Granulation - Rottendorf Pharma GmbH

Granulation - Rottendorf Pharma GmbH

Granulation - Rottendorf Pharma GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

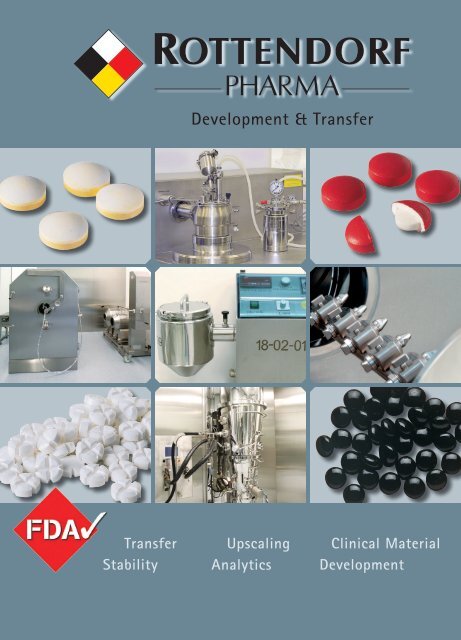

Transfer<br />

Stability<br />

Development & Transfer<br />

Upscaling<br />

Analytics<br />

Clinical Material<br />

Development

2<br />

Inhaltsverzeichnis | Index | Table des matières<br />

Seite | Page | Page<br />

Editorial 3<br />

Einführung | Introduction | Introduction 4<br />

<strong>Rottendorf</strong> Development & Transfer 6<br />

<strong>Granulation</strong> | <strong>Granulation</strong> | <strong>Granulation</strong> 7-8<br />

Siebung | Sieving | Tamisage 9<br />

Mischen | Blending | Mélange 10<br />

Tablettierung | Tabletting | Compression 11<br />

Filmcoating und Dragierung | Film Coating and Sugar Coating | Pelliculage et dragéification 12<br />

Pelletherstellung | Pelletizing | Production de microgranules 14-15<br />

Analytik | Analytics | Analyses 16<br />

Schmelzgranulation | Hot Melt <strong>Granulation</strong> | <strong>Granulation</strong> par fusion 18-19<br />

Schmelzextrusion | Hot Melt Extrusion | Extrusion par fusion 20-21

Editorial<br />

Sehr geehrte Damen und Herren,<br />

die <strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong> ist ein innovativer<br />

Dienstleister rund um die festen<br />

Darreichungsformen. Unsere Kunden<br />

stammen aus Europa, den USA, Kanada<br />

und Japan.<br />

Über 80 Jahre Erfahrung in der Fertigung<br />

von festen Formen bilden die Grundlage<br />

unserer Kernkompetenz - Feststoffe - und<br />

prägen die pharmazeutische Qualität der<br />

Entwicklung.<br />

Um unseren Kunden die Entwicklung und<br />

das Upscaling im geeigneten GMP-Umfeld<br />

anzubieten, haben wir das Development<br />

& Transfer Center errichtet. Mit diesem<br />

schaffen wir auch eine GMP-gerechte<br />

Plattform für innovative Technologien, die<br />

wir Partnern mit neuen technologischen<br />

Herausforderungen zur Verfügung stellen.<br />

Welche Möglichkeiten das Development &<br />

Transfer Center im Einzelnen bietet, haben<br />

wir auf den folgenden Seiten zusammengestellt.<br />

Wir freuen uns auf die Zusammenarbeit!<br />

Ihre <strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong><br />

Dear Reader,<br />

<strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong> is an innovative<br />

