MMT162 User's Guide in English

MMT162 User's Guide in English

MMT162 User's Guide in English

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

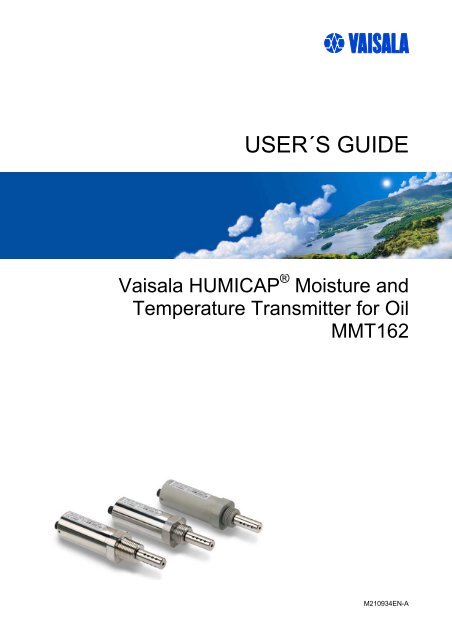

USER´S GUIDEVaisala HUMICAP ® Moisture andTemperature Transmitter for Oil<strong>MMT162</strong>M210934EN-A

PUBLISHED BYVaisala Oyj Phone (<strong>in</strong>t.): +358 9 8949 1P.O. Box 26 Fax: +358 9 8949 2227FIN-00421 Hels<strong>in</strong>kiF<strong>in</strong>landVisit our Internet pages at http://www.vaisala.com/© Vaisala 2008No part of this manual may be reproduced <strong>in</strong> any form or by any means, electronic ormechanical (<strong>in</strong>clud<strong>in</strong>g photocopy<strong>in</strong>g), nor may its contents be communicated to a thirdparty without prior written permission of the copyright holder.The contents are subject to change without prior notice.Please observe that this manual does not create any legally b<strong>in</strong>d<strong>in</strong>g obligations forVaisala towards the customer or end user. All legally b<strong>in</strong>d<strong>in</strong>g commitments andagreements are <strong>in</strong>cluded exclusively <strong>in</strong> the applicable supply contract or Conditions ofSale.

USER´S GUIDE ___________________________________________________________________Install<strong>in</strong>g the Driver for the USB Cable................................26Term<strong>in</strong>al Program Sett<strong>in</strong>gs..................................................27List of Serial Commands .......................................................29Device Information and Status..............................................30Show Device Information ....................................................30Show Firmware Version ......................................................30Configur<strong>in</strong>g Serial L<strong>in</strong>e Operation........................................31Set Serial L<strong>in</strong>e Sett<strong>in</strong>gs .......................................................31Set Serial L<strong>in</strong>e Response Time...........................................32Set Transmitter Address......................................................32Format Measurement Output ..............................................32Select Unit ...........................................................................34Set Serial Interface Mode....................................................34Configur<strong>in</strong>g Measurement Parameters ................................35Select Analog Output Quantity and Scal<strong>in</strong>g ........................35Set Analog Output Mode (mA/V).........................................36Calibrate Analog Output ......................................................36Set Malfunction Alarm Output for Analog Channels............37Set Alarm Limits for Analog Outputs / LED Indication.........37Set Voltage for LED Alarm ..................................................38Extend Analog Output Range..............................................38Serial L<strong>in</strong>e Output Commands..............................................39Start Measurement Output ..................................................39Stop Measurement Output ..................................................39Set Output Interval...............................................................40Output Read<strong>in</strong>g Once..........................................................40Troubleshoot<strong>in</strong>g Commands.................................................41Display the Currently Active Errors .....................................41Test Analog Outputs............................................................41Other Commands ...................................................................42Open<strong>in</strong>g the Transmitter <strong>in</strong> POLL Mode .............................42Clos<strong>in</strong>g the Connection to a Transmitter <strong>in</strong> POLL Mode.....42Display Command List ........................................................43Reset Transmitter................................................................44Restore Factory Sett<strong>in</strong>gs.....................................................44ppm Conversion .....................................................................44<strong>MMT162</strong> ppm Conversion for Transformer Oils..................44Conversion Model with Average Coefficients......................45Conversion Model with Oil-specific Coefficients .................45Sett<strong>in</strong>g Oil Coefficients Us<strong>in</strong>g Serial L<strong>in</strong>e............................46OIL..................................................................................46Determ<strong>in</strong>ation of Oil-Specific Coefficients...........................46CHAPTER 5MAINTENANCE............................................................................................49Clean<strong>in</strong>g...................................................................................49Chang<strong>in</strong>g the Probe Filter......................................................50Chang<strong>in</strong>g the Sensor .............................................................50Error States .............................................................................50Technical Support ..................................................................51Return Instructions ................................................................512 ___________________________________________________________________ M210934EN-A

________________________________________________________________________________Vaisala Service Centers......................................................... 52CHAPTER 6CALIBRATION AND ADJUSTMENT........................................................... 53MM70 <strong>in</strong> Check<strong>in</strong>g and Adjust<strong>in</strong>g......................................... 54One-Po<strong>in</strong>t Relative Humidity Adjustment............................ 54Us<strong>in</strong>g Serial L<strong>in</strong>e ................................................................. 54CRH ............................................................................... 55Us<strong>in</strong>g MI70 .......................................................................... 55One-Po<strong>in</strong>t Temperature Adjustment .................................... 58Us<strong>in</strong>g Serial L<strong>in</strong>e ................................................................. 58CT .................................................................................. 58Us<strong>in</strong>g MI70 .......................................................................... 59Analog Output Adjustment.................................................... 61CHAPTER 7TECHNICAL DATA ...................................................................................... 63Measured Values .................................................................... 63Operat<strong>in</strong>g Environment ......................................................... 64Inputs and Outputs ................................................................ 64Mechanics ............................................................................... 64Spare Parts and Accessories................................................ 65Dimensions <strong>in</strong> mm (<strong>in</strong>ches) .................................................. 66List of FiguresFigure 1 Moisture and Temperature Transmitter for Oil <strong>MMT162</strong>.......... 13Figure 2 The Water Solubility of Transformer Oils versus Temperature 16Figure 3 Remov<strong>in</strong>g the Transportation Protection Cap.......................... 17Figure 4 Install<strong>in</strong>g the Transmitter.......................................................... 18Figure 5 Connect<strong>in</strong>g the Cable............................................................... 18Figure 6 Connectors I and II ................................................................... 19Figure 7 Connector P<strong>in</strong>out...................................................................... 19Figure 8 Cable with Snap-On Connector ............................................... 20Figure 9 Cable with Threaded Connector .............................................. 20Figure 10 Cable with 90° Angle Threaded Connector.............................. 21Figure 11 LED Cable ................................................................................ 21Figure 12 USB Serial Interface Cable ...................................................... 22Figure 13 PuTTY Term<strong>in</strong>al Application .................................................... 28Figure 14 Ma<strong>in</strong> Menu................................................................................ 55Figure 15 Functions Menu........................................................................ 56Figure 16 Metal Hous<strong>in</strong>g Transmitter Dimensions ................................... 66Figure 17 Plastic Hous<strong>in</strong>g Transmitter Dimensions ................................. 67List of TablesTable 1 Manual Revisions ....................................................................... 6Table 2 Related Manuals ........................................................................ 6Table 3 Quantities Measured and Calculated by <strong>MMT162</strong>................... 11VAISALA ________________________________________________________________________ 3

USER´S GUIDE ___________________________________________________________________Table 4 Default Serial Interface Sett<strong>in</strong>gs...............................................25Table 5 Serial L<strong>in</strong>e Commands .............................................................29Table 6 Modifiers ...................................................................................33Table 7 Analog Output Modes...............................................................36Table 8 Error Messages ........................................................................514 ___________________________________________________________________ M210934EN-A

Chapter 1 ________________________________________________________ General InformationCHAPTER 1GENERAL INFORMATIONThis chapter provides general notes for the manual and the product.About This ManualThis manual provides <strong>in</strong>formation for <strong>in</strong>stall<strong>in</strong>g, operat<strong>in</strong>g, andma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g Vaisala HUMICAP ® Moisture and TemperatureTransmitter for Oil <strong>MMT162</strong>.Contents of This ManualThis manual consists of the follow<strong>in</strong>g chapters:- Chapter 1, General Information, provides general notes for themanual and the product.- Chapter 2, Product Overview, <strong>in</strong>troduces the features, advantages,and the product nomenclature- Chapter 3, Installation, provides you with <strong>in</strong>formation that is<strong>in</strong>tended to help you <strong>in</strong>stall the <strong>MMT162</strong>.- Chapter 4, Operation, conta<strong>in</strong>s <strong>in</strong>formation that is needed to operatethis product.- Chapter 5, Ma<strong>in</strong>tenance, provides <strong>in</strong>formation that is needed <strong>in</strong>basic ma<strong>in</strong>tenance of the product.- Chapter 6, Calibration and Adjustment, provides <strong>in</strong>formation that isneeded <strong>in</strong> calibration and adjustment of the product.- Chapter 7, Technical data, provides the technical data of theproduct.VAISALA ________________________________________________________________________ 5

