ACO EuroCover

ACO EuroCover Access Cover - ACO Building Drainage

ACO EuroCover Access Cover - ACO Building Drainage

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

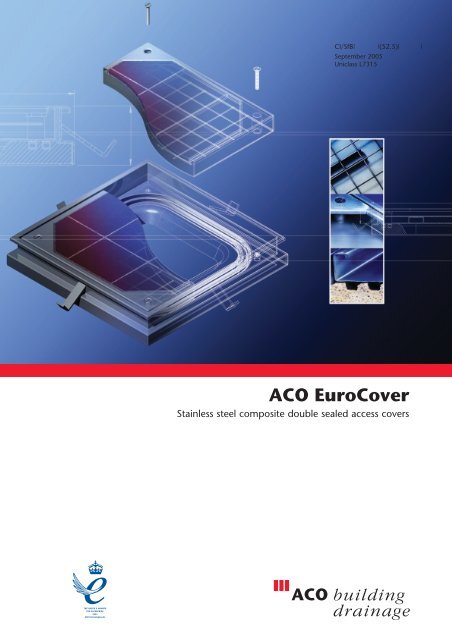

CI/SfB| |(52.5)| |September 2005Uniclass L7315<strong>ACO</strong> <strong>EuroCover</strong>Stainless steel composite double sealed access covers

<strong>ACO</strong> Building Drainage<strong>ACO</strong> Building DrainageOur built environment is becoming ever morecomplex. Applications are becoming moresophisticated and the increasing pressure ofregulations and standards make achieving design,performance and financial goals ever tougher.<strong>ACO</strong> Building Drainage is a new concept within the<strong>ACO</strong> Group. Our mission: to eliminate design risk,to reduce installed and life cost and to deliverexceptional finish and performance in everyproduct application.We achieve this through three factors: High performance materials Design experience and project support Global manufacturing capacityApplied to a range of products for use within, ornear to the building envelope, our solutions offerbest value where high performance is prerequisite.Delivering through understanding, innovationand supportWhatever the material - stainless steel, cast iron,aluminium alloy, polyethylene and polypropylene –our global resources and fabrication capacity makeit possible for us to deliver best value both with ourstandard products and with our bespoke designs.Confidence is further assured with quality systemsthat are in accordance with ISO 9001.<strong>ACO</strong> Building Drainage’sextensive portfolio includes: Stainless steel Modular Channel system Stainless steel EuroGully gully system Stainless steel and polymer compositeaccess covers Biological Grease Management system Gravity Grease Separator system Sewer backflow prevention valves Stainless steel socketed pipe system Rainwater outlets for flat roofsFor further information on these products andservices please consult our comprehensive range ofspecification and installation guides.<strong>ACO</strong> Building Drainage is a division of <strong>ACO</strong>Technologies plc and part of the worldwide<strong>ACO</strong> Group.The Group has sales in excess of £300 millionworldwide with production facilities in the UK,Germany, France, Switzerland, Denmark, Spain,Poland, Czech Republic, Australia and the USA. Intotal more than 3000 people are employed in 30countries throughout the world.Contact Details<strong>ACO</strong> Technologies plc<strong>ACO</strong> Business Park, Hitchin Road, Shefford,Bedfordshire SG17 5TE.Tel:01462 816666Fax:01462 851490e-mail Enquiries:buildingdrainage@aco.co.ukwebsite:www.acobuildingdrainage.com

<strong>ACO</strong> <strong>EuroCover</strong>CONTENTSSystem OverviewIntroduction to <strong>ACO</strong> <strong>EuroCover</strong> 3Features and benefits 4Load Class selection 4Technical Data<strong>ACO</strong> <strong>EuroCover</strong> 5<strong>ACO</strong> Building Drainage Vinyl Seal ® 5InstallationInstallation procedure <strong>ACO</strong> <strong>EuroCover</strong> 6Installation procedure <strong>ACO</strong> Building Drainage Vinyl Seal ® 7Operation and MaintenanceGeneral maintenance 7Specification ClauseNBS Specification Clause Information 7Introduction to<strong>ACO</strong> <strong>EuroCover</strong>Traditional fabricated access covers can posesignificant installation and service issues that canadversely affect the reliability and serviceability ofthe product. A traditional coverin practice is difficult toinstall correctly,resulting in a nonairand water tightinstallation.<strong>ACO</strong> <strong>EuroCover</strong> combines austenitic stainless steeland polyester resin concrete to produce a rigid,reliable, air and watertight installation.Available in a wide range of sizes and suited tomedium or heavy duty applications, <strong>ACO</strong><strong>EuroCover</strong> accommodates a wide range of floorfinishes. When used with <strong>ACO</strong> Building DrainageVinyl Seal ® vinyl sheet flooring can be fitted easilywithout the need for cumbersome clampingmechanisms, reducing potential bug trapssignificantly.Typical applications include: Kitchens Food and drink processing plants Abattoirs Hospitals Chemical and pharmaceutical plants Commercial premises Leisure centres3

