Tensinews 21 - sept2011 - vers 31-8 - TensiNet

Tensinews 21 - sept2011 - vers 31-8 - TensiNet

Tensinews 21 - sept2011 - vers 31-8 - TensiNet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

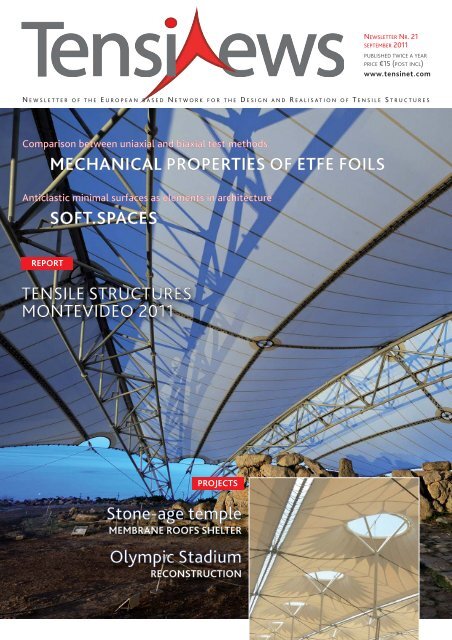

N EWSLETTER OF THE E UROPEAN BASED N ETWORK FOR THE D ESIGN AND R EALISATION OF T ENSILE S TRUCTURES<br />

Comparison between uniaxial and biaxial test methods<br />

MECHANICAL PROPERTIES OF ETFE FOILS<br />

Anticlastic minimal surfaces as elements in architecture<br />

SOFT.SPACES<br />

REPORT<br />

TENSILE STRUCTURES<br />

MONTEVIDEO 2011<br />

PROJECTS<br />

Stone-age temple<br />

MEMBRANE ROOFS SHELTER<br />

Olympic Stadium<br />

RECONSTRUCTION<br />

NEWSLETTER NR. <strong>21</strong><br />

SEPTEMBER 2011<br />

PUBLISHED TWICE A YEAR<br />

PRICE €15 (POST INCL)<br />

www.tensinet.com

form TL<br />

partners<br />

2011<br />

Buro Happold<br />

www.burohappold.com<br />

Canobbio S.p.A.<br />

www.canobbio.com<br />

Ceno Tec<br />

www.ceno-tec.de<br />

Dyneon<br />

www.dyneon.com<br />

FabricArt<br />

Membrane Structures<br />

www.fabricart.com.tr/<br />

Ferrari sa<br />

www.ferrari-textiles.com<br />

Form TL<br />

www.Form-tl.de<br />

Hightex GmbH<br />

www.hightexworld.com<br />

Mehler Texnologies<br />

www.mehlertexnologies.com<br />

Messe Frankfurt<br />

Techtextil<br />

www.techtextil.de<br />

Naizil S.P.A.<br />

www.naizil.com<br />

Saint-Gobain<br />

www.sheerfill.com<br />

Sioen Industries<br />

www.sioen.com<br />

Taiyo Europe<br />

www.taiyo-europe.com<br />

technet GmbH<br />

www.technet-gmbh.com<br />

Verseidag<br />

www.vsindutex.de<br />

INFO<br />

Editorial Board<br />

John Chilton, Evi Corne,<br />

Peter Gosling, Marijke Mollaert,<br />

Javier Tejera<br />

Coordination<br />

Marijke Mollaert,<br />

phone: +32 2 629 28 45,<br />

marijke.mollaert@vub.ac.be<br />

Address<br />

Vrije Uni ver siteit Brussel (VUB),<br />

Dept. of Architectural Engineering,<br />

Pleinlaan 2, 1050 Brus sels, Belgium<br />

fax: +32 2 629 28 41<br />

ISSN 1784-5688<br />

All copyrights remain by each<br />

author<br />

Price €15<br />

postage & packing included<br />

2 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

PROJECTS<br />

RESEARCH<br />

MISC<br />

contents<br />

PAGE<br />

4 France OPEN-AIR THEATER<br />

1800m² suspended structure<br />

4 Germany TEMPORARY ROOF<br />

STRUCTURE<br />

9 Ukraine OLYMPIC STADIUM<br />

Reconstruction<br />

16 China HOME OF THE FUTURE<br />

A showcase for future living<br />

16 Argentina LA PLATA STADIUM<br />

High-light transmission membranes<br />

17 Germany MEMBRANE ROOF Rhein-Galerie<br />

18 Malta STONE-AGE TEMPLE<br />

Membrane roofs shelter<br />

23 Spain TEXTILE WRAP A sustainable construction<br />

PAGE<br />

6 Mechanical properties of ETFE foils<br />

10 SOFT.SPACES<br />

REPORT<br />

PAGE<br />

19 LITERATURE<br />

8 S(P)EEDKITS<br />

n°<strong>21</strong><br />

PAGE<br />

20 Tensile Structures Montevideo 2011<br />

24 INTERNATIONAL "TEXTILE STRUCTURE FOR<br />

NEW BUILDING 2011” COMPETITION FOR STUDENTS AT TECHTEXTIL

E dito<br />

<strong>Tensinews</strong> observes the current trend of expanding<br />

the use of technical membranes and foils in architectural<br />

projects. The variation in available materials is increasing,<br />

with respect to the appearance as well as the (structural)<br />

behaviour. The field of application is widening; more delicate,<br />

creative and intriguing projects are being built and more<br />

architects explore the possibilities of the technology of tensile<br />

surface structures, e.g. textile sustainable wraps, a large<br />

span stadium cover or a heritage shelter to protect an<br />

archaeological temple. A holistic approach is the way to<br />

go for these designs.<br />

Numerous workshops, symposia - like the 4 th Latin American<br />

Symposium on Tensile Structures in Montevideo - and<br />

conferences act as forums to discuss and disseminate<br />

the state of the art. The next <strong>TensiNet</strong> Symposium is planned<br />

for 2013. The younger generation is stimulated to hand in<br />

their student-projects at the bi-annual International "Textile<br />

Structure for New Building 2011” Competition at Techtextil.<br />

There is also an increase in research projects to deepen the<br />

current knowledge, like testing and analysing the material<br />

properties of coated fabrics and foils, the study of deployable<br />

S(P)PEEDKITS for disaster relief or the exploration of<br />

anticlastic minimal surfaces as architectural and constructive<br />

components.<br />

A new <strong>TensiNet</strong> Working Group on Pneumatic Structures is<br />

launched: Matthew Birchall (matthew.birchall@ burohappold.<br />

com) will be the leader of this Working Group.<br />

The <strong>TensiNet</strong> association is part of the expanding topic of<br />

technical membranes and foils and hopes to further contribute<br />

to this evolution.<br />

Forthcoming Meetings<br />

<strong>TensiNet</strong> meetings in Barcelona, Spain<br />

Thursday 4/10/2011<br />

16:30 - 17:00 Welcome<br />

17:00 - 18:00 Partner Meeting (2/2011)<br />

18:00 - 19:00 Annual General Meeting<br />

19:00 - <strong>21</strong>:00 Working Group Meetings "Specifications" (Marijke Mollaert),<br />

"Analysis & Materials" (Ben Bridgens) and "ETFE" (Rogier Houtman)<br />

Location: Technical Uni<strong>vers</strong>ity of Catalonia (UPC),<br />

Master Room, Building A3, Campus Nord, Jordi Girona 1-3, Barcelona, Spain<br />

Forthcoming Events International symposium IABSE-IASS 2011 London,<br />

UK 20-23/09/2011 ● International conference on Structural Membranes 2011<br />

Barcelona, Spain 05-07/10/2011 http://congress.cimne.com/membranes2011/frontal/<br />

Dates.asp ● 1st international Textile Archi tecture Seminar Uni<strong>vers</strong>idad de Castilla-<br />

La Mancha,Toledo, Spain 26-28/10/2011 ● second international conference on flexible<br />

formwork icff 2012 Bath, UK 27 - 29/06/2012 www.icff2012.co.uk<br />

CALL<br />

for Participants for<br />

<strong>TensiNet</strong> Working Group on<br />

Pneumatic Structures<br />

Pneumatic Structures are increasingly being considered for a variety of<br />

applications in the built environment, from stadium roofs to bridges, and<br />

from permanent structures to deployable enclosures. The design, analysis<br />

and specification of these structures is often treated differently by<br />

different consultants in different countries, with occasional reliance upon<br />

qualitative and empirical experience, or applications from other industries.<br />

