SHAMPOO MANUFACURING UNIT - Invest in Assam

SHAMPOO MANUFACURING UNIT - Invest in Assam

SHAMPOO MANUFACURING UNIT - Invest in Assam

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

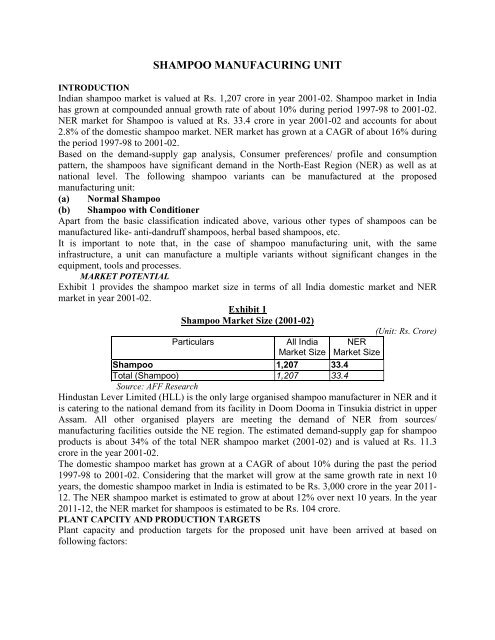

<strong>SHAMPOO</strong> <strong>MANUFACURING</strong> <strong>UNIT</strong>INTRODUCTIONIndian shampoo market is valued at Rs. 1,207 crore <strong>in</strong> year 2001-02. Shampoo market <strong>in</strong> Indiahas grown at compounded annual growth rate of about 10% dur<strong>in</strong>g period 1997-98 to 2001-02.NER market for Shampoo is valued at Rs. 33.4 crore <strong>in</strong> year 2001-02 and accounts for about2.8% of the domestic shampoo market. NER market has grown at a CAGR of about 16% dur<strong>in</strong>gthe period 1997-98 to 2001-02.Based on the demand-supply gap analysis, Consumer preferences/ profile and consumptionpattern, the shampoos have significant demand <strong>in</strong> the North-East Region (NER) as well as atnational level. The follow<strong>in</strong>g shampoo variants can be manufactured at the proposedmanufactur<strong>in</strong>g unit:(a) Normal Shampoo(b) Shampoo with ConditionerApart from the basic classification <strong>in</strong>dicated above, various other types of shampoos can bemanufactured like- anti-dandruff shampoos, herbal based shampoos, etc.It is important to note that, <strong>in</strong> the case of shampoo manufactur<strong>in</strong>g unit, with the same<strong>in</strong>frastructure, a unit can manufacture a multiple variants without significant changes <strong>in</strong> theequipment, tools and processes.MARKET POTENTIALExhibit 1 provides the shampoo market size <strong>in</strong> terms of all India domestic market and NERmarket <strong>in</strong> year 2001-02.Exhibit 1Shampoo Market Size (2001-02)(Unit: Rs. Crore)ParticularsAll IndiaMarket SizeNERMarket SizeShampoo 1,207 33.4Total (Shampoo) 1,207 33.4Source: AFF ResearchH<strong>in</strong>dustan Lever Limited (HLL) is the only large organised shampoo manufacturer <strong>in</strong> NER and itis cater<strong>in</strong>g to the national demand from its facility <strong>in</strong> Doom Dooma <strong>in</strong> T<strong>in</strong>sukia district <strong>in</strong> upper<strong>Assam</strong>. All other organised players are meet<strong>in</strong>g the demand of NER from sources/manufactur<strong>in</strong>g facilities outside the NE region. The estimated demand-supply gap for shampooproducts is about 34% of the total NER shampoo market (2001-02) and is valued at Rs. 11.3crore <strong>in</strong> the year 2001-02.The domestic shampoo market has grown at a CAGR of about 10% dur<strong>in</strong>g the past the period1997-98 to 2001-02. Consider<strong>in</strong>g that the market will grow at the same growth rate <strong>in</strong> next 10years, the domestic shampoo market <strong>in</strong> India is estimated to be Rs. 3,000 crore <strong>in</strong> the year 2011-12. The NER shampoo market is estimated to grow at about 12% over next 10 years. In the year2011-12, the NER market for shampoos is estimated to be Rs. 104 crore.PLANT CAPCITY AND PRODUCTION TARGETSPlant capacity and production targets for the proposed unit have been arrived at based onfollow<strong>in</strong>g factors:

