ORAU TEAM Dose Reconstruction Project for NIOSH

ORAU TEAM Dose Reconstruction Project for NIOSH

ORAU TEAM Dose Reconstruction Project for NIOSH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Document No. <strong>ORAU</strong>T-TKBS-0041 Revision No. 01 Effective Date: 06/02/2009 Page 14 of 89<br />

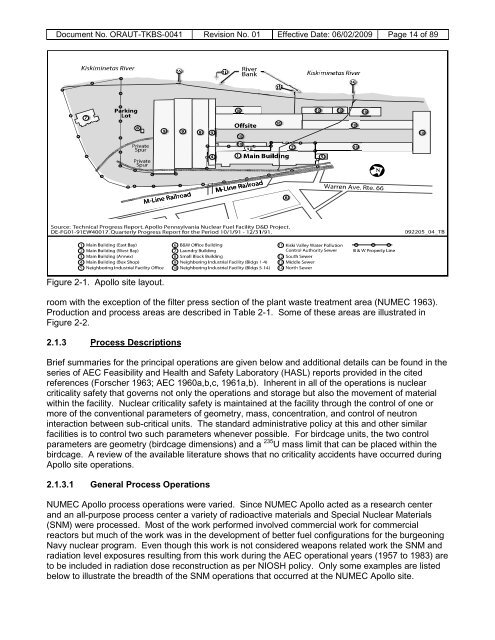

Figure 2-1. Apollo site layout.<br />

room with the exception of the filter press section of the plant waste treatment area (NUMEC 1963).<br />

Production and process areas are described in Table 2-1. Some of these areas are illustrated in<br />

Figure 2-2.<br />

2.1.3<br />

Process Descriptions<br />

Brief summaries <strong>for</strong> the principal operations are given below and additional details can be found in the<br />

series of AEC Feasibility and Health and Safety Laboratory (HASL) reports provided in the cited<br />

references (Forscher 1963; AEC 1960a,b,c, 1961a,b). Inherent in all of the operations is nuclear<br />

criticality safety that governs not only the operations and storage but also the movement of material<br />

within the facility. Nuclear criticality safety is maintained at the facility through the control of one or<br />

more of the conventional parameters of geometry, mass, concentration, and control of neutron<br />

interaction between sub-critical units. The standard administrative policy at this and other similar<br />

facilities is to control two such parameters whenever possible. For birdcage units, the two control<br />

parameters are geometry (birdcage dimensions) and a 235 U mass limit that can be placed within the<br />

birdcage. A review of the available literature shows that no criticality accidents have occurred during<br />

Apollo site operations.<br />

2.1.3.1 General Process Operations<br />

NUMEC Apollo process operations were varied. Since NUMEC Apollo acted as a research center<br />

and an all-purpose process center a variety of radioactive materials and Special Nuclear Materials<br />

(SNM) were processed. Most of the work per<strong>for</strong>med involved commercial work <strong>for</strong> commercial<br />

reactors but much of the work was in the development of better fuel configurations <strong>for</strong> the burgeoning<br />

Navy nuclear program. Even though this work is not considered weapons related work the SNM and<br />

radiation level exposures resulting from this work during the AEC operational years (1957 to 1983) are<br />

to be included in radiation dose reconstruction as per <strong>NIOSH</strong> policy. Only some examples are listed<br />

below to illustrate the breadth of the SNM operations that occurred at the NUMEC Apollo site.