<strong>TensiNet</strong> is launching a working group on Pneumatic Structures to<br />

consolidate the current best practise in this specialist field. It is envisaged<br />

that this working group will focus on analysis techniques, design<br />

processes, applicable standards and technical references, materiality<br />

options, and construction practicalities. Reference will be made to the<br />

existing working groups on ETFE and Analysis & Materials without<br />

duplicating their findings, of course.<br />

The aims, scope and membership of the working group will be discussed<br />

at the start-up meeting to follow after the Annual General Meeting of<br />

<strong>TensiNet</strong> in Barcelona on 4 th October 2011. Any interested parties who<br />

would like to participate should contact the leader of the working group,<br />

Matthew Birchall, at matthew.birchall@burohappold.com<br />

CEN/TC250 WG5 _<br />

core group meeting<br />

in Paris, France<br />

Wednesday 02/11/2011<br />

10:00 - 16:00<br />

Core Group Meeting<br />

Location:<br />

SFEC, 3rd floor, 65 Rue Prony,<br />

Paris, France<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 3

Context<br />

The City of Colmar wanted to<br />

cover the open-air theater of its<br />

Exhibition Park in a lasting and<br />

esthetic way. The challenge was<br />

to cover the existing Eastern and<br />

Western tiers by installing a<br />

textile cover fixed on a metal<br />

framework with particularly short<br />

delays and taking into account the<br />

existing equipment<br />

Context<br />

Built in early 19th century the<br />

“Festung Ehrenbreitstein” is a<br />

landmark in Koblenz, located<br />

opposite of the famous “Deutschen<br />

Eck” between Rhein and Mosel. In<br />

one of the moats of the historical<br />

“Festung Ehrenbreitstein” a main<br />

stage and stands for the<br />

Bundesgartenschau 2011 (BUGA<br />

2011) have been located (Fig. 1).<br />

All kind of concerts will take place<br />

from April until October 2011. The<br />

moat called “Retiriergraben” is<br />

about 24m to 27m wide and 100m<br />

long. The slope of the “Graben”<br />

ends in east direction at the<br />

“Landbastion”, is bordered to the<br />

North by “Kurtine” (both 25m high<br />

ancient walls) and to the South by a<br />

ramp in front of “Contregarde<br />

Rechts”, which is opposite inclined<br />

to the “Retiriergraben”, from 4 to<br />

12m height (Fig. 2). The moat opens<br />

up upwards.<br />

Client and investor was BUGA 2011,<br />

the owner is "Bundesland<br />

Rheinland-Pfalz“.<br />

4 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

and the constraints inherent to<br />

the site. For example, the theater<br />

is located very close to the Colmar<br />

airport and part of the<br />

construction stands inside the<br />

area concerned by the planes’<br />

taking-off and landing operations.<br />

The solution chosen by ESMERY<br />

CARON was to install very big<br />

textile cones suspended at 20m<br />

above the theater stands.<br />

KIEFER TEXTILE ARCHITEKTUR<br />

Project<br />

Kiefer. Textile Architektur provided a<br />

range of architectural solutions,<br />

until the client´s and owner´s<br />

requirements, which changed<br />

Structure and installation<br />

The plan dimensions of the two<br />

covering modules are about 55m by<br />

2 X 65m, i.e. 2 textile co<strong>vers</strong> of<br />

900m² and 2.2 tons each. The metal<br />

structure supporting the tension fabric<br />

cover is mainly made of two triple<br />

masts of 3.5 tons each, holding<br />

a 135m long cable placed at an alti-<br />

ESMERY CARON<br />

Open-air<br />

theater<br />

1 Colmar, France<br />

1800M² SUSPENDED STRUCTURE<br />

during the design process, had been<br />

achieved. The final brief was to<br />

create a temporary covering for a<br />

stage of 8 to12m and<br />

approximately 800 spectators in a<br />

tude of about 20m. The textile co<strong>vers</strong><br />

are completely independent<br />

from the existing open-air theatre<br />

structures by being tensioned on<br />

main cables (56mm in diameter).<br />

The metal frames were treated by<br />

bath galvanization and bolted onsite.<br />

Erection of the elements was<br />

performed using a telescopic crane<br />

Temporary roof structure<br />

Festung Ehrenbreitstein, Germany<br />

Figure 1. Aerial view on the main stage © PP Koblenz<br />

way that no attention is taken away<br />

from the ancient masonry of the<br />

surrounding buildings and the new<br />

construction is not attached to the<br />

old (Fig. 3).<br />

1

installed close to the building site.<br />

The fabric was made in the workshop<br />

and folded in a specific order<br />

allowing a very precise on-site installation<br />

taking into account the<br />

need for working at heights and the<br />

dimensions of the construction. The<br />

fittings and various cables are made<br />

of galvanized steel with a metal<br />

core. Endings are of the rigid fork or<br />

threaded end types.<br />

The obvious solution was to build a<br />

roof<br />

• remarkable higher than the ramp,<br />

to invite looking from the ramp<br />

into the stage;<br />

• horizontally, in order to accentuate<br />

the falling and ascending lines<br />

along the ramp wall;<br />

• with respectful space between<br />

masonry and roof edge;<br />

• light and stringent seemingly,<br />

symmetrical main structure;<br />

• translucent and smooth shaped<br />

elements.<br />

Six portal frames in a grid of 7m,<br />

designed by three girder trusses,<br />

achieve minimum truss diameters.<br />

The horizontal upper girder<br />

cantile<strong>vers</strong> at both ends, in order to<br />

base aside of existing foundations.<br />

Excavations for the new precast<br />

concrete units had to be limited to<br />

max. 50cm. The vertical trusses vary<br />

from 11 to 15m height. Their lowest<br />

part is the adjusting element. The<br />

stiffing of the structure in<br />

longitudinal direction is induced by<br />

vertical cross bracing of each bay, in<br />

cross direction by portal frames. The<br />

fabric co<strong>vers</strong> six bays of 7x 22m.<br />

Each bay gets an accentuated shape<br />

through two valley belts, which<br />

divide the bay into three elongated<br />

areas. The middle one shows a<br />

classical slightly barrel-shaped form.<br />

It effects a reduction of the visual<br />

2 2 3 3 3<br />

Figure 1. Overview<br />

Figure 2. External and internal view of the<br />

two covering modules<br />

Figure 3. Installation<br />

! Olivier Dufour<br />

: olivier.dufour@esmerycaron.com<br />

: www.esmery-caron.com<br />

presence of the upper girder. To<br />

reduce any imperfections in the<br />

fabric there is no assembling along<br />

the top girder but two welded keder<br />

strips to hinder horizontal<br />

movement. At both end frames the<br />

fabric is clamped by standardized<br />

keder-clamping profile from Tennect<br />

to allow for unpunched linear<br />

fixation. Membrane edges are<br />

framed with belts to underline the<br />

temporary character.<br />

The valley belts are slightly curved<br />

to increase the dynamic appearance<br />

of the single bays. The belts are fixed<br />

to a rotatable supported bail<br />

consisting out of steel tubes. These<br />

bails are used to tension the<br />

membrane. Due to the various angle<br />

at the fixation points of tie down<br />

tension struts a standardized readymade<br />

product from Tennect was<br />

used. The roofing structure was<br />

finally completed one day before<br />

opening ceremony at 15th of April.<br />

The complete design, engineering<br />

and cutting pattern was carried out<br />

from Michael Kiefer, Tobias Lüdeke<br />

and Manfred Schieber at Kiefer.<br />

Textile Architektur.<br />

! Michael Kiefer<br />

Kiefer. Textile Architektur.<br />

Architekten und Ingenieure<br />

: info@k-ta.de<br />

: www.k-ta.de<br />

Project Name: Covering of the open-air theater, Exhibition Park<br />

Location address: Colmar, France<br />

Function of the building: Outdoor facilities<br />

Client: Colmar City<br />

Year of construction: July 2009<br />

Project Manager: Colmar City Architecture Department<br />

Metal framework: ACML<br />

Supplier of the membrane material: FERRARI 1502 T2 1500g/m² - EN ISO 2286-2 standard<br />

Membrane and framework Consultant: ARCORA<br />

Supplier of the membrane: ESMERY CARON<br />

Installation of the membrane: ESMERY CARON and EVEREST (3 weeks for a fitting team of 7)<br />

