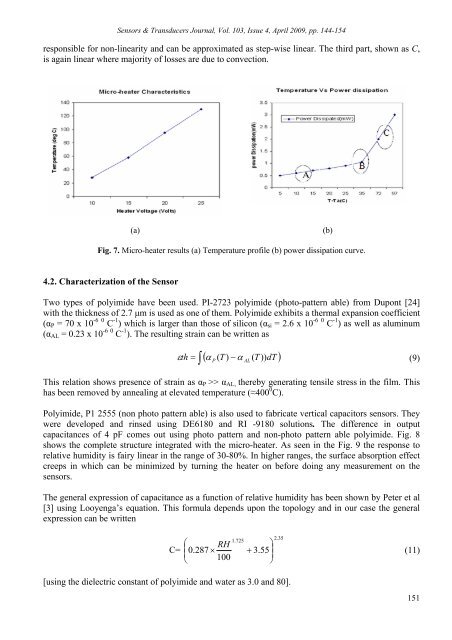

Sensors & Transducers Journal, Vol. 103, Issue 4, April 2009, pp. 144-1544.1. Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the Micro HeaterTwo widely reported methods for temperature extracti<strong>on</strong>s are comm<strong>on</strong>ly employed. [17] The firstmethod employs a calibrati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the resistance versus temperature curve <str<strong>on</strong>g>of</str<strong>on</strong>g> the heating element in auniform temperature envir<strong>on</strong>ment [18]. The other method explo<str<strong>on</strong>g>its</str<strong>on</strong>g> two different metallic resistors, aheating element <str<strong>on</strong>g>and</str<strong>on</strong>g> a temperature sensor, lithographically defined very close to each other, in such away that they share approximately the same temperature [19]. In this paper, former topology which issimpler is used. Equati<strong>on</strong>s (5)-(8) have been used for selecting the dimensi<strong>on</strong>s. The heaters <str<strong>on</strong>g>and</str<strong>on</strong>g>sensing element are realized using TiN layer. Another micro-heater using doped poly silic<strong>on</strong> (PPD)has also been fabricated <str<strong>on</strong>g>and</str<strong>on</strong>g> studied. The comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the measured results <str<strong>on</strong>g>of</str<strong>on</strong>g> different variants [asrepresented (a), (b), (c) in Fig. 3] is shown below in Fig. 4.Resistances values <str<strong>on</strong>g>of</str<strong>on</strong>g> Microheater25Element Value(k-ohms)2015105TiNPPD01 2 3VariantsFig. 6. Values <str<strong>on</strong>g>of</str<strong>on</strong>g> resistances for different types <str<strong>on</strong>g>and</str<strong>on</strong>g> material.The poly-silic<strong>on</strong> resistor has higher resistance due to <str<strong>on</strong>g>its</str<strong>on</strong>g> higher sheet resistivity compared to TiN. Thesensitivity is therefore better. However, most <str<strong>on</strong>g>of</str<strong>on</strong>g> the other parameters, such as linearity, currentcarrying capacity, etc are found to be better. The not so good linearity in poly is due to the fact that it isa semic<strong>on</strong>ductor <str<strong>on</strong>g>and</str<strong>on</strong>g> therefore carrier c<strong>on</strong>centrati<strong>on</strong> (n) <str<strong>on</strong>g>and</str<strong>on</strong>g> mobility (µ) will vary due to temperature.TiN is a metal <str<strong>on</strong>g>and</str<strong>on</strong>g> the temperature effect <strong>on</strong> resistivity will be determined by mobility al<strong>on</strong>e.The sensors were wire b<strong>on</strong>ded to a printed circuit board, <str<strong>on</strong>g>and</str<strong>on</strong>g> were tested inside an envir<strong>on</strong>mentalchamber. The chamber has the humidity range <str<strong>on</strong>g>of</str<strong>on</strong>g> 20-90 % <str<strong>on</strong>g>and</str<strong>on</strong>g> temperature ranges from -25 0 C to+55 0 C. Capacitance measurement is performed using HP4284A capacitance meter. Micro heater isfirst characterized using st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard sensors as well as IR testing employing infrared camera (8-14 micr<strong>on</strong>b<str<strong>on</strong>g>and</str<strong>on</strong>g>). The temperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile <str<strong>on</strong>g>and</str<strong>on</strong>g> power dissipati<strong>on</strong> curves are shown in Fig. 7.The heater temperature depends <strong>on</strong> the dissipated power <str<strong>on</strong>g>and</str<strong>on</strong>g> geometry positi<strong>on</strong> <strong>on</strong> the membrane. Atlow temperatures, heat loss is primarily due to c<strong>on</strong>ducti<strong>on</strong>, so a linear relati<strong>on</strong>ship exists. This relati<strong>on</strong>can be shown to beP = G (T-Ta), (10)where P is the power dissipati<strong>on</strong>, G is the thermal loss coefficient (W/ 0 K) <str<strong>on</strong>g>and</str<strong>on</strong>g> Ta