service provider within the complete solid<br />

dosage forms sector. Our customers come<br />

from Europe, the USA, Canada and Japan.<br />

Over 80 years of experience in producing<br />

solid dosages provide the basis for<br />

our core competence – solid matters<br />

– and fundamentally characterize the<br />

pharmaceutical quality of developments.<br />

To be able to offer our customers adequate<br />

GMP-surroundings for development<br />

and upscaling, we have established a<br />

Development & Transfer Center. We have<br />

thus created a GMP-compliant platform<br />

for innovative technologies which we<br />

can offer business partners with new<br />

technological challenges.<br />

The following pages demonstrate which<br />

potentialities the Development & Transfer<br />

Center offers in detail.<br />

We look forward to working together with<br />

you!<br />

Yours<br />

<strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong><br />

Mesdames, Messieurs,<br />

La société <strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong> est<br />

un sous-traitant toujours à la pointe de<br />

l’innovation. Nos clients sont originaires<br />

de l’Europe, des Etats-Unis, du Canada<br />

et du Japon. Plus de 80 ans d’expérience<br />

dans la fabrication de formes sèches<br />

forment la base de notre compétence<br />

principale – les formes sèches – et<br />

donnent leur empreinte à la qualité de nos<br />

services. Afin de pouvoir proposer à nos<br />

clients un service de développement et de<br />

production de lots pilotes («upscaling»)<br />

dans un environnement conforme aux<br />

Bonnes Pratiques de Fabrication nous<br />

avons créé un centre de développement<br />

et de transfert. Ce centre sert aussi de<br />

plate-forme, conforme aux BPF, destinée à<br />

mettre à la disposition de nos partenaires<br />

des technologies innovantes relevant de<br />

nouveaux défis technologiques.<br />

Nous vous proposons dans cette brochure<br />

un descriptif détaillé de ce centre de<br />

développement et de transfert.<br />

Notre équipe est à votre service!<br />

Sincères salutations<br />

<strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong><br />

3

4 Einführung | Introduction | Introduction<br />

Die stete Nachfrage nach Entwicklungs-<br />

und Up-Scaling-Kapazitäten in einem<br />

GMP- und FDA-konformen Umfeld hat<br />

uns 2009 zu einer richtungsweisenden<br />

Investition bewegt – in das Development<br />

& Transfer Center für Laboransätze

TABLETTIERWERKZEUGE<br />

ERSATZTEILE FUR<br />

TABLETTENPRESSEN<br />

w w w . e p m o . c o m<br />

BLISTERWERKZEUGE<br />

EASYTOOL SOFTWARE

6 <strong>Rottendorf</strong> Development & Transfer<br />

Development & Transfer Team<br />

Unser Dienstleistungsangebot auf einen<br />

Blick:<br />

� Rezeptur- und Prozessentwicklung<br />

sowie -validierung<br />

� Herstellung von Stabilitäts-,<br />

Registrierungs- und Klinikchargen<br />

� Prozessoptimierungen<br />

� Produkttransfer<br />

� Analytische Methodenentwicklung und<br />

-validierung, analytischer Methoden-<br />

transfer<br />

� Optimierung analytischer Methoden<br />

� Chargenfreigabe<br />

� ICH-Stabilitätsstudien<br />

� Erstellung und Update von Zulassungs-<br />

dossiers und Gutachten<br />

An overview of our range of services:<br />

� Formulation and process development as<br />

well as validation<br />

� Production of stability batches,<br />

registration batches and clinical batches<br />

� Process optimisation<br />

� Product transfer<br />

� Analytical method development and<br />

validation, analytical method transfer<br />

� Analytical method optimisation<br />

� Batch release<br />

� ICH-stability studies<br />

� Generation and update of submission<br />

files for marketing authorisation and<br />

expertises<br />

Eventail de nos services proposés :<br />

� Développement et validation des<br />

formulations et des procédés<br />

� Fabrication des lots cliniques, de<br />

stabilité, et d’autorisation<br />

� Optimisation des procédés<br />

� Transferts des produits<br />

� Développement, validation et transfert<br />

des méthodes analytiques<br />

� Optimisation des méthodes analytiques<br />

� Libération des lots<br />

� Etudes de stabilité ICH<br />

� Etablissement et mise à jour des dossiers<br />

d’autorisation et d’expertise

<strong>Granulation</strong> | <strong>Granulation</strong> | <strong>Granulation</strong><br />