Covered surface: 1800m²<br />

Figure 2. View from the ramp to the main stage<br />

Figure 3. View main stage © Kiefer.Textile Architektur.<br />

2 3<br />

3<br />

Name of the project: Temporary roof structure<br />

Location address: Festung Ehrenbreitstein, Germany<br />

Client (investor): BUGA 2011 and Rheinland-Pfalz<br />

Function of building: Temporary roof of main stage and stand<br />

Type of application of the membrane: Valleycable Saddleshaped<br />

Year of construction: 2011<br />

Architects: Michael Kiefer, Sebastian Fey Kiefer.Textile Architektur.<br />

Structural engineers: Tobias Lüdeke, Manfred Schieber Kiefer.Textile Architektur.<br />

Consulting engineer for the membrane: Tobias Lüdeke Kiefer.Textile Architektur.<br />

Main contractor & contractor for the membrane: Ceno-Tec<br />

Supplier of the membrane material: Verseidag<br />

Manufacture and installation: Ceno-Tec<br />

Material: Verseidag B1951, PVC/ PES Typ 1<br />

Covered surface (roofed area): ca. 800m²<br />

Membrane assembling system: Tennect (Carl Stahl)<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 5<br />

3

RESEARCH<br />

6 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011

Preliminary definitions<br />

The mechanical behaviour of materials is<br />

described by relationships between stresses<br />

and strains. There exist however different<br />

definitions, the most commonly used being<br />

the engineering stress s and the engineering<br />

strain e. They are actually simplified<br />

formulations and are only valid under<br />

infinitesimal strains as they always refer to the<br />

material initial configuration. If the strains<br />

exceed a few percents then the true stress σ<br />

and true strain ε must be used. They represent<br />

the true material behaviour which is used in<br />

finite element analyses. The true stress<br />

accounts for change in cross-sectional area by<br />

using the instantaneous sample area. The true<br />

strain accounts for an incremental sample<br />

deformation where the new strain depends on<br />

the updated shape. The comparison between<br />

both definitions is illustrated in the part (B1) of<br />

the summary picture for the uniaxial tension<br />

of an ETFE foil. The engineering stress and<br />

strain are accurate enough in the initial linear<br />

part. Above 2% of strain the difference with<br />

the true stress and strain becomes significant.<br />

Test procedures<br />

Mechanical properties of ETFE foils<br />

Comparison between uniaxial and biaxial test methods<br />

ETFE foils have increasingly been used since the 1980's for roofs and claddings [1-4]. Their excellent<br />

light transmission capability combined with their lightness and flexibility has broadened the scope of<br />

large transparent structures. The low weight properties of ETFE foils allow the design of structures<br />

which would have been impossible to build with conventional materials such as glass.<br />

ETFE is a polymer and therefore it exhibits non-linear stress-strain behaviour as well as rate- and<br />

temperature-dependency [5]. Usually its behaviour is derived from uniaxial tensile tests [3-5].<br />

In that case the behaviour is often measured in both machine (extrusion direction) and trans<strong>vers</strong>e<br />

direction. There is also an increasing interest for biaxial tests because they allow the observation of<br />

the material response under biaxial stresses as occurring in a tensile structure. In particular bursting<br />

tests have become popular during the last years [6] as they enable very large biaxial deformations.<br />

However, the benefits of biaxial testing over uniaxial testing have not been clearly demonstrated so<br />

far for ETFE foils. Three tests methods are here compared [7]: uniaxial tension, biaxial extension of<br />

cruciform specimen and bursting test. The study is focused on the deter mination of the material<br />

mechanical properties from the experimental data. After an adequate post-processing these data<br />

are compared and the advantages of each test method are discussed.<br />

• Uniaxial tension<br />

Specimen shape: standard dumbbell<br />

Control: tra<strong>vers</strong>e displacement<br />

(A1) The tensile load is measured with a load<br />

cell while an optical extensometer measures<br />

the distance between two targets, allowing<br />

the calculation of the engineering stress and<br />

strain. The obtained stress-strain curve shows<br />

the non-linear behaviour of ETFE foils. After an<br />

initial linear part, it exhibit two points where<br />

the stiffness significantly decreases denoted as<br />

two yield points. The material undergoes very<br />

large deformations up to more than 400% at<br />

failure. One can also mention that the<br />

behaviour in the machine and trans<strong>vers</strong>e<br />

direction is very similar.<br />

(B1) The tensile true stress and strain can be<br />

calculated from the engineering stress and<br />

strain. The Poisson's ratio ν is required. It is<br />

however not obtained from the uniaxial test,<br />

unless a strain measurement is operated in the<br />

direction orthogonal to the loading. One can<br />

either assume an incompressible material<br />

behaviour (ν=0.5) or use a typical value for<br />

ETFE (ν=0.43 [7]). With this definition of stress<br />

and strain the increase of stiffness in the<br />

second half of the curve is even more<br />

pronounced. It is due to the reorganization in<br />

the polymer structure, where the molecular<br />

chains are reoriented in the loading direction.<br />

As a result the material is no longer isotropic.<br />

• Biaxial extension of cruciform specimens<br />

Specimen shape: cruciform<br />

Control: load on each grip<br />

(A2) The load is measured for each grip with a<br />

load cell and two needle extensometers<br />

measure the strain in the central area of the<br />

sample. It can be seen from the results that<br />

the failure occurs at small strains, which is due<br />

to the particular geometry of the sample. This<br />

early failure of the specimen at about 7% of<br />

strain is the main disadvantage of this method<br />

as it is not representative of the strains that<br />

the foil undergoes under large biaxial stresses.<br />

Biaxial machines however allow the<br />

application of different load ratios on the<br />

sample contrary to the bursting test.<br />

(B2) The biaxial true stress and true strain can<br />

be calculated from the engineering stress and<br />

strain. In that case the Poisson's ratio can be<br />

obtained from the biaxial tests if at least two<br />

load ratios are explored.<br />

• Bursting test<br />

Specimen shape: circular<br />

Control: air pressure during the inflation<br />

(A3) The material behaviour is observed at the<br />

pole where a 1:1 load ratio is obtained. The<br />

biaxial true strains at the pole are directly<br />

measured by a 3D optical system using digital<br />

image correlation. The air pressure is measured<br />

by a pressure sensor. Without post-processing<br />

no data is obtained as there is no mean of<br />

measuring the stress in the material.<br />

(B3) The true stresses at the pole are<br />

calculated based on pressure vessel theory.<br />

The bubble radius is estimated from the<br />

bubble shape measured with the 3D optical<br />

system using a surface fitting. The foil<br />

thickness at the pole is estimated using the<br />

initial thickness and the measured in-plane<br />

strains assuming that the material is<br />

incompressible (constant material volume).<br />

With the bursting test much higher biaxial<br />

strains are reached. In that case failure occurs<br />

at about 75% of engineering strain (true strain<br />

of 0.56). Therefore the bursting test must be<br />

used in order to observe the behaviour of the<br />

material and its failure under large biaxial<br />

stresses.<br />

Comparison<br />

It is not possible to directly compare the<br />

stress-strain curves that have been previously<br />

presented. Each of these curves represents the<br />

relationship between only one stress component<br />

and one strain component. In reality, the<br />

material behaviour is defined by a relationship<br />

between the stress tensor and the strain tensor.<br />

If one assumes a plane stress state without<br />

shear then for an isotropic material it is<br />

described by 3 equations:<br />

ε x = 1 σ x − ν σ y<br />

E E<br />

ε y = − ν σ x + 1 σ y<br />

E E<br />

ε z = − ν (σ x + σ y )<br />

E<br />

RESEARCH<br />

Under biaxial loading the strain in one direction<br />

is not only related to the stress applied in that<br />

direction but also to the stress applied in the<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 7