(a) Product Mix (based on various shampoo products proposed for manufactur<strong>in</strong>g)(b) Demand : Supply Gap (<strong>in</strong> the North East Region)(c) M<strong>in</strong>imum Economic Plant Size- The economic size for manufactur<strong>in</strong>g for NERregion is 200-Kg batch size (Based on the discussion with large shampoo manufacturersand various units <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g).Rated Capacity of the key equipmentThe proposed plant will have a batch size of 200 kg <strong>in</strong> one shift and will operate on two-shiftbasis. With annual sales realisation of Rs. 2.6 crore, the manufactur<strong>in</strong>g unit will be account<strong>in</strong>gfor about 15 to 16% of the total NER shampoo market (consider<strong>in</strong>g the retail value of theproducts as the unit will be <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g) and about 45% of the demandsupplygap of NER shampoo market <strong>in</strong> year 2001-02.It is proposed that the unit would be <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g for a larger shampoomanufactur<strong>in</strong>g/ market<strong>in</strong>g company. It would primarily cater to the needs of the NER.There is an opportunity for about 2 to 3 shampoo manufactur<strong>in</strong>g units of similar size <strong>in</strong> NER.Summ<strong>in</strong>g up:Batch Size: 200 Kg. on a s<strong>in</strong>gle batch basis (two batches per day)Plant Capacity: 11.4 lakh bottles per annum (@ 100 ml per bottle)Capacity Utilisation: 50% (Year 1)Full Capacity Utilisation: Year 2RAW MATERIALS AND INPUTSRaw MaterialsRaw materials used <strong>in</strong> the process depend upon the type of shampoo manufactured. Typically, <strong>in</strong>any shampoo manufactured there are two types of raw materials used:- Active Ingredients (AIs) – These are the chemicals used <strong>in</strong> manufactur<strong>in</strong>g theshampoo. Active <strong>in</strong>gredients used <strong>in</strong> the manufactur<strong>in</strong>g process are different for differentvariants. Commonly used active <strong>in</strong>gredients <strong>in</strong>clude emulsify<strong>in</strong>g/ suspend<strong>in</strong>g agents likeAmmonium/ Sodium Lauryl Sulfate, Z<strong>in</strong>c Pyrithione, etc.- Others- Other <strong>in</strong>gredients <strong>in</strong>clude Citric Acid, Sodium Hydroxide,Ammonium Chloride, Fragrances, Pigments, etc.WaterThe requirement of water for 200-kg batch shampoo-manufactur<strong>in</strong>g unit is approximately 3,000litres per day.ELECTRICITYApproximate power requirement of a 200-kg batch shampoo-manufactur<strong>in</strong>g unit is 40 kW,which can be availed from the nearest sub-station of respective State Electricity Board (SEB).MANUFACTURING PROCESSThe flow chart for the manufactur<strong>in</strong>g process is as shown below <strong>in</strong> the Exhibit 2.The shampoo manufactur<strong>in</strong>g process is a batch process. Initially, the raw material goes through aQuality Check (QC) and if approved various Active Ingredients (AIs) and other raw materials aredispensed for process<strong>in</strong>g.Initially, active <strong>in</strong>gredients and other raw materials are taken <strong>in</strong>to a vessel known as ‘Mix<strong>in</strong>gVessel’. In this vessel the raw materials are mixed with hot water. The water used for thisprocess should be De-m<strong>in</strong>eralised and free from any k<strong>in</strong>d of impurities. The mix<strong>in</strong>g process iscarried out at a specific temperature (about 75 to 80 0 C).Subsequently, the solution is taken to another vessel (known as ‘Side Vessel’) and other<strong>in</strong>gredients like Fragrances, Pigments, etc. are added. The mixture is agitated for about 20-30

m<strong>in</strong>utes to form a homogenous solution. If required, Citric Acid or Sodium Hydroxide is used toadjust pH of water. F<strong>in</strong>ally, the solution is brought back to room- temperature and is ready forpack<strong>in</strong>g. Before, proceed<strong>in</strong>g with pack<strong>in</strong>g, the solution goes through an Intermediate ProcessQuality Check (IPQC) related to the efficacy of the product.Exhibit 2Flow Chart for Shampoo Manufactur<strong>in</strong>g Process

