update NewS from dNv to the tANker INduStry No 02 2011 - Hays

update NewS from dNv to the tANker INduStry No 02 2011 - Hays

update NewS from dNv to the tANker INduStry No 02 2011 - Hays

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

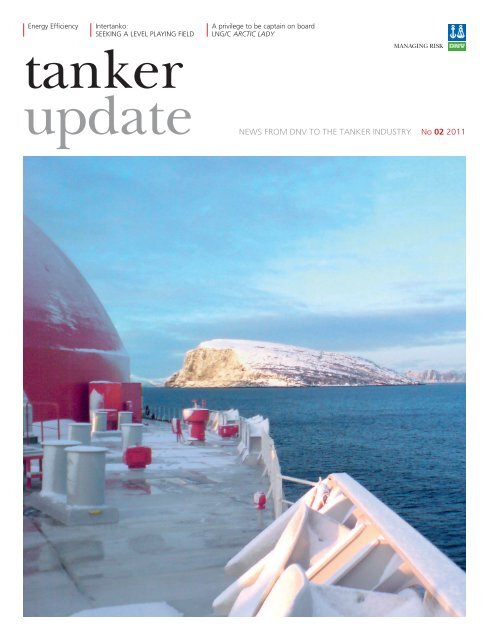

Energy EfficiencyIntertanko:Seeking a level playing fieldA privilege <strong>to</strong> be captain on boardLNG/C ARctic Ladytanker<strong>update</strong> News<strong>from</strong> DNV <strong>to</strong> <strong>the</strong> tanker industry <strong>No</strong> <strong>02</strong> <strong>2011</strong>

contents10 12Intertanko: Seeking a levelplaying field››Energy Efficiency››24A privilege <strong>to</strong> be captain on boardLNG/C Arctic Lady››Front cover: Bjørn NybergCO2 emissions <strong>from</strong> ships –<strong>the</strong> latest IMO regula<strong>to</strong>ry developmentsand what <strong>the</strong>y mean for tankers ........................ 4Impact of EEDI and SEEMP .......................................... 8Intertanko and <strong>the</strong> EEDI:seeking a level playing FIeld .............................. 10DNV’s Fuel Saving Guideline for Tankers ........... 12SEEMP and Energy EfFIciency –DNV offers support ................................................... 14Recent delivery ........................................................... 18Thenamaris FIrst <strong>to</strong> receiveDNV’s Triple-E rating ................................................ 20DNV wins Innovation Awards ............................... 22A privilege <strong>to</strong> be captainon board <strong>the</strong> Arctic Lady ...................................... 24Tanker Week .................................................................. 28RS Pla<strong>to</strong>u markets ..................................................... 29What have we learnt <strong>from</strong> his<strong>to</strong>ry? ............... 30tanker<strong>update</strong>We welcome your thoughts!Published by DNV Global Governance,Market Communications.Edi<strong>to</strong>rial committee:Jan Koren, Business Direc<strong>to</strong>r TankersMagne A. Røe, Edi<strong>to</strong>rLisbeth Aamodt, ProductionDesign and layout: Coor Media 1111-009Please direct any enquiries <strong>to</strong> DNVUpdates@dnv.comOnline edition of tanker <strong>update</strong>:www.dnv.com/tanker<strong>update</strong>DNV (Det <strong>No</strong>rske Veritas AS)NO-1322 Høvik, <strong>No</strong>rwayTel: +47 67 57 99 00Fax: +47 67 57 99 11© Det <strong>No</strong>rske Veritas ASwww.dnv.com2 | Tanker UPDATE NO. 2 <strong>2011</strong>

eDitOriala challeNgiNg DecaDeJan korenBusiness direc<strong>to</strong>r tankersJan.Koren@dnv.compiracy and very high bunkerprices are at <strong>the</strong> <strong>to</strong>pof many tanker owners’agendas right now. <strong>the</strong>sefac<strong>to</strong>rs, combined withdepressed freight rates, aremaking life very challengingfor people in <strong>the</strong> tankerindustry. with <strong>the</strong> curren<strong>to</strong>versupply of <strong>to</strong>nnage andsignificant volume of deliveriesof additional tankers,<strong>the</strong>re is little chance ofsustainable improvementsin <strong>the</strong> short term. as aconsequence, we will seemore cases of restructuring.younger vessels than beforeare candidates for scrappingand lay-ups are alsobeing discussed.new rules and regulationsare now being implemented,and this trendwill increase in <strong>the</strong> years<strong>to</strong> come. significant reductionsin emissions (nOx,sOx and CO2) <strong>to</strong> air will berequired and ballast watertreatment systems are alsoon <strong>the</strong> agenda. <strong>the</strong> implementationof new regulationsis going ahead despite<strong>the</strong> general and seriousdepression in <strong>the</strong> market.Compliance with <strong>the</strong>se regulationsis no “quick fix”.making <strong>the</strong> right decisionswill require understandingand insight plus <strong>the</strong> allocationof suitable humanand economic resources <strong>to</strong>allow serious considerationand planning. those whocan see <strong>the</strong> new regulationsas opportunities andhave <strong>the</strong> resources <strong>to</strong> actaccordingly are, of course,fortunate. some are evenintending <strong>to</strong> stay ahead of<strong>the</strong> market.in this issue of tanker<strong>update</strong>, we have a specialfocus on energy efficiencyand <strong>the</strong> new energy efficiencydesign index(eedi), which significantlylimits CO2 emissions. this isbasically about fuel saving.initially, <strong>the</strong> formal implicationsare limited, but<strong>the</strong> ultimate consequence,as we see it <strong>to</strong>day, is thatabout ten-year-old vesselsmay have <strong>to</strong> compete in<strong>the</strong> marketplace with vesselswhich are at least 30%more fuel efficient. somewill consider such competition<strong>to</strong> be quite dramatic,particularly with <strong>the</strong> fuelprices we may see in <strong>the</strong>coming years. in <strong>the</strong>irefforts <strong>to</strong> cut costs and meetcharterers’ expectations,tanker owners in particularmay <strong>from</strong> now on be lookingfor more fuel efficientvessels when planning neworders. this will drive innovation<strong>to</strong> a greater extentthan we have seen before,and make it more challengingfor owners <strong>to</strong> decide ondesign alternatives whenordering ships in <strong>the</strong> years<strong>to</strong> come. new concepts willbe developed. designers,yards and owners shouldplan for this developmentnow, even ahead of <strong>the</strong> formaldeadlines. <strong>the</strong> winnersmay be those that are able<strong>to</strong> meet market requirementsand expectationsahead of <strong>the</strong> majority.we in dnv have in-depthknowledge of existing andnew regulations and <strong>the</strong>irimplications. dnv does notdesign ships. we will, however,continue <strong>to</strong> presen<strong>to</strong>ur innovative ideas andconcepts <strong>to</strong> <strong>the</strong> industryso that anybody who finds<strong>the</strong>m of interest is free <strong>to</strong>do <strong>the</strong> necessary engineeringwork and developdesigns and specifications.<strong>the</strong> industry feedback hasbeen very positive and wehave won awards for ourwork. we are pleased <strong>to</strong>share our ideas and knowledgewith existing andnew clients. we have alsodeveloped and are offeringinformation and servicesthat support <strong>the</strong> industry inorder <strong>to</strong> meet <strong>the</strong> importantchallenges facing usin <strong>the</strong> coming decade. youwill find more about this on<strong>the</strong> following pages.enjoy <strong>the</strong> read!THEPOWERTOEXCELIN OILAND GASTRANSPORTATIONat dnv, we understand <strong>the</strong> tankerbusiness and offer services designed <strong>to</strong>assist owners and management in <strong>the</strong>irquest for safe, efficient and competitiveoperations.Ship classification • offshore classification •Technology qualification • Winterisation •Ice management • Competence & training• Safety, health & environmental riskmanagementwww.dnv.comit takes strength and agility <strong>to</strong> excel in <strong>the</strong> face of demanding transportationmarkets and <strong>the</strong> maritime safety regime. technical, economical and environmentalissues must be addressed on a day-<strong>to</strong>-day basis.<strong>tANker</strong> updAte NO. 2 <strong>2011</strong> | 3

