CAPSULE MANUFACTURING UNIT Capsule ... - Invest in Assam

CAPSULE MANUFACTURING UNIT Capsule ... - Invest in Assam

CAPSULE MANUFACTURING UNIT Capsule ... - Invest in Assam

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

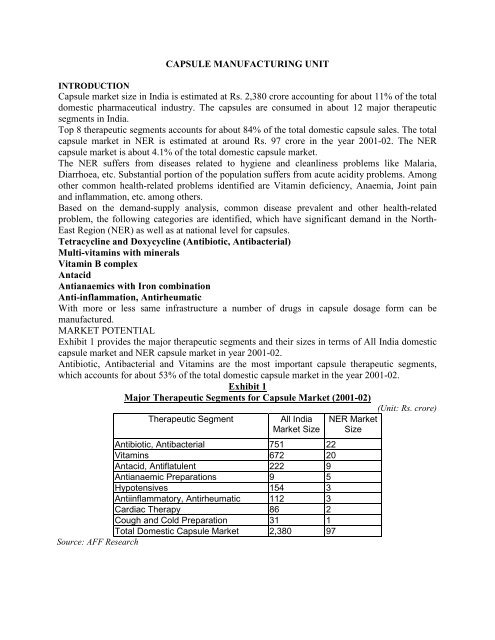

Exhibit 2Flow Chart for <strong>Capsule</strong> Manufactur<strong>in</strong>g Process

lender mach<strong>in</strong>e is sent for Intermediate Process Quality Check (IPQC). If approved, the blendedmaterials are taken to the power fill<strong>in</strong>g section.In the powder fill<strong>in</strong>g section, the blended powder is filled <strong>in</strong> the empty capsules. Once thecapsules are filled they proceed to polish<strong>in</strong>g section where the capsules are polished to removethe excess powder on the outer side of the filled capsule.<strong>Capsule</strong>s from the polish<strong>in</strong>g section go through an <strong>in</strong>spection and an Intermediate ProcessQuality Control (IPQC) to remove the empty capsules or capsule hav<strong>in</strong>g any production defects.IPQC approved capsules are taken to the pack<strong>in</strong>g section where primary pack<strong>in</strong>g for the capsulesis done. The capsules can be packed <strong>in</strong> the follow<strong>in</strong>g ways depend<strong>in</strong>g upon the requirement-Strip Pack<strong>in</strong>gBlister Pack<strong>in</strong>gBulk Pack<strong>in</strong>gKEY ASSUMPTIONSThe key assumptions made while prepar<strong>in</strong>g the project profile are detailed below:Sr.Items Value BasisNo.1. Land development Developmentcharges: Rs. 250per sq. mtr.Lease Rentals:Rs. 3.5 per sft.2. Mach<strong>in</strong>ery and equipmentcost--- Costs of lead<strong>in</strong>g mach<strong>in</strong>erysuppliers <strong>in</strong>clusive of <strong>in</strong>stallationcharges3. Miscellaneous fixed assets --- Industry norm4. Provision for cont<strong>in</strong>gency 10% of total Assumptioncapitalexpenditure5. Raw material prices --- Landed cost (<strong>in</strong>clud<strong>in</strong>gtransportation)6. Labour --- Prevalent rate <strong>in</strong> NER (Guwahati,<strong>Assam</strong>)7. Power and fuel --- Prevalent charges <strong>in</strong> <strong>Assam</strong>8. Repair and ma<strong>in</strong>tenance --- Industry norm9. Inventory: Raw materials 2 Months Industry norm(RM)10. Inventory: F<strong>in</strong>ished goods 1 Month Industry norm(FG)11. Bills receivable 1 Month Industry norm12. Creditors 1 Month Industry norm13. Product distributionexpenses7% Tak<strong>in</strong>g <strong>in</strong>to consideration averagedistribution costs.14. Other Expenses --- Includes cost of conversion dur<strong>in</strong>gmanufactur<strong>in</strong>g (i.e. utilities) andvariable product distribution costs

