Woodworkingand has written numerous books on woodworking and tools. Hisshop is in Santa Cruz, Calif. ]Braces and ball-bearing chucksI was thrilled to find an old brace with a 14-in. swing, butunfortunately, I'm unable to make it work. Someone has replacedthe original jaws with newer ones that are apparentlytoo small. Also, the chuck appears to be designed for ballbearings, but they're missing. Can you help me repair mychuck?-Bob Clark, Collinsville, Va.Richard Starr replies: It's good that your brace has a ball-bearingchuck. TIle ball bearings reduce friction, making it easy to snugup any bit with just a little twist on me chuck shell. This isn't soimportant when chucking an auger bit witll a tapered, squareshank, but it u'emendously improves tlle chuck's ability to firmlyhold round-shank bits, which are more prone to slipping.Most brace chucks have an Loosening setscrew allowsouter shell that rotates around adjustment of shell, to set tightnessthe jaws to tighten them against of ball bearings in race.the bit, and there's considerablefriction between the shell andjaws as tlle collar tightens. Asthe outer shell on a ball-bearingchuck turns, however, a freefloatinginner collar bearsagainst the jaws and closesthem. The outer surface of eachjaw is flat (instead of round ason non ball-bearing chucks) andslides in a groove milled in theinner collar, to keep it alignedas it closes. To minimize friction,the outer shell and innercollar bear against ball bearingsOutershellthat roll freely in a race or groove that's formed between them(see the drawing above). To replace tlle missing ball bearings,first loosen the small setscrew on tlle outer shell, then unscrewthe shell to remove it. You can get replacement balls by scroungingthem from another ball-bearing chuck on a junker brace, oryou can take the chuck to a good bicycle repair shop and ask forthe kind of loose balls used in bicycle hubs. Loosely assemblethe outer shell and inner collar, then dribble in balls until youform a ring of balls in tlle race. Screw the shell back on thechuck until there's just a little play and the ball bearings rollfreely wimout rattling.Fixing the jaws on your brace might be more difficult. Jawsare seldom interchangeable between braces, and finding a pairthat would fit is unlikely. Some chucks are designed with aspring to hold the jaws apart; on others, the jaws flop aroundloosely, separated at the bottom by a protruding tab in the jaws.You could make a pair of jaws yourself, but because you don'thave a pattern, this could be tedious trial-and-error work witll ahacksaw and file. You'd have to use a blank of tool steel softenough to work, then temper it to a color between blue andstraw, so tlle jaws would be hard enough to resist galling, yetnot be brittle.There are lots of good old brflces out tllere, but few wim a 14-in.swing. As a last resort to save yours, you may end up havinganomer chuck welded on-not a pretty solution, but functional.[Richard Starr is a teacher and the author of Woodworking withKids, The Taunton Press, Box 355, Newtown, Conn. 06470.]Northwest red alderRed alder is very plentiful here in the Pacific Northwest, and Ihave been conSidering using it for some custom bathroomcabinets. Is it dimensionally stable, and how should it besealed to prevent moisture damage in a bathroom ? The woodseems rather brittle, and when left in the weather, it rots tomush in only a year's time. Am I asking for trouble?