orthogo nal direction due to the Poisson's effect.<br />

As far as multidirectional stresses are concerned,<br />

the Von Mises formulas can be used to combine<br />

the stresses and strains into an equivalent stress<br />

and an equivalent strain. The corresponding<br />

curves are presented in the summary figure (C)<br />

for two uniaxial tests, two biaxial tests and one<br />

bursting test performed at room temperature at<br />

almost identical strain-rates. Results are very<br />

similar up to the second yield stress. Above the<br />

second yield stress the large deformations<br />

occurring in the material change its<br />

microstructure and therefore its mechanical<br />

properties. The material becomes anisotropic and<br />

its behaviour depends on the applied loading.<br />

Conclusion<br />

It has been shown that if an adequate post-processing<br />

is used then similar stress-strain curves<br />

are obtained up to the second yield stress with<br />

uniaxial and biaxial test procedures. Therefore<br />

uniaxial test can be used for measuring the material<br />

initial behaviour as they are very easy to perform<br />

and do not require much material and time.<br />

If the plastic behaviour or the failure of the material<br />

must be investigated then biaxial stresses<br />

must be applied. In that case the bursting test is<br />

the most suitable method as it allows very large<br />

biaxial deformations. This method is however limited<br />

to a single load ratio (1:1 for a circular sample).<br />

In order to apply different load ratios a<br />

biaxial test machine can be used.<br />

! Cédric Galliot<br />

: cedric.galliot@empa.ch<br />

! Rolf Luchsinger<br />

: rolf.luchsinger@empa.ch<br />

Center for Synergetic Structures<br />

: www.empa.ch/css<br />

REFERENCES<br />

[1] K. Moritz. Bauweisen der ETFE-Foliensysteme.<br />

Stahlbau 2007;76(5):336-342.<br />

[2] S. Robinson-Gayle, M. Kolokotroni, A. Cripps, S.<br />

Tanno. ETFE foil cushions in roofs and atria.<br />

Construction and Building Materials 2001;15:323-327.<br />

[3] Y. Xiang, J. Li. Calculation and design of ETFE<br />

membrane structures. In: Proceedings of the IASS<br />

Symposium, Beijing, 2006.<br />

[4] M. Wu, J. Lu. Experimental studies on ETFE cushion<br />

model. In: Proceedings of the IASS Symposium,<br />

Mexico, 2008.<br />

[5] K. Moritz. Time-Temperature-Shift (TTS) of ETFE-foils.<br />

In: Kröplin B, Oñate E, editors. International<br />

Conference on Textile Composites and Inflatable<br />

Structures, Structural Membranes 2009. CIMNE:<br />

Barcelona, 2009.<br />

[6] L. Schiemann, S. Hinz, M. Stephani. Tests of ETFE-foils<br />

under biaxial stresses. In: Kröplin B, Oñate E, editors.<br />

International Conference on Textile Com posites and<br />

Inflatable Structures, Structural Membranes 2009.<br />

CIMNE: Barcelona, 2009.<br />

[7] C. Galliot, R.H. Luchsinger. Uniaxial and biaxial<br />

mechanical properties of ETFE foils. Polymer Testing<br />

2011;30(4):356-365.<br />

8 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

RESEARCH<br />

S(P)EEDKITS<br />

Rapid deployable kits as<br />

seeds for self-recovery<br />

The project ‘S(P)EEDKITS’ , which will start in 2012, will research rapid<br />

deployable kits as seeds for self-recovery in disaster affected sites. A multidisciplinary<br />

team, consisting of different organizations throughout Europe, will develop a new<br />

emergency system of modular rapid deployable shelters, facilities and medical care.<br />

The kits must be transportable, modular and adaptable, must have a low cost and<br />

must be high-tech in their conception but low-tech in use (Fig. 1 gives an example of a<br />

feasible kit. However the implementation of the kit, in the context of disaster relief<br />

shelters, still needs to be investigated). Current kits will be scanned with regard to<br />

large transportation volumes and/or heavy weight. Out of this knowledge, new<br />

concepts will be developed to drastically reduce the transportation volume and weight.<br />

The goal of these kits will be to provide temporary infrastructure, to establish the<br />

necessary temporary services and to limit the damage to economic and social fabrics.<br />

The kits should provide infrastructure for different purposes, e.g. a hospital,<br />

a communication centre, water facilities or sanitation units. Also four different basic<br />

shelter kits will be designed and analyzed:<br />

- A lightweight safe house unit: this shelter gives coverage for the very first<br />

hours and need to be deployed by the communities<br />

- A collective unit: a shelter which is usable for di<strong>vers</strong>e purposes<br />

- A family house unit: this shelter will be used in the transitional period and<br />

later, it can be referred to as the first <strong>vers</strong>ion of a real house<br />

- A robust warehouse unit: a somewhat larger shelter for the humani-ta rian<br />

organizations, it can be used for storage, offices, medical centers, etc.<br />

The need for these kits becomes evident when thinking about the many disasters,<br />

both nature- and man-made, that occur worldwide. As a result, countless people are<br />

rendered homeless without any medical care, sufficient and clean water, decent<br />

sanitation or energy supply. In case of such an emergency situation, humanitarian<br />

organizations (like the Red Cross, Red Crescent Movement and Médecins Sans<br />

Frontières) emergency response units to rebuild these affected sites. These units are<br />

sent out immediately after a disaster strikes. Each unit has his own field of expertise<br />

and consists of trained people and the necessary equipment (the ‘kit’) needed on site.<br />

The S(P)EEDKITS project wants to develop novel ‘kits’ that can be pre-positioned and<br />

mobilized more quickly and easily than existing ones.<br />

The S(P)EEDKITS project will be a collaboration between : Centexbel (BE),<br />

Shelter Research Unit (LU), Netherlands Red Cross (NL), Sioen Industries (BE),<br />

Vrije Uni<strong>vers</strong>iteit Brussel (BE), Technische Uni<strong>vers</strong>iteit Eindhoven (NL),<br />

Politecnico di Milano (IT), De Mobiele Fabriek (NL), Waste (NL), Practica (NL),<br />

D’Appolonia (IT), Internationales Biogas und Bioenergie Kompetenzzentrum (DE),<br />