15. Interest on work<strong>in</strong>g capital 9% 3% subsidy on work<strong>in</strong>g capitalloan under the Central InterestSubsidy Scheme, 199716. Subsidy on plant andmach<strong>in</strong>ery15% Under the Central Capital<strong>Invest</strong>ment Subsidy Scheme,199717. Subsidy on <strong>in</strong>surancepremium18. Subsidy on Income Tax 100%19. Debt : Equity ratio 60 : 40 Industry normFINANCIAL ASPECTSA. LAND AND SITE DEVELOPMENT100% Under the Central ComprehensiveInsurance Scheme, 1997Sr.No.Particulars Units Unit Rate Total (Rs.)1. Land and Site500 sq. m. Rs. 250/ sq. m. 125,000DevelopmentTotal 125,000B. BUILDING AND CIVIL WORKSSr. Particulars Units Unit Rate Total (Rs.)No.1. Build<strong>in</strong>g and Civil Work 400 sq. m. Rs. 7,500/ sq. m. 3,000,000Total 3,000,000C. PLANT AND MACHINERY

Sr.No.ParticularsQuantity(Nos.)Unit Cost(Rs.)Total Cost(Rs.)Manufactur<strong>in</strong>g EquipmentGranulation Section1 Sifter 1 nos. 50,000 50,0002 Multi Mill 1 nos. 70,000 70,000Blend<strong>in</strong>g Section3 Blender 1 nos. 150,000 150,000Fill<strong>in</strong>g Section4 Powder Fill<strong>in</strong>g and Polish<strong>in</strong>g 1 nos. 2,500,000 2,500,000Mach<strong>in</strong>ePackag<strong>in</strong>g Section5 Strip Pack<strong>in</strong>g Mach<strong>in</strong>e 1 nos. 200,000 200,0006 Blister Pack<strong>in</strong>g Mach<strong>in</strong>e 1 nos. 300,000 300,000Test<strong>in</strong>g Equipment7 PH Meter 1 nos. 10,000 10,0008 Balances 1 nos. 30,000 30,0009 UV Spectrophotometer 1 nos. 100,000 100,00010 High Performance Liquid1 nos. 1,300,000 1,300,000Chromatography (HPLC)11 IR Spectrophotometer 1 nos. 150,000 150,00012 Dissolution Tester 1 nos. 120,000 120,00013 Other Test<strong>in</strong>g Mach<strong>in</strong>ery 1 nos. 203,000 203,000Utilities/ Misc. Other Equipment14 Air Handl<strong>in</strong>g Units, Ventilation,AC Duct<strong>in</strong>g, etc.15 Electrification, Control Panelsand Cabl<strong>in</strong>g, Transformer, etc.16 Water Plant, Generation andDistribution17 Steam Generation Units,Compressors6,000,0003,000,0002,500,000600,000Total Mach<strong>in</strong>ery, Utilities andEquipment17,283,000NOTE: ABOVE MENTIONED EQUIPMENT IS INDICATIVE LIST FOR THE PROPOSED <strong>CAPSULE</strong>-<strong>MANUFACTURING</strong><strong>UNIT</strong>

D. MISCELLANEOUS FIXED ASSETSSr. No.ParticularsTotal (Rs.)1 Furniture and Fitt<strong>in</strong>gs 25,0002 Office Equipment 100,0003 Fire Fight<strong>in</strong>g Equipment 50,0004 Cost of Tube-well 20,000Total Misc. Fixed Assets 195,000E. PRELIMINARY AND PRE-OPERATIVE EXPENSESSr. No.ParticularsTotal Cost (Rs.)1 Detailed Techno-economic Feasibility Study 100,0002 Loan Process<strong>in</strong>g Fees 10,0003 Establishment expenses 200,000Total Prelim<strong>in</strong>ary & Preoperative Expenses 310,000F. PROVISION FOR CONTINGENCYProvision for cont<strong>in</strong>gency- @ 10% of the total capital <strong>in</strong>vestmentOPERATING COSTSA. RAW MATERIALRaw materials consumed for manufactur<strong>in</strong>g any drug are of two typesActive Pharmaceutical Ingredients (APIs)Excipients (used as b<strong>in</strong>d<strong>in</strong>g materials <strong>in</strong> manufactur<strong>in</strong>g process)Raw materials consumed differ significantly from product to product <strong>in</strong> pharmaceutical

