FASTEKS+ KD-TECH ® Blind rivet nuts - KVT-Fastening

FASTEKS+ KD-TECH ® Blind rivet nuts - KVT-Fastening

FASTEKS+ KD-TECH ® Blind rivet nuts - KVT-Fastening

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

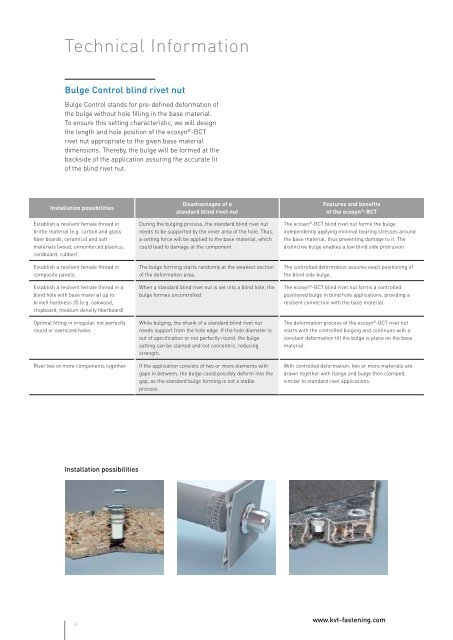

Technical InformationBulge Control blind <strong>rivet</strong> nutBulge Control stands for pre-defined deformation ofthe bulge without hole filling in the base material.To ensure this setting characteristic, we will designthe length and hole position of the ecosyn <strong>®</strong> -BCT<strong>rivet</strong> nut appropriate to the given base materialdimensions. Thereby, the bulge will be formed at thebackside of the application assuring the accurate fitof the blind <strong>rivet</strong> nut.Installation possibilitiesEstablish a resilient female thread inbrittle material (e.g. carbon and glassfiber boards, ceramics) and softmaterials (wood, unreinforced plastics,cardboard, rubber)Establish a resilient female thread incomposite panelsEstablish a resilient female thread in ablind hole with base material up tobrinell hardness 35 (e.g. oakwood,chipboard, medium density fiberboard)Optimal fitting in irregular, not perfectlyround or oversized holesRivet two or more components togetherDisadvantages of astandard blind <strong>rivet</strong> nutDuring the bulging process, the standard blind <strong>rivet</strong> nutneeds to be supported by the inner area of the hole. Thus,a setting force will be applied to the base material, whichcould lead to damage at the component.The bulge forming starts randomly at the weakest sectionof the deformation area.When a standard blind <strong>rivet</strong> nut is set into a blind hole, thebulge formes uncontrolled.While bulging, the shank of a standard blind <strong>rivet</strong> nutneeds support from the hole edge. If the hole diameter isout of specification or not perfectly round, the bulgesetting can be slanted and not concentric, reducingstrength.If the application consists of two or more elements withgaps in between, the bulge could possibly deform into thegap, as the standard bulge forming is not a stableprocess.Features and benefitsof the ecosyn <strong>®</strong> -BCTThe ecosyn <strong>®</strong> -BCT blind <strong>rivet</strong> nut forms the bulgeindependently applying minimal bearing stresses aroundthe base material, thus preventing damage to it. Thedistinctive bulge enables a low blind side protrusion.The controlled deformation assures exact positioning ofthe blind side bulge.The ecosyn <strong>®</strong> -BCT blind <strong>rivet</strong> nut forms a controlledpositioned bulge in blind hole applications, providing aresilient connection with the base material.The deformation process of the ecosyn <strong>®</strong> -BCT <strong>rivet</strong> <strong>nuts</strong>tarts with the controlled bulging and continues with aconstant deformation till the bulge is plane on the basematerial.With controlled deformation, two or more materials aredrawn together with flange and bulge then clamped,similar to standard <strong>rivet</strong> applications.Installation possibilities6www.kvt-fastening.com