Raw Material Sampl<strong>in</strong>gRaw MaterialHandl<strong>in</strong>gQCTestQC Not ApprovedQC ApprovedRaw Material Dispens<strong>in</strong>gMix<strong>in</strong>g VesselRaw MaterialMix<strong>in</strong>gSectionRecoverMix<strong>in</strong>gSide VesselMix<strong>in</strong>g/ AgitationHotWaterFragrances,Preservatives,Dyes, etc.IPQC NotApprovedIPQCTestRejectIPQC ApprovedPrimary Pack<strong>in</strong>gProductPack<strong>in</strong>gProductInformationLeaflet (ifrequired)Inspection (If required)Secondary Pack<strong>in</strong>gQC NotapprovedRe-pack<strong>in</strong>gQCTestQC Approved ProductThereafter, the solution is transferred to the pack<strong>in</strong>g assembly through a pipel<strong>in</strong>e. Normally, thecapacity of the shampoo product assembly l<strong>in</strong>e is dependent on the throughput of pack<strong>in</strong>gmach<strong>in</strong>ery.Primary Pack<strong>in</strong>g for shampoo products can be done <strong>in</strong> the follow<strong>in</strong>g ways depend<strong>in</strong>g upon therequirement-

5. Raw material prices --- Landed cost (<strong>in</strong>clud<strong>in</strong>gtransportation)6. Labour --- Prevalent rate <strong>in</strong> NER7. Power and fuel --- Prevalent charges <strong>in</strong> NER8. Repair and ma<strong>in</strong>tenance --- Industry norm9. Inventory: Raw materials (RM) 2 Months Industry norm10. Inventory: F<strong>in</strong>ished goods (FG) 1 Month Industry norm11. Bills receivable 1 Month Industry norm12. Creditors 1 Month Industry norm13. Product distribution expenses 7% Tak<strong>in</strong>g <strong>in</strong>to consideration averagedistribution costs.14. Other Expenses --- Includes cost of conversion dur<strong>in</strong>gmanufactur<strong>in</strong>g (i.e. utilities) andvariable product distribution costs15. Interest on work<strong>in</strong>g capital 9% 3% subsidy on work<strong>in</strong>g capital loanunder the Central Interest SubsidyScheme, 199716. Subsidy on plant and mach<strong>in</strong>ery 30% Under the Central Capital <strong>Invest</strong>mentSubsidy Scheme, 200717. Subsidy on <strong>in</strong>surance premium 100% Under the Central ComprehensiveInsurance Scheme, 200718. Subsidy on Income Tax 100%19. Debt : Equity ratio 60 : 40 Industry norm20. Interest on term loan 12%21. Marg<strong>in</strong> money for work<strong>in</strong>g25%capital22. RM cost Landed cost at the factory gate(<strong>in</strong>clusive of transportation cost andexcise duty)FINANCIAL ASPECTSA. Land and Site DevelopmentSr. Particulars Units Unit Rate Total (Rs.)No.1. Land and Site Development 500 sq. m. Rs. 250/ sq. m. 125,000Total 125,000B. BUILDING AND CIVIL WORKSSr. Particulars Units Unit Rate Total (Rs.)No.1. Build<strong>in</strong>g and Civil Work 400 sq. m. Rs. 4,000/ sq. m. 1,600,000Total 1,600,000

C. PLANT AND MACHINERYSr.ParticularsNo.Quantity(Nos.)Unit Cost(Rs.)Total Cost(Rs.)Manufactur<strong>in</strong>g Equipment1 Mix<strong>in</strong>g Vessels 1 nos. 1,500,000 1,500,0002 Side Vessel 1 nos. 1,000,000 1,000,0003 Bottle Fill<strong>in</strong>g/ Pack<strong>in</strong>g Mach<strong>in</strong>e 1 nos. 500,000 500,000(16 Station)4 Sachet Fill<strong>in</strong>g/ Pack<strong>in</strong>g Mach<strong>in</strong>e 1 nos. 500,000 500,000Utilities/ Misc. Other Equipment5 Electrification, Control Panels andCabl<strong>in</strong>g, Transformer, etc.6 Water Plant, Generation andDistribution7 Steam Generation Units,Compressors1,000,0002,000,000600,000Total Mach<strong>in</strong>ery, Utilities and7,100,000EquipmentNote: Above mentioned equipment is <strong>in</strong>dicative for the proposed shampoo- manufactur<strong>in</strong>g unitD. MISCELLANEOUS FIXED ASSETSSr. No. Particulars Total (Rs.)1 Furniture and Fitt<strong>in</strong>gs 25,0002 Office Equipment 100,0003 Fire Fight<strong>in</strong>g Equipment 50,0004 Cost of Tube-well 20,000Total Misc. Fixed Assets 195,000E. PRELIMINARY AND PRE-OPERATIVE EXPENSESSr. No. Particulars Total Cost (Rs.)1 Detailed Techno-economic Feasibility Study 100,0002 Loan Process<strong>in</strong>g Fees 10,0003 Establishment expenses 200,000Total Prelim<strong>in</strong>ary & Preoperative Expenses 310,000F. PROVISION FOR CONTINGENCYProvision for cont<strong>in</strong>gency- @ 10% of the total capital <strong>in</strong>vestmentOPERATING COSTA. RAW MATERIALRaw materials consumed for manufactur<strong>in</strong>g any shampoo are of two types-