Sr. No. Particulars Units Total1 Average cost of raw material Rs. 8752 Raw materials consumed per batch Kg. 1203 Number of batches per year Nos. 300Total raw materials consumed per annum Rs. 31,504,000Note: Above raw material consumption pattern is calculated at 100% capacity utilisation of the manufactur<strong>in</strong>gunit work<strong>in</strong>g for 300 days per annum and a s<strong>in</strong>gle shift per day basis.B. LABOURSr.No.Particulars Qualification Nos. SalaryperMonth(Rs.)Direct Labour1 Factory Manager BE/B.Tech +MBA/MMSAnnualManpowerCost(Rs.)1 20,000 264,0002 Production Manager BE/B.Tech 1 15,000 198,0003 Chemists BE/B.Tech 6 12,000 950,4004 Eng<strong>in</strong>eer and Technicians BE/B.Tech 5 10,000 660,0005 Skilled Workers BE 4 5,000 264,0006 Semi-skilled and Un-skilled Matriculate 8 3,000 316,800Workers7 Other Misc. Personnel 8 2,500 264,000Total Direct Labour 33 2,917,200Indirect Labour8 F<strong>in</strong>ance Manager MBA/MMS +CA1 15,000 198,0009 Accountant CA 1 10,000 132,00010 Bus<strong>in</strong>ess Development Graduate 1 8,000 105,600Executives11 Security Personnel 3 3,000 118,800Total Indirect Labour 6 554,400Total Cost of Man-power 39 3,471,600Note: (1) Manpower cost also <strong>in</strong>cludes Perks @ 10% of annual salary(2) There is no specific requirement of other highly skilled and specifically tra<strong>in</strong>ed manpower apart fromthe normally available qualified manpower as mentioned above at the proposed manufactur<strong>in</strong>g location.C. POWER AND FUELParticularsUnits Consumptionper dayUnit Cost(Rs.)Annual Cost(Rs.)Electricity (30 kW) Units 717 6 1,290,000Furnace Oil Litres 75 8 180,000Water Litres 3500 Nil 0Source: It is assumed that ground water is tapped through tubewell and hence water is considered free ofcost.D. OTHER EXPENSESSr. No.FixedParticularsTotal Cost (Rs.)

Sr. No. Particulars Total Cost (Rs.)1 Repairs and ma<strong>in</strong>tenance 1,452,4002 Bus<strong>in</strong>ess Development expenses 500,0003 Lease rent for land 210,0004 Office Adm<strong>in</strong>istration and other misc. expenses 100,0005 Professional and legal fees 300,0006 Bank charges and commissions 20,0007 Pr<strong>in</strong>t<strong>in</strong>g and stationary 100,0008 Insurance and taxes 100,000Total Other Expenses 2,782,400E. Total Work<strong>in</strong>g CapitalParticulars Norms Total (Rs.)Raw Materials 2 Months of raw materials 5,250,667Pack<strong>in</strong>gMaterials2 Month of pack<strong>in</strong>g materials1,718,400F<strong>in</strong>ished Goods 1 Month of cost of production 3,961,867Bills Receivables 1 Month of sales value 4,773,333Outstand<strong>in</strong>gs 1 Month of Raw Material and Pack<strong>in</strong>g Material 3,484,533Total 12,219,733Note: 1. Work<strong>in</strong>g capital requirement <strong>in</strong>dicated above is at 100% capacity utilisation.2. Marg<strong>in</strong> money @ 25% of total Work<strong>in</strong>g Capital – Rs. 3,054,933CAPITAL INVESTMENTThe capital <strong>in</strong>vestment required for the project is Rs. 2.61 crore. The break-up of the capital<strong>in</strong>vestment is <strong>in</strong>dicated <strong>in</strong> below.Sr. No. Particulars Total Value (Rs.)1 Land and Site Development Cost 125,0002 Build<strong>in</strong>g and Civil Works 3,000,0003 Plant and Mach<strong>in</strong>ery 17,283,0004 Misc. Fixed Assets 195,0005 Prelim<strong>in</strong>ary and Pre-operative Expenses 310,0006 Provisions for Cont<strong>in</strong>gency 2,091,3007 Marg<strong>in</strong> Money for Work<strong>in</strong>g Capital 3,054,933Total Cost of the Project 26,059,233Debt and Equity StructureTotal Cost of ProjectPromoter’s Equity:Debt Funds:Rs. 26.06 lakhsRs. 10.42 alkhsRs. 15.64 lakhsFINANCIAL ANALYSISA. Cost of Production