USER´S GUIDE ___________________________________________________________________Version InformationTable 1 Manual RevisionsManual CodeM210934EN-ADescriptionSeptember 2008 - First versionRelated ManualsTable 2Manual CodeM210935EN-ARelated ManualsDescriptionVaisala HUMICAP ® Moisture and TemperatureTransmitter for Oil <strong>MMT162</strong> Quick Reference <strong>Guide</strong>General Safety ConsiderationsThroughout the manual, important safety considerations arehighlighted as follows:WARNINGWarn<strong>in</strong>g alerts you to a serious hazard. If you do not read and follow<strong>in</strong>structions very carefully at this po<strong>in</strong>t, there is a risk of <strong>in</strong>jury oreven death.CAUTIONCaution warns you of a potential hazard. If you do not read andfollow <strong>in</strong>structions carefully at this po<strong>in</strong>t, the product could bedamaged or important data could be lost.NOTENote highlights important <strong>in</strong>formation on us<strong>in</strong>g the product.6 ___________________________________________________________________ M210934EN-A

Chapter 1 ________________________________________________________ General InformationFeedbackVaisala Customer Documentation Team welcomes your commentsand suggestions on the quality and usefulness of this publication. Ifyou f<strong>in</strong>d errors or have other suggestions for improvement, please<strong>in</strong>dicate the chapter, section, and page number. You can sendcomments to us by e-mail: manuals@vaisala.comProduct Related Safety PrecautionsThe Vaisala HUMICAP ® Moisture and Temperature Transmitter forOil <strong>MMT162</strong> delivered to you has been tested for safety and approvedas shipped from the factory. Note the follow<strong>in</strong>g precautions:WARNINGGround the product, and verify outdoor <strong>in</strong>stallation ground<strong>in</strong>gperiodically to m<strong>in</strong>imize shock hazard.CAUTIONDo not modify the unit. Improper modification can damage theproduct or lead to malfunction.Recycl<strong>in</strong>gRecycle all applicable material.Dispose of batteries and the unit accord<strong>in</strong>g to statutory regulations.Do not dispose of with regular household refuse.VAISALA ________________________________________________________________________ 7

USER´S GUIDE ___________________________________________________________________Regulatory CompliancesVaisala HUMICAP ® Humidity and Temperature Transmitter for Oil<strong>MMT162</strong> complies with the follow<strong>in</strong>g performance andenvironmental test standards:Electromagnetic CompatibilityEN 61326-1:1997 + Am1:1998, Electrical equipment formeasurement, control and laboratory use - EMC requirements -Industrial environment.CISPR16/22 Class B, EN/IEC 61000-4-2, EN/IEC 61000-4-3,EN/IEC 61000-4-4, EN/IEC 61000-4-5, EN/IEC 61000-4-6TrademarksHUMICAP ® is a registered trademark of Vaisala.Microsoft ® , W<strong>in</strong>dows ® , W<strong>in</strong>dows ® 2000, W<strong>in</strong>dows Server ® 2003,W<strong>in</strong>dows ® XP, and W<strong>in</strong>dows ® Vista are registered trademarks ofMicrosoft Corporation <strong>in</strong> the United States and/or other countries.License AgreementAll rights to any software are held by Vaisala or third parties. Thecustomer is allowed to use the software only to the extent that isprovided by the applicable supply contract or Software LicenseAgreement.8 ___________________________________________________________________ M210934EN-A

Chapter 1 ________________________________________________________ General InformationWarrantyVaisala hereby represents and warrants all Productsmanufactured by Vaisala and sold hereunder to befree from defects <strong>in</strong> workmanship or materialdur<strong>in</strong>g a period of twelve (12) months from the dateof delivery save for products for which a specialwarranty is given. If any Product proves however tobe defective <strong>in</strong> workmanship or material with<strong>in</strong> theperiod here<strong>in</strong> provided Vaisala undertakes to theexclusion of any other remedy to repair or at itsown option replace the defective Product or partthereof free of charge and otherwise on the sameconditions as for the orig<strong>in</strong>al Product or partwithout extension to orig<strong>in</strong>al warranty time.Defective parts replaced <strong>in</strong> accordance with thisclause shall be placed at the disposal of Vaisala.Vaisala also warrants the quality of all repair andservice works performed by its employees toproducts sold by it. In case the repair or serviceworks should appear <strong>in</strong>adequate or faulty andshould this cause malfunction or nonfunction of theproduct to which the service was performed Vaisalashall at its free option either repair or have repairedor replace the product <strong>in</strong> question. The work<strong>in</strong>ghours used by employees of Vaisala for such repairor replacement shall be free of charge to the client.This service warranty shall be valid for a period ofsix (6) months from the date the service measureswere completed.This warranty is however subject to follow<strong>in</strong>gconditions:a) A substantiated written claim as to any allegeddefects shall have been received by Vaisalawith<strong>in</strong> thirty (30) days after the defect or faultbecame known or occurred, andb) The allegedly defective Product or part shall,should Vaisala so require, be sent to the worksof Vaisala or to such other place as Vaisala may<strong>in</strong>dicate <strong>in</strong> writ<strong>in</strong>g, freight and <strong>in</strong>suranceprepaid and properly packed and labelled,unless Vaisala agrees to <strong>in</strong>spect and repair theProduct or replace it on site.This warranty does not however apply when thedefect has been caused througha) normal wear and tear or accident;b) misuse or other unsuitable or unauthorized useof the Product or negligence or error <strong>in</strong> stor<strong>in</strong>g,ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g or <strong>in</strong> handl<strong>in</strong>g the Product or anyequipment thereof;c) wrong <strong>in</strong>stallation or assembly or failure toservice the Product or otherwise followVaisala's service <strong>in</strong>structions <strong>in</strong>clud<strong>in</strong>g anyrepairs or <strong>in</strong>stallation or assembly or servicemade by unauthorized personnel not approvedby Vaisala or replacements with parts notmanufactured or supplied by Vaisala;d) modifications or changes of the Product as wellas any add<strong>in</strong>g to it without Vaisala's priorauthorization;e) other factors depend<strong>in</strong>g on the Customer or athird party.Notwithstand<strong>in</strong>g the aforesaid Vaisala's liabilityunder this clause shall not apply to any defectsaris<strong>in</strong>g out of materials, designs or <strong>in</strong>structionsprovided by the Customer.This warranty is expressly <strong>in</strong> lieu of and excludesall other conditions, warranties and liabilities,express or implied, whether under law, statute orotherwise, <strong>in</strong>clud<strong>in</strong>g without limitation any impliedwarranties of merchantability or fitness for aparticular purpose and all other obligations andliabilities of Vaisala or its representatives withrespect to any defect or deficiency applicable to orresult<strong>in</strong>g directly or <strong>in</strong>directly from the Productssupplied hereunder, which obligations andliabilities are hereby expressly cancelled andwaived. Vaisala's liability shall under nocircumstances exceed the <strong>in</strong>voice price of anyProduct for which a warranty claim is made, norshall Vaisala <strong>in</strong> any circumstances be liable for lostprofits or other consequential loss whether direct or<strong>in</strong>direct or for special damages.VAISALA_____________________________________________________________________ 9

USER´S GUIDE ___________________________________________________________________This page <strong>in</strong>tentionally left blank.10 _______________________________________________________________ M210934EN-A

Chapter 2 __________________________________________________________ Product OverviewCHAPTER 2PRODUCT OVERVIEWThis chapter <strong>in</strong>troduces the features, advantages, and the productnomenclature of Moisture and Temperature Transmitter for Oil<strong>MMT162</strong>.Introduction to <strong>MMT162</strong>The <strong>MMT162</strong> transmitter is a microprocessor based <strong>in</strong>strument for themeasurement of moisture <strong>in</strong> terms of water activity, for example <strong>in</strong> thelubrication of circulation systems or <strong>in</strong> transformer oil. The probe<strong>in</strong>corporates a capacitive th<strong>in</strong> film sensor. The operation of the sensoris based on changes <strong>in</strong> its capacitance as the th<strong>in</strong> polymer film absorbswater molecules.The <strong>MMT162</strong> transmitter is available with either metal or plastichous<strong>in</strong>g. The transmitter can be configured <strong>in</strong> many ways: two analogoutput signals can be scaled, the measurement ranges can be changedwith<strong>in</strong> certa<strong>in</strong> limits and there are two mechanical connection options,ISO and NPT 1/2. The <strong>MMT162</strong> probe is supplied with a three or fivemeter connection cable.The <strong>MMT162</strong> also provides for accurate temperature measurement. Itis an easy-to-<strong>in</strong>stall on-l<strong>in</strong>e probe which can be calibrated aga<strong>in</strong>st, forexample, traceable salt solutions.Table 3 Quantities Measured and Calculated by <strong>MMT162</strong>Quantity Abbreviation Metric Unit Non Metric UnitWater activityA wTemperature T °C °FMass concentration ofwater <strong>in</strong> oilppmVAISALA____________________________________________________________________ 11