High Shear Mixing - Diosna P 60<br />

Further Sizes: 1l / 4 l / 10 l / 25 l / 60 l<br />

High Shear Mixing - Diosna P 1<br />

Further Sizes: 1l / 4 l / 10 l / 25 l / 60 l<br />

Oven Drying<br />

7

8 <strong>Granulation</strong> | <strong>Granulation</strong> | <strong>Granulation</strong><br />

Fluid Bed <strong>Granulation</strong>/Drying/Coating – Glatt GPCG<br />

Batch Sizes: 1-5 kg<br />

Fluid Bed <strong>Granulation</strong>/Drying -<br />

Aeromatic MP 3/4<br />

Roller Compacting - Gerteis Compactor<br />

Batch Sizes: 10-50 kg Batch Sizes: from 5 kg

Siebung | Sieving | Tamisage<br />

Quadro CoMil U 20<br />

Quadro CoMil U 10<br />

Further Sieving Machines:<br />

� Frewitt<br />

� Fitzmill<br />

� Bohle<br />

Waters <strong>GmbH</strong> - Helfmann-Park 10 - 65760 Eschborn<br />

Ihr Partner für<br />

Chromatographie<br />

Massenspektrometrie<br />

Labor-Datenmanagement<br />

Verbrauchsmaterialien<br />

Services<br />

www.waters.com/<br />

germany<br />

Rufen Sie uns an:<br />

06196 400 600<br />

9

10 Mischen | Blending | Mélange<br />

Bohle Free Fall Blender 10 l<br />

Further Sizes:<br />

0.5 l / 5 l / 10 l / 20 l / 50 l / 100 l / 250 l / 400 l<br />

Lödige Force Blender 20 l<br />

So viel Dienstleistung, wie Sie benötigen<br />

Wir bieten Ihnen sowohl Komplettlösungen<br />

als auch einzelne Dienstleistungen.<br />

Die Umsetzung der Ergebnisse in den<br />

industriellen Maßstab ist uns sehr wichtig.<br />

Alle Aktivitäten im Development &<br />

Transfer sind in das etablierte FDA-abgenommene<br />

Qualitätsmanagementsystem<br />

eingebunden.<br />

Organisiert ist das <strong>Rottendorf</strong> <strong>Pharma</strong><br />

Development & Transfer Center als Competence<br />

Center, das auch Teilschritte Ihrer<br />

Produktentwicklung übernimmt.<br />

Wir entwickeln maßgeschneidert auf<br />

die späteren Produktionsanlagen, die sich<br />

sowohl in unserem als auch einem<br />

anderen Herstellungsbetrieb befinden<br />

können. Immer begleiten wir dabei Ihr<br />

Produkt bis zum positiven Abschluss des<br />

Transfers.<br />

As much service as you require<br />

Free Fall Blender 0.5 l<br />

We offer you both complete solutions as<br />

well as individual services. The conversion<br />

of the results into an industrial scale is<br />

very important to us.<br />

All activities in the Development & TransTransfer Center are embedded into the already<br />

established and FDA-approved Quality<br />

Management System. The <strong>Rottendorf</strong><br />

<strong>Pharma</strong> Development & Transfer Center<br />

is designed as a competence centre, also<br />

capable of processing individual steps of<br />

your product development.<br />

Our developments are customised for<br />

the production facilities intended for<br />

use, which can be located either on our<br />

production site or at other manufacturing<br />

plants. We constantly supervise your<br />

product up until the successful completion<br />

of the transfer.<br />

Further Sizes:<br />

0.5 l / 5 l / 10 l / 20 l / 50 l / 100 l / 250 l / 400 l<br />

Lödige Force Blender 20 l<br />

Further Sizes: 5 l / 10 l / 20 l / 130 l / 300 l Further Sizes: 5 l / 10 l / 20 l / 130 l / 300 l<br />

