Nondestructive Evaluation: Wood (PDF) - The Association For ...

Nondestructive Evaluation: Wood (PDF) - The Association For ...

Nondestructive Evaluation: Wood (PDF) - The Association For ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

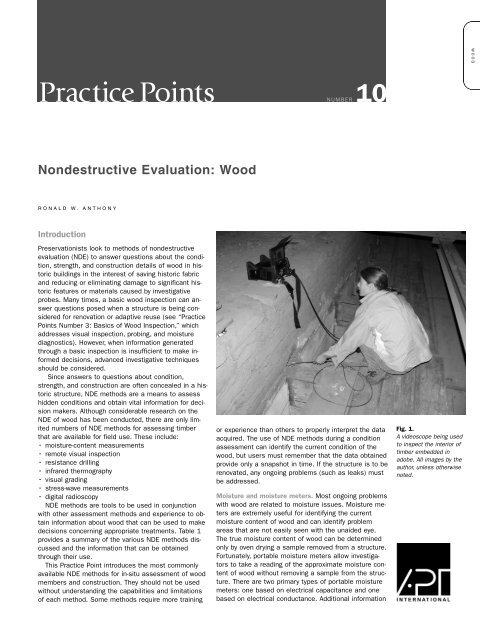

W OODPractice PointsNUMBER10<strong>Nondestructive</strong> <strong>Evaluation</strong>: <strong>Wood</strong>RONALD W. ANTHONYIntroductionPreservationists look to methods of nondestructiveevaluation (NDE) to answer questions about the condition,strength, and construction details of wood in historicbuildings in the interest of saving historic fabricand reducing or eliminating damage to significant historicfeatures or materials caused by investigativeprobes. Many times, a basic wood inspection can answerquestions posed when a structure is being consideredfor renovation or adaptive reuse (see “PracticePoints Number 3: Basics of <strong>Wood</strong> Inspection,” whichaddresses visual inspection, probing, and moisturediagnostics). However, when information generatedthrough a basic inspection is insufficient to make informeddecisions, advanced investigative techniquesshould be considered.Since answers to questions about condition,strength, and construction are often concealed in a historicstructure, NDE methods are a means to assesshidden conditions and obtain vital information for decisionmakers. Although considerable research on theNDE of wood has been conducted, there are only limitednumbers of NDE methods for assessing timberthat are available for field use. <strong>The</strong>se include:• moisture-content measurements• remote visual inspection• resistance drilling• infrared thermography• visual grading• stress-wave measurements• digital radioscopyNDE methods are tools to be used in conjunctionwith other assessment methods and experience to obtaininformation about wood that can be used to makedecisions concerning appropriate treatments. Table 1provides a summary of the various NDE methods discussedand the information that can be obtainedthrough their use.This Practice Point introduces the most commonlyavailable NDE methods for in-situ assessment of woodmembers and construction. <strong>The</strong>y should not be usedwithout understanding the capabilities and limitationsof each method. Some methods require more trainingor experience than others to properly interpret the dataacquired. <strong>The</strong> use of NDE methods during a conditionassessment can identify the current condition of thewood, but users must remember that the data obtainedprovide only a snapshot in time. If the structure is to berenovated, any ongoing problems (such as leaks) mustbe addressed.Moisture and moisture meters. Most ongoing problemswith wood are related to moisture issues. Moisture metersare extremely useful for identifying the currentmoisture content of wood and can identify problemareas that are not easily seen with the unaided eye.<strong>The</strong> true moisture content of wood can be determinedonly by oven drying a sample removed from a structure.<strong>For</strong>tunately, portable moisture meters allow investigatorsto take a reading of the approximate moisture contentof wood without removing a sample from the structure.<strong>The</strong>re are two primary types of portable moisturemeters: one based on electrical capacitance and onebased on electrical conductance. Additional informationFig. 1.A videoscope being usedto inspect the interior oftimber embedded inadobe. All images by theauthor, unless otherwisenoted.