USER´S GUIDE ___________________________________________________________________NOTEppm is only applicable to transformer oil.Vaisala HUMICAP ® Moisture and Temperature Transmitter for Oil<strong>MMT162</strong> provides reliable moisture measurement <strong>in</strong> wide range ofapplications. Analog outputs can be chosen between current andvoltage signals. Alternatively, digital output RS-485 comes asstandard.Basic Features and OptionsTransmitter Structure- Two analog outputs- Digital output: RS-485- USB connectivity for service connections via the optionalUSB M8 cable- Different cable lengths available- Available with two different thread options: ISO G1/2" andNPT 1/2"- Low ma<strong>in</strong>tenance requirements due to excellent long term stability- LED cable option that enables a visual alarm function- Field calibration possible with MM70- Two filter types available: sta<strong>in</strong>less steel grid filter and high flowsta<strong>in</strong>less steel grid filter (>> 1 m/s)The structure of the <strong>MMT162</strong> is shown <strong>in</strong> Figure 1 on page 13. Thetransmitter body does not have user serviceable parts <strong>in</strong>side, and is notdesigned to be opened. Open<strong>in</strong>g the transmitter will void the warranty.When the transmitter is delivered, the filter is protected by a yellowtransport protection cap. Remove the transport protection cap before<strong>in</strong>stall<strong>in</strong>g the transmitter.12 _______________________________________________________________ M210934EN-A

Chapter 2 __________________________________________________________ Product OverviewFigure 10805-007Moisture and Temperature Transmitter for Oil<strong>MMT162</strong>where1 = 4-p<strong>in</strong> M8 connector I: analog output channels and operat<strong>in</strong>gpower2 = 4-p<strong>in</strong> M8 connector II (shown with protective cap):digital output (RS-485) and operat<strong>in</strong>g power3 = 30 mm nut4 = HUMICAP ® sensor protected with sta<strong>in</strong>less steel grid filter5 = Connection thread: ISO G1/2" or NPT 1/2"VAISALA____________________________________________________________________ 13

USER´S GUIDE ___________________________________________________________________Typical ApplicationsMethod Used for Measur<strong>in</strong>gMoisture <strong>in</strong> OilThe <strong>MMT162</strong> transmitter measures water <strong>in</strong> oil <strong>in</strong> terms of wateractivity (aw) which can be determ<strong>in</strong>ed as follows: water activity<strong>in</strong>dicates the amount of water on the scale of 0 - 1 aw. In this scale, 0aw is an <strong>in</strong>dication of completely water free oil and 1 aw an <strong>in</strong>dicationof oil fully saturated with water. Water is present <strong>in</strong> free form.The most important feature which dist<strong>in</strong>guishes the measurement ofwater activity (aw) from the traditional measurement of absolute watercontent (<strong>in</strong> ppm) is that the saturation po<strong>in</strong>t rema<strong>in</strong>s stable regardlessof the oil type or the ag<strong>in</strong>g of oil, additives used etc. As water activityexceeds 0.9 aw <strong>in</strong> any system, there is a risk for segregation(especially if the temperature decreases).The water activity is used for alarm<strong>in</strong>g at the po<strong>in</strong>t of >0.9 aw that therisk for free water <strong>in</strong> the system is obvious. The most importantadvantages of this system are the fact that water activity is immune tothe ag<strong>in</strong>g of oil and to additives, and that the <strong>MMT162</strong> transmitter canbe used for cont<strong>in</strong>uous on-l<strong>in</strong>e measurements. In addition, the<strong>MMT162</strong> can be calibrated aga<strong>in</strong>st salt solutions and no reference oilsare needed.NOTETo avoid self-heat<strong>in</strong>g of the probe and consequential measurementerrors, make sure there is some flow <strong>in</strong> the application process.Lubrication OilIn many <strong>in</strong>dustrial plants, like paper mills, hydro power plants andoff-shore w<strong>in</strong>d turb<strong>in</strong>es, there is a certa<strong>in</strong> amount of free moistureconstantly present. This means that there is a high risk of the freemoisture becom<strong>in</strong>g <strong>in</strong>to contact with the mach<strong>in</strong>e bear<strong>in</strong>gs. The mostcommon reasons for the entrance of water are <strong>in</strong>adequate seal<strong>in</strong>g ofthe hous<strong>in</strong>g or moisture absorbtion from ambient air. Accidentalleakages from oil coolers and other equipment can also cause damage.Free water <strong>in</strong> lubrication oil prevents oil from form<strong>in</strong>g a uniform layeron the metal surfaces and thus deteriorat<strong>in</strong>g its lubrication properties.14 _______________________________________________________________ M210934EN-A

Chapter 2 __________________________________________________________ Product OverviewThis can cause, for example, spot heat<strong>in</strong>g, cavitation, corrosion andmicro pitt<strong>in</strong>g. Free water also ru<strong>in</strong>s additives like AW (antiwear) andEP (extreme pressure). Note that bear<strong>in</strong>gs should never be exposed tooils that have high water content; this is also important dur<strong>in</strong>gstandstill because the risk for corrosion <strong>in</strong>creases as the oiltemperature decreases. It is essential to monitor the water content andto keep it on a suitable level, mean<strong>in</strong>g below saturation.When measur<strong>in</strong>g the water content of oil, it is best to measure thewater activity before an oil reservoir and from a pressure l<strong>in</strong>e flow.This way the performance of dehumidifiers can be kept under controlto ensure that no free water reaches the bear<strong>in</strong>gs.Transformer OilThe determ<strong>in</strong>ation of moisture <strong>in</strong> oil is an essential part of acomprehensive transformer ma<strong>in</strong>tenance program. Ag<strong>in</strong>g anddeterioration <strong>in</strong>crease the capacity of oil to absorb water. The primary<strong>in</strong>terest <strong>in</strong> transformers is to measure the water not <strong>in</strong> oil but <strong>in</strong> thecellulosic <strong>in</strong>sulation around the transformer w<strong>in</strong>d<strong>in</strong>gs. Heat<strong>in</strong>g andcool<strong>in</strong>g have a considerable effect on moisture levels <strong>in</strong> oil. Whiletemperature raises, the paper <strong>in</strong>sulation of transformers tends to loosemoisture which is absorbed by the oil surround<strong>in</strong>g it. Saturation levelis thus a true <strong>in</strong>dicator of moisture present. The <strong>MMT162</strong> methodprovides for a reliable detection of the ag<strong>in</strong>g of oil and possibleleakages.Oil immersed transformers rely on the oil for cool<strong>in</strong>g, protection fromcorrosion and as an important component of their <strong>in</strong>sulation.Excessive moisture contents <strong>in</strong> oil causes accelerated age<strong>in</strong>g of the<strong>in</strong>sulation materials and reduces their dielectric strength. In extremecases this can result <strong>in</strong> arc<strong>in</strong>g and short circuits with<strong>in</strong> the w<strong>in</strong>d<strong>in</strong>gs.Accurate moisture measurements can also warn about leaks <strong>in</strong> the oilsystem, as water is absorbed from the surround<strong>in</strong>g air.Heat<strong>in</strong>g and cool<strong>in</strong>g of a transformer effect moisture levels <strong>in</strong> oil. Thisis due to the fact that the water solubility of oil is temperaturedependent. In general, water solubility <strong>in</strong>creases as temperature raises,see Figure 2 on page 16 below. Changes <strong>in</strong> temperature affect also onwater desorption of the paper <strong>in</strong>sulation around the transformerw<strong>in</strong>d<strong>in</strong>gs. Desorption of water from the <strong>in</strong>sulation <strong>in</strong>creases astemperature raises and the surrounded oil absorbs desorbed water.Moisture level <strong>in</strong> oil is thus a true <strong>in</strong>dicator of moisture present <strong>in</strong> thepaper <strong>in</strong>sulation.VAISALA____________________________________________________________________ 15

USER´S GUIDE ___________________________________________________________________In addition, it must be noted that capacity of oil to absorb waterdepends both on the chemical structure of the oil and the additives.WATER SOLUBILITY IN MINERAL TRANSFORMER OIL100001000average watersolubility100range ofvariation due tooil typerange ofvariation due tooil type100 10 20 30 40 50 60 70 80 90 100Temperature (°C)Figure 2The Water Solubility of Transformer Oils versusTemperature0510-029The marg<strong>in</strong>s show the range of variation of water solubility found <strong>in</strong>m<strong>in</strong>eral oils.16 _______________________________________________________________ M210934EN-A