Active Ingredients (AIs)Others (like b<strong>in</strong>d<strong>in</strong>g materials, fragrances, pigments, etc. used <strong>in</strong> manufactur<strong>in</strong>g process)Sr. No. Particulars Units Value1 Average cost of raw material Rs. per Kg. 1102 Raw materials consumed per batch Kg. 2003 Number of batches per year Nos. 600Total Raw Materials Consumed per Annum Rs. 13,167,000Note: Above raw material consumption pattern is calculated at 100% capacity utilisation of themanufactur<strong>in</strong>g unit work<strong>in</strong>g for 300 days per annum and two shifts per day basis.B. LABOURSr.No.Particulars Qualification Nos. SalaryperMonth(Rs.)Direct Labour1 Factory Manager BE/B.Tech +MBA/MMSAnnualManpowerCost(Rs.)1 20,000 264,0002 Production Manager BE/B.Tech 1 15,000 198,0003 Chemists BE/B.Tech 2 12,000 316,8004 Eng<strong>in</strong>eer and Technicians BE/B.Tech 4 10,000 528,0005 Skilled Workers BE 2 5,000 132,0006 Semi-skilled and Un-skilled Workers Matriculate 8 3,000 316,8007 Other Misc. Personnel 8 2,500 264,000Total Direct Labour Cost 26 2,019,600Indirect Labour8 F<strong>in</strong>ance Manager MBA/MMS +CA1 15,000 198,0009 Accountant CA 1 10,000 132,00010 Bus<strong>in</strong>ess Development Executives Graduate 2 8,000 211,20011 Security Personnel 2 3,000 79,200Total Indirect Labour 6 620,400Total Cost of man-power 32 2,640,000Note: (1) Manpower cost also <strong>in</strong>cludes Perks @ 10% of annual salary(2) There is no specific requirement of other highly skilled and specifically tra<strong>in</strong>ed manpower apart fromthe normally available qualified manpower as mentioned above at the proposed manufactur<strong>in</strong>g location.C. POWER AND FUELParticulars Units Consumptionper dayUnit Cost(Rs.)Annual Cost(Rs.)Electricity (40 kW) Units 527 6 948,000Furnace Oil Litres 75 8 180,000Water Litres 3,000 0 0Total 1,128,000Source: It is assumed that ground water is tapped through tubewell and hence water is considered free ofcost.D. OTHER EXPENSESSr. No. Particulars Total Cost(Rs.)