Sr. No. Particulars Total (Rs.)1 Raw materials 31,504,0002 Pack<strong>in</strong>g materials 10,310,4003 Adm<strong>in</strong>istrative overheads 2,917,2004 Other overheads 1,470,0005 Interest on work<strong>in</strong>g capital 824,872Total cost of production 47,026,472Note: Cost of production <strong>in</strong>dicated above is at 100% capacity utilisation.B. TurnoverAnnual sales realisation of the manufactur<strong>in</strong>g unit with the assumed product mix is illustratedbelow. Sales realisation at 100% capacity utilisation are around Rs. 5.73 crores.Sr.No.ParticularsNo. of<strong>Capsule</strong>s(Lakhs)Sales Realisationper '000<strong>Capsule</strong>s (Rs.)Total SalesRealisation(Rs.)1 Tetracycl<strong>in</strong>e and Doxycycl<strong>in</strong>e 192 1,000 19,200,0002 Omeprazole (Antipeptic Ulcerants) 128 1,000 12,800,0003 Multi-vitam<strong>in</strong>s with m<strong>in</strong>erals 96 900 8,640,0004 Vitam<strong>in</strong> B complex 96 600 5,760,0005 Antianaemics with iron64 500 3,200,000comb<strong>in</strong>ations6 Antirheumatic 64 1,200 7,680,000Total 640 57,280,000Note: Total annual realisation mentioned above is at 100% capacity utilisationC. Profit and Loss Statement for 10 Years(Unit: Rs. lakhs)Particulars Formula Yr 1 Yr 2 Yr 3 Yr 4 Yr 5 Yr 6 Yr 7 Yr 8 Yr 9 Yr 10Capacity Utilisation 25% 75% 100% 100% 100% 100% 100% 100% 100% 100%Sales Realisation A 95 430 573 573 573 573 573 573 573 573Operat<strong>in</strong>g Costs BRM and PM Costs 70 314 418 418 418 418 418 418 418 418Labour Costs 29 29 29 29 29 29 29 29 29 293. Other Overheads 5 12 15 15 15 15 15 15 15 15Interest on Work<strong>in</strong>gCapitalGross Profit <strong>in</strong>cl.Transport Subsidy1 6 8 8 8 8 8 8 8 8C=A-B -10 69 103 103 103 103 103 103 103 103Interest D 17 17 15 13 11 9 8 6 4 2Depreciation E 27 24 20 18 15 13 11 10 9 7PBT F=C-(D+E) -54 29 67 72 76 80 84 87 90 93Tax G 0 0 0 0 0 0 0 0 0 0PAT H=F-G -54 29 67 72 76 80 84 87 90 93Cash Profit I=H+E -27 52 88 89 91 93 95 97 99 101GP Marg<strong>in</strong> J=C/A -10% 16% 18% 18% 18% 18% 18% 18% 18% 18%NP Marg<strong>in</strong> K=H/A -57% 7% 12% 13% 13% 14% 15% 15% 16% 16%Note:1. Figures <strong>in</strong>dicated above are rounded-off2. Annual sales values <strong>in</strong>dicated above are after tak<strong>in</strong>g <strong>in</strong>to consideration open<strong>in</strong>g and clos<strong>in</strong>g stockReturn on <strong>Invest</strong>ment (ROI): 27%D. Breakeven AnalysisThe breakeven analysis for the proposed capsule-manufactur<strong>in</strong>g unit is <strong>in</strong>dicated below. The

unit does not achieve operational break-even po<strong>in</strong>t <strong>in</strong> the first year of operations. Fromsecond year onwards, the unit achieves operational break-even.