Chapter 3 _______________________________________________________________ InstallationCHAPTER 3INSTALLATIONThis chapter provides you with <strong>in</strong>formation that is <strong>in</strong>tended to helpyou <strong>in</strong>stall the <strong>MMT162</strong>.Install<strong>in</strong>g the TransmitterAfter select<strong>in</strong>g a suitable measurement location, follow the procedurebelow to <strong>in</strong>stall the transmitter:1. Remove the yellow transport protection cap from thetransmitter.Figure 3Remov<strong>in</strong>g the Transportation Protection Cap0805-0052. Prepare the seal<strong>in</strong>g of the connection:- If the transmitter has a parallel ISO G1/2" thread, place theseal<strong>in</strong>g r<strong>in</strong>g at the base of the thread. Always use a newseal<strong>in</strong>g r<strong>in</strong>g; do not re-use a previously <strong>in</strong>stalled one.- If the transmitter has an NPT 1/2" thread, do not use theseal<strong>in</strong>g r<strong>in</strong>g. Instead, apply PTFE tape or suitable pastesealant to the thread. Follow the application <strong>in</strong>structions ofthe sealant.3. Make sure that the threads on the mount<strong>in</strong>g po<strong>in</strong>t are of thecorrect type, and fasten the transmitter to the measurementVAISALA____________________________________________________________________ 17

USER´S GUIDE ___________________________________________________________________po<strong>in</strong>t. Use your hands to turn the probe until it feels tight. Donot use force at this po<strong>in</strong>t, and check that the seal<strong>in</strong>g r<strong>in</strong>g(if used) rema<strong>in</strong>s centered.Figure 4Install<strong>in</strong>g the Transmitter0805-0064. Use a 30mm wrench to tighten the connection to 25 N m, asshown <strong>in</strong> Figure 4 above. If you do not have a 30mm wrench,use a 1 3/16” wrench or an adjustable wrench <strong>in</strong>stead.CAUTIONOnly tighten the probe from the 30mm nut. Do NOT apply force toother po<strong>in</strong>ts <strong>in</strong> the probe body.5. Connect the wires of the connection cable.Figure 5Connect<strong>in</strong>g the Cable0710-1306. Plug <strong>in</strong> the cable to the transmitter. Be sure to use the correctconnector; refer to section Wir<strong>in</strong>g on page 19.18 _______________________________________________________________ M210934EN-A

Chapter 3 _______________________________________________________________ Installation7. Cover the unused connector on the transmitter with the rubberplug that is attached to the transmitter.Wir<strong>in</strong>gP<strong>in</strong> I II Wire Colour1 Vcc Vcc Brown2 Analog output 1 RS-485 B White3 GND GND Blue4 Analog output 2 / LED RS-485 A BlackFigure 60707-035Connectors I and IIFigure 7Connector P<strong>in</strong>out0707-036VAISALA____________________________________________________________________ 19

USER´S GUIDE ___________________________________________________________________Connection CablesThe follow<strong>in</strong>g connection cable options are available for <strong>MMT162</strong>:- Unshielded cable with M8 female straight snap-on connector- Shielded cables with M8 female straight threaded connector- Shielded cables with M8 female 90° angle threaded connector- LED cable- USB serial <strong>in</strong>terface cableFigure 8, Figure 9, Figure 12 and Figure 10 below show the differentcable options that are available.Figure 80510-036Cable with Snap-On ConnectorFigure 90510-037Cable with Threaded Connector20 _______________________________________________________________ M210934EN-A

Chapter 3 _______________________________________________________________ InstallationFigure 10Cable with 90° Angle Threaded Connector0809-004Figure 11LED Cable0809-003VAISALA____________________________________________________________________ 21

USER´S GUIDE ___________________________________________________________________Figure 12USB Serial Interface Cable0809-002For the cable order codes, see section Spare Parts and Accessories onpage 65.Power Supply RequirementsThe <strong>MMT162</strong> transmitters are designed to operate with a supplyvoltage of 14 … 24 VDC.The power supply should ma<strong>in</strong>ta<strong>in</strong> the voltage for all load conditions.Current consumption dur<strong>in</strong>g normal measurement is 20 mA + loadcurrent. For more specific <strong>in</strong>formation, see chapter Technical data onpage 63.22 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationCHAPTER 4OPERATIONThis chapter conta<strong>in</strong>s <strong>in</strong>formation that is needed to operate thisproduct.Gett<strong>in</strong>g Started<strong>MMT162</strong> is ready to be used once it has been connected to a powersource.Analog Output Operation ModesThe <strong>MMT162</strong> has two analog output channels. These channels canfunction <strong>in</strong> two different modes, which can be set <strong>in</strong>dividually for bothchannels:1. Normal operation mode2. Limit alarm modeWhen the transmitter is ordered from Vaisala, the modes areconfigured as specified <strong>in</strong> the order form. You can change theoperation sett<strong>in</strong>gs after delivery by us<strong>in</strong>g serial commands and theUSB cable accessory.VAISALA____________________________________________________________________ 23

USER´S GUIDE ___________________________________________________________________Normal Operation Mode andMalfunction AlarmIn the normal operation mode, a channel outputs voltage or currentthat corresponds to the read<strong>in</strong>g of the selected quantity.If the transmitter is malfunction<strong>in</strong>g, the channel output is set to a predef<strong>in</strong>edlevel. This level can be changed us<strong>in</strong>g the AERR command;see page 37.NOTEThe malfunction alarm overrides the limit alarm mode. If thetransmitter is malfunction<strong>in</strong>g, the analog outputs are always set to thelevels specified with the AERR command.Limit AlarmThe limit alarm is activated when the measured quantity goes belowthe low limit, or above the high limit. The alarm levels and limits areconfigurable us<strong>in</strong>g the ALARM command (see page 37). By default,the alarm levels are set as follows:- For current output, an active alarm is <strong>in</strong>dicated by the currentbe<strong>in</strong>g at the maximum of the scale (20 mA).- For voltage output, an active alarm is <strong>in</strong>dicated by the voltagebe<strong>in</strong>g at the maximum of the selected scale. For example, if thevoltage output scale is 0 … 5 V, an output of 5 V <strong>in</strong>dicates thealarm is active.- For LED alarm, an active alarm is <strong>in</strong>dicated by a lit LED. Whenthe alarm status is low, the LED is not lit. If the transmitter ismalfunction<strong>in</strong>g or it cannot measure for some reason, this causesthe LED to bl<strong>in</strong>k at 0.5 Hz frequency.LED alarm <strong>in</strong>dicator is <strong>in</strong>tegrated to a LED cable (Vaisala itemMP300LEDCBL) that can be ordered and used <strong>in</strong>stead of a regularconnection cable.24 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationSerial CommunicationConnect<strong>in</strong>g to Serial InterfaceThe <strong>MMT162</strong> can be connected to a PC us<strong>in</strong>g the RS-485 l<strong>in</strong>e,for example us<strong>in</strong>g the USB serial connection cable (Vaisala item219690). The cable also provides operation power to the transmitterfrom the USB port. It is OK to connect the USB serial connectioncable even if the transmitter is already supplied with operation powerfrom another cable.To connect to serial <strong>in</strong>terface:1. If you have not used the <strong>MMT162</strong> USB serial connection cablebefore, <strong>in</strong>stall the driver that came with the cable. Refer tosection Install<strong>in</strong>g the Driver for the USB Cable on page 26 fordetailed <strong>in</strong>structions.2. Connect the USB serial connection cable between your PC andthe RS-485 port of the <strong>MMT162</strong> (port II).3. Open the term<strong>in</strong>al program (e.g. PuTTY <strong>in</strong> MicrosoftW<strong>in</strong>dows ® ).4. Set the serial sett<strong>in</strong>gs of the term<strong>in</strong>al program, and open theconnection. See the follow<strong>in</strong>g table.Table 4 Default Serial Interface Sett<strong>in</strong>gsPropertyDescription / ValueBaud rate 19200ParitynoneData bits 8Stop bits 1NOTEIn case the transmitter starts up <strong>in</strong> an error state, the serial <strong>in</strong>terfacesett<strong>in</strong>gs are automatically returned to the default sett<strong>in</strong>gs given <strong>in</strong>Table 4 above.VAISALA____________________________________________________________________ 25