Sr. No. Particulars Total Cost(Rs.)Fixed1 Repairs and ma<strong>in</strong>tenance 609,7502 Advertis<strong>in</strong>g and promotion expenses 500,0003 Lease rent for land 210,0004 Office Adm<strong>in</strong>istration and other misc. expenses 100,0005 Professional and legal fees 300,0006 Bank charges and commissions 20,0007 Pr<strong>in</strong>t<strong>in</strong>g and stationary 100,0008 Insurance and taxes 100,000Total other expenses 1,939,750E. Total Work<strong>in</strong>g CapitalParticulars Norms Total (Rs.)Raw Materials 2 Months of raw materials 2,194,500Pack<strong>in</strong>g 2 Month of pack<strong>in</strong>g materials 790,020MaterialsF<strong>in</strong>ished Goods 1 Month of cost of production 1,711,710Bills Receivables 1 Month of sales value 2,194,500Outstand<strong>in</strong>gs 1 Month of Raw Material and Pack<strong>in</strong>g Material 1,492,260Total 5,398,470Note: 1. Work<strong>in</strong>g capital requirement <strong>in</strong>dicated above is at 100% capacity utilisation.2. Marg<strong>in</strong> money @ 25% of total Work<strong>in</strong>g Capital – Rs. 1,349,618CAPITAL INVESTMENTThe capital <strong>in</strong>vestment required for the project is Rs.1.16 crore. The break-up of the capital<strong>in</strong>vestment is <strong>in</strong>dicated <strong>in</strong> below.Sr. No. Particulars Total Value (Rs.)1 Land and Site Development Cost 125,0002 Build<strong>in</strong>g and Civil Works 1,600,0003 Plant and Mach<strong>in</strong>ery 7,100,0004 Misc. Fixed Assets 195,0005 Prelim<strong>in</strong>ary and Pre-operative Expenses 310,0006 Provisions for Cont<strong>in</strong>gency 933,0007 Marg<strong>in</strong> Money for Work<strong>in</strong>g Capital 1,349,618Total Cost of the Project 11,612,618Means of F<strong>in</strong>anceTotal Cost of ProjectRs. 11.61 lakhsPromoter’s Equity (40%) Rs. 4.64Loan from Bank/FI (60%) Rs. 6.97Note - * Transportation subsidy is added to Gross Profit while calculat<strong>in</strong>g the profitability of the unitFINANCIAL ANALYSISA. Cost of Production

Sr. No. Particulars Total (Rs.)1 Raw materials 13,167,0002 Pack<strong>in</strong>g materials 4,740,1203 Adm<strong>in</strong>istrative overheads 2,019,6004 Other overheads 1,128,0005 Interest on work<strong>in</strong>g capital 364,397Total cost of production 21,419,117Note: Cost of production <strong>in</strong>dicated above is at 100% capacity utilisation.B. TurnoverAnnual sales realisation of the manufactur<strong>in</strong>g unit with the assumed product mix is illustratedbelow. Sales realisation at 100% capacity utilisation is around Rs. 2.63 crore.Sr.No.ParticularsNo. ofBottles(Nos.)SalesRealisationper Bottle(Rs.)Total SalesRealisation(Rs.)1 Shampoo (Various variants) 1,140,000 26,334,000Total 1,140,000 23.1 26,334,000Note: For simplicity purpose all the sales mentioned above are <strong>in</strong> bottle of 100-ml weightC. Profit and Loss Statement for 10 Years(Unit: Rs. lakhs)Particulars Formula Yr 1 Yr 2 Yr 3 Yr 4 Yr 5 Yr 6 Yr 7Capacity Utilisation 50% 100 100% 100% 100% 100% 100%%Sales Realisation A 110 263 263 263 263 263 263Operat<strong>in</strong>g Costs BRM and PM Costs 75 179 179 179 179 179 179Labour Costs 20 20 20 20 20 20 203. Other Overheads 6 11 11 11 11 11 11Interest on Work<strong>in</strong>g2 4 4 4 4 4 4CapitalGross Profit <strong>in</strong>cl.Transport SubsidyC=A-B 7 49 49 49 49 49 49Interest D 8 8 7 6 5 4 3Depreciation E 12 10 9 8 7 6 5PBT F=C-(D+E) -12 31 34 36 37 39 41Tax G 0 0 0 0 0 0 0PAT H=F-G -12 31 34 36 37 39 41Cash Profit I=H+E 0 42 42 43 44 45 46GP Marg<strong>in</strong> J=C/A 7% 19% 19% 19% 19% 19% 19%NP Marg<strong>in</strong> K=H/A -11% 12% 13% 14% 14% 15% 15%Note:1. Figures <strong>in</strong>dicated above are rounded-off2. Annual sales values <strong>in</strong>dicated above are after tak<strong>in</strong>g <strong>in</strong>to consideration open<strong>in</strong>g and clos<strong>in</strong>g stocksReturn on <strong>Invest</strong>ment (ROI): 32%D. Breakeven AnalysisThe breakeven analysis for the proposed shampoo-manufactur<strong>in</strong>g unit is <strong>in</strong>dicated below. Theunit achieves operational breaks-even <strong>in</strong> the first year of operations.