Nous répondons à toutes vos demandes<br />

Nous vous offrons non seulement des<br />

solutions clé en main pour votre<br />

développement mais également des<br />

services ponctuels.<br />

L’adéquation des résultats de<br />

développement aux normes industrielles<br />

est une priorité et c’est pourquoi toutes<br />

les activités du centre de développement<br />

et de transfert sont aménagées pour<br />

répondre aux exigences de qualité FDA.<br />

Le centre de développement et de<br />

transfert de <strong>Rottendorf</strong> est organisée<br />

tel un centre de compétences pouvant<br />

notamment gérer des étapes partielles de<br />

votre développement.<br />

Nous développons également sur mesure<br />

des installations de production dans notre<br />

usine ou sur d’autres sites de fabrication.<br />

Nous accompagnons votre produit tout au<br />

long du développement, jusqu’à la réussite<br />

du transfert.

Tablettierung | Tabletting | Compression<br />

Kilian T 100 (Euro B/D)<br />

Kapselfertigung | Capsule Production | Remplissage de gélules<br />

Bosch GKF 400<br />

Kilian S 250 ZS -M<br />

Others: Kilian T 200 (Euro B), Kilian Eifel Double-Layer and Presscoated Tablets<br />

11

12 Filmcoating und Dragierung | Film Coating and Sugar Coating<br />

| Pelliculage et dragéification<br />

Bohle BFC 50 Bohle BFC 50<br />

Exchangeable Drums 5-55 l Exchangeable Drums 5-55 l<br />

Bohle BFC 50<br />

Exchangeable Drums 5-55 l<br />

Bohle BFC 50<br />

Conventional Pans<br />

5-60 kg

SYNTHESIS. Improving Time to Market<br />

GMP development requires<br />

a flexible and proven<br />

technology.<br />

Synthesis 330, with Galenic<br />

software, ensures fast data<br />

acquisition for small scale or pilot<br />

plant batches.<br />

Due to standard design, scale up for<br />

future production purposes is easily<br />

achieved.<br />

The interchangeable die table<br />

guarantees flexibility.<br />

SYNTHESIS<br />

Tablet Press<br />

Mirror finished surfaces, easy cleaning, quick changeover.<br />

IMA ACTIVE DIVISION<br />

Via 1° Maggio 14 • 40064 Ozzano Emilia • Italy<br />

Phone +39 051 6514111 • Fax +39 051 6514287 • e-mail: mktg.soliddose@ima.it<br />