Millson BV (NL), MSF Nederland (NL) and Norwegian Refugee Council (NO).<br />

! Jan Roekens - Vrije Uni<strong>vers</strong>iteit Brussel<br />

: jan.roekens@vub.ac.be<br />

! Guy Buyle - Centexbel<br />

: guy.buyle@centexbel.be<br />

Figure 1: First<br />

steps in the<br />

design of a<br />

possible disaster<br />

relief shelter kit

Introduction<br />

Over the last decades Hightex has<br />

been dedicated to the construction<br />

of innovative fabric roofs for<br />

sporting venues. One of the stadium<br />

projects for the EURO 2012 in the<br />

Ukraine and Poland is the Olympic<br />

Stadium in Kiev, which is currently<br />

undergoing a comprehensive<br />

revitalization. The design for the<br />

reconstruction of the stadium<br />

respects the historical building with<br />

its significant filigree prestress<br />

concrete upper tier tribunes from<br />

1968, by arranging the<br />

superstructure of the new roof<br />

system detached and with a<br />

distance to the existing seating<br />

bowl. The most prominent part of<br />

the “Kiev Central Stadium” will be<br />

enclosed with a new delicate glazing<br />

façade and, like an exhibit in a glass<br />

cabinet, will be put in perspective<br />

with lighting. This is how the<br />

architect von Gerkan, Mark and<br />

Partner (gmp) describe their design.<br />

With its fabric roofing system<br />

shaped by filigree flying struts into<br />

an ocean of conicals covered with<br />

light domes the Olympic Stadium<br />

should receive a unique and<br />

distinctive identity as an urban<br />

landmark within the texture of the<br />

city centre of Kiev. The main<br />

structural system of the roof derives<br />

from the spoke wheel principal. It<br />

consists of two outer compression<br />

rings, steel plate box girders, which<br />

rest on the 80 kinked columns, also<br />

made of tapered steel box girders.<br />

80 cable trusses of upper and lower<br />

radial cables, coupled with hanger<br />

cables build up a light cable net,<br />

which are anchored into these<br />

compression rings and meet at the<br />

centre in a tension ring. The tension<br />

ring encases approximately the<br />

playing pitch. The horizontal forces<br />

are balanced out between the outer<br />

compression rings and the inner<br />

tension ring. The vertical forces are<br />

HIGHTEX GMBH<br />

RECONSTRUCTION<br />

Olympic Stadium<br />

Kiev, Ukraine<br />

transferred from the cable net into<br />

the 80 columns and into the<br />

foundations. 80 axes are very<br />

uncommon for stadium roof<br />

constructions. Similar projects<br />

usually make do with about half the<br />

number of axes.<br />

One of the reasons for this design<br />

was the original material choice of<br />

the main membrane. First concepts<br />

envisioned the use of a single layer<br />

of ETFE foil. It has much lower<br />

structural capacity than typical<br />

coated fabrics, which are usually<br />

used for stadium roofs. While the<br />

fabrication and installation of the<br />

steel columns was already under<br />

way, the material choice of the<br />

highly transparent foil was<br />

dismissed over the course of the<br />

planning. The 80 columns still<br />

dominate the overall impression of<br />

the architecture of the stadium and<br />

will impress a unique character<br />

onto the stadium. The roof cover,<br />

the translucent membrane field<br />

elements, will now be made of<br />

PTFE coated Glass fabric. Eight<br />

flying struts in each bay impress a<br />

series of conical shapes into the<br />

main membrane. These flying struts<br />

flare up like a funnel and the main<br />

membrane is connected to the top<br />

rings of the flying struts. The round<br />

openings between 2.5m to 3.2m<br />

diameter are covered with light<br />

domes spanned with ETFE foil. This<br />

generates a unique translucent<br />

roofing landscape with in total 640<br />

light spots. For this project Hightex<br />

is responsible for the cable<br />

structure and membrane roof.<br />

Cable structure (Fig. 1 to Fig. 5)<br />

The ten ring cables are 115mm<br />

diameter also fully locked galvan<br />

cables and have a total length of<br />

about 469m each. They are bundle<br />

into two layers of 5 cables each and<br />

Installation of the cable structure<br />

Figure 1. Connection of upper radial cable and<br />

ring cable<br />

Figure 2. Layout of ring cable<br />

connected to the so called ring<br />

cable connectors. These are 2.5t<br />

castings, which have two vertically<br />

arranged cleats, connect the upper<br />

and lower radial cables to the ring<br />

cables. The upper and lower radial<br />

cable, also fully locked galvan<br />

cables are interconnected with<br />

8 hanger cables each build up the<br />

80 cable trusses. The cables are<br />

fabricated with fork terminals at<br />

each end. One end connects to the<br />

ring cable connector and the other<br />

end connects to cleats at the upper<br />

and lower compression rings.<br />

1 3 5<br />

2<br />

Figure 3. Lifting of spreader bar<br />

Figure 4. Cable net roof construction<br />

Figure 5. Pinning of fork terminal<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 9<br />

4

For the installation the radial<br />

cables and ring cables are laid out<br />

in the stadium bowl. The open ends<br />

of the radial cables are fitted with<br />

temporary spreader bars to take on<br />

the lifting equipment. The upper<br />

radial cables are pulled towards the<br />

upper compression ring with strand<br />

jacks and pinned. This process will<br />

lift the cable net completely off<br />

the ground. Then the last 1.5m of<br />

the lower radial cables are pulled<br />

with the threaded bars and hollow<br />

hydraulic cylinders towards the<br />

lower compression ring until all<br />

cables can be pinned. This process<br />

is called the “big lift” and takes<br />

about 30 days.<br />

Membrane structure<br />

(Fig. 6 to Fig. 11)<br />

For the next installation step the<br />

membrane roof panels are fitted<br />

onto the completely stressed cable<br />

net. Each of the 80 bays consists of<br />

about 600m² PTFE/Glass mem -<br />

brane panels with an approximate<br />

weight of one tone. The membrane<br />

Installation of the membrane<br />

Figure 6. Beginning of membrane installation<br />

Figure 7. Roof view from below<br />

Figure 8. High point installation<br />

10 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

fields will be cut from the virgin roll<br />

material, welded and assembled<br />

ready-to-install off site in the<br />

factory. They get packed, shipped to<br />

site and directly lifted onto the roof.<br />

The membranes are unfurled from<br />

the rolling rack on the lower<br />

compression ring. The membrane is<br />

then connected at the circular cut<br />

outs to the already positioned but<br />

lowered flying struts. The final<br />

shape and prestress is brought into<br />

the membrane by lifting the flying<br />

struts into their final position.<br />

This process is assisted by hydraulic<br />

jacks at the footing of the flying<br />

struts. The roof structure is<br />

completed after all the 640 light<br />

domes are mounted.<br />

! Gregor Grunwald<br />

: gregor.grunwald@<br />

hightexworld.com<br />

! Markus Seethaler<br />

markus.seethaler@<br />

hightexworld.com<br />

: www.hightexworld.com<br />

© Pictures: Hightex GmbH<br />

Name of the project: Olympic Stadium Kiev<br />

Location address: City of Kiev, Ukraine<br />

Client (investor): Olympic National Sports Complex, Ukraine<br />

Function of building: sport stadium<br />

Year of construction: 2010-11<br />

Architects: gmp • Architekten von Gerkan, Marg und Partner,<br />

Personal Creative Architectural Bureau Y. Serjogin<br />

Structural engineers: SBP – Schlaich Bergermann und Partner<br />

Manufacture and installation of cable net and membrane: Hightex GmbH<br />

Supplier of the membrane material: Verseidag-Indutex GmbH<br />

Material: PTFE-Glass<br />

Covered surface (roofed area): approx. 45.000m²<br />

6 7<br />

8<br />

10<br />

Figure 9. Roof top view<br />

Figure 10. Different stages of high point<br />

installation<br />

Figure 11. Installation of the high point<br />

clamping profile<br />

9<br />

11<br />

Anticlastic minimal<br />

surfaces as elements<br />

in architecture<br />

Introduction<br />

On the basis of the research of Frei Otto<br />

and his team at IL (Uni<strong>vers</strong>ity of Stuttgart)<br />

and the resulting exceptional pioneer<br />

constructions, building with textiles as an<br />

alternative to traditional materials like wood,<br />

stone, steel, glass, and concrete was<br />

rediscovered during the last decades.<br />

Deriving from self organizing forms of Minimal<br />

Surfaces, prestressed, spatially curved<br />

Membrane Structures were up to today<br />

mainly used for wide span, lightweightstructures.<br />

For this reason membrane<br />

structures tend to be seen from a<br />

structural or material point of view only.<br />

In contrast to our right-angled, conventionally<br />

built environment the desire for fluent<br />

“soft” spaces in architecture cannot be<br />

o<strong>vers</strong>een any more. The possibility to create<br />

light and fluent spaces as a symbiosis of<br />

form and structure offers new qualities<br />

and chances in the architectural design<br />

of residential or office buildings for example.<br />

Subject<br />

This article presents the overview of the<br />

research on spatially curved Minimal Surfaces<br />

that considers the infinite possibilities of<br />

membrane forms as elements in architecture<br />

in combination with common buildingtechnologies<br />

and shows new capabilities in<br />

designing and creating spaces. Seen as an<br />

element in the design of architecture these<br />

anticlastic, fluent forms caused by structural<br />

conditions, follow the rules of formfinding in<br />

its initially (by Frei Otto) defined sense.<br />

Very often we misuse the term „formfinding“.<br />

What Architects mostly mean and do is a man<br />

controlled process of shaping - a process that<br />

happens on a consciously controllable and<br />

formal level. In contrast to the mancontrolled<br />

process of shaping, forms that are<br />

arising from self organizing processes can only<br />

be influenced by the design of their<br />

boundaries. The form itself can only be found<br />

and represents the result which cannot be<br />

manipulated. The architect finds himself in the<br />

unusual position of a creative “formfinder”<br />

instead of the “shaper”.<br />

The fluent forms of Minimal-Surfaces are<br />

fascinating by their variety, structural<br />

performance, reduction to the minimal in<br />

terms of material use and resources and their<br />

special fashion-resistant aesthetics.