Particulars Unit Yr 1 Yr 2 Yr 3 Yr 4 Yr 5 Yr 6 Yr 7Capacity Utilisation (%) 50% 100% 100% 100% 100% 100% 100%Sales Realisation Rs. lakhs 110 263 263 263 263 263 263Variable Cost of SalesDirect MaterialRs. 55 132 132 132 132 132 132lakhsPack<strong>in</strong>g CostRs. 20 47 47 47 47 47 47lakhsConversion CostRs. 6 11 11 11 11 11 11lakhsDirect LabourRs. 20 20 20 20 20 20 20lakhsInterest on Work<strong>in</strong>g Rs. 2 4 4 4 4 4 4CapitallakhsTotal Variable Costs Rs. lakhs 102 214 214 214 214 214 214Contribution Rs. lakhs 7 49 49 49 49 49 49Fixed CostsOther overheads (excl. Rs.Repairs and Ma<strong>in</strong>tenance) lakhs7 12 12 12 12 12 12Repairs and Ma<strong>in</strong>tenance Rs. 6 6 6 6 6 6 6lakhsManpower CostRs. 6 6 6 6 6 6 6lakhsInterest on Term Loan Rs. 8 8 7 6 5 4 3lakhsTotal Fixed Cost Rs. lakhs 27 32 31 31 30 29 28Break Even Po<strong>in</strong>t Rs. lakhs 405 173 168 163 159 154 150Actual Sales Realisation Rs. 110 263 263 263 263 263 263lakhsBreak Even Sales at % ofCapacity% 154% 66% 64% 62% 60% 59% 57%Note: 1. Figures <strong>in</strong>dicated above are rounded-off2. Annual sales values <strong>in</strong>dicated above are after tak<strong>in</strong>g <strong>in</strong>to consideration open<strong>in</strong>g and clos<strong>in</strong>g stocksSOURCE OF RAW MATERIALS AND PACKING MATERIALSThe raw materials that are required for manufactur<strong>in</strong>g shampoo products are not locally available<strong>in</strong> NER. In case of the herbal shampoos, certa<strong>in</strong> raw materials like Heena and other herbs areavailable <strong>in</strong> NER (<strong>in</strong> hilly states like Meghalaya, Arunachal Pradesh, etc.) through theGovernment approved agencies. The closest source for procur<strong>in</strong>g raw materials (apart fromherbal <strong>in</strong>gredients) is Hyderabad or Delhi. As far as pack<strong>in</strong>g materials are concerned, fewvendors are present <strong>in</strong> NER but they are relatively small <strong>in</strong> size.Additionally, the raw materials and pack<strong>in</strong>g materials can be procured from West Cluster(Mumbai, Ahmedabad, etc) but the cost of transportation will <strong>in</strong>crease substantially.Mentioned below are few sources of raw materials-

EI Dupont India LimitedSahar Plaza Complex, 7 Th Floor, Bandra (E), Mumbai- 400067Tel: +(91)-(022)-28390770Rolex Lanol<strong>in</strong> Products Ltd.52/58 Babu Genu Road, 24-26 Jivraj Shamji Build<strong>in</strong>g, Mumbai- 400002Tel: +(91)-(022)-22012251, 22017395Fax: +(91)-(022)-22015990Silicones Industries (India) Limited502, Arcadia Build<strong>in</strong>g, Nariman Po<strong>in</strong>t, Mumbai-400021Tel: +(91)-(022)-22855033, 22855034Fax: +(91)-(022)-22821779Standard Silica Pvt. Ltd.Industrial Assurance Build<strong>in</strong>g, 5 Th Floor, J. Tata Road, Churchgate, Mumbai- 400020Tel: +(91)-(022)-22821113Suru Chemicals and Pharmaceuticals11 Sona Udyog, P. P. Road, Andheri (E), Mumbai- 400069Tel: +(91)-(022)-28378500Fax: +(91)-(022)-28376321Email: <strong>in</strong>fo@suru.comIndia Dye ChemD 9, Ground Floor, Rana Pratap Bagh, G. T. Road, Delhi- 110007Tel: +(91)-(011)-27244736Fax: +(91)-(011)-27459097Jayant Vitam<strong>in</strong>s Limited12, Bhargava Lane, Civil L<strong>in</strong>es, Delhi- 110054Tel: +(91)-(011)- 22911653, 22519414Mentioned below are few sources of pack<strong>in</strong>g materials-