CO2 emissions <strong>from</strong> shipsCO2 emissions <strong>from</strong> ships– <strong>the</strong> latest IMO regula<strong>to</strong>ry developmentsand what <strong>the</strong>y mean for tankersThe first formal CO2 control regulations were adopted by IMO at <strong>the</strong> MEPC 62 in July<strong>2011</strong>. These comprise <strong>the</strong> Energy Efficiency Design Index (EEDI) and Ship Energy EfficiencyManagement Plan (SEEMP), both of which will enter in<strong>to</strong> force on 1 January 2013.Text: Tore Longva, DNVA new International Energy EfficiencyCertificate (IEEC) will be introduced forall vessels, and this includes a supplementrecording particulars related <strong>to</strong> <strong>the</strong> ship’senergy efficiency, such as <strong>the</strong> propulsionsystem, <strong>the</strong> Attained EEDI for new buildsand <strong>the</strong> presence of a SEEMP.Energy Efficiency Design Index(EEDI) The EEDI requirements will apply<strong>to</strong> new ships above 400 GT only, where“new ship” means a ship:■■for which <strong>the</strong> building contract is placedon or after 1 January 2013; or■■in <strong>the</strong> absence of a building contract,<strong>the</strong> keel of which is laid or which is at asimilar stage of construction on or after1 July 2013; or■■<strong>the</strong> delivery of which is on or after 1 July2015The EEDI will be calculated for individualships and basically expressesgrams CO2<strong>to</strong>nne – nautical mileThe yard, designer or a consultant willhave <strong>to</strong> develop an EEDI technical filecontaining <strong>the</strong> necessary documentationand calculations. Verification will be donein two stages: a preliminary verificationat <strong>the</strong> design stage based on tank tests,manufacturers’ data and design particulars.During <strong>the</strong> sea trial, <strong>the</strong> speed willbe measured and <strong>the</strong> technical file will be<strong>update</strong>d, <strong>to</strong>ge<strong>the</strong>r with engine certificatesand o<strong>the</strong>r necessary documentation. TheEEDI technical file will <strong>the</strong>n be verifiedby a flag administration or RecognizedOrganisation and <strong>the</strong> IEEC will be issued.The regulation differentiates betweenship types which are required <strong>to</strong> calculateReduction fac<strong>to</strong>rs (in percentage) for <strong>the</strong> EEDI relative <strong>to</strong> <strong>the</strong> reference line for each ship type.Bulk CarrierGas tankerTanker and combinationcarriersContainer shipGeneral cargo shipsRefrigerated cargocarrier›› Table 1Size Phase 01 Jan 2013–31 Dec 2014>20,000 DWT10-20,000 DWT>10,000 DWT2-10,000 DWT>20,000 DWT4-20,000 DWT>15,000 DWT10-15,000 DWT>15,000 DWT3-15,000 DWT>5,000 DWT3-5,000 DWT0%n/a0n/a0%n/a0%n/a0%n/a0%n/aPhase 11 Jan 2015–31 Dec 2019100-10%*100-10%*100-10%*100-10%*100-10%*100-10%*Phase 21 Jan 2<strong>02</strong>0–31 Dec 2<strong>02</strong>420%0-20%*20%0-20%*20%0-20%*20%0-20%*20%0-20%*20%0-20%*Phase 31 Jan 2<strong>02</strong>5 onwards30%0-30%*30%0-30%*30%0-30%*30%0-30%*30%0-30%*30%0-30%** The reduction fac<strong>to</strong>r is <strong>to</strong> be linearly interpolated between <strong>the</strong> two values depending on <strong>the</strong> vessel size. The lower value of <strong>the</strong> reduction fac<strong>to</strong>r is <strong>to</strong> beapplied <strong>to</strong> <strong>the</strong> smaller ship size.4 | Tanker UPDATE NO. 2 <strong>2011</strong>

CO2 emissions <strong>from</strong> shipsShip type Capacity a cEEDI reference lineslarger tankersBulk carrier dwt 961.79 0.47710Gas tanker dwt 1120.00 0.456Tanker dwt 1218.80 0.488Container 70% – dwt 174.22 0.201General cargo dwt 107.48 0.216Reefer dwt 227.01 0.244EEDI (g CO2/<strong>to</strong>nne-nm)EEDI (g CO2/<strong>to</strong>nne-nm)98765432140353<strong>02</strong>5201510500 10000 20000 30000 40000 50000050000 15000<strong>02</strong>50000 350000 450000Combination dwt 1218.80 0.488›› Table 2DwtDwtTanker and combinationGas tankerTanker and combinationGas tanker›› Figure 1 EEDI reference lines based on average for tankers built during last ten years.›› Tore Longva, Business Development ManagerInternational Affairs.wan Attained EEDI and those that musthave an Attained EEDI below a certainRequired EEDI. Ship types needing <strong>to</strong>comply with a specific Required EEDI level<strong>to</strong> obtain <strong>the</strong> IEEC are listed in Table 1,which also indicates <strong>the</strong> time line for <strong>the</strong>tightening of <strong>the</strong> requirement levels.A ship’s reference line value is calculatedbased on <strong>the</strong> following formula:a · Capacity –cwhere <strong>the</strong> a and c parameters are given inTable 2 above.Pho<strong>to</strong>: DNVA ship which can load 100% deadweightwith both liquid and dry cargo is considered<strong>to</strong> be a combination carrier and canuse <strong>the</strong> same reference line as tankers. Gastankers have a separate reference line. Thereference lines for tanker and combinationcarriers as well as for gas tankers areshown in Figure 1. The lines s<strong>to</strong>p at <strong>the</strong>lower cut off lines for <strong>the</strong> ship types, belowwhich <strong>the</strong> required EEDI does not apply.In order <strong>to</strong> address concerns raisedby developing countries, <strong>the</strong> regulationsinclude a clause allowing any Administration<strong>to</strong> waive <strong>the</strong> EEDI requirements forships flying its flag for a period of up <strong>to</strong>four years (linked <strong>to</strong> <strong>the</strong> contract date),or six years and six months (linked <strong>to</strong> <strong>the</strong>delivery date) after 1 January 2013. However,<strong>the</strong> preliminary indications are that<strong>the</strong> major flag states will be reluctant <strong>to</strong>invoke <strong>the</strong> waiver clause.Ship Energy Efficiency ManagementPlan (SEEMP) <strong>No</strong> changes weremade <strong>to</strong> <strong>the</strong> SEEMP at MEPC 62, butits inclusion in <strong>the</strong> MARPOL Annex VIamendments makes it manda<strong>to</strong>ry forall ships– both new and existing – afterit enters in<strong>to</strong> force. The presence of aSEEMP onboard will be checked during<strong>the</strong> first intermediate or renewal surveyfor <strong>the</strong> IAPP certificate, at which point <strong>the</strong>IEEC will be issued. The EEDI will not becalculated for existing vessels and thus notincluded in <strong>the</strong> IEEC.Future CO2 regulations The adoptionof <strong>the</strong> amendments is a significantstep by IMO <strong>to</strong>wards <strong>the</strong> regulation ofGHG emissions. Never<strong>the</strong>less, <strong>the</strong> EU islikely <strong>to</strong> consider it insufficient in ligh<strong>to</strong>f its own ambitions. The EU processfor establishing a regional CO2 emissionreduction mechanism for shipping is<strong>the</strong>refore expected <strong>to</strong> continue.O<strong>the</strong>r parts of <strong>the</strong> international communityalso consider <strong>the</strong>se regulationsinsufficient. There is <strong>the</strong>refore a strongpolitical drive <strong>to</strong> regulate shipping fur<strong>the</strong>r,e.g. through regional or international MarketBased Measures (MBMs). Proposalsunder review range <strong>from</strong> a contribution orlevy on CO2 emissions <strong>from</strong> shipping, viaemission trading systems <strong>to</strong> schemes basedon ship efficiency. If agreed, MBMs mayappear <strong>to</strong>wards <strong>the</strong> end of this decade.Commercial energy efficiency requirementsare becoming increasingly important.The creation of various voluntaryschemes for rating environmental performance,including CO2 performance, isproviding <strong>to</strong>ols that allow charterers andcargo owners <strong>to</strong> use only ships that satisfy<strong>the</strong>ir environmental requirements. Theserating schemes must be based on robustmethods and verifiable data in order <strong>to</strong>Tanker <strong>update</strong> NO. 2 <strong>2011</strong> | 5

CO2 emissions <strong>from</strong> shipsMf( ∏ f) nME P ME (1) C FME (1) SFC( ∑ME (1)f=1f=1Main engine. . PAux, engine Shaft mo<strong>to</strong>r Energy efficienttechnology (electrical)Mf f f( ∏PTI effeff+ ( .AE C FAE. SFC AE- ) + . ∑ P PTI (1) – ∑ eff (1) P AEeff (f) C FAE SFC AEf=1f=1f=1–) (f=1f . Capacity . V .) )freff wEnergy efficienttechnology (mechanical)∑ ). . f eff (1). P eff (1). C FME. SFC MECorrection fac<strong>to</strong>rs›› Figure 2: IMO’s formula for calculation of EEDI (g CO2 / <strong>to</strong>nne-mile)Transport workMethod Measures Parameter affectedReduce <strong>the</strong> main engine installedpowerLower <strong>the</strong> specific fuelconsumptionIncrease <strong>the</strong> speed (withoutincreasing <strong>the</strong> installed power)Use fuel/an energy source with alower carbon contentInnovative mechanical energyefficient tehnologyInnovative electrical energyefficient technologyImproved hull and propellerefficiency Speed reduction/de-rate engineSwitch <strong>to</strong> a more efficient engine.Engine control tuning.Improved hull and propellerefficiency (i.e. Mewis duct,propeller boss cap fin, or o<strong>the</strong>rflow devices).I.e. LNG biofuel (no guideline yet)I.e. kites (no guideline yet)I.e. waste heat recoveryIncrease <strong>the</strong> capacity Larger ships Capacity›› Table 3: Alternatives <strong>to</strong> improve EEDIP MESFC ME, SFC AEV refC FME, C FAEP effP AEeffcreate a level playing field for <strong>the</strong> shipowner.Reducing <strong>the</strong> EEDI Any measure consideredfor reducing <strong>the</strong> EEDI must affec<strong>to</strong>ne or more of <strong>the</strong> parameters in Figure 2and Table 3.In addition, <strong>the</strong>re will be compensationwhen using shaft genera<strong>to</strong>rs (PPTO) andapplying ice streng<strong>the</strong>ning (fj). O<strong>the</strong>rcorrection fac<strong>to</strong>rs, for example for voluntarystructural enhancement, are underdevelopment.Some proposed measures, such as kitesor solar panels, cannot provide power all<strong>the</strong> time and will not enable <strong>the</strong> mainengine power and thus <strong>the</strong> EEDI <strong>to</strong> bereduced. At <strong>the</strong> moment, <strong>the</strong>re are noguidelines for how such measures can beapplied <strong>to</strong> reduce <strong>the</strong> EEDI, but <strong>the</strong>seare expected <strong>to</strong> be developed at a laterstage, most likely through <strong>the</strong> Peff parameter.Propulsion efficiency devices, suchas Mewis ducts or propeller boss cap finscan ei<strong>the</strong>r reduce <strong>the</strong> main engine power(Pme), or enable <strong>the</strong> ship <strong>to</strong> obtain a higherspeed (Vref).Fur<strong>the</strong>r, <strong>the</strong> use of biofuels is not coveredby <strong>the</strong> current framework as <strong>the</strong>ir6 | Tanker UPDATE NO. 2 <strong>2011</strong>