-Robert Moen-Starr, Raymond, Wash.Jon Arno replies: I certainly don't see any tragedy in using redalder for interior cabinets. In fact, because it is readily availableand inexpensive in your area, it is probably the best choice youcould make. If it was equally available here in the Midwest, Iwould prefer it to birch, even though birch is one of the primarywoods for commercial cabinets.COinCidentally, red alder (Alnus rubra) is a member of thebirch family (Betulaceae), and I would choose this wood as thepick of the litter. With an average specific gravity of only 0.37(oven-dty weight/green volume), it is much softer and easier towork than yellow birch, which has an average specific gravity of0.55. Red-alder heartwood has a beautiful rose-pink color, andbecause it produces a fibrous layer of cells along the annual rings,its tangential figure is more like cherty than it is like its cousinbirch. Red alder is also more stable than birch: Its average volumetricshrinkage is only 12.6%, versus 16.8% for yellow birch.If the stock you use for tlle cabinets is thoroughly seasoned,you shouldn't have any trouble. Red alder holds nails and screwswell, accepts glues and sealers without difficulty, and because itis a diffuse-porous wood, polishes down to a smooth finish withoutrequiring fillers. As for finishing alder, or any other cabinetwood, Irecommend first applying a penetrating oil stain to achieve thedesired color, then follow this with at least three coats of satinpolyurethane varnish. Polyurethane may not rub down as well asotller varnishes-I don't use them on fine furniture-but for yourpurpose, you want the most impervious moisture barrier youcan achieve. The polyurethane will prevent raised grain and waterspotting when the wood gets that inevitable splash from thesink or the shower stall. Although neither alder nor birch areknown for their durable weatllering properties, normal interiorhumidity levels are low enough so this should not be a problem.Uon Arno is a woodworker and amateur wood technologist inSchaumburg, IlL]Send queries, comments and sOUl'ces oj supply to Q & A, FineWoodworking, Box 355, Newtown, Conn. 0.6470.14 Fine Woodworking

PORTER-CAB' FPUTS THE SCREWS TOTHE COMPEl IliON.If you want a cordless driverldrill that works as hard as you do,pick up PORTER-CABLE'S NEWMODEL 9850 12-VOLT 3/8"DRIVER/DRILL with exclusiveMAGNEQUENCH® power. Thistough tool has the guts to do thejobs other units can't handle. Andto keep working long after thecompetition has run down.Why? The 12-volt battery packhas full-size, select, gradednickel-cadmium cells for maximumenergy. Combined with thenext generation in cordless toolmotors-MAGNEQUENCH usingrare-earth magnets that dramaticallyincrease the power ofmotors-you get higher torquewith less battery drain. In fact, the9850 produces substantiallyhigher watts output than competitivecordless driver/drills.So take charge of your next jobwith Porter-Cable's new 9850Cordless DriverlDrill. At PorterCable distributors everywhere.x TESr RESULtS11/2 wood of 1112 Independent labofatorytests shOwthe quantityscrews vanous COtdtess dnver/drills candnve on one charge195America's Working ClassPORTER+[ABLEPROFESSIONAL POWER TOOLSP. o. BOX 2468 · JACKSON,TN 38302