Particulars Unit Yr 1 Yr 2 Yr 3 Yr 4 Yr 5 Yr 6 Yr 7Capacity Utilisation (%) 25% 75% 100% 100% 100% 100% 100%Sales Realisation Rs. lakhs 98 440 587 587 587 587 587Variable Cost of SalesDirect MaterialRs.lakhs 39 176 235 235 235 235 235Pack<strong>in</strong>g CostRs.lakhs 20 88 117 117 117 117 117Conversion CostRs.lakhs 5 12 15 15 15 15 15Direct LabourRs.lakhs 29 29 29 29 29 29 29Interest on Work<strong>in</strong>gCapitalRs.lakhs 1 6 8 8 8 8 8Total Variable Costs Rs. lakhs 94 311 404 404 404 404 404Contribution Rs. lakhs 3 130 183 183 183 183 183Fixed CostsOther overheads (excl. Rs.Repairs and Ma<strong>in</strong>tenance) lakhs5 10 12 12 12 12 12Repairs and Ma<strong>in</strong>tenance Rs.lakhs 15 15 15 15 15 15 15Manpower CostRs.lakhs 6 6 6 6 6 6 6Interest on Term Loan Rs.lakhs 17 17 15 13 11 9 7Total Fixed Cost Rs. lakhs 41 47 47 45 44 42 40Break Even Po<strong>in</strong>t Rs. lakhs 1,168 158 151 145 139 133 127Actual Sales Realisation Rs. 98 440 587 587 587 587 587lakhsBreak Even Sales at % of %Capacity199% 27% 26% 25% 24% 23% 22%Note: 1. Figures <strong>in</strong>dicated above are rounded-off2. Annual sales values <strong>in</strong>dicated above are after tak<strong>in</strong>g <strong>in</strong>to consideration open<strong>in</strong>g and clos<strong>in</strong>g stocksSOURCES OF RAW MATERIALSAjanta Chemicals21, Cloth Commercial Centre, Kalupur, Ahmedabad- 380002Tel: +(91)-(079)- 2335755, 2384605Fax: +(91)-(079)- 22121182Alkyl Am<strong>in</strong>es Chemicals Limited207-A, Kakad Chambers, 132, Dr. A. B. Road, Worli, Mumbai- 400018Tel: +(91)-(022)- 24925564, 24930699Fax: +(91)-(022)- 27671932Email: aac.vsh.@alkyl.spr<strong>in</strong>trpg.ems.vsnl.net.<strong>in</strong>Abbott Labs (India) Limited17 R, Kamani Marg, Mumbai- 400001Tel: +(91)-(022)- 256319797

Email: webmaster@abbott.co.<strong>in</strong>Gufic Chemical Private LimitedSubhash Road, ‘A’, Vile Parle (E), Mumbai- 400037Tel: +(91)-(022)- 28341521/22, 28344523Fax: +(91)-(022)- 28369008Gujarat Organic Chemicals32, GIDC, Vithal Udyognagar, Kaira, Gujarat- 388121Tel: +(91)-(02692)- 231478, 231489Impex India8-2-333/ 14-A, Road No. 3, Banjara Hills, Hyderabad- 500034Tel: +(91)-(040)- 23548409Fax: +(91)-(040)- 23548409Email: impex.<strong>in</strong>dia@gnhyd.globalnet.ems.vsnl.net.<strong>in</strong>Indian Drugs and Pharmaceuticals LimitedP.O. Virbhadra- 249202 (Rishikesh), Utter PradeshJayant Vitam<strong>in</strong>s Limited12, Bhargava Lane, Civil L<strong>in</strong>es, Delhi- 110054Tel: +(91)-(011)- 22911653, 22519414Lake Chemicals Private Limited12, Ravi Kiran, Pla<strong>in</strong> Street, Bangalore- 560001Tel: +(91)-(080)- 22860394, 22866353Fax: +(91)-(080)- 22867734Email: md@lake.<strong>in</strong>dia.comMentioned below are few sources of pack<strong>in</strong>g materials-Ajanata Pack<strong>in</strong>g Company8939/1, Multani Dhanda, Paharganj, New Delhi- 110055Tel: +(91)-(011)- 23629420, 23514419Fax: +(91)-(011)- 23629420Email: ajantabottle@usa.netBoxcare Packag<strong>in</strong>g Pvt. Ltd.83, B & C Sheth Gov<strong>in</strong>drao Smruti, Dr. A. B. Road, Worli, Mumbai- 400018Tel: +(91)-(022)- 24960985, 24960986Flexible Packag<strong>in</strong>g Company128/129, New Sadguru Nashik Industrial Estate, Goregaon (E), Mumbai- 400063Tel: +(91)-(022)- 28733602Fax: +(91)-(022)- 28734856Email: vilam@bom4.vsnl.net.<strong>in</strong>Wonderpack Industries (Pvt) LimitedPO Box No. 29127, TV Indl. Estate, S. K. Ahire Road, Worli, Mumbai- 400025Tel: +(91)-(022)- 24936496, 24949580Fax: +(91)-(022)- 24938796Email: wonder@bom3.vsnl.net.<strong>in</strong>SOURCE OF MACHINERY AND EQUIPMENTMost of the mach<strong>in</strong>ery for manufactur<strong>in</strong>g the pharmaceutical products is not manufactured <strong>in</strong>NER. Most of the mach<strong>in</strong>ery manufacturers are based <strong>in</strong> Mumbai, Ahmedabad. Smaller clustersfor mach<strong>in</strong>ery manufacturers <strong>in</strong>clude Delhi, Haryana, Kolkata, etc.Mentioned below are few sources of mach<strong>in</strong>ery and equipment-