CO2 emissions <strong>from</strong> shipsPho<strong>to</strong>: Geos<strong>to</strong>ckcarbon content cannot easily be determined.There are no indications regardingif and when guidelines for biofuelswill be developed.Fur<strong>the</strong>r work A number of guidelinesare going <strong>to</strong> be developed during <strong>the</strong> nextfew years, with <strong>the</strong> most important beingissued before <strong>the</strong> EEDI and SEEMP enterin<strong>to</strong> force in 2013:■■February 2012 – MEPC 63: Guidelinesfor minimum propulsion power■■■■■■Oc<strong>to</strong>ber 2012 – MEPC 64: Guidelines onvoluntary structural enhancementJuly 2013 – MEPC 65: Guidelines forCO2 abatement technologiesMarch 2014 – MEPC 66: Guidelines forcalculation of EEDI for roro, passenger,diesel-electric and hybrid propulsionshipsThe requirements and dates are subject<strong>to</strong> two reviews: <strong>the</strong> first is on <strong>the</strong> requirementsfor small ships and large bulkersand tankers and is due in July 2013. Thesecond review allows for a discussion ofboth <strong>the</strong> requirements and <strong>the</strong> time linefor when Phases 2 and 3 are <strong>to</strong> enter in<strong>to</strong>force, and is due in January 2015. Tanker <strong>update</strong> NO. 2 <strong>2011</strong> | 7

Impact of EEDI and SEEMPImpact of EEDI and SEEMPThe amendments <strong>to</strong> MARPOL Annex VI on CO2 emissions were adopted by IMOin July <strong>2011</strong> and will enter in<strong>to</strong> force in 2013. IMO commissioned a joint study byLloyd’s Register and DNV <strong>to</strong> estimate <strong>the</strong> impact of <strong>the</strong> new requirements.Text: Tore Longva, DNVThe results <strong>from</strong> <strong>the</strong> study show that, asnew ships are built, <strong>the</strong> EEDI will graduallyreduce <strong>the</strong> emissions <strong>from</strong> <strong>the</strong> world fleetby 3% in 2<strong>02</strong>0, 13% in 2030 and 30% in2050. The SEEMP will not directly mandatean emission reduction but, due <strong>to</strong>increased awareness of costs and reductionpotentials, <strong>the</strong> study estimated <strong>the</strong> reduction<strong>to</strong> be 5-10% <strong>from</strong> 2015 onwards.Effect of a Ship Energy EfficiencyManagement Plan (SEEMP) The EEDIwill mandate improvements in hull designand machinery, while <strong>the</strong> SEEMP willrequire ship owners <strong>to</strong> develop a plan for<strong>the</strong>ir ships. Operational measures havesignificant reduction potentials that, basedon current fuel prices, are cost-effective.However, <strong>the</strong>re seems <strong>to</strong> be limited uptakeof <strong>the</strong>se measures caused by non-financialbarriers, such as lack of competence, lackof cooperation between players and splitincentives. Higher fuel prices will onlylead <strong>to</strong> a limited extra implementationof measures, but over time <strong>the</strong>y will drivetechnology development and innovation.O<strong>the</strong>r incentives will have <strong>to</strong> be in place<strong>to</strong> implement <strong>the</strong> existing set of measures.The SEEMP will initiate moni<strong>to</strong>ring andtarget setting as well as <strong>the</strong> examinationof concrete measures <strong>to</strong> be implementedfor each vessel. Awareness of <strong>the</strong> potentialsavings is expected <strong>to</strong> increase <strong>the</strong> uptakeof measures.Pho<strong>to</strong>: DNVWaiver clause In <strong>the</strong> final negotiations,a clause was inserted in <strong>the</strong> regulations8 | Tanker UPDATE NO. 2 <strong>2011</strong>

Impact of EEDI and SEEMPWorld fleet – Average scenario: A1B-4 and B2-135003000CO2 [mill <strong>to</strong>nnes]250<strong>02</strong>00015001000500<strong>02</strong>010 20152<strong>02</strong>0 2<strong>02</strong>5 2030 2035 2040 2045 2050allowing flag states <strong>to</strong> waive <strong>the</strong> EEDIrequirements for <strong>the</strong>ir fleets for up <strong>to</strong> fouryears after entry in<strong>to</strong> force. It is still uncertainhow many flag states will apply thiswaiver clause. Complying with <strong>the</strong> requirementsin Phases 0 and 1 is expected <strong>to</strong> comeat low cost. There is no commercial reason<strong>to</strong> order a ship without a calculated EEDI,as <strong>the</strong> second-hand value may be lower and<strong>the</strong> ability <strong>to</strong> get a charter may be reducedas charterers will prefer ships with a low(and thus calculated) EEDI. If only <strong>the</strong> threeflag states opposing <strong>the</strong> amendments waive<strong>the</strong> requirements, 5% of <strong>the</strong> fleet will beexempted.VLCC case The new regulations wereapplied <strong>to</strong> a VLCC <strong>to</strong> see <strong>the</strong> developmentsin its fuel consumption and cost.The baseline case was a tanker using 23000 <strong>to</strong>nnes of fuel per year, which at presentfuel prices would cost around USD10 million. The first figure shows how anew vessel would perform year by yearup <strong>to</strong> 2050. A ship built according <strong>to</strong> <strong>the</strong>requirements in 2030 would use about 14000 <strong>to</strong>nnes per year in 2030. The figuresbelow show <strong>the</strong> fuel consumption of a newbuildVLCC. The fuel cost calculations in<strong>the</strong> second chart are based on a scenariowhere <strong>the</strong> sulphur regulations being introducedin 2<strong>02</strong>0 will significantly increasefuel prices, but <strong>the</strong> increase in energyefficiency will reduce <strong>the</strong> expected cost<strong>from</strong> USD 50 million <strong>to</strong> USD 30 millionper year. Annual fuel consumption [<strong>to</strong>nnes]Fuel cost [mill USD]2500<strong>02</strong>0000150001000050006050403<strong>02</strong>010EEDI reductionBusiness as usual<strong>02</strong>010 2015<strong>02</strong>010 2015SEEMP reductionNew emission levelShip type: VLCC – scenario: A1B-4Fuel: High, SEEMP uptake: High, <strong>No</strong> waiverAnnual fuel cost for new built VLCC – Scenario A1B-4Fuel price: High, SEEMP uptake: High, <strong>No</strong> waiverEEDI reductionBusiness as usual2<strong>02</strong>0 2<strong>02</strong>5 2030 2035 2040 2045 2050EEDI reduction SEEMP reduction New fuel consumption2<strong>02</strong>0 2<strong>02</strong>5 2030 2035 2040 2045 2050SEEMP reductionNew emission levelTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 9

Intertanko and <strong>the</strong> EEDIIntertanko and <strong>the</strong> EEDI:seeking a level playing fieldIntertanko fully supported IMO’s adoption of manda<strong>to</strong>ry measures <strong>to</strong> reduce <strong>the</strong>industry’s contribution <strong>to</strong> greenhouse gases (GHG) this summer. But with someissues yet <strong>to</strong> be settled, Intertanko insists that Energy Efficiency Design Index (EEDI)requirements should apply equally <strong>to</strong> all ships on <strong>the</strong> same effective date.Interview by Jan Koren and Alexander Wardwell›› Graham Westgarth, Chairman of IntertankoEEDI – reducing carbon emissions,one vessel at a timeThe EEDI applies <strong>to</strong> all vessels built after 2013. Bysome estimates, <strong>the</strong> measure will help remove 45<strong>to</strong> 50 million <strong>to</strong>nnes of CO2 <strong>from</strong> <strong>the</strong> atmosphereannually by 2<strong>02</strong>0, depending on <strong>the</strong> growthin world trade. For 2030, <strong>the</strong> reduction will bebetween 180 and 240 million <strong>to</strong>nnes annually since<strong>the</strong> introduction of <strong>the</strong> EEDI.Pho<strong>to</strong>: DNV/Nina E. RangøyThis summer, <strong>the</strong> IMO’s Marine ProtectionCommittee (MEPC) introducedmanda<strong>to</strong>ry measures <strong>to</strong> reduce GHG and<strong>the</strong>se measures have been adopted by <strong>the</strong>parties <strong>to</strong> Marpol. The amendments <strong>to</strong>Marpol Annex VI regulations on energyefficiency include <strong>the</strong> EEDI, which applies<strong>to</strong> new ships built after 2013. Over <strong>the</strong> pastfour years, IMO has worked with a broadrange of industry stakeholders <strong>to</strong> develop aframework for <strong>the</strong> EEDI. These stakeholdersinclude Intertanko, which providedtechnical support <strong>to</strong> <strong>the</strong> project.According <strong>to</strong> Graham Westgarth, <strong>the</strong>Chairman of Intertanko, <strong>the</strong> organisation’smembers welcomed <strong>the</strong> introduction of<strong>the</strong> EEDI. “We recognise that shippingaccounts for about three per cent of globalcarbon emissions, and have long supportedsmart and fair measures <strong>to</strong> reducegreenhouse gases,” he says. “Our activeparticipation with <strong>the</strong> IMO in <strong>the</strong> developmen<strong>to</strong>f EEDI for new ships is a clear demonstrationof our shared commitment <strong>to</strong>managing this issue more effectively.”Mr Westgarth notes that while marinetransportation is generally recognisedas <strong>the</strong> most fuel-efficient mode of bulktransportation, a 2009 IMO GHG studyconcluded that improvements in energyefficiency, mainly through <strong>the</strong> use ofalready existing technologies, can achievesignificant reductions in fuel consumptionand corresponding emissions. “At <strong>the</strong>same time, <strong>the</strong> rising cost of bunkering hasincreased <strong>the</strong> industry focus on fuel efficiency,”he says. “The relationship betweengrowing environmental concerns and <strong>the</strong>desire <strong>to</strong> reduce fuel costs has createdstrong incentives for <strong>the</strong> industry <strong>to</strong> work<strong>to</strong>ge<strong>the</strong>r, a cooperative spirit which has <strong>the</strong>full support of our membership.”Indeed, while <strong>the</strong> EEDI is likely beamended over time, <strong>the</strong> initiative enjoys<strong>the</strong> widespread support of governments,industry organisations, owners, opera<strong>to</strong>rsand <strong>the</strong> public and has included input<strong>from</strong> politicians, naval architects, classsocieties, shipyards and equipment manufacturers,among o<strong>the</strong>r stakeholders. “Foran industry not always known for concertedaction, <strong>the</strong> broad-based support for<strong>the</strong>se measures is encouraging,” says MrWestgarth. “And while some issues remainunresolved, we are confident <strong>the</strong> EEDI willmake a genuine difference.”In brief, <strong>the</strong> EEDI requires a minimumenergy efficiency level for new vesselsentering <strong>the</strong> world fleet through technicaland design-based measures, such asmore efficient engines and propulsionsystems, improved hull designs and largerships, which transport more cargo usingproportionally less fuel. At present, <strong>the</strong>10 | Tanker UPDATE NO. 2 <strong>2011</strong>