Pollou'-upby Dick BurrowsMore on tool reviews -We have been regularly publishing articlesevaluating hand and power tools, like the review on scrollsaws in this issue (see pp. 50-54). Judging from the telephonecalls and mail we receive, most readers enjoy the reviews andwant more. But, these articles are difficult to produce, requiringa great deal of research. They also provoke a good bit of controversyamong readers and manufacturers.Manufacturers often are concerned that the tools do not showup as well in our tests as they do in their factory tests. The factorytests are often more scientific than our reviews, but we feelobligated to test the tools in actual workshops under typical jobsituations, rather than in laboratories under ideal conditions. Wesee more value in determining how many holes a cordless drillcan bore on a single charge than hooking it up to an instrumentto get a digital readout of its torque or RPM. After all, our readersare primarily woodworkers and must decide how the tool willoperate in their shop situation.This need for real-shop situations is one reason why the authorswe recruit to test tools are people who have worked withthe particular tool for years. This work experience is essentialto separate the gimmicks from the real innovations. It is alsoinvaluable when evaluating such things as balance, power, easeof operation, performance versus price, and the other somewhatsubjective factors that determine whether or not a tool can getthe job done accurately, effiCiently and safely.In addition to actual testing, we often talk with manufacturingrepresentatives and engineers to clear up problems with thetools, have them answer technical questions and obtain theirviews on what they see as their tools' strong points. We also welcomeletters from readers about their experiences with thetools, and we will try to present as many letters as possible inthe "Follow-up" or "Letters" columns.Skil's cordless drill-The Skil Corporation is disappointed withour review of their cordless drill in the September issue (FWW#72). They say they don't feel the review is accurate or objective.First of all, Skil disagrees with some of the general statementson the drills. The company says we are describing old-stylenickle-cadmium batteries when we state that the batteries have amemory and you should let the battery drain completely beforecharging. Our research indicates that if you charge a partiallydrained battery often, you can reduce the battery's capacity. Skilsays we are wrong."The batteries we have been putting into our tools for the lastfew years have virtually no measureable memory," Skil says. "Theeffect is still dlere, but it requires some velY accurate laboratOlYinsu-uments and a complex test procedure in order to measure ....At least in the case of our supplier, which also supplies batteries tosome of our competitors, dle memOlY effect phenomenon nolonger exists." Skil also maintains dlat draining a battery beforerecharging could damage dle battery under some conditions, so besure to read the owner's manual for your particular tool.Skil's letter also offered some good advice on the care of batteries.They say dlat generally you should avoid excessively high orlow temperatures when charging batteries. Also, avoid prolongedexposure to high temperatures: A car u-unk or a metal storage shedwould be a particularly bad place to store a ni-cad battery. In anodlertemperature-related problem, Skil disputed our claim thatwe had killed one of their batteries by recharging it before itcooled down. They say the battery would have been okay ifcharged after it cooled. But, that doesn't match our experience.Again, check your owner's manual for the specifics on your tool.Ryobi radial-saw and planer modifications- Ryobi AmericaCorp. has asked its dealers to stop sales of the RA-200 radial-armsaw until the company can change dle carriage center componentthat joins the motorlblade assembly to the saw arm. Undercertain conditions, the component could break, the companysays, which would affect accuracy