is the ambienttemperature. The value <str<strong>on</strong>g>of</str<strong>on</strong>g> G is temperature dependent <str<strong>on</strong>g>and</str<strong>on</strong>g> at high temperatures as c<strong>on</strong>vective lossesovertakes the c<strong>on</strong>ducti<strong>on</strong> losses giving rise to, n<strong>on</strong>-linearity. This can be seen in Fig. 8 which can bedivided into three sub-areas. The first part marked as A, which shows linear resp<strong>on</strong>se, is due toc<strong>on</strong>ducti<strong>on</strong> losses. The transiti<strong>on</strong> part from c<strong>on</strong>ducti<strong>on</strong> to c<strong>on</strong>vecti<strong>on</strong> loss marked as B, which is150

Sensors & Transducers Journal, Vol. 103, Issue 4, April 2009, pp. 144-154resp<strong>on</strong>sible for n<strong>on</strong>-linearity <str<strong>on</strong>g>and</str<strong>on</strong>g> can be approximated as step-wise linear. The third part, shown as C,is again linear where majority <str<strong>on</strong>g>of</str<strong>on</strong>g> losses are due to c<strong>on</strong>vecti<strong>on</strong>.(a)(b)Fig. 7. Micro-heater results (a) <str<strong>on</strong>g>Temperature</str<strong>on</strong>g> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile (b) power dissipati<strong>on</strong> curve.4.2. Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the SensorTwo types <str<strong>on</strong>g>of</str<strong>on</strong>g> polyimide have been used. PI-2723 polyimide (photo-pattern able) from Dup<strong>on</strong>t [24]with the thickness <str<strong>on</strong>g>of</str<strong>on</strong>g> 2.7 µm is used as <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> them. <str<strong>on</strong>g>Polyimide</str<strong>on</strong>g> exhib<str<strong>on</strong>g>its</str<strong>on</strong>g> a thermal expansi<strong>on</strong> coefficient(α P = 70 х 10 -6 0 C -1 ) which is larger than those <str<strong>on</strong>g>of</str<strong>on</strong>g> silic<strong>on</strong> (α si = 2.6 х 10 -6 0 C -1 ) as well as aluminum(α AL = 0.23 х 10 -6 0 C -1 ). The resulting strain can be written as∫( α ( T ) −α( T )ε th =P AL)) dT(9)This relati<strong>on</strong> shows presence <str<strong>on</strong>g>of</str<strong>on</strong>g> strain as α P >> α AL, thereby generating tensile stress in the film. Thishas been removed by annealing at elevated temperature (≈400 0 C).<str<strong>on</strong>g>Polyimide</str<strong>on</strong>g>, P1 2555 (n<strong>on</strong> photo pattern able) is also used to fabricate vertical capacitors sensors. Theywere developed <str<strong>on</strong>g>and</str<strong>on</strong>g> rinsed using DE6180 <str<strong>on</strong>g>and</str<strong>on</strong>g> RI -9180 soluti<strong>on</strong>s. The difference in outputcapacitances <str<strong>on</strong>g>of</str<strong>on</strong>g> 4 pF comes out using photo pattern <str<strong>on</strong>g>and</str<strong>on</strong>g> n<strong>on</strong>-photo pattern able polyimide. Fig. 8shows the complete structure integrated with the micro-heater. As seen in the Fig. 9 the resp<strong>on</strong>se torelative humidity is fairy linear in the range <str<strong>on</strong>g>of</str<strong>on</strong>g> 30-80%. In higher ranges, the surface absorpti<strong>on</strong> effectcreeps in which can be minimized by turning the heater <strong>on</strong> before doing any measurement <strong>on</strong> thesensors.The general expressi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> capacitance as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> relative humidity has been shown by Peter et al[3] using Looyenga’s equati<strong>on</strong>. This formula depends up<strong>on</strong> the topology <str<strong>on</strong>g>and</str<strong>on</strong>g> in our case the generalexpressi<strong>on</strong> can be writtenC=2.351.725⎛⎞⎜0.2873.55⎟× RH +100(11)⎝⎠[using the dielectric c<strong>on</strong>stant <str<strong>on</strong>g>of</str<strong>on</strong>g> polyimide <str<strong>on</strong>g>and</str<strong>on</strong>g> water as 3.0 <str<strong>on</strong>g>and</str<strong>on</strong>g> 80].151