RESEARCH<br />

SOFT.SPACES<br />

Together these parameters represent the<br />

common basis of a potential design or design<br />

concept and characterize its grade of<br />

sustainability.<br />

Objectives<br />

Since self organizing processes follow precise<br />

rules and contain optimization by their<br />

nature descriptions and especially in<br />

architecture illustrations of these rules can be<br />

used as design tools [1] . To find out about the<br />

chances for an architecture between „hard“<br />

and „soft“ morphology, basic research on the<br />

systematic determination of very different<br />

boundaries - the interface between<br />

membranes and common construction<br />

technologies - enables the opportunity to<br />

analyze anticlastic Minimal Surfaces<br />

regarding form and curvature. Vice <strong>vers</strong>a we<br />

get an idea of the correlation between 3dcurvature,<br />

deflection and determined<br />

boundary and further on an idea of formal<br />

and structural behavior. In this context the<br />

assessment and visualization of the Gaussian<br />

curvature, which were adapted especially to<br />

this research, played an important role.<br />

Special Specifications<br />

1 Minimal surface<br />

All experiments are restricted to forms that<br />

can be derived from the results of soapfilm<br />

models – the Minimal Surface. As long as<br />

boundary conditions are not changed,<br />

Minimal Surfaces can be arranged as a unity<br />

arbitrarily in space without changing its<br />

form/geometry.<br />

2 Interface<br />

Linear, maximal 2dimmensionally curved,<br />

bending resistant, line supported boundaries<br />

Figure 1. Physical study model -<br />

showing catenoids between<br />

shifted circular rings<br />

Figure 2. Sequence of Soapfilm<br />

Models<br />

turned out to be the ideal interface between<br />

membranes and common construction<br />

technologies. All further experiments were<br />

restricted to boundaries of that kind.<br />

3 Membranes as an integrative<br />

element<br />

Membranes are seen as an integrative<br />

component of architecture and are directly<br />

connected to other elements of common<br />

construction methods. In terms of structural<br />

effectiveness the surfaces themselves are<br />

considered to be highly efficient by their<br />

spatial curvature but not to be load bearing<br />

elements for other structural members<br />

although newest approaches in the author`s<br />

research are dealing with this possibility.<br />

Investigations<br />

The range of exploration co<strong>vers</strong> wall-like<br />

elements, T-shaped connections, solutions<br />

for vertical, horizontal and free corners and<br />

the tubular entities of the Catenoid.<br />

Methods<br />

Besides physical (Fig. 1) and soapfilm models<br />

(Fig. 2) mainly digital experiments (Fig. 3)<br />

were used for the interpretation and the<br />

verification of results. Soapfilm models were<br />

mainly considered to fulfill a control<br />

function. Digital models were essential for<br />

the analysis and evaluation of forms (section<br />

curves, their diagrammatic overview, analysis<br />

of angles in space,…) of Minimal Surfaces. In<br />

this context the assessment and visualization<br />

of the Gaussian curvature (Fig. 4), which were<br />

adapted especially to this research, made it<br />

possible to compare and to draw one`s<br />

conclusions on different forms and their<br />

structural behavior.<br />

Figure 3. Digital model of a<br />

catenoid between circular rings<br />

and Visualization of Gaussian<br />

Curvature<br />

Figure 4. Special unification of<br />

assessment and visualization of<br />

the Gaussian curvature for this<br />

research<br />

Results of<br />

investigation<br />

The results of physical, soapfilm and mainly<br />

digital experiments show surprising and<br />

partly new correlations between form and<br />

boundary proportions and so far unknown<br />

rules of the self organizing processes of<br />

Minimal Surfaces – especially in the field of<br />

the Catenoid. The overview and the<br />

comparison of the results as well as the<br />

possibility of a targeted selection can<br />

therefore be the basis for creative<br />

applications.<br />

1 Minimal surfaces between<br />

straight lines and boundaries<br />

consisting of segments of a circle<br />

All experiments related to this series (Fig. 5)<br />

show, that for this boundary condition it is<br />

not possible to find a fully anticlastic curved<br />

Minimal Surface. Those surfaces which show<br />

few flat areas are generated within a<br />

relatively small spectrum of boundary<br />

conditions. They concentrate on boundary<br />

conditions consisting of semicircles with a<br />

diameter that corresponds to the distance of<br />

the boundaries. Independent of the<br />

amplitude of the curved boundary Minimal<br />

Surfaces tend to be flat in the near of the<br />

straight line boundary.<br />

Experiments show that in average up to 96%<br />

of the horizontal deflection that was given by<br />

the curved boundary is disappearing halfway<br />

between the upper and lower boundary.<br />

Horizontally shifted boundaries (Fig. 6) can<br />

be interesting from the architectural point of<br />

view. But in terms of anticlastic Gaussian<br />

Curvature this always means a further<br />

increase of flat areas.<br />

1 2 3 4 5<br />

6<br />

Figure 5. Minimal Surfaces<br />

between straight lines and<br />

boundaries consisting of<br />

segments of a circle<br />

Figure 6. Horizontally shifted<br />

boundaries<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 11

RESEARCH<br />

2 Minimal surfaces between<br />

boundaries consisting of<br />

segments of a circle<br />

In this case the boundaries of wall like Minimal<br />

Surfaces can have the same direction or they<br />

can be arranged in<strong>vers</strong>ely. Horizontally shifted<br />

boundaries represent special cases and show<br />

interesting architectural effects. The horizontal<br />

offset can be in longitudinal, cross or diagonal<br />

direction.<br />

Minimal Surfaces between boundaries<br />

consisting of segments of a circle<br />

in the same direction<br />

Boundaries that are curved in the same<br />

direction (Fig. 7) generally effect strong<br />

anticlastic curvature of Minimal Surfaces.<br />

Boundary conditions consisting of semicircles<br />

with a diameter that equals the distance of the<br />

boundaries can be qualified as 100% spatially<br />

curved. Section lines show the smallest circle<br />

of curvature exactly on half height and<br />

harmonic development of the surfaces (Fig. 8).<br />

Minimal Surfaces between boundaries<br />

consisting of in<strong>vers</strong>ely arranged segments<br />

of a circle<br />

Curved and in<strong>vers</strong>ely arranged boundary<br />

conditions effect anticlastic curvature covering<br />

most of the surface, even if the boundaries have<br />

little oscillation from the longitudinal axis. The<br />

mostly curved surface can be developed with<br />

boundaries consis ting of semicircles with a<br />

diameter of 2/3 of the distance of the<br />

boundaries (Fig. 9). Areas with little spatial<br />

curvature can first of all be found exactly at the<br />

maxima of boundary curvature and on half<br />

height. Starting from the ideal case these flat<br />

areas increase with increasing as well as with<br />

decreasing diameters of the base-circles.<br />

Surfaces arising from boundary conditions with<br />

base-circles bigger than the height show<br />

12 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

Figure 7. Boundary configurations consisting of<br />

segments of circles having the “same direction”<br />

Figure 8. Vertical section of digital models and<br />

their circles of curvature, all having their center<br />

at half height.<br />

Figure 9. EM KK 2/3 _ 1,00HK ggs<br />

Figure 10. EM KK 2/1 _ 0,50HK ggs<br />

Figure 11. EM KK 1/2 _ 1,00HK ggs<br />

Figure 12. Horizontal Corner<br />

Figure 13. Vertical Corner<br />

Figure 14. Free Corner 7 8<br />

9 10<br />

11<br />

flattened vertical stripes (Fig. 10) whereas<br />

flattened horizontal stripes (Fig. 11) appear with<br />

boundaries consisting of segments of circles<br />

with less than the height.<br />

3 Membranes corners<br />

Regarding corner solutions, boundaries can be<br />

arranged horizontally (Fig. 12) or vertically (Fig.<br />

13). The free corner (Fig. 14) describes a special<br />

case. The vertical and free membrane corner<br />

will not be described in this article..<br />

Horizontal membrane Corner<br />

All executed experiments with horizontal rightangled<br />

corners show almost constant surface<br />

curvature (Fig. 15) and deflection in the area of<br />

12 13 14<br />

15 16 17<br />

18 19<br />

the corner (Fig. 16). This happens<br />

independently form the leg length and from<br />

being arranged symmetrically or asym metri -<br />

cally. The section lines of digital models are<br />

congruent (Fig. 17). Leg length being shorter<br />

than the height cause surfaces with little<br />

anticlastic curvature. Surfaces of maximum<br />

spatial curvature in all areas can be achieved<br />

with a ratio 1/1 to 3/2 of leg length/height.<br />

Increased leg length causes areas with little<br />

anticlastic curvature at the end of the legs.<br />

4 T-connection<br />

Surfaces meeting in a T-connected boundary<br />

(Fig. 18) generate a Y-intersection (Fig. 19).<br />