and might even cause operatorinjUly. Anyone who owns one of these saws and has not beencontacted by a company representative should call their customerservicedepartment at the number listed below.Ryobi is also offering a free upgrade kit to owners of earlymodels of the AP-10 planer (bearing serial numbers lower thanand including #064155) and the Sears/Craftsman Portable lO-in.Thickness Planer, model #351.23372. The kits are designed toeliminate the space between the main body of the planer andthe rear feed-support roller. This upgrade will prevent an operator'sfingers from being caught between dle emerging board andthe rear feed-support roller, which could cause serious injUly.For more information on dle radial-arm saw or planer, contactRyobi America Corp., 1433 Hamilton Parkway, 1r. '1Sca, Illinois 60143;(800) 323-4615, eA'\:. 235 (in Illinois, 312-350-7999, ext 235).Inca 810 radial-ann saw-The Austrian-made Inca radial-armsaw, which we reviewed in FWW #73, will probably not be availablefor much longer in the United States. The manufacturer hasdecided it will no longer sell the machine outside of Austria,because of insurance considerations. Inca dealers will still sellthe models they have in stock and intend to continue to provideparts and service for the models already sold.Safety and photography-Safety is a prime concern wheneverwe describe or picture any woodworking operation. Woodworkingis, by nature, a dangerous activity, and caution is essential.Sometimes things can appear to be worse than dley actually are,but even these incidents are good reminders of what could happen.One recent case involved the cover of FWW #73, whichshowed a cut being made on a radial-arm saw.Doug Smith of Miami, Fla., wrote, "The photographer sure forgotthe tree-coming-out-of-the-person's-head lesson. It appearsas though a thumb is just about to be lost. A well-composed,beautiful cover picture, but that blade is sure to get that thumb."Actually, the thumb was a safe distance from the blade all duringthe operation, and the operator was velY conscious of theposition at all times. I have this on good authority, because I wasthe operator. On my own saw, I've followed Frank Klausz's adviceand painted a red strip on the crosscut area of the saw tableas a warning of the potential danger.Tools-To-Go-We have been contacted by several readers whosay they have ordered and paid for tools from Tools-To-Go Inc.(15935 N.W 57th Ave., Hialeah, Fla. 33014) and have never receivedtheir merchandise. We have been unable to contact dlecompany ourselves and unfortunately have not yet been able toidentify any avenue for readers who wish to file a claim. We willpublish that information as soon as it is available.Antique tool association-The Crescent Universal Associationhas changed its name and broadened its scope to include ma. chines other than its classic namesake. TIle Universal Wood-Workeris a do-everything combination madline, which was producedfrom the late 1890s to the early 1940s. TIle machine tipped thescales at 1,700 to 5,200 Ibs., depending on the model, and includeda bandsaw, jointer, shaper, tablesaw and horizontal borer.The two-year-old organization is now called the AntiqueWoodworking Power Tool Association. According to presidentWalter S. Vinoski, the group provides members with advice onthe acquiSition, restoration, preservation and operation of classicwoodworking machinely. The group also publishes a bimonthlyjournal. For more information, write the organization at Box1027, Connellsville, Penn. 15425. DDick Burrows is managing editor at FWW16 Fine Woodworking