USER´S GUIDE ___________________________________________________________________Install<strong>in</strong>g the Driver for the USBCableBefore tak<strong>in</strong>g the USB cable <strong>in</strong>to use, you must <strong>in</strong>stall the providedUSB driver on your PC. When <strong>in</strong>stall<strong>in</strong>g the driver, you mustacknowledge any security prompts that may appear. The driver iscompatible with W<strong>in</strong>dows ® 2000, W<strong>in</strong>dows ® XP, W<strong>in</strong>dows Server ®2003, and W<strong>in</strong>dows ® Vista.1. Check that the USB cable is not connected. Disconnect the cableif you have already connected it.2. Insert the media that came with the cable, or download thedriver from www.vaisala.com.3. Execute the USB driver <strong>in</strong>stallation program (setup.exe), andaccept the <strong>in</strong>stallation defaults. The <strong>in</strong>stallation of the drivermay take several m<strong>in</strong>utes.4. After the driver has been <strong>in</strong>stalled, connect the USB cable to aUSB port on your PC. W<strong>in</strong>dows will detect the new device, anduse the driver automatically.5. The <strong>in</strong>stallation has reserved a COM port for the cable. Verifythe port number, and the status of the cable, us<strong>in</strong>g the VaisalaUSB Instrument F<strong>in</strong>der program that has been <strong>in</strong>stalled <strong>in</strong> theW<strong>in</strong>dows Start menu.W<strong>in</strong>dows will recognize each <strong>in</strong>dividual cable as a different device,and reserve a new COM port. Remember to use the correct port <strong>in</strong> thesett<strong>in</strong>gs of your term<strong>in</strong>al program. If you are us<strong>in</strong>g the Vaisala MI70L<strong>in</strong>k application, you do not need to check the COM port, as the MI70L<strong>in</strong>k detects the USB connection automatically.There is no reason to un<strong>in</strong>stall the driver for normal use. However, ifyou wish to remove the driver files and all Vaisala USB cable devices,you can do so by un<strong>in</strong>stall<strong>in</strong>g the entry for Vaisala USB InstrumentDriver from the Add or Remove Programs (Programs andFeatures <strong>in</strong> W<strong>in</strong>dows Vista) <strong>in</strong> the W<strong>in</strong>dows Control Panel.26 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationTerm<strong>in</strong>al Program Sett<strong>in</strong>gsThe default sett<strong>in</strong>gs of the <strong>MMT162</strong> serial <strong>in</strong>terface are presented <strong>in</strong>Table 4 on page 25. If the sett<strong>in</strong>gs of your <strong>MMT162</strong> have beenchanged and you do not know what they are, refer to section RestoreFactory Sett<strong>in</strong>gs on page 44.The steps below describe how to connect to the <strong>MMT162</strong> us<strong>in</strong>g thePuTTY term<strong>in</strong>al application for W<strong>in</strong>dows (available for download atwww.vaisala.com) and a USB serial <strong>in</strong>terface cable:1. Connect the USB serial <strong>in</strong>terface cable between your PC and theRS-485 port of the <strong>MMT162</strong> (port II).2. Start the PuTTY application.3. Select the Serial sett<strong>in</strong>gs category, and check that the correctCOM port is selected <strong>in</strong> the Serial l<strong>in</strong>e to connect to field.Note: You can check which port the USB cable is us<strong>in</strong>g with theVaisala USB Instrument F<strong>in</strong>der program that has been<strong>in</strong>stalled <strong>in</strong> the W<strong>in</strong>dows Start menu.4. Check that the other serial sett<strong>in</strong>gs are correct for yourconnection, and change if necessary. Flow control should be setto None unless you have a reason to change it.5. Click the Open button to open the connection w<strong>in</strong>dow and startus<strong>in</strong>g the serial l<strong>in</strong>e.Note: If PuTTY is unable to open the serial port you selected, itwill show you an error message <strong>in</strong>stead. If this happens, restartPuTTY and check the sett<strong>in</strong>gs.6. You may need to adjust the Local echo sett<strong>in</strong>g <strong>in</strong> the Term<strong>in</strong>alcategory to see what you are typ<strong>in</strong>g on the serial l<strong>in</strong>e. To accessthe configuration screen while a session is runn<strong>in</strong>g, click theright mouse button over the session w<strong>in</strong>dow, and select ChangeSett<strong>in</strong>gs... from the pop-up menu.VAISALA____________________________________________________________________ 27

USER´S GUIDE ___________________________________________________________________Figure 13PuTTY Term<strong>in</strong>al Application0807-00428 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationList of Serial CommandsThe bold text <strong>in</strong> the brackets is the default sett<strong>in</strong>g. To issue acommand, type it on your computer and press the Enter key.Table 5Serial L<strong>in</strong>e CommandsCommandDescription? Output <strong>in</strong>formation about the device?? Output <strong>in</strong>formation about the device <strong>in</strong>POLL modeACALAnalog output calibrationADDR [0 ... 99]Set the transmitter address (for POLLmode)AERRChange the analog error output valuesALARMSet analog output limit alarm modesAMODEView the analog output modesAOVER [ON/OFF]Allow analog outputs to exceed their range10%ASELSelect the parameters for the analogoutputsATESTSet and display current output valuesCLOSEClose the temporary connection (Back toPOLL mode)CRHRelative humidity calibrationCTTemperature calibrationERRSList present transmitter errorsFORMSet the output format of SEND and RcommandsFRESTORERestore factory sett<strong>in</strong>gsHELPList the most common commandsINTV [0 ... 255 S/MIN/H] Set the cont<strong>in</strong>uous output <strong>in</strong>terval(for RUN mode)LEDSet voltage for LED alarmOILDisplay oil parametersOILISet new oil parametersOPEN [0 ... 99]Open a temporary connection to a POLLmode deviceRStart the cont<strong>in</strong>uous outputt<strong>in</strong>gRESETReset the transmitterSStop the cont<strong>in</strong>uous outputt<strong>in</strong>gSDELAYView or set user port (RS-485) answerm<strong>in</strong>imum delaySEND [0 ... 99]Output the read<strong>in</strong>g onceSERI [baud p d s] User Port sett<strong>in</strong>gs (Default: 4800 E 7 1)baud: 300 ... 115200SMODESet the serial <strong>in</strong>terface mode[STOP/RUN/POLL]UNIT [M/N]Select the metric or non-metric output unitsVERSDisplay the software version <strong>in</strong>formationVAISALA____________________________________________________________________ 29

USER´S GUIDE ___________________________________________________________________Device Information and StatusShow Device InformationThe ? command outputs a list<strong>in</strong>g of device <strong>in</strong>formation. If you wish todisplay the list<strong>in</strong>g for all devices on the current serial l<strong>in</strong>e, issue thecommand ??.???Example:>?<strong>MMT162</strong> 0.92Serial number : G0000002Batch number : D0720012Module number : ????????Sensor number : C6010000Sensor model : Humicap L2Cal. date : YYYYMMDDCal. <strong>in</strong>fo : NONETime : 00:21:19Serial mode : STOPBaud P D S : 4800 E 7 1Output <strong>in</strong>terval: 2 SSerial delay : 0Address : 0Pressure : 1.0132 barFilter : 0.800Ch1 output : 0 ... 20 mACh2 output : 0 ... 20 mACh0 error out : 0.000 mACh1 error out : 0.000 mACh0 aw lo : 0.00Ch0 aw hi : 1.00Ch1 T lo : -20.00 'CCh1 T hi : 80.00 'CShow Firmware VersionUse the VERS command to display software version <strong>in</strong>formation.Example:vers<strong>MMT162</strong> 1.0230 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationConfigur<strong>in</strong>g Serial L<strong>in</strong>e OperationSet Serial L<strong>in</strong>e Sett<strong>in</strong>gsUse the serial l<strong>in</strong>e command SERI [b p d s] to set communicationsett<strong>in</strong>gs for the user port.SERI [b p d s]whereb = Bit rate (110, 150, 300, 600, 1200, 2400, 4800, 9600,19200,38400)p = Parity (n = none, e = even, o = odd)d = Data bits (7 or 8)s = Stop bits (1 or 2)Example:>SERI 600 N 8 1600 N 8 1>You need to reset the transmitter to activate the new communicationsett<strong>in</strong>gs set with the SERI command.The sett<strong>in</strong>gs can be changed one parameter at a time or all parametersat once:>SERI O4800 O 7 1>SERI 600 N 8 1600 N 8 1>chang<strong>in</strong>g parity onlychang<strong>in</strong>g all parametersYou can use the SERI command to change/view the user port sett<strong>in</strong>gseven if you are currently connected to the service port.VAISALA____________________________________________________________________ 31

USER´S GUIDE ___________________________________________________________________Set Serial L<strong>in</strong>e Response TimeWith the SDELAY command, you can set delay (response time) foruser port RS-485, or view currently set delay value. Valuecorresponds to tens of milliseconds (for example 5 = 0.050s m<strong>in</strong>imumanswer delay). The value can be set between 0...255.Example:>sdelaySerial delay : 0 ? 10>sdelaySerial delay : 10 ?Set Transmitter AddressAddresses are required only for POLL mode (see Set Serial InterfaceMode on page 34). Use the ADDR command to <strong>in</strong>put the RS-485transmitter address.ADDR [aa]whereaa = address (0 ... 99) (default = 0)Example: the transmitter is configured to address 99.>ADDRAddress : 2 ? 99>Format Measurement OutputUse the serial l<strong>in</strong>e command FORM to change the format or select acerta<strong>in</strong> quantities for the output commands SEND and R.FORM [x]wherex = Formatter str<strong>in</strong>g32 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationFormatter str<strong>in</strong>g consists of quantities and modifiers. The <strong>MMT162</strong>measures the follow<strong>in</strong>g quantities:- water activity (aw)- temperature (T) (metric unit: ºC, non metric unit:ºF)- ppm for transformer oil only (H 2 O)When select<strong>in</strong>g the quantity, use the abbreviations of the quantities.The modifiers are presented <strong>in</strong> Table 6 on page 33 below.Table 6 ModifiersModifier Descriptionx.yLength modifier (number of digits and decimal places)#t Tabulator#r Carriage-return#n L<strong>in</strong>e feed“” Str<strong>in</strong>g constant#xxx Special character, code "xxx" (decimal), for example#027 for ESCU5Unit field and length (optional)Example:>form "aw=" 6.4 aw #t "t=" 6.2 t #r#n1>>sendaw= 0.2644 t= 25.50>>form "Oil ppm= " h2o " " u3 #r#n>sendOil ppm= 16.6 ppm>Command FORM / will return the default output format. The defaultoutput format depends on the device configuration.>form />sendaw= 0.087 T= 24.0 'C>VAISALA____________________________________________________________________ 33