w w w . i m a . i t

14<br />

Pelletherstellung | Pelletizing | Production de microgranules<br />

Extruder E 140<br />

Spheronizer S 450<br />

Dieter Haselhorst <strong>GmbH</strong><br />

Bedachungen<br />

Flachdachabdichtungen<br />

Feuchtigkeitsisolierungen<br />

Flachdachsanierungen<br />

Stockheimer Straße 19 · 33775 Versmold<br />

Telefon 0 54 23/94 49-0 · Fax 0 54 23/94 49-49<br />

Internet: www.haselhorst.com<br />

E-Mail: info@haselhorst.com

Pelletherstellung | Pelletizing | Production de microgranules<br />

Glatt GPCG<br />

Batch Sizes: 1-5 kg<br />

Wurster System - Glatt GPCG<br />

Aeromatic MP 3/4<br />

Batch Sizes: 10-50 kg<br />

15

16 Analytik | Analytics | Analyses<br />

Digital Microscope<br />

HPLC / UPLC<br />

◆ Methodenentwicklung<br />

◆ Methodenvalidierung<br />

◆ Methodentransfer<br />

◆ ICH-Stabilitätsstudien<br />

◆ physikalische Charakterisierung von<br />

Granulaten, Mischungen und Darrei-<br />

chungsformen<br />

◆ HPLC, UPLC, Texture Analyzer, Digitalmi-<br />

kroskop sowie alle Standardmessverfah-<br />

ren für Feststoffe<br />

◆ Method development<br />

◆ Method validation<br />

◆ Method transfer<br />

◆ ICH-stability studies<br />

◆ Physical characterization of granular<br />

material, blends and dosage forms<br />

◆ HPLC, UPLC, texture analyzer, digital<br />

microscope and all standard methods of<br />

measurement for solid dosage forms<br />

◆ Développement de méthodes<br />

◆ Validation de méthodes<br />

◆ Transfer de méthodes<br />

◆ Etude de stabilité ICH<br />

◆ Caractérisation physique des granules,<br />

des mélanges et des formes de dosage<br />

◆ HPLC, UPLC, texture analyzer, micros-<br />

cope numérique et toutes les mé-<br />

thodes de mesure standard pour des<br />

formes sèches

www.glatt.com<br />

Innovation with tradition<br />

WELDING was founded in 1955 and is privately owned.<br />

With headquarters in Hamburg, a sales offi ce in Frankfurt/M<br />

and a subsidiary in Lyon, France, WELDING today employs<br />

more than 120 people.<br />

On the basis of the traditional values of our company and<br />

the many years of experience gained by our staff in the<br />

international market place, we have not only adapted to<br />

continually changing demands but have also made it our<br />

duty to be aware of future trends and to timely implement<br />

appropriate concepts.<br />

As a consequence we are in a position to offer both customers<br />

and suppliers a comprehensive package of tailormade<br />

services.<br />

WELDING GMBH & CO. KG<br />

Esplanade 39<br />

D-20354 Hamburg<br />

Phone: +49 40 35908-0<br />

Fax: +49 40 35908-251<br />

email: mailbox@welding.de<br />

www.welding.de<br />

Gratulation zum neuen Technikum!<br />

Glatt <strong>GmbH</strong> Process Technology<br />

Werner-Glatt-Straße 1<br />

79589 Binzen / Deutschland<br />

Telefon: +49 7621 6 64 0<br />

Fax: +49 7621 6 47 23<br />

eMail: info@glatt.com<br />

GPCG 2 LabSystem<br />

WELDING GMBH & CO. KG<br />

Sales Office<br />

Speicherstr. 59<br />

D-60327 Frankfurt<br />

Phone: +49 69 955277-0<br />

Fax: +49 69 955277-21<br />

email: mailbox@welding.de<br />

www.welding.de<br />

Batchgröße 0,3 kg bis 5 kg<br />

Optimale Prozesskontrolle<br />

Problemlose Reinigung<br />

Fertigung von Klinikmustern<br />

Trocknung<br />

<strong>Granulation</strong><br />

Coating<br />

Pelletierung<br />

Fields of business:<br />

Trading in active pharmaceutical ingredients, excipients and<br />

natural substances for human and veterinary medicines.<br />

Development, registration and marketing of generic drugs.<br />

Trading in additives for the food and feed industries.<br />

Offering an extensive range of services covering the fi elds<br />

of quality management, marketing and regulatory affairs.<br />

50 years<br />

experience<br />

Fluid Bed Processing,<br />

High Shear, Pelletizing<br />

and Coating solutions<br />

for the pharmaceutical<br />

industry<br />

We are proud to be<br />

associated with<br />

<strong>Rottendorf</strong> <strong>Pharma</strong><br />

<strong>GmbH</strong><br />

GEA <strong>Pharma</strong> Systems AG<br />

WELDING PHARMA FRANCE<br />

Subsidiary<br />

22, avenue René Cassin<br />

F-69009 Lyon Cedex<br />

Phone: +33 478 642323<br />

Fax: +33 478 837310<br />

email: info@weldingpharma.fr<br />

www.weldingpharma.fr<br />

Aeromatic-Fielder <br />

Aeromatic-Fielder Hauptstrasse 145, PO Box 112, CH-4416 Bubendorf, Switzerland<br />

Tel. +41 61 936 36 36, aeromatic-fielder@geagroup.com<br />

www.geapharmasystems.com<br />

17

18<br />

Schmelzgranulation | Hot Melt <strong>Granulation</strong> | <strong>Granulation</strong> par fusion<br />