Fig. 2.A videoscope imagetaken from a bore holein a timber showinga live termite andinternal termitedamage on the left.Fig. 3.A resistance drill beingused to quantify theextent of decay in a log.on the significance of wood moisture content and theuse of moisture meters can be found in “PracticePoints Number 3: Basics of <strong>Wood</strong> Inspection.”What is the Condition of the <strong>Wood</strong>?<strong>The</strong> first questions that should be asked when renovationsor alterations are considered for a historic structurewith wooden elements are: What is the conditionof the wood? Does it have any hidden decay? Is thereevidence of current or past insect activity?While most of the available NDE methods can beused to provide some information to answer thesequestions, there are two methods that stand out fortheir usefulness in assessing conditions: remote visualinspection and resistance drilling. Infrared thermography,stress-wave measurements, and digital radioscopyhave also been used to determine wood condition,but with limited success. Methods of conditionassessment are discussed below.Remote visual inspection. Remote visual inspectionallows for the imaging of wood that is inaccessible tobasic visual inspection and beyond the capabilities ofsuch other NDE methods as resistance drilling, digitalradioscopy, and stress waves. It can be used to viewconditions or construction within inaccessible areas,such as within beam pockets or within wall constructionwith embedded timbers. Remote visual inspectioninvolves the use of either a flexible borescope or avideoscope — both of which have a very small cameramounted at the end of a long, flexible tube. A videoscopealso has a monitor that displays the imagestransmitted from the camera (borescopes are not discussedhere, but information about them can be foundin Practice Points Number 9 on nondestructive evaluationof masonry). A portable videoscope camera andinsertion tube may be as small as 1 /8-inch (3.8 mm) indiameter (Fig. 1). On some models, the camera tip articulatesin up to four directions and can have a fieldof view as large as 120 degrees. <strong>The</strong> depth of fieldvaries by camera; some models have interchangeablecamera tips that allow for a depth of field from 5 /32inch (4 mm) to infinity. Advanced models also havestereoscopic measurement tools for determining distances,lengths, and widths of viewed objects. Mostvideoscope models allow for capturing still images,and more advanced models can record video (Fig. 2).Use of a videoscope may be nondestructive if it isinserted into existing gaps, cracks, holes, or crevicestoo small for access using other forms of inspection.An alternative methodology is to drill a small hole (justlarger than the diameter of the insertion tube) into awood member to determine the interior conditions ofthe wood; this approach necessitates some destructionof the historic fabric and therefore is quasi-nondestructivein nature. As such, remote visual inspectionshould be used only where it is warranted and whenother methods are inadequate.Resistance drilling. Resistance drilling provides informationabout the condition of the wood that may behidden from visual inspection. <strong>The</strong> term “resistancedrilling” has been used to describe any drilling techniqueintended to measure the ease of drill penetrationinto wood. Portable drills with standard bits haveTable 1. Factors that Can be Determined Using NDEMETHODSRemoteFACTORS visual Resistance Infrared Stress Visual Digital Moistureinspection drilling thermography waves grading radioscopy measurementsMeasuremoisture content Limited YesLocatedeterioration Limited Yes Limited Limited YesQuantifydeterioration Limited Yes Limited LimitedAssess strength Limited EstimateDeterminemodulus of Estimate EstimateelasticityIdentify hiddenconstruction Yes Limited Limited YesdetailsLocate andassess fastenersYes2 PRACTICE POINTS 10

Fig. 6.Radiograph showingsurface corrosion of awrought-iron rod embeddedin a timber beam.Fig. 7.Radiograph illustratingpost-processing imageenhancement to betterillustrate the overlappingwood grain of a mortiseand-tenonjoint.cracks, or deterioration can attenuate and slow stresswavepropagation.To determine stress-wave transmission time, an impactdevice fitted with an accelerometer sends a startsignal to a timer at the moment of impact. A secondaccelerometer, held against the opposite side of thewood member, determines the front edge of the waveand sends a stop signal to the timer, which then displaysthe transmission time. Access to both sides ofthe wood member is required. Grain orientation affectsthe speed of the transmission, as will moisture contentsbelow 30 percent. <strong>The</strong> lower the moisture content,the faster the transmission time (for moisturecontents less than 30 percent). Moisture contentsgreater than 30 percent have little effect on transmissiontimes. Stress-wave measurements are useful