Figure 15.<br />

Horizontal corner with<br />

ratio of 1 1 1<br />

(leg/leg/height)<br />

Figure 16.<br />

Horizontal corner with<br />

ratio of 111 Gaussian<br />

Curvature<br />

Figure 17.<br />

Horizontal section lines<br />

„Horizontal Membrane<br />

Corner“ – in comparison<br />

Figure 18.<br />

Geometry of right angled<br />

T-connection<br />

Figure 19.<br />

Minimal Surface generated<br />

from a right angled<br />

T-connection

Figure 20. Displacement of vertical section lines from right<br />

angled T-connection with symmetric wing length and<br />

different element length [EL]<br />

Figure <strong>21</strong>. T-connection with square boundary geometry<br />

FL = EL/2<br />

Figure 22. Linear increase of displacement at increasing<br />

element length up to EL/2=FL, then nonlinear<br />

Figure 23. T-connections different from 90°<br />

Figure 24. T-connection with an angle of 60°<br />

Figure 25. Vertical section lines T30°, T45°, T60°, T75°<br />

Figure 26. Spatially curved intersection line for T60°<br />

This happens independently from the angle<br />

of the boundary connection. The 3 different<br />

parts of the Minimal Surface meet with 120°<br />

and form an arch-like intersection. This arch<br />

is less curved at its angular point and more<br />

curved the closer it is to the T-connection of<br />

the boundary. „In very special cases only, a<br />

circular intersection can be formed .” [2]<br />

These special cases were used to form<br />

pressure resistant arches for real structures.<br />

Right-angled T-connection<br />

In terms of right-angled configurations the<br />

leg length of H (0) has no influence on the<br />

form of the generated Minimal Surface as<br />

long as it is longer than the deflection of the<br />

Y-intersection. This happens to be the same,<br />

independently from the wings being<br />

arranged symmetrically or asymmetrically.<br />

> Symmetric wing lenght [FL]: For symmetric<br />

wing length [FL] one can determine that the<br />

magnitude of the Y-intersection is directly<br />

connected to the ratio of wing length and<br />

element length. For all boundary conditions<br />

with FL ≥ EL/2 the magnitude of the<br />

Y-intersection equals 20,6% of the element<br />

length. For wing length shorter than the<br />

element length, a nonlinear behavior of the<br />

Y-intersection can be determined. So the<br />

boundary condition FL=EL/2 represents the<br />

borderline between linear and nonlinear<br />

development of displacement in the<br />

direction of H (Fig. 20). A square geometry in<br />

plan causes evenly distributed curvature in<br />

the surface (Fig. <strong>21</strong>).<br />

The curved Y-intersection is similar to a<br />

basket arch (Fig. 22). Starting from a square<br />

geometry in plan increased wing length<br />

results in the generation of insufficiently<br />

curved areas at the ends of the wings. On the<br />

other hand there are no effects on the form,<br />

radii of curvature of the Minimal Surface and<br />

the transitional zone with anticlastic<br />

curvature to insufficiently curved areas does<br />

not move. The enlargement of the element<br />

length which corresponds propor tionally to a<br />

reduction of the wing length causes<br />

insufficiently curved areas which are merged<br />

together in the element middle. Strong<br />

anticlastic curvature is limited to the areas of<br />

the T-connection of the boundary.<br />

> Asymmetric wing lenght [FL]: Spatially<br />

curved Y-intersections and spatially<br />

curvature of all partial areas are generated by<br />

asymmetric wing length. The horizontal<br />

component of the deflection always occurs<br />

in direction of the larger wing.<br />

Non-right-angled T-connections<br />

When using T-connected boundaries with<br />

angles different from 90° the surface of H<br />

(Fig. 23), which is totally flat for the 90° case,<br />

will be spatially curved too. Increasing<br />

deviation of 90° goes along with increasing<br />

anticlastic curvature of surface H (Fig. 24).<br />

The formally interesting Minimal Surfaces<br />

which develop as a result of a T-connection<br />

with a not at right angles deviating surface H<br />

show spatially curved intersection lines. The<br />

more the angle differs from 90° the more the<br />

anticlastic curvature of H increases. At the<br />

same time the vertical deflection of the<br />

former horizontal parts decreases.<br />

RESEARCH<br />

<strong>21</strong> 22<br />

23<br />

25 26<br />

5 Catenoid<br />

The shape of the catenoid is basically<br />

generated by a catenary that rotates around<br />

a longitudinal axis. It is the only rotational<br />

body that can be minimal surface at the<br />

same time. As we know from SFB230 the<br />

maximum attainable height of a catenoid<br />

spanning two circular rings is approximately<br />

1,3 times the radius of a ring. [3]<br />

For conceptual designs in architecture,<br />

boundaries different from two identical<br />

circles but with different diameters, not<br />

being arranged in one axis and/or not being<br />

symmetrically arranged are needed. So the<br />

maximum attainable heights of catenoids<br />

with different boundary geometries and<br />

arrangements were examined. New rules<br />

could be found for major boundary<br />

configurations [4] . The resulting diagrams can<br />

be scaled at will.<br />

Catanoids between circular rings<br />

of different diameters<br />

Starting from the extreme of 1,3 times the<br />

radius of a ring the maximum height of a<br />

20<br />

24<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 13

RESEARCH<br />

catenoid is decreasing if one of the rings<br />

diameter is decreasing (Fig. 27).<br />

Fig. 27 also illustrates that upper rings<br />

smaller than 1/5 (upper ring /lower ring)<br />

effect very little maximum attainable<br />

height and surfaces with little Gaussian<br />

Curvature at the same time. Several<br />

experiments showed that all the<br />

attainable maxima in dependence from<br />

the given diameters are located on a<br />

common circle - the extreme value circle.<br />

This circle again is in direct proportion to<br />

the circular base ring (Fig. 28).<br />

The developed diagram allows a<br />

determination of the maximal attainable<br />

height when the diameters of the two<br />

rings are given. The other way round<br />

the maximal diameter of the upper ring<br />

can be found by predefining the desired<br />

height and the diameter of the base ring<br />

(Fig. 29).<br />

Case-Study A (Fig. 30)<br />

A catenoid is perforating several floors<br />

and creates a courtyard situation.<br />

Its position is chosen the way that the<br />

ground floor gets a spatial incision whilst the<br />

other floors are still connected by a catwalk<br />

between catenoid and facade.<br />

14 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

28<br />

32<br />

35<br />

Case-Study G (Fig. <strong>31</strong>)<br />

The form of the catenoid is intersected with<br />

a rectangular building. In this case the<br />

catenoid was tilted in the direction from<br />

(left) and towards (right) the building. For<br />

this reason the opening in the façade opens<br />

on top and narrows to the sky inside the<br />

courtyard (left) and vice <strong>vers</strong>a (right).<br />

Catenoids between shifted circular<br />

rings<br />

A displacement of the boundary rings<br />

effects lower maximum heights of<br />

catenoids<br />

(Fig. 32).<br />

This correlation also follows precise rules.<br />

The interrelation of displacement of<br />

boundary rings and maximal attainable<br />

height of the catenoid can be found on<br />

circular movements defined by the center<br />

of the base ring and the diameter of the<br />

rings (Fig. 33).<br />

At the same time we can observe that a<br />

displacement of more than ¾ of the<br />

diameter of the rings effects areas with<br />

little Gaussian Curvature. Strongly curved<br />

areas can always be found at half height of<br />

the catenoid. A displacement of 1 diameter<br />

27<br />

29<br />

33<br />

36<br />

of the boundary rings cannot be attained<br />

with a catenoid but forms two separated<br />

surfaces within the rings.<br />

Case-Study K (Fig. 34)<br />

A horizontal displacement of one of the<br />

boundaries of the catenoid enables a spatial<br />

movement. For the fact that the base rings of<br />

displaced catenoids have equal diameter<br />

they can act like swivel plates. This way<br />

vertical connections or orientation to natural<br />

light can be solved.<br />

Catenoids between square rings<br />

of the same side lenght<br />

Compared to catenoids generated by two<br />

circular rings, catenoids between two equal<br />

square rings (Fig. 35) are having their<br />

maximum height at 1,44times of the side<br />

length of the square (Fig. 36). In analogy to<br />

catenoids between circular rings the maximal<br />

attainable height or the smallest possible<br />

upper square can be found on a common<br />

extreme value circle too.<br />

Catenoids between a square and<br />

a circular ring<br />

Catenoids between a square and a circular<br />

ring don`t follow an extreme value circle but<br />

30<br />

<strong>31</strong><br />

34<br />

37<br />

38

a catenarylike line starting from the center of<br />

the square and going through the quadrant<br />

of the upper circular boundary.<br />

The maximal attainable height equals<br />

1,39times the radius of the inscribed<br />