<strong>ACO</strong> <strong>EuroCover</strong>SYSTEM OVERVIEWFeatures and benefits123456789101112Removable ‘grit seal’ facilitates coverremoval even after long periods of traffickingFour point lockdown and lifting keymechanism for safe and convenient accessCover supplied without infill, allowing matchto surrounding floor finishCorrosion resistant grade 304 austeniticstainless steel cover and framePurpose made covers available in grade 316for chemically aggressive environments.Six standard size options availableFACTA Load Class AAA and E to suit mostapplicationsIntegral polymer concrete support frameprovides economical structural rigidity‘4 lip’ creep resistant EPDM double sealensures air and watertight operationCompatible with a wide range of floorfinishes including epoxy, polyurethane andconcrete screeds, ceramic tile and vinylsheet flooringAnchor tangs ensure a positive key to thesurrounding haunchOptional <strong>ACO</strong> Building Drainage Vinyl Seal ®provides robust and safe interface with vinylfloors and can be fitted to both externalframe and internal cover area123456789101112Load Class SelectionWide range of sizes available for medium and heavy duty applications as follows:Slow MovingSlow Moving SolidPneumatic Wheel Load Wheel LoadFACTA Load Class (Tonnes) (Tonnes) Typical ApplicationsAAA 2.5 0.5 Light industrial areas, trolleys andlight pallet trucks.E 16.0 5.0 Heavy duty industrial areas, heavyduty fork lift trucks and HGV’s.4

<strong>ACO</strong> <strong>EuroCover</strong>TECHNICAL DETAIL<strong>ACO</strong> <strong>EuroCover</strong> StandardAll <strong>ACO</strong> <strong>EuroCover</strong>s supplied with lifting keys and grit sealA x BCDFACTA WeightDescription Part No. A B C D Load Class (kg)300mm x 300mm clear opening 49556 492mm 492mm 85mm 50mm AAA 27.5450mm x 450mm clear opening 49550 642mm 642mm 85mm 50mm AAA 38.0600mm x 450mm clear opening 49551 792mm 642mm 85mm 50mm AAA 44.0600mm x 600mm clear opening 49552 792mm 792mm 85mm 50mm AAA 50.5750mm x 600mm clear opening 49560 942mm 792mm 85mm 50mm AAA 58.0750mm x 750mm clear opening 49558 942mm 942mm 85mm 50mm AAA 61.5300mm x 300mm clear opening 49557 492mm 492mm 145mm 110mm E 31.0450mm x 450mm clear opening 49553 642mm 642mm 145mm 110mm E 43.5600mm x 450mm clear opening 49554 792mm 642mm 145mm 110mm E 51.0600mm x 600mm clear opening 49555 792mm 792mm 145mm 110mm E 58.0750mm x 600mm clear opening 49561 942mm 792mm 145mm 110mm E 65.0750mm x 750mm clear opening 49559 942mm 942mm 145mm 110mm E 71.0Lifting key for <strong>ACO</strong> <strong>EuroCover</strong> 49069 - - - - - -<strong>ACO</strong> Building Drainage Vinyl Seal ®Channel Edge Flexible seal Heat welded jointVinyl sheet flooring(2-4mm thick) Floor adhesiveRigid seal extrusion(Patent applied for)DescriptionPart No.300mm x 300mm vinyl seal kit 49562450mm x 450mm vinyl seal kit 49428450mm x 600mm vinyl seal kit 49429600mm x 600mm vinyl seal kit 49430750mm x 600mm vinyl seal kit 49563750mm x 750mm vinyl seal kit 495645