forconducting an initial screening of areas of timber thatmay warrant further investigation, and they can also beused for estimating the modulus of elasticity, describedlater in this paper.Digital radioscopy. Structures have been examinedwith traditional x-ray technology using film and highenergyx-ray sources for quite some time; however, theuse of x-rays was limited due to safety concerns andhigh costs. <strong>The</strong> use of digital radioscopy for structureinvestigation is a more recent technological developmentand presents many advantages over earlier techniques:the x-ray source is a cathode-type x-ray tube(i.e., it does not contain radioactive elements) andemits low-energy pulses of x-rays. <strong>The</strong> digital image isimmediately available for viewing, so there is minimalprocessing time, which is a particularly important featurein building investigation where conditions are variableand future access may be difficult. Finally, theavailability of relatively inexpensive mass-market postprocessingsoftware extends the power of digital radioscopy.<strong>Wood</strong> conditions, including internal deterioration,due to decay fungi or insect activity, and hidden woodfailures can be determined using digital radioscopy. Itis possible, but somewhat difficult, to quantify decay orinsect damage. Decayed wood can often be identifiedin a radiograph due to the lighter color(s) of the reducedcross section, a transition from an intact grainpattern to the lack of a visible grain pattern, or a generallymottled appearance.Additionally, wood that has been attacked by insectswill also show lighter areas in a radiograph, correspondingto a loss of material. <strong>The</strong> boundaries between undamagedand damaged wood are more abrupt than fordecayed wood and tend to display a ragged or tunneledpattern. Colorization and additional image enhancementthrough post-processing manipulation canhelp to quantify the extent of damage or decay.Generally, resistance drilling, in conjunction with visualinspection, is the recommended method for assessingwood condition.How Strong is the <strong>Wood</strong>?<strong>For</strong> wood in good condition, with no decay or insectdamage, an estimate of strength can be made by determiningthe species of the wood and visually gradingthe wood members. This process of visual grading hasbeen described in a publication available through theNational Center for Preservation Technology and Trainingand is listed in the additional references section ofthis Practice Point. A summary of visual grading is describedbelow.Visual grading. <strong>For</strong> wood construction, structural engineersrely on design values referenced in the buildingcode to determine an acceptable species, size,and grade for a particular load condition. <strong>The</strong> designvalues given in the building codes for solid wood productsare established by the American <strong>For</strong>est and Paper<strong>Association</strong> and American <strong>Wood</strong> Council and publishedas the National Design Specification for <strong>Wood</strong> Construction.<strong>The</strong> published design values are based onvarious test data and procedures published by ASTMInternational that demonstrate the engineering performanceof the material.4 PRACTICE POINTS 10

Structures built before the establishment of buildingcodes or design values for wood products — and thattherefore lack grade stamps on individual wood members— present a quandary when determining what designvalues are appropriate. Frequently an assumedspecies and grade are assigned based on currentstandards and design values. However, the result ofassuming a species and/or grade is often an overlyconservative estimate of the design values and unnecessaryreplacement, repair, and retrofit decisions,along with associated unnecessary project costs anddestruction of historic fabric. Visual grading of in-situmembers allows for a more accurate assessment ofwood strength and engineering performance.<strong>The</strong> first step in visual grading is identifying thewood species. To determine the species of a wood elementof interest, a small sample should be taken froman inconspicuous location. A representative number ofsamples should be taken from every framing membertype (not from every member) to be graded. <strong>The</strong>sesamples can be analyzed for species identification bya number of wood consultants or laboratories for afee, or they can be processed by the Center for <strong>Wood</strong>Anatomy at the U.S. <strong>For</strong>est Products Laboratory inMadison, Wisconsin, at no charge.Once the species is identified, then wood-membercharacteristics, including width and thickness, knotsize, knot location, and slope of grain, can be measuredin the field and used to determine the appropriategrade. Knowing the grade allows for determiningstrength properties for design and structural analysis.Stress-wave measurements. Stress-wave