Diesel Engine Series 50 and 60 for Petroleum Applications

Diesel Engine Series 50 and 60 for Petroleum Applications

Diesel Engine Series 50 and 60 for Petroleum Applications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

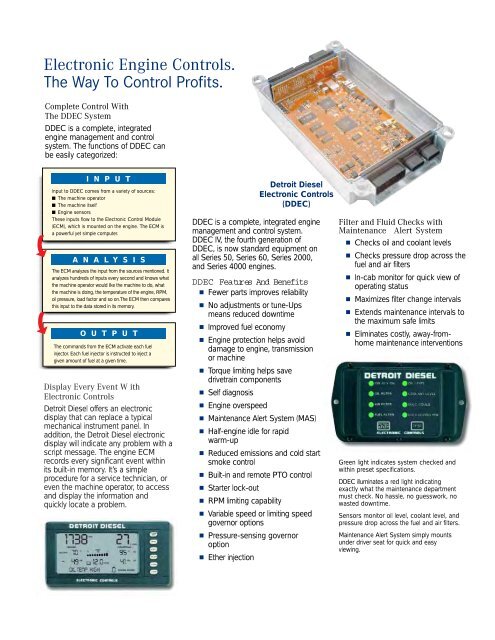

Electronic <strong>Engine</strong> Controls.The Way To Control Profits.Complete Control WithThe DDEC SystemDDEC is a complete, integratedengine management <strong>and</strong> controlsystem. The functions of DDEC canbe easily categorized:I N P U TInput to DDEC comes from a variety of sources:■ The machine operator■ The machine itself■ <strong>Engine</strong> sensorsThese inputs flow to the Electronic Control Module(ECM), which is mounted on the engine. The ECM isa powerful yet simple computer.A N A L Y S I SThe ECM analyzes the input from the sources mentioned. Itanalyzes hundreds of inputs every second <strong>and</strong> knows whatthe machine operator would like the machine to do, whatthe machine is doing, the temperature of the engine, RPM,oil pressure, load factor <strong>and</strong> so on.The ECM then comparesthis input to the data stored in its memory.O U T P U TThe comm<strong>and</strong>s from the ECM activate each fuelinjector. Each fuel injector is instructed to inject agiven amount of fuel at a given time.Display Every Event W ithElectronic ControlsDetroit <strong>Diesel</strong> offers an electronicdisplay that can replace a typicalmechanical instrument panel. Inaddition, the Detroit <strong>Diesel</strong> electronicdisplay will indicate any problem with ascript message. The engine ECMrecords every significant event withinits built-in memory. It’s a simpleprocedure <strong>for</strong> a service technician, oreven the machine operator, to access<strong>and</strong> display the in<strong>for</strong>mation <strong>and</strong>quickly locate a problem.Detroit <strong>Diesel</strong>Electronic Controls(DDEC)DDEC is a complete, integrated enginemanagement <strong>and</strong> control system.DDEC IV, the fourth generation ofDDEC, is now st<strong>and</strong>ard equipment onall <strong>Series</strong> <strong>50</strong>, <strong>Series</strong> <strong>60</strong>, <strong>Series</strong> 2000,<strong>and</strong> <strong>Series</strong> 4000 engines.DDEC Features And Benefits■ Fewer parts improves reliability■ No adjustments or tune-Upsmeans reduced downtime■ Improved fuel economy■ <strong>Engine</strong> protection helps avoiddamage to engine, transmissionor machine■ Torque limiting helps savedrivetrain components■ Self diagnosis■ <strong>Engine</strong> overspeed■ Maintenance Alert System (MAS)■ Half-engine idle <strong>for</strong> rapidwarm-up■ Reduced emissions <strong>and</strong> cold startsmoke control■ Built-in <strong>and</strong> remote PTO control■ Starter lock-out■ RPM limiting capability■ Variable speed or limiting speedgovernor options■ Pressure-sensing governoroption■ Ether injectionFilter <strong>and</strong> Fluid Checks withMaintenance Alert System■ Checks oil <strong>and</strong> coolant levels■ Checks pressure drop across thefuel <strong>and</strong> air filters■ In-cab monitor <strong>for</strong> quick view ofoperating status■ Maximizes filter change intervals■ Extends maintenance intervals tothe maximum safe limits■ Eliminates costly, away-fromhomemaintenance interventionsGreen light indicates system checked <strong>and</strong>within preset specifications.DDEC illuminates a red light indicatingexactly what the maintenance departmentmust check. No hassle, no guesswork, nowasted downtime.Sensors monitor oil level, coolant level, <strong>and</strong>pressure drop across the fuel <strong>and</strong> air filters.Maintenance Alert System simply mountsunder driver seat <strong>for</strong> quick <strong>and</strong> easyviewing.