26 SHOWS IN 1989!<strong>Free</strong> Workshops * 100 Exhibits * Prize/DrawingEverything you for setting andjointer and planer knives and rollersTraditional knife changing methods take too long and can bedangerous. One or more knives can be reset too high or too low,out of parallel, or sqirm out of position when tightened. Eliminatethese miseries with the Magna-Set system! The patentedmagnetic design grips each knife in perfect alignment. Great for+ Add 2.50 for shipping & handeling. C.O.D.charges if any. Allow one week for deliveryshifting knicked blades in seconds!Planer Jig pair 159.95a:v 800-331-1748 Jointer Jig 49.95Rotocator 159.95Phone your order TOLL FREE and use your VISAor MA STERCARD or simply mail payment to:UNIOUESTCORP 585W. 3900 SO. #6 MURRAY,UTAH 84123 801-265-1400WOODWORKER II best on TABLE SAW WOODWORKER I Best on RADIAL SAW• With this ONE ALL PURPOSE blade 40 Teeth and I/S kerf.SMOOTH RIP & CROSSCUT 1" - 2" ROCKHAROS andSOFTWOODS with smooth,as,sanded surface.PLY-VENEERS oak/birch crosscut with NO BOnOMSPLINTER.MostlyDOUBLE I/S HARDER kerf 15' ATB and 20' face hook (easyfeed).and 40% STRONGER CARBIDE.Endscutting 1/16" oversize to allow for RESURFACE.blade instead of 3, 24T rip, 50T• blade changing (does rip, combo and crosscut).Ends scratchy saw cuts (for the rest of your life).Ends second step finishing (jointing and sanding).EndsBuy and sharpen ONE• Strongly recommend our .001 flat large stlflener 30T il ripping mostly 2" -3" hardwoods.Side wobble held .001 - others .004/.010 is commonlRAISE for THICK woods, LOWER for THIN woods andperfect cut everything!12"x 30T x I" 162•Combination, 80T Crosscut.dampener against outside 01 blade lor smoothest. Quietest,cuts by this and any other blade.UseList Sale List Sale12"x40Txl" SlS3 S109 S"x40T JI32'" 5136 S8297 30T 3132" 115 6910'"x40T 156 94 71/4"' x30T JI32'" 112 4930T 135 Sl T' x30T 3/32" 112 49ALSO help your SEARS blade.THIN SAW, DML, LEITZ, FREUD, PIRANHA, JAPANESEelc.9'" xji S 6":.. b Ihl; 50OooFREE dampenerFOR BETTER CUTSIUse our large 1/8"' DAMPENERSTIFFENERS. against one side6'" , S25 Parallel and flat to .0015'" - 24 Stops vibration. flutter,cuHing noise and bladering.Full cash refund.$10.00O(4'" - 21 Tlyable and RETURNABLE.all with any 2nd blade.518" holes bOle to 11/," $7.50 extra. Othersavailable. Add $2.00 Shipping.•(tablesaw too) This ALL PURPOSE blade gives scratch freePOLISHED cuts on all materials RIP or CROSSCUT up to 2'".All 60T and THIN 3/32" kerf 20' ATB and 5' face hook.DOUBLE HARDER and 40% STRONGER carbide.•THIN KERF:Saves lf3 wood loss on each cut, radial or table.Feeds easy when used for moderate rip and crosscut ontable saw.Reduces "JUMP IN" greatly lor better "PULL-CONTROL".Practically elinlinates bottom splinter on RADIALCROSSCUT . .Totally stops ALL bottom and top splinter on ply veneersin push-cut mode on RADIAL.• Our STIFFENER STRONGLY RECOMMENDED AGAINSToutside of blade only for best cuts.Made and serviced in USA for your benefit.12'" 60Tx l'"or 5/8"10'" x 60T x 5/8'"9'" x 60T x SIS"S" x 60T x 518"150New SII'" x40Tx 518"RYOBf RA200 TS200HITACHI PSM8l .. ercut DADO KING MUlTITOOTH dad. set culs ALL II''"SEE THE WIDEST VARIETY OF WOODWORKINGPRODUCTS ALL UNDER ONE ROOFMachinery . Power & Hand Tools · SuppliesCentral Florida Jan. 13-14-15 Curtis Hixon Conv. Ctr./TampaKansas City Jan. 27-28-29 Kansas City Convention CenterIndianapolis Feb. 3-4-5 Indiana Convention CenterColorado Feb. 10-1 1-12 National Western Complex, DenverNorth Texas Feb. 17-18-19 Dallas Convention CenterGreater Milwaukee Mar. 3-4-5 