transmissiontimes in wood and estimates of the density of thewood have been correlated to modulus of elasticity(stiffness). This value is useful when deflection of astructural member is important and for calculatingloads that can cause column buckling. <strong>The</strong> estimate ofthe modulus of elasticity relies on the assumed wooddensity, which can vary between trees of the samespecies, as well as along the length of any individualtree. Typically, a species-specific average value isused. However, it should be noted that the actual specificgravity can vary considerably from piece to piece.Strength estimates have also been determined fromstress-wave measurements. However, these estimatesrely on the correlation between the modulus of elasticity(which is estimated using the procedure describedabove) and a strength property, usually the modulus ofrupture (bending). Since both correlations used in thisapproach can be quite variable (due to the range ofdensity, moisture content, and strength that wood exhibitswithin a given species), the usefulness of thismethod to estimate strength is questionable for fieldapplications. <strong>The</strong> use of strength-stiffness correlationsis a reasonable statistical approach for grading newlumber involving perhaps thousands of pieces of lumber,but for individual pieces of lumber in an existingbuilding, using visual grading rules provides a deterministicapproach for providing an estimate of strengthbased on well-established procedures.Visual grading is the recommended method for assessingthe strength of wood members in situ.How is It Constructed: Are <strong>The</strong>re HiddenConstruction Details?Digital radioscopy. Digital radioscopy is used to documentconstruction details, help develop a chronologyof the construction of a historic structure, and/or identifyfastener materials, types, and sizes (Fig. 5). Digitalradioscopy can also identify alterations to a historicstructure based on construction modifications that arenot visible, as well as provide a means to evaluate interiorwood condition.Locating and determining the condition of metal fastenersembedded in wood is possible, in part, due tothe different densities of wood and metal. <strong>The</strong> highcontrast of density between the metal and surroundingwood allows for the identification of metal fasteners.Nail types, including hand-forged nails, cut nails, roseheadnails, and common wire nails, are all easily distinguished.Thread patterns for screws, bolts, and reinforcingrods can also be distinguished.Of equal significance to the historian or architect,and perhaps of greater significance to the structuralengineer, is the condition of the fasteners. Corrosion isoften hidden within the timber and can lead to catastrophicfailure. Digital radioscopy is able not only todetect embedded metal and fasteners but also toshow the presence of corrosion of the metal (Fig. 6).<strong>For</strong> wood connections, such as mortise-and-tenonjoints, the interpretation of the radiographs is morechallenging. Differences in the grain orientation of themortise and tenon within a wood joint can be seen ona radiograph when it is possible to place the sourceand imager perpendicular to the face of the joint (Fig.5). A cross-hatched pattern is typically visible wherethe two pieces of wood overlap as the tenon penetratesthe mortise (Fig. 7).Infrared thermography. Infrared thermography canbe used to determine some wood construction details,such as wood framing-member locations, when thewood is covered with plaster (Figs. 8 and 9). Althoughthis application of IRT is fairly recent and shows promise,further investigation is needed to better under-Fig. 8.Plaster ceiling with unknownsupport framing.Courtesy of JonathanSpodek.Fig. 9.Infrared thermograph ofplaster ceiling showingwood support framingabove the plaster.Courtesy of JonathanSpodek.PRACTICE POINTS 10 5

stand the capabilities and limitations when the woodis covered by a variety of materials.Digital radioscopy is the recommended method foridentifying hidden construction details.Summary of <strong>Nondestructive</strong> <strong>Evaluation</strong> of<strong>Wood</strong><strong>Nondestructive</strong> evaluation methods, when used in conjunctionwith other assessment methods and experience,can provide valuable information about woodused in structures. <strong>The</strong> information gathered throughNDE methods can yield better decisions concerning appropriatetreatments during rehabilitation, restoration,and renovation projects. It should be noted that thedata obtained from NDE methods represent a snapshotin time; therefore, any ongoing problems affectingthe wood must be addressed prior to conducting preservationor restoration efforts. Use of NDE for woodassessment as summarized below:• Moisture meters are extremely useful for identifyingthe current moisture content of wood and can identifyproblem areas that are not easily seen with theunaided eye.