USER´S GUIDE ___________________________________________________________________Select UnitUse the UNIT command to select metric or non-metric output units:UNIT [x]wherex = M or NwhereM = Metric unitsN = Non-metric unitsSet Serial Interface ModeUse the SMODE command to set the default serial <strong>in</strong>terface mode.SMODE [xxxx]wherexxxx = STOP, RUN or POLLIn STOP mode: measurements output only by command SEND, allcommands can be usedIn RUN mode: outputt<strong>in</strong>g automatically, only command S can beused to stop.In POLL mode: measurements output only with command SEND[addr].When several transmitters are connected to the same l<strong>in</strong>e, eachtransmitter must be entered an own address <strong>in</strong> the <strong>in</strong>itial configuration,and POLL mode must be used.34 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationConfigur<strong>in</strong>g Measurement ParametersSelect Analog Output Quantity andScal<strong>in</strong>gSelect and scale the quantities for the analog outputs with the ASELcommand. Note that the optional quantities can be selected only ifthey have been selected when order<strong>in</strong>g the device.ASEL [xxx yyy]wherexxx = Quantity of channel 1yyy = Quantity of channel 2Always enter all the quantities for all outputs. The <strong>MMT162</strong> measuresthe follow<strong>in</strong>g quantities:- water activity (aw)- temperature (T) (metric unit: ºC, non metric unit:ºF)- ppm for transformer oil only (H 2 O)Example:aselCh0 aw lo : 0.00 ?Ch0 aw hi : 1.00 ?Ch1 T lo : -20.00 'C ?Ch1 T hi : 80.00 'C ?VAISALA____________________________________________________________________ 35

USER´S GUIDE ___________________________________________________________________Set Analog Output Mode (mA/V)The AMODE command can be used to change the analog outputmode of channels 1 and 2. When used without parameters it displaysthe current sett<strong>in</strong>gs and with parameters new sett<strong>in</strong>gs can be set. Theavailable parameters are listed <strong>in</strong> Table 7 on page 36 below.Table 7 Analog Output ModesParameterOutput mode1 0 … 20 mA2 4 … 20 mA3 0 … 1 V4 0 … 5 V5 0 … 10 V6 LED alarm7 Current alarm8 Voltage alarmExample:amode 1 2Ch1 outputCh2 output: 0 ... 20 mA: 4 ... 20 mACalibrate Analog OutputUse the ACAL command to adjust analog output channels. To adjustchannel 1, use parameter 1 and to adjust channel 2, use parameter 2 as<strong>in</strong> the example below.After enter<strong>in</strong>g the ACAL command, use a calibrated current/voltagemeter to measure the output, and enter the values.Example (current outputs):acal 1Ch1 U1 ( V ) ? 1.001Ch1 U2 ( V ) ? 9.011acal 2Ch2 U1 ( V ) ? 0.0988Ch2 U2 ( V ) ? 0.899736 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationSet Malfunction Alarm Output forAnalog ChannelsUse the AERR command to set the analog output levels that areoutput <strong>in</strong> case of a device malfunction. The default output level is 0.AERRExample:aerrCh1 error out : 10.000V ? 0Ch2 error out : 1.000V ? 0NOTEThe error output value must be with<strong>in</strong> a valid range of the outputmode.NOTEThe error output value is displayed only when there are m<strong>in</strong>orelectrical faults such as a humidity sensor damage. When there is asevere device malfunction, the error output value is not necessarilyshown.Set Alarm Limits for AnalogOutputs / LED IndicationUse the ALARM command to set the analog output alarm limits andquantities. For an explanation of the alarm limits, see section LimitAlarm on page 24.ALARMBefore sett<strong>in</strong>g the alarm limits, verify the currently set analog outputmodes us<strong>in</strong>g the AMODE command.The follow<strong>in</strong>g example shows that a high limit alarm has been enabledfor channel 2. If the measured value rises above the limit ( 0.90 a w ), anerror is reported. If you are us<strong>in</strong>g a LED cable, the LED lights up to<strong>in</strong>dicate an error state.VAISALA____________________________________________________________________ 37

USER´S GUIDE ___________________________________________________________________Example:alarm ?Channel 1:Low Limit : OFFHigh Limit : OFFAerr : ONQuantity : TLimit Lo : 15.00Limit Hi : 30.00Hysteresis : 0.50Level Lo : 0.20Level Hi : 0.80Channel 2:Low Limit : OFFHigh Limit : ONAerr : OFFQuantity : awLimit Lo : 0.10Limit Hi : 0.90Hysteresis : 0.01Level Lo : 0.20Level Hi : 0.80Set Voltage for LED AlarmWith the LED command, you can set a different voltage level for eachchannel.Example:led ?Ch 1 Led Voltage : 2.80 VCh 2 Led Voltage : 2.80 VExtend Analog Output RangeUse the AOVER command to allow the analog output channels toexceed their specified range by 10%. The scal<strong>in</strong>g of the quantityrema<strong>in</strong>s as before; the extra range is used for additional measurementrange <strong>in</strong> the wet end.AOVER [ON/OFF]Example:>aover on: ON>38 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationSerial L<strong>in</strong>e Output CommandsStart Measurement OutputUse the R command to start the cont<strong>in</strong>uous outputt<strong>in</strong>g of measurementvalues as an ASCII text str<strong>in</strong>g to the serial l<strong>in</strong>e. The format of themeasurement message is set with the FORM command.RExample:>raw= 0.261 T= 23.8 'C H2O= 15 ppm>You can change the format of the output with the follow<strong>in</strong>gcommands:- Outputt<strong>in</strong>g <strong>in</strong>terval can be changed with the INTV command.- Output message format can be changed with the FORM command.Stop Measurement OutputUse the S command to end the RUN mode. After this command allother commands can be used. You can also press the Esc button orreset the transmitter to stop the outputt<strong>in</strong>g.SSee SMODE command on page 34 to change the default (power-up)operation mode.VAISALA____________________________________________________________________ 39

USER´S GUIDE ___________________________________________________________________Set Output IntervalUse the INTV command to set or display the output <strong>in</strong>terval.INTV [n xxx]wheren = time <strong>in</strong>terval = 0 ... 255xxx = time unit = "S", "MIN", or "H"Example:><strong>in</strong>tv 1 m<strong>in</strong>Output <strong>in</strong>terval:>1 MINThe shortest output <strong>in</strong>terval (with n = 0) is approximately one seconddue to the <strong>in</strong>ternal measurement cycle.Output Read<strong>in</strong>g OnceUse the SEND command to output the read<strong>in</strong>g once <strong>in</strong> STOP mode.The output format depends on which parameters the transmitter canoutput.SEND [aa]whereaa = Transmitter address (0 ... 99). Must be specified if thetransmitter is <strong>in</strong> POLL mode, and a l<strong>in</strong>e has not been openedus<strong>in</strong>g the OPEN command.Example:>SENDT= 25.2 'C aw= 0.299 H2O= 19 ppm RS= 29.9 %>40 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationTroubleshoot<strong>in</strong>g CommandsDisplay the Currently Active ErrorsUse the ERRS command to display the currently active transmittererror states. Possible errors and their causes are listed <strong>in</strong> Table 8 onpage 51.ERRSExample:>errsNo errors>Test Analog OutputsThe operation of the analog outputs can be tested with the ATESTcommand by forc<strong>in</strong>g the output to a given value which can then bemeasured with calibrated multimeter. The command uses the currentlyselected analog output types for the channels (voltage or current) soyou do not have to specify the unit.Before test<strong>in</strong>g, you can verify the currently set analog output modesus<strong>in</strong>g the AMODE command. After test<strong>in</strong>g the output, give theATEST command aga<strong>in</strong> to exit the test mode.ATEST [xxx yyy]Wherexxx = Channel 1 output value (V or mA)yyy = Channel 2 output value (V or mA)The output shows the test values of the analog channels, anddiagnostic <strong>in</strong>formation that may be useful to Vaisala Service if there isa problem with the analog outputs.VAISALA____________________________________________________________________ 41