Intertanko and <strong>the</strong> EEDIEEDI covers <strong>the</strong> industry’s most energyintensivesegments, including oil andgas tankers, bulk carriers, general cargoships, refrigerated cargo carriers andcontainer ships. However, <strong>the</strong> EEDI is notapplicable <strong>to</strong> all ship types or propulsionsystems (such as hybrid or diesel electricengines). IMO has indicated that <strong>the</strong>Marine Environment Protection Committee(MEPC) will consider ship types notcovered by <strong>the</strong> EEDI at future sessions,focusing on <strong>the</strong> most carbon-intensiveship types first.An issue of concern <strong>to</strong> INTERTANKOis <strong>the</strong> four-year waiver provision includedin <strong>the</strong> newly adopted regulations. Thisprovision allows flag states <strong>to</strong> waive <strong>the</strong>2013 implementation date until 2017. JoeAngelo, Intertanko’s Managing Direc<strong>to</strong>r,believes that any regulation must apply <strong>to</strong><strong>the</strong> whole industry equally. “In our view,<strong>the</strong>re should be a level playing field. TheEEDI requirements should apply equally <strong>to</strong>all new ships that are built between 2013and 2017,” he says. “Carving out exceptionsundermines <strong>the</strong> spirit and intent of<strong>the</strong> initiative.”Ano<strong>the</strong>r critical issue <strong>to</strong> INTERTANKOis compliance with <strong>the</strong> EEDI. Reducing <strong>the</strong>design speed on new ships is an easy way <strong>to</strong>comply with <strong>the</strong> EEDI requirements, butINTERTANKO believes that complianceshould be achieved through o<strong>the</strong>r means.“Our position is that compliance shouldfocus on improved hull design, propulsionefficiency and energy optimisation,ra<strong>the</strong>r than predominantly on reduceddesign speeds,” says Mr Angelo. “The EEDIshould not jeopardise or have an adverseeffect on <strong>the</strong> vessel’s safety.”While more work clearly needs <strong>to</strong> bedone, both Mr Westgarth and Mr Angeloagree this is a good start. “For <strong>the</strong> firsttime in our industry’s his<strong>to</strong>ry, ships willhave <strong>to</strong> meet a minimum energy efficiencystandard , and <strong>the</strong>se standards will bestreng<strong>the</strong>ned,” says Mr Westgarth. “It willtake some time before <strong>the</strong> existing globalfleet is replaced by EEDI-compliant vessels,but we are confident that this is <strong>the</strong> rightthing <strong>to</strong> do.” “Our active participation with <strong>the</strong> IMOin <strong>the</strong> development of EEDI for newships is a clear demonstration of ourshared commitment <strong>to</strong> this issue,”says Graham Westgarth, Chairman ofIntertanko.›› Graham Westgarth and Joseph Angelo, Managing Direc<strong>to</strong>r of Intertanko.Pho<strong>to</strong>: DNV/Nina E. RangøyTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 11

Fuel Saving GuidelineDNV’s Fuel SavingGuideline for TankersIn order <strong>to</strong> help designers and owners navigate <strong>the</strong> jungle of measures available<strong>to</strong> improve fuel efficiency, DNV has recently issued a Fuel Saving Guideline forTankers, prepared in cooperation with Hamburg Ship Model Basin HSVA.Text: Vidar Ådnegård, DNV›› Wake Equalizing Duct›› Becker Mewis Duct ® ›› Contra rotating propellerThe aim is <strong>to</strong> provide an independen<strong>to</strong>verview of different fuel saving measuresfeasible for both newbuilds and retrofit onships in operation, meeting <strong>the</strong> needs ofand requests <strong>from</strong> ship owners, charterers,designers and yards. The Guideline mayserve as decision support.Additionally, a <strong>to</strong>ol for calculating <strong>the</strong>return on an investment has been developedfor <strong>the</strong> project in cooperation withDNV ProNavis.With fuel costs for oil carriers normallyin <strong>the</strong> range of more than 60% of <strong>the</strong> <strong>to</strong>taloperating costs, reducing fuel costs is amajor issue, particularly when <strong>the</strong> freightmarket is as low as it is nowadays.A variety of individual measures andstrategies for optimising fuel consumption12 | Tanker UPDATE NO. 2 <strong>2011</strong>

Fuel Saving Guidelineare known and partly applied in <strong>the</strong> industry.Some of <strong>the</strong> alternatives are applicable<strong>to</strong> newbuilds, while o<strong>the</strong>rs may be applied<strong>to</strong> existing ships <strong>to</strong>o. Up <strong>to</strong> now, however,<strong>the</strong>re has been no systematic and impartialsummary of <strong>the</strong> most relevant measuresand assessment of <strong>the</strong>ir savings potential.The Guideline contains four main categoriesof measures – those which:■■■■■■■■Reduce <strong>the</strong> hull resistanceImprove <strong>the</strong> propulsion efficiencyImprove <strong>the</strong> power plant efficiencyImprove <strong>the</strong> operational efficiencyIts content covers <strong>the</strong> following scope:■■Description of each measure■■Compatibility of measures with eacho<strong>the</strong>r■■Complexity of manufacturing■■Range of expected fuel savings■■Expected maintenance needs■■Indication of price range■■Class requirementsThe market jungle There is a varietyof different fuel saving measures in<strong>the</strong> market <strong>to</strong>day, and selecting <strong>the</strong> mostappropriate ones is challenging. Forinstance, <strong>the</strong>re are several options forimproving propeller efficiency. Sta<strong>to</strong>rs,ducts and fins are some of <strong>the</strong> possibledevices installed pre- or post-swirl in order<strong>to</strong> save energy.The machinery suppliers deliver solutionsthat increase <strong>the</strong> flexibility andoptimise <strong>the</strong> efficiency of <strong>the</strong> engine. And<strong>the</strong>n <strong>the</strong>re are all <strong>the</strong> measures associatedwith <strong>the</strong> operation and management of<strong>the</strong> vessel, for example should you optimise<strong>the</strong> trimming of <strong>the</strong> vessel <strong>to</strong> reduceresistance? Do you route <strong>the</strong> vessel according<strong>to</strong> <strong>the</strong> forecasted wea<strong>the</strong>r, speed andcontracted time of arrival in order <strong>to</strong> optimise<strong>the</strong> operation?A matter of cost and savings. Themeasures described in <strong>the</strong> Guideline span<strong>from</strong> easily implemented low-cost solutions<strong>to</strong> more complex and technologically challengingsystems, all presented <strong>to</strong>ge<strong>the</strong>rwith an indicative return on investmentassessment.Some of <strong>the</strong> presented measures arera<strong>the</strong>r complex and need <strong>to</strong> be consideredand decided upon during <strong>the</strong> designprocess. O<strong>the</strong>rs can be retrofit but requiredry docking. However, in many cases fuelsaving does not need <strong>to</strong> be that comprehensiveat all. The Guideline includes anumber of measures with a short paybacktime which are ra<strong>the</strong>r easy <strong>to</strong> implement.Examples are:■■■■■■Trim Optimisation: by changing <strong>the</strong> trimof <strong>the</strong> vessel, <strong>the</strong> wave pattern around<strong>the</strong> vessel will also change. Optimising<strong>the</strong> trim by minimising <strong>the</strong> wave resistanceleads <strong>to</strong> a reduction in <strong>the</strong> powerneeded, which again means lower fuelconsumption. The most favourable trimmay be found by CFD analysis.Propeller Polishing: cleaning <strong>the</strong> propellerwill help avoid an increase in <strong>the</strong>propeller’s friction losses due <strong>to</strong> marinegrowth. The cleaning itself is ra<strong>the</strong>rsimple and may be carried out when <strong>the</strong>ship is anchored or berthing.Engine Tuning: <strong>the</strong> engine performancegradually worsens. By tuning <strong>the</strong> engines<strong>to</strong> maintain a low SFOC, this trend maybe interrupted. A diesel engine analysis<strong>to</strong>ol is necessary in order <strong>to</strong> continuouslyoptimise <strong>the</strong> maximum combustion pressureand mean indicated pressure, leading<strong>to</strong> an optimised SFOC.The net fuel saving The expectedfuel savings are given as ranges in <strong>the</strong>Guideline, as <strong>the</strong> net effect will vary <strong>from</strong>case <strong>to</strong> case. The best way of validatinga fuel saving measure is <strong>to</strong> compare twoidentical vessels trading <strong>the</strong> same route,one with and one without <strong>the</strong> respectivemeasure deployed. However, <strong>the</strong>re arealternatives <strong>to</strong> full-scale results. Measuresrelated <strong>to</strong> resistance and propulsion maybe validated through model tests in a <strong>to</strong>wingtank and by CFD calculations. ›› Vidar Ådnegård, Project TeamMember, Senior EngineerShip Hydronynamics and Stability›› Etienne Gernez, Project LeaderDNV SERVING THE MARITIME INDUSTRYDNV Fuel Saving Guideline – For TankersDNV Fuel Saving Guideline– For TankersJOINT PROJECT BETWEEN HSVA AND DNVTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 13