MECCA Convention CenterMetro-Richmond Mar. 1 0-1 1-12 Richmond CentreArizona Mar. 17-18-19 Phoenix Civic PlazaNo. California Mar. 31-Apr. 2 Santa Clara Convention CenterSo. California Apr. 7-8-9 Los Angeles Convention CenterTennessee Apr. 14-15-16 Nashville Convention CenterNew England Apr. 21-22-23 Hartford Civic CenterChicagoland Apr. 28-29-30 Odeum, Villa Park/ChicagoGreater Cleveland May 5-6-7 Cleveland Convention Center1·800-826-8257 or 213-4n-8521Seminars by Ian Kirby - Roger Cliffe - Bob RosendahlRude Osolnik - Nick Cook - and other Master CraftsmanCall for free brochure, 8:30-5 Pacific TimeSave $1 off reg. $6 admission with this adListSale519S 511997162156 9490136 S2MAKITA 5008 NBAPORTER CABLE 368-1-13/16"'u a Ii'Ls ao N8 s sUTrR9gti I :nfillers and 24T outside saws. NOTHING LIKE IT IN THE USA!!••• ••S'" x 24T x 4T x ST lillers 501 13116"' 5299S'" 24T x 4T10" x 24T x 4T x ST fillers3/4"' sel 24913/16'" sel 362SIS" sel 5209112"' set 179FOR Mep MELAMINE & LOW PRESSURE LAMINATESS'" Neg-shear 24T x 2T or 4T fillers 525910'" Neg-shear 24T x 2T al4T lillers 314SIS" holes - boring exira - SHIPPING 55.50WE RECOMMEND OUR FACTORY SHARPENING 2-3 DAYS ON THESE AND ALL MAKES OF CARBIDE TIP SAWS SHIP IN UPS(500 grit microscoped) 10 X40T$14 25. 60T$16.83 Add leluln UPS $3 or 2nd Day All $5NOW ORDER [he one blade that Will outlast you! (10-20 sharpenlngs possible)SATISFACTION GUARANTEED OR FULL CASH REFUND.40 Dealer Inquiries Welcome.years of fine American saw making & sharpeningFORREST250 DelawannaMANUFACTURINGAveCOMPANY. INC... Clifton, NJ 07014For TABLE and RADIAL SAW(very good on chop saw loa!) STOP SPLINTERINGIhose SPLINTERY OAKS, HARDWOOD VENEERS andthin 2 SIDE LAM INATES ON PARTICLE BOARD.FOR FASTER FEED RATES AND MORE ABSOLUTESPLINTER CONTROL.DURALINE HI-ATEditorial Nov'/Dec. 1988No. 73 pg. 65 S.N.Note: Fine Woodworkingrecommends !1!IJ!!.alternating top bevel (ATB)1l1i!1 kerfs and!MM bladestit/eners for smoothestcuts on RA DIAL SAWS ,etc. FREE dampener'I '2nd', . .' .'Jim Forrest, President and deSigner,mlcroscoping cutting edge.AII 5/e" hole. Boring up to 11/4" $7.50 extra- Larger holes - time basis .Shipping $3.50.HI-AT Price ListS" SOT 5202 14'" x SOT 52329'" x SOT 207 lOOT 26610'"x SOT 207 16'" x SOT 26212'"x SOT 212 lOOTlOOT 253All CARBIDE is THE HARDEST OF THE C-4 gladesand 40% STRONGER. NOT WEAKER!'For 50% to 300% longer life!orS'O,OO 011 wilh anybfade.. CHOPMASTER SERIES FOR MITER SAWS fOI294flghl. smooth. splintel-ftee mltel-Ialnts. NEWHitachi Sl/2'" DeWalt SII2" S1/2'" x60T x 518"" 5179 S l-S9Use small stiffener where possible.w";,!... & Money We Orders. honor Amex, Personal Visa Checks MasterCard. and COD's IIiIiIITo order BY MAIL clip ad. Circle chOices and!' ., . . AVAILABLE SIZES.list SaleDelta 9" x SOT 5/S'" 204 99Ryabi-Makila 10'" SOT x 5/S" 207 1 09Ryobl-Maklta 14" x lOOT x I'" 266 160Hitachi IS'" x l OOT x I" 277 1641-800-526-7852 PHONE TOLL FREE!(In NJ: 201-473-5236)enclose payment Specify Dept FW when ordering ___January/February 1989 17

Easy toStep by Step DrawingsBuildOnly a few simple tools req uired$12,95 for a complete set of plans. tax includedplus $2,00 postage and handlingOak Roll Top Center Table, Dept. BK12JDL Industries. 15721 Ryan. Holland. MI 49424'The Bester is the best waterstone for the professional"Jay van Arsdale, Author of ShojiThe harder, wider waterstoneBlends natural stoneand ceramic to workfaster and last longer(Three-inch width -perfect for wide blades.)Bester #700 #1000 #1200 Polish #8000Prices $19.80 $23.80 $25.80 $38.80Special set of four $100<strong>Free</strong> shipping in cont. U.S.(AK &HI add $18. CA tax 7%)Comes with #150 surface flattening stone(list $9.80) Sale ends 3/31/89Send $3 for complete tool catalog.HIDA JAPANESE TOOL 415-524-37001333 San Pablo, Berkeley, CA 94702The SawmillFOR WHOLFSALE INQUIRIESEXOTIC AND ooMESTIC HARDW OODSMUSICAL INSTRUMENT WOODSTOLL FREECUSTOM CU TTING. RESA WING. ABRASIVE PLANINGEBONIES. ROSEW OODS. MAHOGANIES. PADAUK.PLUS ALL OTHER EXOTIC W OOD SPECIES800 345-3103PA RESIDENTS CALL (215)759-2064GWOO