<strong>ACO</strong> <strong>EuroCover</strong>INSTALLATION GUIDELINESInstallation procedureGeneralAllow sufficient time for mortars and concrete toreach required minimum compressive strength.Step 1Ensure the supporting structure and / or theground conditions are adequate to support theexpected operating service load.The frame assembly must be continuouslysupported along its entire length and width on amortar of minimum compressive strength30N/mm 2 to a minimum depth of 10mm.Position the top edge of the rigid frame assemblyso that it is level with the finished floor, or at amaximum of 1.5mm below the finished floor.Step 2Backfill around the <strong>ACO</strong> <strong>EuroCover</strong>, and, if using<strong>ACO</strong> Building Drainage Vinyl Seal ® with sheetflooring refer to the installation details overleaf.A mastic sealant of bead width 5-8mm isrecommended to the edge of the <strong>ACO</strong> <strong>EuroCover</strong>to ensure a watertight seal.Step 3Place the recessed cover on a level and flat surfaceand fill with a suitable 10mm aggregate concreteinfill of minimum compressive strength of40N/mm 2 . To accommodate various floor finishesthe cover may be filled to within 12mm of thefinished floor level.Step 4Ensure the double seal gasket is clean and inposition. Lift the complete recessed cover intoplace using supplied lifting keys and appropriatelifting apparatus; depending on size and infillmaterial the complete cover may exceed Healthand Safety Regulation lifting recommendations.Lubricate and insert all 4 fixings, locating eachpositively before tightening. Fasten down the coveruntil resistance is felt, observing the followingsequence: top left hand, bottom right hand,bottom left hand, top right hand. Finally tightena further one quarter turn.Step 5Insert supplied grit seal between the recess coverand frame.<strong>ACO</strong> <strong>EuroCover</strong> installation diagram2 1 26 3 4558 761 <strong>ACO</strong> Building Drainage Vinyl Seal ®5234Sheet flooringSpecified floor material, maximum depth12mm, for example: ceramic tile, epoxy,polyurethane or concrete screeds.Removable grit seal678Mastic sealantFinished floor level maximum 1.5mm above<strong>ACO</strong> <strong>EuroCover</strong>.Bearing width of mortar bed.10mm aggregate concrete infill of minimumcompressive strength of 40N/mm 2 to within12mm of finished floor level.

<strong>ACO</strong> <strong>EuroCover</strong>INSTALLATION GUIDELINES<strong>ACO</strong> Building DrainageVinyl Seal ®Step 1Ensure the assembled rigid and flexible Vinyl Seal ®sits square and horizontal in the <strong>ACO</strong> <strong>EuroCover</strong>edge detail.Step 2Install the <strong>ACO</strong> <strong>EuroCover</strong> into the groundensuring that the flooring screed is flush to the topedge of the rigid PVC extrusion. Protect the <strong>ACO</strong><strong>EuroCover</strong> and seal assembly from splashes ofconcrete/screed.Step 3Depending upon the installation, additionalsuitable fixings may be required to secure the rigidextrusion to the floor substrate. If this should berequired, separately drill and countersink the rigidextrusion making sure that all fixings are finishedflush with the top of the extrusion.Step 4Grout any voids at connecting rigid PVC joints atmitred corners, straight joints or fixings, to ensurea continuous supported floor finish.Prior to laying the vinyl sheet flooring, peel theprotective film from the rigid extrusion (a knife maybe required to cut the film adjacent to the flexibleseal) and ensure all surfaces are clean and dry.Apply a compatible adhesive also to the top surfaceof the rigid PVC extrusion, for example, Altrofix 19two-part water resistant eurethane adhesive, takingcare not to apply adhesive to the flexible seal.Lay the sheet flooring against the flexible seal edgeand prepare the welded joint between the flexibleseal and vinyl sheet flooring as normal by scoringthe sheet / seal joint to approximately half thedepth of the sheet flooring thickness.Either in-colour or black welding filler rod may beused to weld the joint. Remove surplus weldmaterial from the joint using a spatula when thewelded joint has cooled.Channel Edge Flexible seal Heat welded joint(Patent applied for)Vinyl sheet flooring(2-4mm thick) Floor adhesiveRigid seal extrusionOperation and MaintenanceFor general maintenance and cleaning of stainlesssteel refer to <strong>ACO</strong> Building Drainage Eurogully orModular channel catalogues.To remove the recessed cover remove the push fitgrit seal, then undo hexagonal cap screws. Undogradually observing the sequence in step 4 ofinstallation instructions. Insert lifting key fully intothe cover at two or more points. Lift withappropriate apparatus. To replace the cover followstep 4 of installation instructions.NBS Specification Clause ReferenceFor relevant NBS specification, refer to NBS SectionP31 holes/chases/covers/support for services,Clause 370 access covers/gratings and insert theappropriate model reference number.7

<strong>ACO</strong> Technologies plc<strong>ACO</strong> Business Park,Hitchin Road,Shefford,BedfordshireSG17 5TETel: 01462 816666Fax: 01462 851490e-mail: buildingdrainage@aco.co.ukwebsite: www.acobuildingdrainage.co.uk© September 2005 <strong>ACO</strong> Technologies plc. All reasonable care has been taken in compiling the information in this document. All recommendations and suggestions on the use of <strong>ACO</strong> products aremade without guarantee since the conditions of use are beyond the control of the Company. It is the customer's responsibility to ensure that each product is fit for its intended purpose, and thatthe actual conditions of use are suitable. This brochure and any advice is provided by <strong>ACO</strong> Technologies plc (the Company) free of charge and accordingly on terms that no liability includingliability for negligence will attach to the Company or its servants or agents arising out of or in connection with or in relation to this brochure or any such advice. Any goods supplied by theCompany will be supplied solely upon its standard conditions of sale, copies of which are available on request. The Company's policy of continuous product development and improvement rendersspecifications liable to modification. Information provided in this brochure is therefore subject to change without prior notification.