SEEMPSEEMP and Energy Efficiency– DNV offers supportThe required Ship Energy Efficiency Management Plan (SEEMP) is a potential <strong>to</strong>ol for owners <strong>to</strong> reduce<strong>the</strong> fuel billl. While <strong>the</strong> requirement of having SEEMP on board vessels is still a year or more away, DNVis already making great efforts <strong>to</strong> help shipping companies get this right. This builds on a long traditionof working on energy efficiency with owners/opera<strong>to</strong>rs around <strong>the</strong> globe in most ship segments.Text: Sverre Alvik, DNVDNV has been assisting shipping companies<strong>to</strong> improve energy efficiency for manyyears. The two main areas DNV are workingon are:■■■■Ship design, where we are working closelywith yards, designers and owners <strong>to</strong>improve hull design, hull and propelleroptimisation and o<strong>the</strong>r resistance-relatedissues.Ship operation, where we are workingwith shipowners and charterers <strong>to</strong>reduce fuel consumption during operation,focusing on all areas <strong>from</strong> voyagemanagement and <strong>the</strong> culture on board<strong>to</strong> ship and machinery performance.At DNV’s headquarters at Høvik, a groupof 10 people is working exclusively on <strong>the</strong>energy efficiency of operations and providingexperience and expertise <strong>to</strong> supportDNV personnel in this area around <strong>the</strong>globe.When <strong>the</strong> focus on operational energyefficiency started in DNV five years ago,<strong>the</strong> price of fuel was lower and slowsteamingwas not a priority in <strong>the</strong> industry.Since <strong>the</strong>n and 50 projects later, energyefficiency has forced its way higher andhigher up our cus<strong>to</strong>mers’ agendas. Andwhile <strong>the</strong> first projects were undertakenfor companies paying high fuel bills <strong>the</strong>mselves,current projects are equally oftenundertaken for <strong>the</strong> offshore, gas or tankerindustry, where <strong>the</strong> charterers are oftenpaying for <strong>the</strong> fuel.›› Sverre Alvik, Head of Section Environment andEnergy EfficiencyThe incentives are different for <strong>the</strong>secompanies. However, generally speaking,improved energy efficiency means lowermaintenance costs, improved brand positioningand meeting stakeholders’ expectations.And someone is always paying for<strong>the</strong> fuel, making <strong>the</strong> projects and companyinitiatives an excellent business case in<strong>the</strong>ir own right!A snapshot of DNV’s experiences –where do we find fuel savings?Although energy efficiency is onPho<strong>to</strong>: DNV/Nina E. Rangøyeverybody’s agenda, DNV’s experiencessuggest that large improvements can beachieved in all companies – even thoseconsidered <strong>to</strong> be ‘leading’ or ‘best practice’.Initial savings typically represent a5-15% reduction in fuel consumption,fuel costs and emissions, and are mostcommonly achieved by measures such aspropeller polishing, trim calculations andengine performance <strong>to</strong>ols. Fur<strong>the</strong>r savingsare identified in relation <strong>to</strong> companyculturecampaigns that aim <strong>to</strong> improve <strong>the</strong>awareness and ownership of fuel savingprogrammes, as well as improved ownercharterercooperation on joint initiatives.The measures identified by DNV are seldomnew <strong>to</strong> <strong>the</strong> companies we work with,but what is not so common are <strong>the</strong> systematicsof an energy efficiency programme,<strong>the</strong> clear business cases it presents and <strong>the</strong>focus all <strong>the</strong> way <strong>from</strong> idea <strong>to</strong> implementationin order <strong>to</strong> ensure tangible results.SEEMP When IMO resolved <strong>to</strong> make aShip Energy Efficiency Management Plan(SEEMP) manda<strong>to</strong>ry earlier this year, itforcefully pushed energy efficiency evenhigher up <strong>the</strong> shipping agenda. Within15-40 months (depending on each vessel’ssurvey schedule), all 70,000+ vessels in <strong>the</strong>world fleet will need <strong>to</strong> have a SEEMP inplace. Unlike <strong>the</strong> traditional energy efficiencyinitiatives often run by <strong>the</strong> shoreorganisation, a SEEMP must be ship-specificra<strong>the</strong>r than company-specific.14 | Tanker UPDATE NO. 2 <strong>2011</strong>

SEEMP›› Energy Efficiency – scope of DNV services.There is a lot of freedom regarding<strong>the</strong> way in which <strong>the</strong> plans are <strong>to</strong> bemade, and although <strong>the</strong> current IMOSEEMP guideline provides a good startingpoint, DNV’s experience is that <strong>the</strong>average owner/opera<strong>to</strong>r needs somethingthat places more attention ondeveloping a tailored solution that suitsits operations as well as an implementationplan.When working on SEEMP, DNV looksat <strong>the</strong> intention behind <strong>the</strong> new regulation.A rubber-stamped document copyinga template will only serve <strong>the</strong> ‘ticket-<strong>to</strong>trade’mission and not deliver any actualimprovement in energy efficiency. A moreclosely defined SEEMP, on <strong>the</strong> o<strong>the</strong>r hand,will save costs as well as emissions, and withrelatively little effort will deliver an excellentbusiness case for <strong>the</strong> owner.For companies that want <strong>to</strong> develop aSEEMP <strong>the</strong>mselves, DNV Maritime Advisoryhas developed a free SEEMP guidelineexplaining DNV’s experiences and adviceon current best practice. In addition, manyDNV advisory units worldwide are alreadyworking closely with a number of cus<strong>to</strong>mers<strong>to</strong> provide help in developing shipspecificplans.Later, DNV will also verify that companieshave a SEEMP as a part of <strong>the</strong>MARPOL Annex 6, International EnergyEfficiency Certificate – and this verificationwill be carried out by DNV Class.SEEMP has put energy efficiency near<strong>the</strong> <strong>to</strong>p of companies’ agendas and DNV’sextensive experience in this area suggeststhat this is a sound development for <strong>the</strong>industry. The increased focus will producemonetary as well as environmental benefits,and DNV is happy <strong>to</strong> contribute <strong>to</strong>this development. SEEMP (Ship Energy EfficiencyManagement Plan)At <strong>the</strong> IMO MEPC 62nd session in July <strong>2011</strong>,amid mounting pressure <strong>from</strong> <strong>the</strong> industry ando<strong>the</strong>r authorities, <strong>the</strong> SEEMP was adopted andwill become manda<strong>to</strong>ry for all vessels at <strong>the</strong>ir firstrenewal or intermediary survey after 1 January2013.• Under <strong>the</strong> proposed amendments <strong>to</strong> MARPOLAnnex 6, Regulation 22, all ships will have<strong>to</strong> have an International Energy EfficiencyCertificate (IEEC)• The IEEC requires, amongst o<strong>the</strong>r things, <strong>the</strong>presence of a SEEMP on boardVISITIMO Guidelinewww.dnv.com/SEEMPCONTACTSEEMP@dnv.comenvironmentandenergyefficiency@dnv.comsverre.alvik@dnv.comjonathan.abrahams@dnv.comTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 15

Energy efficiency design index30.00EEDI value (g CO2/ <strong>to</strong>nne*nm)25.0<strong>02</strong>0.0015.0010.005.00Reference line samplesIMO EEDI reference lineCase vessel0.000 50,000 100,000 150,000 200,000 250,000 300,000 350,000 400,000 450,000 500,000Capacity (DWT)Energy Efficiency Design Index- How DNV can assist you <strong>to</strong> successfully implement <strong>the</strong> EEDI for your fleetEnergy Efficiency Design Index - EEDIAs a measure <strong>to</strong> support <strong>the</strong> objective <strong>to</strong> reduce emissionsof greenhouse gases <strong>from</strong> international shipping, IMO’sMarine Environment Protection Committee (MEPC) hasdeveloped <strong>the</strong> Energy Efficiency Design Index (EEDI).Being a measurable method for determining <strong>the</strong> energyefficiency of a ship, <strong>the</strong> EEDI quantifies <strong>the</strong> amount ofcarbon dioxide a ship emits in relation <strong>to</strong> its value forsociety.Adopted at MEPC 62 in July <strong>2011</strong> as an amendment <strong>to</strong>MARPOL Annex VI, <strong>the</strong> EEDI will enter in<strong>to</strong> force 1January 2013 as a manda<strong>to</strong>ry requirement, requiring aminimum energy efficiency level for new ships. The EEDIwill as such stimulate continuous technical development offuel efficient ships. At <strong>the</strong> same time it enables acomparison of <strong>the</strong> energy efficiency of individual ships <strong>to</strong>similar ships of <strong>the</strong> same size and ship type. The EEDI willbe included in a new International Energy EfficiencyCertificate (IEEC) that will be introduced for all vessels.The EEDI is based on a formula for calculation of shipspecific emissions of CO2. The result for each ship, whichis <strong>to</strong> be based on design documentation and engineperformance, is expressed in grams of CO2 per capacitymile.Once <strong>the</strong> EEDI is put in<strong>to</strong> force <strong>the</strong> attained EEDI fora specific ship must be less or equal <strong>to</strong> <strong>the</strong> required EEDI,expressed by reference lines developed by IMO for eachship type. The EEDI reference lines will become morestringent with time as reduction fac<strong>to</strong>rs are planned <strong>to</strong> beapplied in different phases starting in 2013.Det <strong>No</strong>rske Veritas AS16 | Tanker UPDATE NO. 2 <strong>2011</strong>