circle of the square respectively half of<br />

its side length. This is valid for configurations<br />

where the circle is the incircle at the<br />

most.<br />

Congruent cut-outs from<br />

Minimal Surfaces of Catenoids<br />

All executed investigations have shown<br />

that each randomly selected cut-out<br />

from a Minimal Surface of a catenoid<br />

will be a Minimal Surface with equal<br />

position in space and equal curvature of<br />

the surface itself. This can be explained<br />

by the absolute identical stresses in all<br />

directions of Minimal Surfaces.<br />

The example in Fig. 37 is showing a<br />

randomly selected closed curve that<br />

is projected on the surface of a catenoid.<br />

For this reason this curve is exactly<br />

matching the surface of the initial<br />

catenoid. By defining this curve as a<br />

new boundary line the new surface<br />

within this boundary is also matching<br />

the surface of the initial catenoid.<br />

40<br />

39<br />

Figure 27. Change of form and change of Gaussian<br />

Curvature of a Catenoid with decreasing<br />

diameter of upper ring and therefore decreasing<br />

height<br />

Figure 28. 3dimensional diagram for catenoids<br />

between circular rings of different diameters<br />

Figure 29. Soapfilm model and diagram for<br />

catenoids between circular rings of different<br />

diameters<br />

Figure 30. Case-Study A<br />

Figure <strong>31</strong>. Case-Study G<br />

Figure 32. 3d view of overlayed catenoids between<br />

shifted circular rings showing the circular<br />

movement of the upper ring and the<br />

dependence of horizontal displacement of the<br />

rings and the loss of height.<br />

Case-Study M2 (Fig. 38)<br />

The intersection of several catenoids is<br />

possible without changing of form of the<br />

different parts. This way 3dimensionally<br />

curved ridges are developed by the inter sec -<br />

tion line.The definition of the new boundary<br />

can be found as described before, but it can<br />

also be found by intersecting different<br />

independent catenoids or by intersection<br />

with other forms. As shown in case-study M2<br />

(Fig. 38) catenoids even don`t need to have<br />

the same position in space or the same size.<br />

This way a lot of possibilities are open for a<br />

potential design in architecture.<br />

Conclusion on research,<br />

case-studies and<br />

experimental structures<br />

The characteristics that Minimal Surfaces<br />

can be proportional scaled and that a<br />

predefined cut-out of minimal surface<br />

keeps unchanged multiplies the<br />

possibilities for the design. Using the found<br />

rules case studies give an idea of the<br />

infinite possibilities that are open to create<br />

very special „soft spaces”, with new<br />

architectural qualities like shown in above<br />

case studies and experimental structures<br />

(Fig. 39 to Fig.41) and furthermore.<br />

Figure 33. Side view of overlayed catenoids between<br />

shif ted circular rings showing the circular move -<br />

ment of the upper ring and the dependence of<br />

ho ri zontal displacement of the rings and the loss<br />

of heigh<br />

Figure 34. Case-study K<br />

Figure 35. 3dimensional diagram for catenoids<br />

between square rings of the same side length<br />

Figure 36. Diagram for catenoids between square<br />

rings of the same side length<br />

Figure 37. Congruent cut-outs from Minimal<br />

Surfaces of Catenoids<br />

Figure 38. Case Study M2<br />

Figure 39. “Cube of Clouds” experimental<br />

structure in model and in scale 1/1 by<br />

koge, Institute of Structure and Design,<br />

Perspective<br />

Latest approaches are dealing with alter na -<br />

tive boundary-conditions and with software<br />

implementation in terms of scripting found<br />

rules [5] (Fig. 42). The aspect of geometrical<br />

regularity a visual irregu larity of anticlastic<br />

Minimal Surfaces is subject of an actual re -<br />

sear ch project. An investigation on the<br />

cor re lation of self organizing forms, their<br />

close relation to nature and their aesthetic<br />

values also seems to be interesting questions<br />

for the future.<br />

! Günther H. FILZ<br />

: guenther.filz@uibk.ac.at<br />

© www.koge.at<br />

RESEARCH<br />

REFERENCES<br />

[1] Filz, Günther, “DAS WEICHE HAUS soft.spaces”,<br />

Dissertation, Leopold-Franzens-Uni<strong>vers</strong>ität Innsbruck,<br />

Fakultät für Architektur, Juli 2010<br />

[2] Otto, Frei, IL 18, Seifenblasen, Karl Krämer Verlag,<br />

Stuttgart 1988<br />

[3] Mitteilungen des SFB230, Heft7, Sonderforschungsbereich<br />

230, “Natürliche Konstruktionen – Leichtbau in Architektur<br />

und Natur“, Uni<strong>vers</strong>ität Stuttgart, Uni<strong>vers</strong>ität Tübingen,<br />

Sprint Druck GmbH, Stuttgart 199<br />

[4] Filz, Günther, “minimal is maximal _ soft.spaces”, accep ted<br />

for Paper Proceedings, IABSE-IASS Symposium London 2011<br />

“Taller, Longer, Lighter”, London, 20-23 September 2011<br />

[5] Filz, Günther ; Maleczek, Rupert; “From Basic Research to<br />

Scripting in Architecture”, Workshop at “2nd International<br />

Conference on Architecture and Structure” and “3rd<br />

National Conference on Spatial Structures“, Centre of<br />

Excellence in Architectural Technology of the Uni<strong>vers</strong>ity of<br />

Tehran, Iran, 15-18 June 2011.<br />

41 42<br />

head E. Schaur, Uni<strong>vers</strong>ity of Innsbruck,<br />

exhibited and published at Premierentage 2005,<br />

Best of 2005 and Ziviltechnikertagung 2005<br />

Figure 40. “Cut.enoid.tower” - experimental<br />

structure with a height of about 13m in scale 1/1.<br />

The distorted appearance is generated by the<br />

interaction of pin-joint columns, which work on<br />

compression only and different <strong>vers</strong>ions of<br />

prestressed catenoids.<br />

Figure 41. “minimal T”– structure shows the<br />

possibility to deflect surfaces that were flat<br />

before being assembled by using special<br />

geometries in arrangement<br />

Figure 42. Grasshopper script “Catenoids between<br />

horizontally shifted circular rings”<br />

TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011 15

Context<br />

LAVA’s Home of the Future is a<br />

showcase for future living, with<br />

nature, technology and man in a<br />

new harmony. The Home of the<br />

Future will start construction in late<br />

2011 on the rooftop of a new<br />

furniture mall in Beijing, China (Fig.1).<br />

Project<br />

An ETFE geodesic skydome provides<br />

a year-round microclimate that<br />

opens up the home to a garden filled<br />

with sun, light and fresh air, away<br />

from the pollution and noise of the<br />

city (Fig. 2). Visitors will experience<br />

fifteen different living spaces, from<br />

internal/external bathroom zones to<br />

kitchens flowing to veggie patches<br />

and barbeques to sunken bedrooms<br />

with dream inducing lighting. At<br />

night the home and the tropical<br />

garden turn into an otherworldly<br />

experience, with the underlying<br />

technology, the electronic veins of<br />

the system, coming to life.The<br />

design is inspired by nature’s<br />

efficiencies – corals, cells and<br />

bubbles - and creates an environ -<br />

ment where technologies are<br />

invisibly integrated to satisfy every -<br />

day needs and senses. Its fluid design<br />

16 TENSINEWS NR. <strong>21</strong> – SEPTEMBER 2011<br />

Figure 1. Visualization Future Living day and night.<br />

® Doug and Wolf<br />

and organisational strategy based on<br />

cells is easily modified to suit specific<br />

requirements. The Home of the<br />

Future integrates the latest improve -<br />

ments in comfort and instantaneous<br />

information technology with a space<br />

that embraces nature.<br />

Figure 2. Section trough the ETFE geodesic skydome. ® Doug and Wolf<br />

La Plata Stadium<br />

Argentina<br />

Chris Bosse, Director of LAVA says:<br />

'The Home of the Future acts as a<br />

metaphor for the questions of our<br />

times, our relationship with nature,<br />

with technology and with ourselves'.<br />

LAVA’s Home of the Future is a<br />

showcase for future living - it<br />

balances man’s needs with nature<br />

and technology in perfect harmony.<br />

Team LAVA: Chris Bosse, Tobias<br />

Wallisser, Alexander Rieck<br />

Landscape: Aecom<br />

Engineering support: Arup<br />

ETFE: Vector Foiltec<br />

! Jane Sil<strong>vers</strong>mith<br />

: jane_sil<strong>vers</strong>mith@mac.com<br />

: www.l-a-v-a.net<br />

A COMPLETED ROOF MADE OF 30.000M² HIGH-LIGHT TRANSMISSION MEMBRANES<br />

SAINT-GOBAIN BIRDAIR<br />

Context<br />

More than 10 years ago, over 30.000m² of ULTRALUX® I Architectural<br />

Membrane was manufactured to top a new stadium in La Plata, Argentina.<br />

For various reasons, the stadium was built but the roof was never installed<br />

until last year . The roof features a unique style, a double cable dome which<br />

provides a figure eight shape, was added to complete this beautiful stadium.<br />

Today, the stadium is completed and looks amazing (Fig. 1).<br />

Membrane<br />

For the membrane the high translucency architectural membrane ULTRALUX<br />

was chosen. ULTRALUX is made of fiberglass and polytetrafluoroethylene<br />

(PTFE) and provides about 25% light transmission as opposed to standard<br />

products which provide 10 to 16% light transmission. ULTRALUX is<br />

manufactured by Saint-Gobain in the Merrimack, NH plant.<br />