PROCESS EQUIPMENTAlliance Eng<strong>in</strong>eer<strong>in</strong>g Company97, Trisandhya Build<strong>in</strong>g, D. Phalke Road, Mumbai- 400014Tel: +(91)-(022) 24112461, 24156510Fax: +(91)-(022) 24138307Pharmalab Eng<strong>in</strong>eer<strong>in</strong>g India LimitedStar Metal Compound, L. B. S. Road, Vikhroli (W), Mumbai- 400083Tel: +(91)-(022) 25782559Fax: +(91)-(022) 25775219Email: poma@gbom.3vsnl..net.<strong>in</strong>Tapasya Eng<strong>in</strong>eer<strong>in</strong>g Works Private LimitedA-212, Road No. 30, Wagle Industrial Estate, Thane, Mumbai- 400604Tel: +(91)-(022)- 25823250Unipack Mach<strong>in</strong>es Private LimitedB-270, Joshi Wadi, Off Manpada Road, Dombivali (E), Mumbai- 421201ABMA Mach<strong>in</strong>esPlot No. 40/1, Phase I, GIDC, Ahmedabad- 382445Ambica Eng<strong>in</strong>eer<strong>in</strong>g WorksPlot No. 1804, Phase-III, GIDC Industrial Area, Vatva, Ahmedabad- 382445Tel: +(91)-(079) 25894796, 25830729Gansons LimitedThe Shopp<strong>in</strong>g Mall, Arjun Marg, DLF Qutab Enclave (Phase-I), Gurgaon- 122002Tel: +(91)-(0124) 2359596/7Fax: +(91)-(0124) 2359041Neomach<strong>in</strong>e Mfg. Co. Private Limited39/2A, Purna Das Road, Kolkata- 700053AUXILIARY EQUIPMENTThermax (India) LimitedThermax House, 4, Mumbai-Pune Road, Shivaj<strong>in</strong>agar, Pune- 411019Tel: +(91)-(020)- 25512122Fax: +(91)-(020)- 25512242Website: www.thermax<strong>in</strong>dia.comAtlas Copco (India) LimitedSevanagar, Dapodi, Pune- 411012Tel: +(91)-(020)- 27146416/17Fax: +(91)-(020)- 27146637Website: www.atlascopco.comAquatech India LimitedPlot No. 3, Baner Park, Near D. P. Road, Aundh, Pune- 411007Tel: +(91)-(020)- 27292103, 27291104Fax: +(91)-(020)- 7291805Website: www.aquatech.comEmail: asa@aquatech.comAlfa Laval (India) LimitedShivaj<strong>in</strong>agar, Pune- 4110112

Tel: +(91)-(020)- 27147721Fax: +(91)-(020)- 27147711Ion Exchange, MumbaiTiecicon House, Dr. E. Moses Road, Mahalaxmi, Mumbai- 400011Tel: +(91)-(022)- 24939520/23/25Fax: +(91)-(022)- 24938737Website: www.ion<strong>in</strong>dia.comEmail: ho.commun@ho.ionxchng.co.<strong>in</strong>Courtesy:NEDFi