Energy efficiency design indexProviding your EEDI Technical File<strong>to</strong> be submitted for verificationDNV Maritime Advisory assist yards, designers, owners and opera<strong>to</strong>rs <strong>to</strong> prepare <strong>the</strong> EEDITechnical File package with necessary documentation ready for verification.Maritime Advisory covers <strong>the</strong> complete span in <strong>the</strong> EEDIcalculation process for your vessels:Gap Assessment Review of all design documents required <strong>to</strong> calculate<strong>the</strong> EEDI and identify possible missing data Review design and sea trial procedures for estimatingvessel speed and powerEEDI CalculationEstimate <strong>the</strong> EEDI based on IMO guidelinesAssess <strong>the</strong> design speed and power using model test orsea trial dataEEDI ImprovementThe EEDI Technical File developed by Maritime Advisory isreadily prepared <strong>to</strong> be submitted <strong>to</strong> a verifier forverification as proof of EEDI assessment. DNV hasprepared EEDI Technical Files and identified EEDIimprovement areas for a number of ship designs <strong>to</strong> yardsand owners on a world-wide basis.Calculation and verification of <strong>the</strong> EEDI is performed attwo stages:1) Preliminary assessment of <strong>the</strong> EEDI at <strong>the</strong> design stage2) Final assessment of <strong>the</strong> EEDI at final stage ofconstruction, accounting for <strong>the</strong> results <strong>from</strong> sea trialsDNV also offers third party verification services for EEDI,including issuance of EEDI verification statement. Theverification is based upon <strong>the</strong> EEDI Technical File and asurvey onboard <strong>the</strong> ship at sea trials.Identify areas which could lead <strong>to</strong> significant EEDIimprovement with a minimum impact on <strong>the</strong> basicdesignEEDI Technical FileDeliver a complete technical document package, anEEDI Technical File, <strong>to</strong> support <strong>the</strong> EEDI verificationDet <strong>No</strong>rske Veritas ASMaritime Advisory, Ship Hydrodynamics and StabilityE-mail: ntano362@dnv.comFor fur<strong>the</strong>r information please contact your local or main DNV office.Tanker <strong>update</strong> NO. 2 <strong>2011</strong> | 17

Recent delivery18 | Tanker UPDATE NO. 2 <strong>2011</strong>

Recent deliveryAl Riqqa• Owner: Kuwait Oil Tanker Company S.A.K.• Yard: Daewoo Shipbuilding & Marine Engineering Co., Ltd.• Ship Type: Crude oil Carrier• Flag: Kuwait• Class <strong>No</strong>tations: @1A1 CSR Tanker for Oil ESP SPM COMF-V(3) E0 NAUT-OCVCS-2 HMON(A1,G4) CLEAN PLUS BIS TMON NAUTICUS(Operation)• LOA: 332 m• LBP: 320 m• Breadth: 60 m• Depth: 30.5 m• Design Draught: 21 m• Main Engine: MAN-B&W1 x 7S80ME-C8, 2 Stroke, Single Acting, In-Line (Vertical)7 Cy. 800 x 3200, Mcr: 29,260 kW (39,782 hp) at 78 rpm• Speed: 16.4 knots• Deadweight: 319 704 tdwTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 19

ThenamarisThenamarisfirst <strong>to</strong> receive DNV’sTriple-E ratingGreek ship opera<strong>to</strong>r Thenamaris is <strong>the</strong> first company <strong>to</strong> receive DNV’s newTriple-E rating, which was awarded for <strong>the</strong> Seabravery tanker. The rating,which is designed <strong>to</strong> demonstrate active environmental management and <strong>the</strong>energy efficient transportation of goods, is a voluntary scheme developedin close cooperation with Thenamaris Ship Management in addition <strong>to</strong>Stena RoRo, Seaspan Ship Management and Skaugen Petrotrans.Text: Magne A. Røe, DNVCaptain John M. Mavrides is head ofThenamaris’s safety and quality supportdepartment and he underlines Thenamaris’slong tradition of quality, energyefficiency and operational excellence:“Triple-E is a continuation of our ongoingefforts <strong>to</strong> improve our energy efficiencyand <strong>to</strong> focus on this in our daily operations.The crew of Seabravery finds thatTriple-E gives <strong>the</strong>m a measure of how <strong>the</strong>yperform, and helps <strong>the</strong>m focus on thisduring <strong>the</strong> daily operations. In <strong>to</strong>day’ssluggish tanker market, we must ensure<strong>the</strong> efficiency of our operations.”Triple-E is a voluntary environmentalrating scheme for ships that represent asustainability benchmark for players in <strong>the</strong>maritime industry, including ship opera<strong>to</strong>rs,ports and cargo owners. The ratingrepresents <strong>the</strong> individual ship’s level ofenvironmental performance, and it isdesigned <strong>to</strong> help shipowners obtain a competitiveadvantage both commercially andwith regard <strong>to</strong> environmental performanceand efficiency. Triple-E delivers a rating ona scale <strong>from</strong> four <strong>to</strong> one where one is best,based on an independent assessment of aship’s environmental performance.“The Seabravery obtained a score ofthree on <strong>the</strong> Triple-E scale,” continuesCaptain Mavrides. “To us, this is a verygood rating. It underlines <strong>the</strong> success ofour efforts <strong>to</strong> focus on environmental performance,which is an important corners<strong>to</strong>neof <strong>the</strong> Thenamaris company culture.Fur<strong>the</strong>rmore, a score of three means thatwe have an implemented environmentalmanagement system in place.”A Triple-E level three means that clearenergy efficiency targets have been setthrough, and established in, <strong>the</strong> Ship EnergyEfficiency Management Plan (SEEMP)and in <strong>the</strong> calculation of <strong>the</strong> Energy EfficiencyOperational Indica<strong>to</strong>r (EEOI). Also,it means that an environmental awarenesssurvey has been completed <strong>to</strong> identifytraining needs and improvement areas.“Our most important cus<strong>to</strong>mers are<strong>the</strong> oil majors, who have <strong>the</strong>ir own vettingsystems as well, in addition <strong>to</strong> those of<strong>the</strong> port authorities and TMSA. We havea good reputation among <strong>the</strong> oil majors.In this industry we must be truly transparentin our operations and procedures, asbusiness relationships are based on mutualtrust at all levels. In this equation, wemust also demonstrate very clearly how weoperate, and how we ensure that we arevery sensitive <strong>to</strong>wards <strong>the</strong> environmentas well. We started out with <strong>the</strong> GreenAward back in ‘97, <strong>the</strong>n we received ISO14001 and ISO 9000 certification beforemoving in<strong>to</strong> <strong>the</strong> efficiency aspects of ouroperations and environmental excellence.Our Triple-E certification fur<strong>the</strong>r underlines<strong>the</strong>se commitments <strong>to</strong> our clientsas well, and this is highly appreciated by<strong>the</strong>m.”“The issues we focus on through Triple-E are good for <strong>the</strong> crew as well as it createsawareness. For <strong>the</strong>m, <strong>the</strong> rating is evidencethat <strong>the</strong> results <strong>the</strong>y work hard <strong>to</strong> achievecan be measured. They find this bothinspiring and challenging. Inspiring in <strong>the</strong>sense that <strong>the</strong> figures measured are expressionsof a good safety culture. Challengingas <strong>the</strong>re is always room for improvement,but <strong>the</strong>n, <strong>to</strong> good working crews <strong>the</strong> challengeis also <strong>the</strong> inspiration. We have acompany culture of being proactive, and<strong>to</strong> me that is what Triple-E helps us be. We20 | Tanker UPDATE NO. 2 <strong>2011</strong>