RockinghamCommunity CollegeProgram:Degree:Fine and Creatille Woodworking2Associate year of Applied ScienceInstructors: Dallid Kenealy and Ted CurrinEmphasizes designing and building of finequality, custom furniture. Related areasstudied in depth.•Curriculum includes:Furniture Construction (Period andContemporary).Finishing.Wood Turning.Chair Construction· Design and DraftingWood Forming and Bending·BusinessOperations.Equipment and Maintenance·AndMoreLocated near the furniture center of the Southeast,Ree offe rs low tuition, outstanding facilities,small classes, and experienced instructors.A balance between the use of hand/ools andwoodworking machinery enables students toacquire the knowledge and skills of a wellroundedcraftsman.CALL (919) 342-4261ARockingtlamCommunity Collegep.o. Box 38·Wentworth, NC 27375-0038Equal Opportunity/Affirmative Action CollegeL EARN THE SE CRETSOF WOOD'SG REATEST FINIS HER111"Secrets of the Old Master:Wood Finishing byGeorge Frank"A l20-minute videotapesharing the skill of amaster wood finisherand author ofAdventures Finishing in WoodandFrank on Wood George Finishin..?1 930 's, heFew people know wood tinishing like GeorgeFrank. As one of Europe's Illost sought-aftercraftsmen during the f920'5 andperformed incredible work fex a distinguishedarray of clients, perfecting a vast knowredge offinishing techniques. He refined old methodsand invented new ones. George Frank is a ConsultingEditor of Fille Wr}()d WIJrkiltl1 magazineand Honorary Editor of The Wr)()d Flllisim'quarterly. In this video, he shares that knowledgein an entertaining manner direct from hisown workshop as he describes the techniques,shortcuts and se rets behind his success.$39.95 plus $3.75 shipping and handlingORDER TODAY!Send your check or money order to:WOODFINISHER INDUSTRIES, INC.P.O. Box 6923Arli ngton, VA 22206(703) 553-9694THE GREATEST ADVANCE IN WOODTURNING IN 50 YEARS!SYMTEC has re-examined every aspect of woodturning, introducingnew design principles which make turning fluting and copying easier andmore accurate than ever before.FOR FURTHERINFORMATION166 Robie St.Truro, N.S., Canada 902-893-1915• Two models available. 1800mm and1500mm length bed.• Easier to use than any othercomparable lathe .• Motor, drive belt and cone pulleysare completely enclosed for maximumsafety .• Exact replicas and repetition workaccomplished in a fraction of the timepreviously required.• Copies can be turned from a flattemplate.• Built in sharpening feature and resettingdevice.• Can be used with traditional chiselsand tool rest.• Many accessories, including routerSyrnTEr: AMERICA...NEW INFINITELY VARIABLE FEED RATE gives you totalcontrol in any sanding situation!EXCLUSIVE QUAD-DRIVE FEED SYSTEM four powersandingat first and last few inches of a board!and holder, 'steady' for long work, fullrange of centres and faceplates, and1-800-565-1490the exclusive SYMTEC centering guide.At last! A complete power-feed Drum Sander at an affordableprice! Choose from 12" and 26" modelsSAVES TIME .. .IMPROVES RESULTS. Use this high-tolerancemachine for light dimensioning as well as the