USER´S GUIDE ___________________________________________________________________Example:>atest 1 151.00 266015.00 19425>>atest0.00 790.00 20110>Other CommandsOpen<strong>in</strong>g the Transmitter <strong>in</strong> POLLModeUse the OPEN command to connect to a transmitter that is <strong>in</strong> POLLmode.OPEN [aa]whereaa = address (0 ... 99)Example:open 0<strong>MMT162</strong>0 l<strong>in</strong>e opened for operator commandsClos<strong>in</strong>g the Connection to aTransmitter <strong>in</strong> POLL ModeThe CLOSE command closes the connection to the transmitter.CLOSEExample:>closel<strong>in</strong>e closed>42 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationDisplay Command ListUse the HELP command to list the available commands.HELPExample:help???ACALADDRADJDAERRALARMAMODEAOVERASELATESTCDATECLOSECRHCTCTEXTERRSFILTFORMFRESTOREHELPINTVLLEDOILOILIOPENPCOMPPRESRRESETSDELAYSENDSERISMODEUNITVAISALA____________________________________________________________________ 43

USER´S GUIDE ___________________________________________________________________Reset TransmitterWhen the RESET command is given, the transmitter will restart as ifit had just been powered on. All transmitter sett<strong>in</strong>gs are reta<strong>in</strong>ed. Theserial l<strong>in</strong>e mode of the transmitter will be set to the mode that was setus<strong>in</strong>g the SMODE command.RESETRestore Factory Sett<strong>in</strong>gsUse the FRESTORE command to restore the factory sett<strong>in</strong>gs to thetransmitter. All user sett<strong>in</strong>gs will be lost.FRESTOREppm Conversion<strong>MMT162</strong> ppm Conversion forTransformer OilsTraditionally, moisture <strong>in</strong> transformer oil is measured by us<strong>in</strong>g ppmunits. The ppm output shows the average mass concentration of water<strong>in</strong> oil.The moisture and temperature transmitter <strong>MMT162</strong> has an option forppm-output provided that this has been notified when plac<strong>in</strong>g theorder for the transmitter. Vaisala has this conversion readily availablefor m<strong>in</strong>eral transformer oils.44 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationConversion Model with AverageCoefficientsThe conversion model of the <strong>MMT162</strong> is based on the average watersolubility behaviour of transformer oils. The ppm-output is calculatedas follows:((A/T+273.16)+B)ppm = aw x10Where:aw = water activityA,B = coefficients (average/oil-specific)T = temperature (ºC)Generally, measurements with <strong>MMT162</strong> give accuracy better than 10% of the read<strong>in</strong>g. If additional accuracy is needed, refer to sectionConversion Model with Oil-specific Coefficients below.Conversion Model with Oil-specificCoefficientsFor additional accuracy, oil-specific conversion model can be usedboth for m<strong>in</strong>eral and silicon based oils. An oil sample has to be sent toVaisala for modell<strong>in</strong>g. As a result, the specific coefficients (A and B,see formula 1) for the transformer oil are determ<strong>in</strong>ed by Vaisala. Foradditional <strong>in</strong>formation, please contact Vaisala.The determ<strong>in</strong>ed coefficients of the transformer oil can be programmedto the <strong>MMT162</strong> by Vaisala or by a user accord<strong>in</strong>g to the <strong>in</strong>structionspresented <strong>in</strong> this chapter.NOTEConversion model with oil-specific coefficients is always needed forsilicone based oils.VAISALA____________________________________________________________________ 45

USER´S GUIDE ___________________________________________________________________Sett<strong>in</strong>g Oil Coefficients Us<strong>in</strong>gSerial L<strong>in</strong>eIf the ppm conversion and oil-specific coefficients have beenprogrammed at Vaisala, you do not have to set the conversion coefficients.If you have def<strong>in</strong>ed the coefficients or separately received fromVaisala the oil-specific coefficients A and B, related to your own oiltype, the coefficients can be set to the software of <strong>MMT162</strong> by us<strong>in</strong>gserial l<strong>in</strong>e.OILUse the serial l<strong>in</strong>e command OIL to display oil-specific parametersfor ppm conversion. With OILI command you can set new oilparameters.Example:oilOil[0] : -1.66269994E+03Oil[1] : 7.36940002E+00Oil[2] : 0.00000000E+00whereOil [0]Oil [1]Oil [2]corresponds to parameter Acorresponds to parameter BCorresponds to parameter CDeterm<strong>in</strong>ation of Oil-SpecificCoefficientsThe equation of the ppm calculation is:ppm = aw*10 (B+A/T)With the follow<strong>in</strong>g procedure the coefficients A and B can be def<strong>in</strong>edfor the equation:LOG(PPM sat )= B + A/T46 _______________________________________________________________ M210934EN-A

Chapter 4 ________________________________________________________________ OperationEquipment needed:- Apparatus for determ<strong>in</strong><strong>in</strong>g water content ( for example,coulometric titrator and e.g. magnetic stirrer.)- Oil test station:- a temperature test chamber- for example, a conical flask (1L) sealed by PTFE stopperwith an <strong>in</strong>let for a moisture probe- <strong>MMT162</strong> by Vaisala- magnetic stirrer.Procedure:1. Def<strong>in</strong>e the water content of the oil sample with the titration. Usethe oil moisture level that is close to real conditions <strong>in</strong> theprocess.2. Measure the water activity of this sample with <strong>MMT162</strong> at twotemperatures that differ at least 20 °C. Follow the measurementstabilization illustrated by the graph.NOTEThe sample has to be sealed very carefully i.e. not to be <strong>in</strong> contactwith ambient air, which would change the water content.NOTEIf the oil sample is very dry and the temperatures are close to eachother, it may cause <strong>in</strong>accuracy to the calculation model. In order toget the best possible performance it is recommended to use oilconditions that represent real conditions <strong>in</strong> application.Recommended values for sample are aw approx. 0.5 at 20 °C.3. Def<strong>in</strong>e the correlation between aw, T and PPM (w/w) from themeasured values. Calculate A and B accord<strong>in</strong>g to the follow<strong>in</strong>gexample.A =LOG(PPM[ T 2] ) - LOG(PPMsat [ T1]( T 2) -1/( T1)sat)1/B = LOG PPM( [ T1] )-A/T1satVAISALA____________________________________________________________________ 47

USER´S GUIDE ___________________________________________________________________Example:measured water content 213 ppmT (°C) aw ppm saturation24.1 0.478 213/0.478 = 445.606757.6 0.188 213/0.188 = 1132.979A = (LOG(1132.98)-LOG(445.607))/(1/(57.6+273.16)-1/(24.1+273.16)) = -1189.4581B= LOG(445.607)-(-1189.4581)/(24.1 + 273.16) = 6.6503583Assumptions:The isoterm of water activity versus water concentration is l<strong>in</strong>ear andthe solubility curve has the form of the given equation.48 _______________________________________________________________ M210934EN-A

Chapter 5 ______________________________________________________________ Ma<strong>in</strong>tenanceCHAPTER 5MAINTENANCEThis chapter provides <strong>in</strong>formation that is needed <strong>in</strong> basic ma<strong>in</strong>tenanceof the product.Clean<strong>in</strong>gClean the transmitter enclosure with a soft. l<strong>in</strong>t-free cloth moistenedwith mild detergent.Clean the sensor before stor<strong>in</strong>g the <strong>MMT162</strong> probe and beforecalibration. For clean<strong>in</strong>g the the probe you need <strong>in</strong>strument air andheptane (C 7 H 16 ) liquid. If heptane is not available, you can also usediesel oil or petrol. Dry with <strong>in</strong>strument air to prevent oxidation of theoil on the sensor. The oxidation of the oil on the sensor can causeextended response times or drift<strong>in</strong>g.1. Blow the probe head (with filter) with <strong>in</strong>strument air to removethe rema<strong>in</strong>s of oil.2. Immerse the probe head <strong>in</strong>to heptane liquid and r<strong>in</strong>se out the oil(for one m<strong>in</strong>ute maximum).3. Dry the probe head with <strong>in</strong>strument air. In case you are go<strong>in</strong>g tocalibrate the probe, remove the filter and dry the sensor with<strong>in</strong>strument air. Check that the sensor looks clean.NOTEDo not immerse the sensor <strong>in</strong> any polar solvents, for example ketonesor alcohols.VAISALA____________________________________________________________________ 49

USER´S GUIDE ___________________________________________________________________Chang<strong>in</strong>g the Probe Filter1. Remove the filter from the probe.2. Install a new filter on the probe. When us<strong>in</strong>g the sta<strong>in</strong>less steelfilter (for oil and fuel cell), take care to tighten the filter properly(recommended force 130 Ncm).New filters can be ordered from Vaisala, see section Spare Parts andAccessories on page 65.Chang<strong>in</strong>g the SensorIf you need to change the sensor on your <strong>MMT162</strong>, send it to Vaisalawhere the sensor will be changed for you.Error States<strong>MMT162</strong> has the follow<strong>in</strong>g states that <strong>in</strong>dicate a problem with theprobe:- Analog 4 - 20 mA current output at 0 mA- Analog voltage output at 0V- Serial l<strong>in</strong>e outputs asterisk characters (*** **)The asterisk characters on the serial l<strong>in</strong>e may also appear dur<strong>in</strong>g thestart-up procedure.You can also check the error message via the serial <strong>in</strong>terface by us<strong>in</strong>gthe ERRS command. In case of constant error, please contact Vaisala;see section Vaisala Service Centers on page 52.50 _______________________________________________________________ M210934EN-A