MELTDOSE ® – A BETTER WAY TO BETTER DRUG ABSORPTION<br />

WITH MELTDOSE ® YOU GET A TECHNOLOGY WHICH IS:<br />

� Clinically proven to improve bioavailability and/or reduce food effects<br />

� Commercially viable with the first MeltDose ® product approved by the FDA on the market in the US<br />

� Patent protected<br />

� Easily scalable and requiring only conventional manufacturing equipment<br />

� Economical as the cost of goods is comparable to conventional tablets<br />

Textile Dienstleistungen seit 1851<br />

Individuelle Berufskleidung:<br />

Service mit System<br />

KAMPSCHULTE bietet neben dem breiten Sortiment an attraktiver Berufskleidung auch<br />

individuelle Sonderlösungen für die <strong>Pharma</strong>industrie an. Hohe Qualität, hautsympathische<br />

Materialien und validierte, desinfi zierende Aufbereitungsverfahren geben die erforderliche<br />

Sicherheit im Berufsalltag.<br />

Kampschulte <strong>GmbH</strong> & Co. KG<br />

Oelmüllerweg 3-15 · 59494 Soest<br />

Tel. 02921-3970

Schmelzgranulation | Hot Melt <strong>Granulation</strong> | <strong>Granulation</strong> par fusion<br />

MELTDOSE ® - HOW IT WORKS<br />

Process patented as ”Controlled<br />

Agglomeration” works by<br />

incorporating drug substance<br />

(API) with low water solubility<br />

into a ”meltable” vehicle<br />

or a combination of vehicles<br />

www.lehvoss-pharmacosmet.de<br />

Heat and pressure are then<br />

applied to the mixture in<br />

order to prepare the “melt”<br />

for spraying onto the carrier<br />

particles<br />

www.lohmann4minerals.com<br />

Formulieren<br />

Sie mit Erfolg!<br />

The “melt” is sprayed on<br />

carrier particles in a conventional<br />

fluid bed where it<br />

solidifies when deposed on<br />

the carrier thus capturing the<br />

API in a solid solution state<br />

or as a stable solid dispersion<br />

Your competent partner<br />

in mineral salts!<br />

The resulting granulate can<br />

be directly compressed into<br />

tablets without additional<br />

processing steps besides<br />

blending with a lubricant<br />

Tablettenbinder · Zerfallsbeschleuniger · Mineralstoffe DC · Hilfsstoffsysteme<br />

Alsterufer 19<br />

20354 Hamburg<br />

Tel. +49 (0) 40 44 197-264<br />

Fax +49 (0) 40 44 197-364<br />

e-mail: pharma@Lehvoss.de<br />

19

20<br />

Schmelzextrusion | Hot Melt Extrusion | Extrusion par fusion<br />

PHARMACEUTICAL MELT EXTRUSION<br />

Melt extrusion is understood as a continuous or<br />

discontinuous pressing of a strand from mouldable<br />

material.<br />

By using thermoplastic materials such as<br />

EUDRAGIT ® -copolymers melt extrusion leads to<br />

significant advantages for certain formulations and<br />

improves the availability of APIs.<br />

� Enhancement of poorly soluble APIs<br />

� Sustained release<br />

� Controlled release<br />

� Taste masking<br />

THE MELT EXTRUSION PROCESS<br />

Dosing<br />

www.evonik.com<br />

Weighing<br />

Extrusion<br />

Mixing<br />

Output forms of this specific technology:<br />

� Granules<br />

� Microspheres<br />

� Powders<br />

� Sheets<br />

� Films<br />

Melting Homogenizing +<br />

Discharge<br />

Downstreaming<br />

Cooling<br />

Granulating

Schmelzextrusion | Hot Melt Extrusion | Extrusion par fusion<br />

Leistritz ZSE 18 HP-PH<br />

www.becom.com<br />

Die becom Informationssysteme <strong>GmbH</strong> ist als Teil der TDMi-Gruppe und einer der größten<br />

IBM Premier Business Partner für alle IBM Plattformen zertifiziert und entwickelt individuelle<br />