ThenamarisTriple-EThe Triple-E environmental rating and energyefficiency rating scheme for ships has been developed<strong>to</strong> provide ship opera<strong>to</strong>rs with a well-documented<strong>to</strong>ol <strong>to</strong> improve <strong>the</strong>ir organisational performance,identify ways <strong>to</strong> minimise <strong>the</strong>ir environmental impactand, ultimately, optimise <strong>the</strong>ir fuel consumption and<strong>the</strong>reby reduce costs.Triple-E has four rating levels – 4, 3, 2 and 1 (where1 is <strong>the</strong> highest). For each of <strong>the</strong>se levels, <strong>the</strong>reare requirements within <strong>the</strong> areas of management,operation and design. To reach a specific level, all <strong>the</strong>requirements stated for this level and <strong>the</strong> levels belowit have <strong>to</strong> be complied with.A Triple-E rating is a verification of a ship’s actualenvironmental performance, and each leveldemonstrates a different level of environmentalcompetence and pro-activeness for a vessel andcompany:Level 4: Heightened environmental performancethrough a company environmental policy andtargets in place Verified compliance with all currentenvironmental rules and regulations Reliableoperation through quality testing of all fuel used.Level 3: Systemised environmental performancethrough an implemented environmentalmanagement system Clear energy efficiency targetsthrough an established Ship Energy EfficiencyManagement Plan (SEEMP) and calculation of <strong>the</strong>Energy Efficiency Operational Indica<strong>to</strong>r (EEOI) Anenvironmental awareness survey completed withtraining needs and improvement areas identified.Level 2: Sustained environmental performance andimprovements documented through a certifiedenvironmental management system Minimisedemissions <strong>to</strong> air and optimal fuel efficiencythrough an implemented Ship Energy EfficiencyManagement Plan (SEEMP) and <strong>the</strong> EnergyEfficiency Operational Indica<strong>to</strong>r (EEOI) moni<strong>to</strong>redover time <strong>to</strong> document performance Verifiable fueloil measurements and an Inven<strong>to</strong>ry of HazardousMaterials (IHM).Level 1: Leading environmental performance throughoperational risk assessment and enhanced crewcompetence levels Minimised environmental impactthrough state-of-<strong>the</strong>-art ship and equipment designA verified Energy Efficiency Design Index (EEDI).›› The Seabravery.Pho<strong>to</strong>: Thenamaris›› Captain John M. Mavrides Head of Thenamaris’s Safety and Quality Support Department receiving <strong>the</strong>Triple-E Certificate <strong>from</strong> President Tor E. Svensen, DNV (<strong>to</strong> <strong>the</strong> left).feel that we’ve developed Triple-E <strong>to</strong>ge<strong>the</strong>rwith DNV and that this has been time wellspent,” says Captain Mavrides. He addsthat <strong>the</strong>re are indeed many – and enough– safety and environmental regulations,and that regula<strong>to</strong>rs should ensure implementationof <strong>the</strong> existing schemes and notimpose additional requirements.“Thenamaris is currently expandingits fleet <strong>to</strong> include two Suezmax tankers,four 50,000-<strong>to</strong>n product tankers and oneVLCC. But we are also expanding in<strong>to</strong>o<strong>the</strong>r ship segments – with four containerships and three LNG carriers. Our strategyis <strong>to</strong> expand through diversification,” addsCaptain Mavrides.The Triple-E rating is based on <strong>the</strong>ship’s environmental and operational data.The rating focuses on fac<strong>to</strong>rs such as <strong>the</strong>ship’s environmental management practices,<strong>the</strong> energy efficiency of its operations,and <strong>the</strong> verifiable moni<strong>to</strong>ring, measurementand documentation schemes that arein place. Many of <strong>the</strong>se fac<strong>to</strong>rs can easilybe influenced, ei<strong>the</strong>r by <strong>the</strong> ship’s owneralone or with <strong>the</strong> assistance of third partiessuch as DNV. Triple-E encourages a processof continuous improvement. ThenamarisThenamaris Ship Management is a leading globalprovider of ship management services. The fleetunder management consists of oil tankers for <strong>the</strong>transportation of crude oil, oil products and bulkcarriers.• Owned fleet: a modern fleet of 34 tankers, sixbulk carriers and one container carrier.• Under construction: two Suezmax, four producttankers, one VLCC. The company is diversifyingin<strong>to</strong> container and LNG shipping by having fourcontainer ships and three LNG ships.• Headquarters: A<strong>the</strong>ns• Number of employees in <strong>the</strong> Group: 2,500• Thenamaris Ship Management manages 41ships, 54 including newbuildings.Tanker <strong>update</strong> NO. 2 <strong>2011</strong> | 21

Innovation AwardsDNV winsInnovation AwardsDuring <strong>the</strong> months of September through <strong>No</strong>vember this year,DNV has received three different innovation awards, as describedbelow. Triality has been an important contribu<strong>to</strong>r <strong>to</strong> this, in addition<strong>to</strong> DNV’s o<strong>the</strong>r innovation projects over <strong>the</strong> last couple of years.TEXT: JAN KOREN, DNVPho<strong>to</strong>: Lloyd’s List›› Lloyd’s List Global Innovation Award,London, 21 September <strong>2011</strong>Ioannis Kourmatzis, Chief Operating Officer, DivisionEurope and <strong>No</strong>rth Africa, receives <strong>the</strong> prize on behalfof DNV <strong>from</strong> Chris Potter, Chief Executive of ASRY.<strong>the</strong> Lloyd’s List InnovationAward “The DNV Triality project s<strong>to</strong>odout <strong>from</strong> <strong>the</strong> pack because it offered atruly innovative attempt <strong>to</strong> look in<strong>to</strong> <strong>the</strong>future and address real problems with realsolutions.”This was <strong>the</strong> reason stated by Lloyd’sList and its nine-member highly skilledand experienced international judgingpanel when <strong>the</strong> award for <strong>the</strong> best innovationproject in <strong>the</strong> global shipping industry<strong>2011</strong>was presented at a ceremony in Londonin late September.“I was really pleased and honoured<strong>to</strong> accept <strong>the</strong> award on behalf of a lot ofskilled, hardworking DNV colleagues,” saidIoannis Kourmatzis, DNV’s COO Europe& <strong>No</strong>rth Africa.When <strong>the</strong> financial crisis hit <strong>the</strong> shippingindustry in late 2008, DNV decided <strong>to</strong>meet <strong>the</strong> upcoming challenges by focusingeven more on innovation. Triality was oneof several innovation projects initiated,and a group of almost 30 talented, mostlyyoung engineers representing a wide set ofdisciplines was formed <strong>to</strong> run it. The projectwas completed and presented at <strong>the</strong>beginning of December last year.Triality is a VLCC concept that isfuelled by liquefied natural gas (LNG)and has a hull shape that eliminates <strong>the</strong>need for ballast water. The very low LNGtemperature is used <strong>to</strong> recover cargovapours (VOCs) and cool <strong>the</strong> combustionair supplied <strong>to</strong> <strong>the</strong> main engine in order<strong>to</strong> increase engine efficiency. All this willreduce emissions <strong>to</strong> <strong>the</strong> atmosphere <strong>to</strong> significantlybelow <strong>the</strong> level stipulated in anyregulations that are foreseeable <strong>to</strong>day.Lloyd’s List stated that: “DNV won thisyear’s award because <strong>the</strong>y dared <strong>to</strong> thinkwell beyond <strong>the</strong> current conservatisminherent in shipping and handed a seriousproblem <strong>to</strong> a team of talented youngengineers unencumbered by entrenchedthinking.”And <strong>the</strong> judging panel continued: “Theresulting project was a fascinating seriesof solutions and concepts that ultimatelyproduced a radical design for an LNGpoweredvery large crude oil carrier.”The innovation category presented <strong>the</strong>judges with <strong>the</strong>ir <strong>to</strong>ughest debate, as noo<strong>the</strong>r category had that many candidates– 20 strong entries. All in all, awards weremade in 14 different categories, representingall parts of <strong>the</strong> extensive, global shippingindustry.Like most o<strong>the</strong>r concepts – such asthose created in <strong>the</strong> car industry – Trialitywill probably never be built exactly as ithas been presented. However, major partsof its solutions and ideas will certainly bepicked up and used.As <strong>the</strong> tanker shipping industry is facingmajor challenges due <strong>to</strong> very low freightrates and few newbuilding orders arebeing signed right now, <strong>the</strong> time should beright <strong>to</strong> look in<strong>to</strong> new opportunities –suchas those represented by Triality.There was an extensive presentation ofTriality in Tanker Update <strong>No</strong> 2, 2010.22 | Tanker UPDATE NO. 2 <strong>2011</strong>

Innovation Awards›› Sea Trade Middle East Innovation Award<strong>2011</strong>, Dubai, 17 Oc<strong>to</strong>ber <strong>2011</strong>DNV’s Jörgen Traun receiving DNV’s TechnicalInnovation Award <strong>from</strong> Mr Mohammed S. Al-Gusaier(President & CEO of Vela International MarineLimited).›› Lloyd’s List Middle East Innovation Award<strong>2011</strong>, Dubai, 16 <strong>No</strong>vember <strong>2011</strong>DNV’s Jörgen Traun, here seen <strong>to</strong>ge<strong>the</strong>r with RichardMeade, <strong>the</strong> edi<strong>to</strong>r of Lloyd’s List.›› Sea Trade Middle East Class Society Award<strong>2011</strong>, Dubai, 17 Oc<strong>to</strong>ber <strong>2011</strong>Jörgen Traun receiving DNV’s Classification SocietyAward <strong>from</strong> Mr Ali Al Yabhouni, President of <strong>the</strong>UAE Shipping Association.Technical Innovation Award andClassification Society AwardDNV was declared <strong>the</strong> winner of <strong>the</strong> TechnicalInnovation Award and ClassificationSociety Award at <strong>the</strong> Seatrade Middle East& Indian Subcontinent Awards <strong>2011</strong> on 17Oc<strong>to</strong>ber <strong>2011</strong>Held at <strong>the</strong> Atlantis The Palm hotelin Dubai, <strong>the</strong> awards ceremony was wellattended by leading players in <strong>the</strong> maritimeindustry, and DNV won both <strong>the</strong>categories it was nominated for; <strong>the</strong> ClassificationSociety Award and TechnicalInnovation Award.The Technical Innovation Awardreflects DNV’s innovation efforts, particularly<strong>the</strong> VLCC Triality concept and Quantum,an innovative container ship conceptalso developed by DNV.“Winning <strong>the</strong> Classification SocietyAward for <strong>the</strong> sixth time and <strong>the</strong> TechnicalInnovation Award for <strong>the</strong> first time meansDNV will face high expectations in subsequentyears,” says Jörgen Traun, DNV’sRegional Manager for India and MiddleEast. “We need <strong>to</strong> continuously evolve,”he declared <strong>to</strong> his colleagues after <strong>the</strong>ceremony.Lloyd’s List Middle East andIndian Subcontinent InnovationAwards Mr Sultan Al Zaabi, Finance DivisionManager of ADNATCO & NGSCO,handed over <strong>the</strong> Innovation Award wonby DNV <strong>to</strong> Mr Jörgen Traun during a galadinner in Dubai on 16 <strong>No</strong>vember <strong>2011</strong>.DNV’s innovation projects It isimportant <strong>to</strong> distinguish between an innovationproject developing a concept andone developing a ship design. We entirelyagree with those who claim that classsocieties should not be involved with shipdesign.What DNV has done is, based on itsexpertise, <strong>to</strong> come up with ideas whichmay bring <strong>the</strong> shipping industry forwardin compliance with new regulations anddemands. DNV has no patents or proprietaryrights associated with <strong>the</strong>se projects.They have been openly presented <strong>to</strong> <strong>the</strong>media and shipping world. Anybody –designers, yards and owners – is completelyfree <strong>to</strong> reject <strong>the</strong>se ideas or see <strong>the</strong>m asa commercial business opportunity. In <strong>the</strong>latter case, engineering and design workhas <strong>to</strong> be carried out <strong>to</strong> prepare specificationsand drawings based on <strong>the</strong> completeinnovation concepts or part of <strong>the</strong>m. Inthis way, our innovation projects maytrigger new ideas and opportunities fordesigners and yards.Based on <strong>the</strong> awards described hereand feedback we have received <strong>from</strong> <strong>the</strong>media and shipping community at large,<strong>the</strong>re is strong evidence that this type ofinnovation is highly appreciated. Tanker <strong>update</strong> NO. 2 <strong>2011</strong> | 23