finest finish work. Nowyou can add new beauty to each woodworking project. .. savehours of tedious hand sanding! In a matter of seconds youcan produce a satin-smooth finish impossible to duplicatewith hand methods or hand-held powersanders ... no more low spots, waves or cross-grainmarks! Check these advantages ...FREE FACTS!Send for complete facts on how you can try this'-----,low-cost tool in your own shop for one fullmonth without risk. See how the sander candimension and finish-sand cabinet pieces,resawn stock, paneling, toys, tabletops,knees, burls, crotches and much, muchmore! You'll oon find it's one of the mostvaluable tools in your shop! Made in U.S.A.r'lEasy Terms.Call Toll-<strong>Free</strong> 1 (800)538-4200, Ext. 5228DYES! ;;,; ::h"';Y"';R7E'.--•••NAME'. 1\I INFORMATION KIT and details on.your 30-day <strong>Free</strong> Trial Guarantee .- Woodmaster Tools, Dept. 0528,."2908 Oak, Kansas City, MO 64108_...feed rollers for maximum traction. Eliminates over-• •NEW FELT-BACKED ABRASIVE mounts in just seconds •______________ADDRESS •to Velcro covered drum. The harder you sand, the•CITY•... _ ---------_tighter it stays! Eliminates stretching ... allows fastremoval and re-use! _ STATE ZIP-_January/February 1989 19

(25 years)P-SOO20" PlANERSEATTLE:1 000 Andover Park E.Seattle, WA 98188(206) 575-4131CT-60F- 6"JOINTERATLANTA:3184 Marjan Dr.Chamblee, GA 30340(404) 455-8109It takes experience to serve you right!NORTHSTATE15" PlANERS LENEAVE mUALITVNORTHSTATE PlANERSCABINETDOOR MAKERNORTHSTATEWIDE BELT SANDERNORTHSTATEOUST COl1£CTORS• Model 310: $725Powerful 3 hp motorCast iron constructionMagnetic switch1 year warrantyDust hood• Anti·kickbackNORTHSTATE10",12",14" CABINETSHOP SAWS• Model 315: $795• Same featJJres as theModel 310 plus:Table extension• 2 speedsDElTA SHAPER• 20", 5 hp: $1,295. 24", $2,595• 5 hp & 7Y, hpNORTHSTATEBANDSAWS14", 1 hp: $29518", 2 hp: $695• 20": $1,495.24": $2,465DELTA "UNISAW'Heavy cast iron canst• 2 hp, single phase.9" x 01" bed3 kne cutter headDual ti fenceMagnetic controlsSALE: $775FREE FREIGHT6" jointer: $325• 12""rr_jointer: $1,895. .• Delta 8" jointer: $1,245DELTA 18" VARIABLESPEED SCHOU SAWModel-... ...3 hp/l ph, 5 hp/3 ph43-3753, 5, 7Y, hp motors" ..' & y," spindles 2 speed·reversible1'h. 3, 5 hp motorsMagnetic controls$1,399 I2 spindles: "" 1Pricing starts at $1, 150Cast iron top• <strong>Free</strong>born & Freud Shaper • Specials on unijence V ..'Y,", 1" availableReg.: $1,114UnHock fenceCutters available. models SALE: Router collets avail.$656VERY HIGH QUAUTY• 96 Cast iron tablefree blades • Spring hold down &$1,050 w/std fencemiter gauge$1, 150 with 50" rip fence LENEAVE MACHINERY•& SUPPLY COMPANYExtra heavy dutyFREE FREIGHT305Charlotte,WestNorthMoreheadCarolinaStreet1 year warranty$1,05028202 • FREE FREIGHT(704) 376·7421Requires 6 sq It space• Set·up time reduced by 80%Easy top side adjustmentsAll cutters fully guardedCutters included• Safe, easy operationNORTHSTATE CABINETSHOPBest buy in the induSl!y!Variable speedPlaten headDual motorsHeavy cast iron & steel• Plate construction10, 15 & 20 hp25" ust: SALE: $7,950$5,695, 15 hp37" ust: $1 2.llX)• SALE: $8, 100, 20 hp• Phase converter avail..2 hp. 2 bag: $350• 3 hp, 4 bag: $520• Reg. $1,479• • SALE: $879•• CELTASPECIALSComplete Delta Une Available37-350: 8" jointer w/stand: $1,24534-444: 10" contractor saw: $59528-2835: 14" bandsaw: $59828-243: 14" bandsaw: $47840-601: scroll saw:17-900:$65616 y," drill press: $32543-122: shaper: $49933-990: 10" radial anm saw: $53534-985: stock feeder: $53933-150: sawbuck: $50920 Fine Woodworking