Anil Tubes524 Sandharst Build<strong>in</strong>g, S V P Road, Opera House, Mumbai- 400004Tel: +(91)-(022)-23896559Fax: +(91)-(022)-23802286Email: anilchem.mktg@vsnl.net.<strong>in</strong>Caravan Packag<strong>in</strong>g LimitedG 3, H<strong>in</strong>d Service Estate, Off. Ranade Road, Shivaji Park, Mumbai- 400028Tel: +(91)-(022)-24467704Fax: +(91)-(022)-24368477Vora Packag<strong>in</strong>g Pvt. Ltd.467/A, TV Indl. Estate, S. K. Ahire Marg, K<strong>in</strong>g’s Circle, Mumbai- 400019Tel: +(91)-(022)-24078193, 24095829Fax: +(91)-(022)-24078219Email: sales@vorapack.comClassic Crown & Closures21, Crescent I E, Kherani Road, Saki Naka, Andheri (E), Mumbai -400072Tel: +(91)-(022)-28522859SOURCE OF MACHINERY AND EQUIPMANTMost of the mach<strong>in</strong>ery for manufactur<strong>in</strong>g shampoo products is manufactured locally. Most of themach<strong>in</strong>ery manufacturers are based <strong>in</strong> Mumbai, Ahmedabad. Smaller clusters for mach<strong>in</strong>erymanufacturers <strong>in</strong>clude Delhi, Haryana, Kolkata, etc.

PROCESS EQUIPMENTAutopack Mach<strong>in</strong>es Pvt. Ltd.101 C, Poonam Chambers, Dr. A. B. Road, Worli, Mumbai- 400018Tel: +(91)-(022)- 24974800, 24934406Fax: +(91)-(022)- 24964926Email: autopack@bom3.vsnl.net.<strong>in</strong>Pack<strong>in</strong>g Mach<strong>in</strong>ery Pvt. Ltd.M/ Celler, Ambekar Nagar, G. D. Amsedkar Road, Parel, Mumbai- 400012Tel: +(91)-(022)- 24162551Fax: +(91)-(022)- 24168516Spanpak SystemsB 136, Ghatkopar, Industrial Estate, LBS Marg, Ghatkopar (W), Mumbai- 400080Tel: +(91)-(022)- 28597620Ambica Eng<strong>in</strong>eer<strong>in</strong>g WorksPlot NO. 1804, Phase III, GIDC Industrial Area, Vatva, Ahmedabad, 380045Tel: +(91)-(079)-22744262Fax: +(91)-(079)-22744262Cadmach Mach<strong>in</strong>ery Co. Pvt. Ltd.Plot No. 3604/ 05, GIDC Phase IV, Vatva, Ahmedabad, 382445Tel: +(91)-(079)-25831491Emkey Eng<strong>in</strong>eer<strong>in</strong>g WorksB 33, DDA Shed, Okhla Industrial Area, Phase II, New Delhi- 110020Tel: +(91)-(011)- 25415882Mitsubishi Heavy Industries Limited1 St Floor, Gopal Das Bhawan, 28- Barakhamba Road, New Delhi- 110001Tel: +(91)-(011)- 23354465Swastik IndustriesA 76, Clock Tower, Hari Nagar, New Delhi-110064Tel: +(91)-(011)- 27538203AUXILIARY EQUIPMENTThermax (India) LimitedThermax House, 4, Mumbai-Pune Road, Shivaj<strong>in</strong>agar, Pune- 411019Tel: +(91)-(020)- 25512122Fax: +(91)-(020)- 25512242Website: www.thermax<strong>in</strong>dia.comAtlas Copco (India) LimitedSevanagar, Dapodi, Pune- 411012Tel: +(91)-(020)- 27146416/17Fax: +(91)-(020)- 27146637Website: www.atlascopco.comAquatech India LimitedPlot No. 3, Baner Park, Near D. P. Road, Aundh, Pune- 411007Tel: +(91)-(020)- 27292103, 27291104Fax: +(91)-(020)- 7291805Website: www.aquatech.com

Email: asa@aquatech.comAlfa Laval (India) LimitedShivaj<strong>in</strong>agar, Pune- 4110112Tel: +(91)-(020)- 27147721Fax: +(91)-(020)- 27147711Ion Exchange, MumbaiTiecicon House, Dr. E. Moses Road, Mahalaxmi, Mumbai- 400011Tel: +(91)-(022)- 24939520/23/25Fax: +(91)-(022)- 24938737Website: www.ion<strong>in</strong>dia.comEmail: ho.commun@ho.ionxchng.co.<strong>in</strong>Courtesy : NEDFi