• Resistance drilling is the recommended method forquantifying internal wood conditions.• Visual grading is the recommended method for determiningthe strength of wood members in situ.• Digital radioscopy is the recommended method foridentifying hidden construction details.RONALD W. ANTHONY, wood scientist for Anthony & Associates,Inc., received an MS and a BS in wood science and technologyfrom Colorado State University. Since 1985 he has conductedNDE research and development for assessment of timber structures.In 2002 he received the James Marston Fitch Foundationgrant for his approach to evaluating wood in historic buildings.He can be reached at woodguy@anthony-associates.com.Additional ReferencesAmerican <strong>For</strong>est and Paper <strong>Association</strong>, Inc. Supplement: NationalDesign Specification. Design Values for <strong>Wood</strong> Construction.2005.American Society of Civil Engineers. Guideline for Structural ConditionAssessment of Existing Buildings. New York: ASCE, 1991.Anthony, R. W., K. D. Dugan, and D. J. Anthony. A Grading Protocolfor Structural Lumber and Timber in Historic Structures. NationalCenter for Preservation Technology Training, NCPTT GrantNumber MT-2210-05-NC-05, 2009.Anthony, R. W., K. D. Dugan, and D. J. Anthony. “A Grading Protocolfor Structural Lumber and Timber in Historic Structures.” APTBulletin 40, No. 2 (2009): 3–9.Anthony & Associates, Inc., and City Visions, Inc. Advances inDigital Radioscopy for Use in Historic Preservation. NationalCenter for Preservation Technology Training, NCPTT GrantNumber MT-2210-03-NC-07, 2005.Anthony, R. W. “Basics of <strong>Wood</strong> Inspection: Considerations forHistoric Preservation.” APT Bulletin 38, No. 2-3 (2007): 1–6.Anthony, R. W. “Condition Assessment of Timber Using ResistanceDrilling and Digital Radioscopy.” APT Bulletin 35, No. 4 (2004):21–26.Anthony, R. W. “Use of Portable X-Ray Equipment to InvestigateHistoric Timber Structures.” Proceedings of the Workshop onHistoric Roof Timber Frames, organized under auspices ofCzech National Committee of ICOMOS, Trest Castle, CzechRepublic, May 31-June 6, 2004.ASTM D245-00, Standard Practice for Establishing StructuralGrades and Related Allowable Properties for Visually GradedLumber. ASTM International.ASTM D2555-05a. Standard Practice for Establishing Clear <strong>Wood</strong>Strength Values. ASTM International.Gilberg, M., J. Leonard, B. Melia, and C. Riegel. “Detecting SubterraneanActivity with Infrared <strong>The</strong>rmography: A Case Study.” APTBulletin 34, No. 2-3 (2003): 47–53.James, W. L. “Fundamentals of Hand-held Moisture Meters: AnOutline.” In Proceedings of the ASTM Hand-held Moisture MeterWorkshop: May 5, 1993, Madison, WI. Madison, Wisc.: <strong>For</strong>estProducts Society (1994), 13–16.Luong, M. P. “Infrared <strong>The</strong>rmography of Damage in <strong>Wood</strong>.” Proceedingsof the Spring Conference of the Society for ExperimentalMechanics (June 1997): 225–230.Pellerin, R. F., and R. J. Ross. <strong>Nondestructive</strong> <strong>Evaluation</strong> of <strong>Wood</strong>.Madison, Wisc.: <strong>For</strong>est Products Society, 2002.Radcliffe-Trenner, A., R. W. Anthony, and E. Meade. “<strong>Wood</strong> Assessmentand Repair of Gustav Stickley’s Log House at CraftsmanFarms, New Jersey.” APT Bulletin 36, No. 2-3 (2005): 29–36.Rosina, E., and E. C. Robinson. “Applying Infrared <strong>The</strong>rmography toHistoric <strong>Wood</strong> Framed Buildings in North America.” APT Bulletin33, No 4 (2002): 37–44.Ross, R. J., B. K. Brashaw, X. Wang, R. H. White, and R. F. Pellerin.<strong>Wood</strong> and Timber Condition Assessment Manual. Madison,Wisc.: <strong>For</strong>est Products Society, 2004.Spencer, M., L. Penn, J. Nychka, L. Boyer, J. Liebertz and L.Everdale, 2008. Applying Infrared <strong>The</strong>rmography for the Purposeof Identifying Concealed <strong>Wood</strong> Framing Member Type and SubsurfaceAnomalies with Intended Application Towards HistoricStructures. National Center for Preservation TechnologyTraining, NCPTT Grant Number MT-2210-06-NC-10.Spodek, J., and E. Rosina. “Application of Infrared <strong>The</strong>rmography toHistoric Building Investigation.” Journal of Architectural Conservation15, No. 3 (2009): 65–82.© 2010 by the <strong>Association</strong> for Preservation Technology International.This Practice Point originally appeared in Vol. XLI, No.4, of the APT Bulletin, <strong>The</strong> Journal of Preservation Technology.Reprint requests should be submitted in writing to the<strong>Association</strong> for Preservation Technology International, 3085Stevenson Drive, Suite 200, Springfield, IL 62703, or toinfo@apti.org.<strong>The</strong> <strong>Association</strong> for Preservation TechnologyInternational3085 Stevenson Drive, Suite 200Springfield, IL 62703217.529.9039fax (toll free) 888.723.4242administration@apti.orgwww.apti.org