SHAMPOO MANUFACURING UNIT - Invest in Assam

SHAMPOO MANUFACURING UNIT - Invest in Assam

SHAMPOO MANUFACURING UNIT - Invest in Assam

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

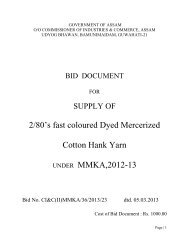

(a) Product Mix (based on various shampoo products proposed for manufactur<strong>in</strong>g)(b) Demand : Supply Gap (<strong>in</strong> the North East Region)(c) M<strong>in</strong>imum Economic Plant Size- The economic size for manufactur<strong>in</strong>g for NERregion is 200-Kg batch size (Based on the discussion with large shampoo manufacturersand various units <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g).Rated Capacity of the key equipmentThe proposed plant will have a batch size of 200 kg <strong>in</strong> one shift and will operate on two-shiftbasis. With annual sales realisation of Rs. 2.6 crore, the manufactur<strong>in</strong>g unit will be account<strong>in</strong>gfor about 15 to 16% of the total NER shampoo market (consider<strong>in</strong>g the retail value of theproducts as the unit will be <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g) and about 45% of the demandsupplygap of NER shampoo market <strong>in</strong> year 2001-02.It is proposed that the unit would be <strong>in</strong>volved <strong>in</strong> contract manufactur<strong>in</strong>g for a larger shampoomanufactur<strong>in</strong>g/ market<strong>in</strong>g company. It would primarily cater to the needs of the NER.There is an opportunity for about 2 to 3 shampoo manufactur<strong>in</strong>g units of similar size <strong>in</strong> NER.Summ<strong>in</strong>g up:Batch Size: 200 Kg. on a s<strong>in</strong>gle batch basis (two batches per day)Plant Capacity: 11.4 lakh bottles per annum (@ 100 ml per bottle)Capacity Utilisation: 50% (Year 1)Full Capacity Utilisation: Year 2RAW MATERIALS AND INPUTSRaw MaterialsRaw materials used <strong>in</strong> the process depend upon the type of shampoo manufactured. Typically, <strong>in</strong>any shampoo manufactured there are two types of raw materials used:- Active Ingredients (AIs) – These are the chemicals used <strong>in</strong> manufactur<strong>in</strong>g theshampoo. Active <strong>in</strong>gredients used <strong>in</strong> the manufactur<strong>in</strong>g process are different for differentvariants. Commonly used active <strong>in</strong>gredients <strong>in</strong>clude emulsify<strong>in</strong>g/ suspend<strong>in</strong>g agents likeAmmonium/ Sodium Lauryl Sulfate, Z<strong>in</strong>c Pyrithione, etc.- Others- Other <strong>in</strong>gredients <strong>in</strong>clude Citric Acid, Sodium Hydroxide,Ammonium Chloride, Fragrances, Pigments, etc.WaterThe requirement of water for 200-kg batch shampoo-manufactur<strong>in</strong>g unit is approximately 3,000litres per day.ELECTRICITYApproximate power requirement of a 200-kg batch shampoo-manufactur<strong>in</strong>g unit is 40 kW,which can be availed from the nearest sub-station of respective State Electricity Board (SEB).MANUFACTURING PROCESSThe flow chart for the manufactur<strong>in</strong>g process is as shown below <strong>in</strong> the Exhibit 2.The shampoo manufactur<strong>in</strong>g process is a batch process. Initially, the raw material goes through aQuality Check (QC) and if approved various Active Ingredients (AIs) and other raw materials aredispensed for process<strong>in</strong>g.Initially, active <strong>in</strong>gredients and other raw materials are taken <strong>in</strong>to a vessel known as ‘Mix<strong>in</strong>gVessel’. In this vessel the raw materials are mixed with hot water. The water used for thisprocess should be De-m<strong>in</strong>eralised and free from any k<strong>in</strong>d of impurities. The mix<strong>in</strong>g process iscarried out at a specific temperature (about 75 to 80 0 C).Subsequently, the solution is taken to another vessel (known as ‘Side Vessel’) and other<strong>in</strong>gredients like Fragrances, Pigments, etc. are added. The mixture is agitated for about 20-30