Chapter 5 ______________________________________________________________ Ma<strong>in</strong>tenanceTable 8Error MessageVoltage errorT meas errorF meas errorVoltage too low errorVoltage too low for mA outputVoltage is too low for VoutputAmbient temperature errorProgram flash check sumerrorParameter check sum errorINFOA check sum errorSCOEFS check sum errorCURRENT check sum errorUnknown errorError MessagesActionInternal error, can be caused by damage to the sensor.Internal error, can be caused by damage to the sensor.Supplied operat<strong>in</strong>g voltage is too low for reliable operation.Supplied operat<strong>in</strong>g voltage is too low for reliable operationof the analog current output.Supplied operat<strong>in</strong>g voltage is too low for reliable operationof the analog voltage output.Ambient temperature out of operat<strong>in</strong>g range (probably toohot).Internal errorInternal errorInternal errorInternal errorInternal errorTechnical SupportFor technical questions, contact the Vaisala technical support:E-mail helpdesk@vaisala.comFax +358 9 8949 2790Return InstructionsIf the product needs repair, please follow the <strong>in</strong>structions below tospeed up the process and to avoid extra costs to you.1. Read the section Warranty on page 9.2. Contact a Vaisala Service Center or a local Vaisalarepresentative. The latest contact <strong>in</strong>formation and <strong>in</strong>structionsare available from www.vaisala.com. Addresses of the ServiceCenters are provided <strong>in</strong> section Vaisala Service Centers on page52.Please have the follow<strong>in</strong>g <strong>in</strong>formation on hand:- serial number of the unit- date and place of purchase or last calibration- description of the fault- circumstances <strong>in</strong> which the fault occurs/occurredVAISALA____________________________________________________________________ 51

USER´S GUIDE ___________________________________________________________________- name and contact <strong>in</strong>formation of a technically competentperson who can provide further <strong>in</strong>formation on the problem3. Pack the faulty product <strong>in</strong> a strong box of adequate size, withproper cushion<strong>in</strong>g material to avoid damage.4. Include the <strong>in</strong>formation specified <strong>in</strong> step 2 <strong>in</strong> the box with thefaulty product. Also <strong>in</strong>clude a detailed return address.5. Ship the box to the address specified by your Vaisala contact.Vaisala Service CentersVaisala Service Centers perform calibrations and adjustments as wellas repair and spare part services. See contact <strong>in</strong>formation below.Vaisala Service Centers also offer accredited calibrations,ma<strong>in</strong>tenance contracts, and a calibration rem<strong>in</strong>der program. Do nothesitate to contact them to get further <strong>in</strong>formation.52 _______________________________________________________________ M210934EN-A

Chapter 6 ___________________________________________________Calibration and AdjustmentCHAPTER 6CALIBRATION AND ADJUSTMENTThis chapter provides <strong>in</strong>formation that is needed <strong>in</strong> calibration andadjustment of the product.The <strong>MMT162</strong> is fully calibrated and adjusted as shipped from factory.The calibration <strong>in</strong>terval depends on the application. It is recommendedthat calibration is done always when there is a reason to believe thatthe device is not with<strong>in</strong> the accuracy specifications.You can calibrate the <strong>MMT162</strong> yourself or send it to Vaisala forcalibration. Calibration and adjustment is usually carried out throughserial l<strong>in</strong>e. One-po<strong>in</strong>t calibrations and adjustments can also be done byus<strong>in</strong>g an MI70 <strong>in</strong>dicator and Vaisala humidity calibrator HMK15.Before the calibration, the used sensor needs to be cleaned with<strong>in</strong>strument air to blow out exist<strong>in</strong>g oil or gently first flush withhepthane (C 7 H 16 ) and dry with <strong>in</strong>strument air to decrease responsetime, see section Clean<strong>in</strong>g on page 49.NOTEIt is important to clean the sensor before calibration as the oilysensor can contam<strong>in</strong>ate the salt bath and change the referencecondition.Vaisala HUMICAP ® hand-held moisture and temperature <strong>in</strong> oil meterMM70 can also be used for calibration.VAISALA____________________________________________________________________ 53

USER´S GUIDE ___________________________________________________________________MM70 <strong>in</strong> Check<strong>in</strong>g and Adjust<strong>in</strong>g<strong>MMT162</strong> can be checked and adjusted by us<strong>in</strong>g the MM70. In thefield you can check and adjust the probe's read<strong>in</strong>g aga<strong>in</strong>st thecalibrated reference probe of the MM70.To check the <strong>MMT162</strong> transmitter with MM70:1. Connect the <strong>MMT162</strong> to the MM70 <strong>in</strong>dicator with theappropriate connection cable (Vaisala item 219980).2. Turn on the MM70.3. Prepare the probe for adjustment by open<strong>in</strong>g the adjustmentmenu on the MM70 (Menu → Functions → Adjustments)NOTEMake sure that both probes are stabilized to same conditions so thatthe temperature read<strong>in</strong>gs are the same.4. Press the OK key to start adjustment.One-Po<strong>in</strong>t Relative Humidity AdjustmentNote that the humidity reference must be at least 50% RH. The<strong>MMT162</strong> must be unpowered dur<strong>in</strong>g stabilization which can take 30m<strong>in</strong>utes or more.Us<strong>in</strong>g Serial L<strong>in</strong>eTo adjust the relative humidity:1. Remove the filter from the probe and <strong>in</strong>sert the probe <strong>in</strong>to ameasurement hole of the dry end reference chamber (forexample, NaCl: 75 % RH <strong>in</strong> the humidity calibrator HMK15).Use the adapter fitt<strong>in</strong>g.2. Wait at least 30 m<strong>in</strong>utes for the sensor to stabilize.3. Connect the <strong>MMT162</strong> to a PC, see section SerialCommunication on page 25. Then open a term<strong>in</strong>al program.4. Enter the CRH command and press ENTER.54 _______________________________________________________________ M210934EN-A

Chapter 6 ___________________________________________________Calibration and AdjustmentCRH5. Type C and press ENTER a few times to check if the read<strong>in</strong>ghas stabilized.6. When the read<strong>in</strong>g is stable, give the reference humidity after thequestion mark and press ENTER.crhRH : 25.21 Ref1 ?RH : 25.22 Ref1 ?RH : 25.22 Ref1 ? 30.1Press any key when ready ...RH : 25.19 Ref2 ?OK7. OK <strong>in</strong>dicates that the adjustment has succeeded and the newcalibration coefficients are calculated and stored.8. Take the probe out of the reference conditions and replace thefilter.Us<strong>in</strong>g MI70To adjust the relative humidity:1. Connect MI70 to <strong>MMT162</strong>.2. Turn MI70 on.3. On the MI70, go to Menu → Functions → AdjustmentsFigure 14Ma<strong>in</strong> MenuVAISALA____________________________________________________________________ 55

USER´S GUIDE ___________________________________________________________________Figure 15Functions Menu4. Follow the <strong>in</strong>structions given on the display.5. Select RH from the list and press Select.6. When adjust<strong>in</strong>g relative humidity, you need to check theenvironment sett<strong>in</strong>gs before mak<strong>in</strong>g the adjustment.56 _______________________________________________________________ M210934EN-A

Chapter 6 ___________________________________________________Calibration and Adjustment7. In adjustment mode, enter the correct reference value and thenexit by press<strong>in</strong>g Back.VAISALA____________________________________________________________________ 57

USER´S GUIDE ___________________________________________________________________One-Po<strong>in</strong>t Temperature AdjustmentThe <strong>MMT162</strong> must be unpowered dur<strong>in</strong>g stabilization which can take30 m<strong>in</strong>utes or more.Us<strong>in</strong>g Serial L<strong>in</strong>e1. Remove the probe filter and <strong>in</strong>sert the probe <strong>in</strong>to the referencetemperature.2. Enter the command CT and press ENTER.CT3. Type C and press ENTER a few times to check if the read<strong>in</strong>g isstabilized. Let the read<strong>in</strong>g stabilize, give the referencetemperature after the question mark and press ENTER threetimes.Example:ctT : 22.03 Ref1 ?T : 22.03 Ref1 ?T : 22.03 Ref1 ? 25.0Press any key when ready ...T : 22.02 Ref2 ?OK4. OK <strong>in</strong>dicates that the calibration has succeeded.5. Take the probe out of the reference conditions and replace thefilter.58 _______________________________________________________________ M210934EN-A