Infrastrukturlösungen für große und mittelständische Kunden.<br />

Das Portfolio umfasst unter anderem IT Consulting & Services, Virtualisierung und<br />

Konsolidierung von Server- und Storagelandschaften, Business Recovery- und Continuity-<br />

Lösungen, Security-Lösungen, Betriebsunterstützung und Informationmanagement.<br />

becom Informationssysteme <strong>GmbH</strong><br />

Konrad-Zuse-Straße 14<br />

D-58239 Schwerte<br />

Germany<br />

Tel. +49 (0) 2304-931 - 3<br />

Fax +49 (0) 2304-931 - 401<br />

Ihr Ansprechpartner Herr René Busar<br />

www.becom.com<br />

info@becom.com<br />

21

The DT 720 / 820 generation<br />

of ERWEKA Dissolution Baths<br />

reflects more than 50 years of<br />

experience in the development<br />

of high-quality Dissolution<br />

Testers.<br />

As a result this new generation<br />

of ERWEKA instruments sets the<br />

benchmark in Dissolution<br />

Testing and represents the most<br />

advanced, durable and userfriendly<br />

units available on the<br />

market today.<br />

✔ Low-Evaporation<br />

Dissolution Tester with 6, 7, 8<br />

or 14 test stations<br />

✔ Smooth Move ® lifter column<br />

for the effortless lifting and<br />

lowering of the drive head<br />

within seconds<br />

✔ Can be used in low-head –<br />

(low evaporation)<br />

and high-head mode<br />

(easy access)<br />

✔ Corrosion-free design<br />

✔ Fully USP/EP compliant<br />

sampling station with<br />

individual temperature<br />

documentation for each<br />

vessel<br />

✔ Automated vessel centering<br />

and covering<br />

✔ Moulded water bath with<br />

water outlet and illumination<br />

✔ External heater to avoid<br />

vibrations<br />

✔ Integrated tablet drop<br />

magazine<br />

✔ Membrane sealed<br />

sampling openings through<br />

the drive head<br />

For further information see:<br />

www.erweka.com<br />

www.pimp-ur-lab.com<br />

Reliable Testing in Style<br />

The DT 720 has been designed for users, who want<br />

to perform dissolution tests with little preparation<br />

time rather than clicking through extensive menus.<br />

The advanced new<br />

MagniShaft ®<br />

system allows for<br />

the easy and fast<br />

exchange of the<br />

stirrers via a<br />

magnetic holding<br />

system. Methods<br />

are made of Teflon<br />

and PEEK to avoid<br />

corrosion. No<br />

height adjustment<br />

is required.<br />

The heart of the ERWEKA Offline Dissolution System<br />

is the 8-channel Syringe Pump with sturdy mechanic<br />

4-way valves, which generates a dosing accuracy of<br />

typically ± 0.1 ml.<br />

The DT 820<br />

is the ideal unit<br />

for advanced<br />

stand-alone<br />

and Off-/Online<br />

operations.<br />

Data can be<br />

exchanged<br />

between units<br />

via USB<br />

memory stick.<br />

Quality through Experience.<br />

®

Production, Ennigerloh<br />

Production and Packaging, Valenciennes (France)<br />

Development & Transfer<br />

Packaging, Ennigerloh<br />

Development & Transfer, Ennigerloh<br />

<strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong> | Ostenfelder Straße 51-61 | 59320 Ennigerloh, Germany<br />

Phone: +49 (0) 2524 – 268-0 | Fax: +49 (0) 2524 – 268-100 | info@rottendorf.de<br />

www.rottendorf.de

Development & Transfer<br />

<strong>Rottendorf</strong> <strong>Pharma</strong> <strong>GmbH</strong><br />

Ostenfelder Straße 51-61<br />

59320 Ennigerloh<br />

Germany<br />

Phone: +49 (0) 2524 – 268-0<br />

Fax: +49 (0) 2524 – 268-100<br />

info@rottendorf.de<br />

www.rottendorf.de