Arctic LadyA privilege <strong>to</strong> be captainon board <strong>the</strong> Arctic Lady24 | Tanker UPDATE NO. 2 <strong>2011</strong>

Arctic LadyThe Arctic Lady and her sister ship <strong>the</strong> Arctic Princess are Moss-design LNG carriers purposebuilt <strong>to</strong> serve Sta<strong>to</strong>il’s Melkøya LNG terminal close <strong>to</strong> <strong>the</strong> <strong>No</strong>rwegian city of Hammerfest, <strong>the</strong>nor<strong>the</strong>rnmost city in <strong>the</strong> world. The Melkøya LNG terminal is also <strong>the</strong> nor<strong>the</strong>rnmost LNG terminalin <strong>the</strong> world, and <strong>the</strong> Snøhvit LNG carriers were <strong>the</strong> first winterized LNG carriers in <strong>the</strong> world.Text: Magne A. Røe, DNVPho<strong>to</strong>: <strong>No</strong>rvald KjærstadTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 25

Arctic PrincessSvein-Are Gusdal, a captain on board <strong>the</strong>Arctic Lady, has been a sailor since he was22 years old, in <strong>the</strong> gas trade since 1976and has just turned 60. We recently discussedhis experiences <strong>from</strong> <strong>the</strong> specialtrade of braving <strong>the</strong> <strong>No</strong>rth Atlantic, <strong>No</strong>rwegianSea and Barents Sea close <strong>to</strong> <strong>the</strong>nor<strong>the</strong>rn tip of <strong>No</strong>rway during <strong>the</strong> winter,when s<strong>to</strong>rms can be fierce.“The nor<strong>the</strong>rn part of <strong>the</strong> sea route <strong>to</strong>Melkøya has unpredictable wea<strong>the</strong>r as it isat 70 degrees north. Arctic lows (low pressuresystems) often appear suddenly, bringinggale force winds, and <strong>the</strong> terminal atMelkøya is not <strong>the</strong> place <strong>to</strong> be for <strong>to</strong>o longin those wea<strong>the</strong>r conditions. To me, quickin and out again is <strong>the</strong> preferred mode.We have experienced temperatures down<strong>to</strong> minus 15 <strong>to</strong> 20 degrees centigrade. With<strong>the</strong> wind chill on <strong>to</strong>p, this trade can beextremely cold and completely different<strong>from</strong> o<strong>the</strong>r worldwide trades.”The Arctic Lady is ‘winterized’. What does thatmean in practical terms?“It means <strong>the</strong> ship has additional insulationof <strong>the</strong> accommodation and s<strong>to</strong>ragespaces, heating systems in <strong>the</strong> form ofelectrical coils on walkways and laddersand deicing systems for o<strong>the</strong>r areas. Firelines on deck and o<strong>the</strong>r piping systemsare also protected against ice formation.This works very well, as does <strong>the</strong> heatingin <strong>the</strong> cargo manifold area <strong>to</strong> prevent ice<strong>from</strong> building up. In addition, <strong>the</strong> bridgeis extended <strong>to</strong> <strong>the</strong> enclosed and heatedbridge wings <strong>to</strong> protect <strong>the</strong> crew <strong>from</strong> <strong>the</strong>bitterly cold wea<strong>the</strong>r when entering andleaving <strong>the</strong> terminal. The biggest problemwith <strong>the</strong> Winterized class notation is how<strong>to</strong> explain <strong>the</strong> difference between ice classand winterized <strong>to</strong> <strong>the</strong> many vetting agentsand port authorities. They don’t alwaysknow or understand <strong>the</strong> difference. Iceclass means a stronger hull when needed<strong>to</strong> be able <strong>to</strong> travel through varying typesof ice. There is no ice any time of <strong>the</strong> yearat Melkøya, just bad wea<strong>the</strong>r. So we don’tneed a streng<strong>the</strong>ned hull for this purpose.Winterized is, however, mainly intended <strong>to</strong>make <strong>the</strong> vessel fit for purpose in low temperaturesthrough special features above<strong>the</strong> waterline. The degree of winterizationneeds <strong>to</strong> be tailormade for different tradesin different parts of <strong>the</strong> world.Have you personally experienced any problemswith icing?“Actually, we haven’t during <strong>the</strong> first fouryears of operation. I’ve never had any›› Captain Svein-Are Gusdal onboard <strong>the</strong> Arctic Lady.26 | Tanker UPDATE NO. 2 <strong>2011</strong>

Arctic Princessmajor ice forming on <strong>the</strong> ship, in spite ofsub-zero temperatures and sea spray coveringmost of <strong>the</strong> ship. The combination ofwind force and direction, wave heights, seaand air temperatures has so far never beenright for major icing. The Snøhvit vesselsare modern state-of-<strong>the</strong>-art ships and it isreally a privilege <strong>to</strong> be a captain on board<strong>the</strong> Arctic Lady. It’s like being a captain ofa cruise ship.”So you like <strong>the</strong> way <strong>the</strong> ship handles?The ship is strong and with a few exceptionsnormally handles like a dream. Wehave some 9,800 sq m of steel surfaceabove <strong>the</strong> waterline and can operateat a cruising speed of 19.5 knots. Thenavigation systems are, of course, <strong>the</strong>best <strong>the</strong>re are, so yes, it handles like ayacht.”Can you describe <strong>the</strong> trade you do – once youleave Melkøya?“Our two ships were originally designed<strong>to</strong> trade <strong>the</strong> <strong>No</strong>rth Atlantic <strong>from</strong> Melkøya<strong>to</strong> <strong>the</strong> US East Coast. However, this haschanged since <strong>the</strong> shale gas projects weredeveloped in <strong>the</strong> US, significantly reducing<strong>the</strong> need for imported LNG. Today,we sail <strong>to</strong> different European ports butwe have also done <strong>the</strong> long haul <strong>from</strong> <strong>the</strong>Melkøya terminal <strong>to</strong> KOGAS’s Incheonterminal outside Seoul in Korea. Thattrip is 15,000 nautical miles one way, eventaking <strong>the</strong> shortest route through <strong>the</strong>Suez channel.”Captain Gusdal was off duty when wetalked <strong>to</strong> him, but in late <strong>No</strong>vember heis joining his favourite ship in Singaporewhere she will continue on ano<strong>the</strong>r voyage<strong>to</strong> Korea. He captained LPG carriersuntil 2007 when he joined Höegh andstarted <strong>to</strong> sail on <strong>the</strong> Arctic Lady. Höegh LNGOslo-based Höegh LNG operates a fleet ofseven LNG carriers, including two shuttle andregasification vessels. Höegh has close <strong>to</strong> 40 yearsof experience as a carrier of liquefied natural gasfor cus<strong>to</strong>mers such as Gasnatural, GDF Suez,Sta<strong>to</strong>il, Total and Repsol.›› The loading terminal at Melkøya, <strong>No</strong>rway, is <strong>the</strong> nor<strong>the</strong>rnmost LNG terminal in <strong>the</strong> world.Pho<strong>to</strong>: Darko Kucic©Wikipedia user: BerkutTanker <strong>update</strong> NO. 2 <strong>2011</strong> | 27

Tanker WeekTanker WeekA practical and extensive training event, called Tanker Week, was heldat <strong>the</strong> DNV Academy in Gdynia, Poland, on Oc<strong>to</strong>ber 17–21.TEXT: Anna Moen, DNV›› Anna Moen, Senior Cus<strong>to</strong>merRelations Management Coordina<strong>to</strong>r›› Image <strong>from</strong> tanker simula<strong>to</strong>r.The target group consisted of ship owners/shipmanagers of operating tankers,superintendents and ships’ officers.Each of <strong>the</strong> scheduled sessions wasattended by about 18 participants <strong>from</strong>various companies, including owner representatives,consultants (independentsurveyors and loss adjusters) and crewingagents. All <strong>the</strong> sessions combined lectures,discussions, exercises and group work.Virtual ship inspections were also incorporatedin<strong>to</strong> <strong>the</strong> course.The week began with a one-day TankerHull Inspection Course. This consisted ofseveral modules, based on <strong>the</strong> virtual hullinspection of typical tanker spaces. After ashort <strong>the</strong>oretical introduction in <strong>the</strong> classroom,participants stepped on<strong>to</strong> <strong>the</strong> deck ofa virtual tanker. They conducted a raftinginspection of a cargo oil tank and inspecteda water ballast tank and <strong>the</strong> main deck.The participants also attended a onedayTMSA & Vetting course. This aimed<strong>to</strong> provide a sound understanding of <strong>the</strong>principles and objectives behind <strong>the</strong> vettingprocess and TMSA (Tanker ManagementSelf Assessment) scheme. The course28 | Tanker UPDATE NO. 2 <strong>2011</strong>