Friatec Electrofusion Assembly Instructions

Friatec Electrofusion Assembly Instructions

Friatec Electrofusion Assembly Instructions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

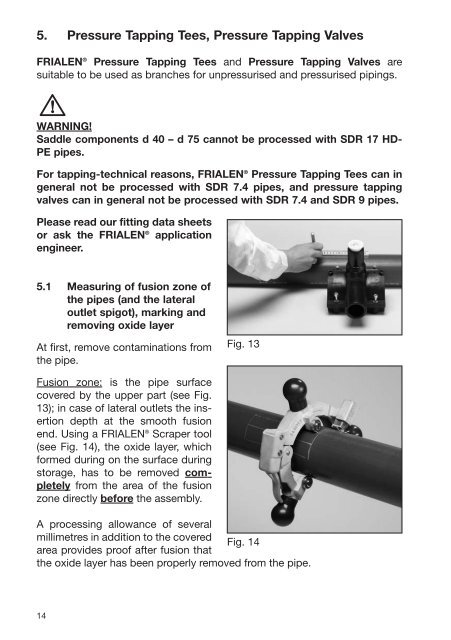

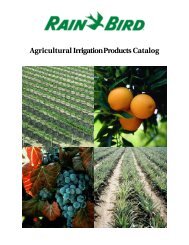

5. Pressure Tapping Tees, Pressure Tapping ValvesFRIALEN ® Pressure Tapping Tees and Pressure Tapping Valves aresuitable to be used as branches for unpressurised and pressurised pipings.WARNING!Saddle components d 40 – d 75 cannot be processed with SDR 17 HD-PE pipes.For tapping-technical reasons, FRIALEN ® Pressure Tapping Tees can ingeneral not be processed with SDR 7.4 pipes, and pressure tappingvalves can in general not be processed with SDR 7.4 and SDR 9 pipes.Please read our fitting data sheetsor ask the FRIALEN ® applicationengineer.5.1 Measuring of fusion zone ofthe pipes (and the lateraloutlet spigot), marking andremoving oxide layerAt first, remove contaminations fromthe pipe.Fig. 13Fusion zone: is the pipe surfacecovered by the upper part (see Fig.13); in case of lateral outlets the insertiondepth at the smooth fusionend. Using a FRIALEN ® Scraper tool(see Fig. 14), the oxide layer, whichformed during on the surface duringstorage, has to be removed completelyfrom the area of the fusionzone directly before the assembly.A processing allowance of severalmillimetres in addition to the coveredFig. 14area provides proof after fusion thatthe oxide layer has been properly removed from the pipe.14