Sto BTS Plus

FSD 727 BTS plus tb.pdf

FSD 727 BTS plus tb.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

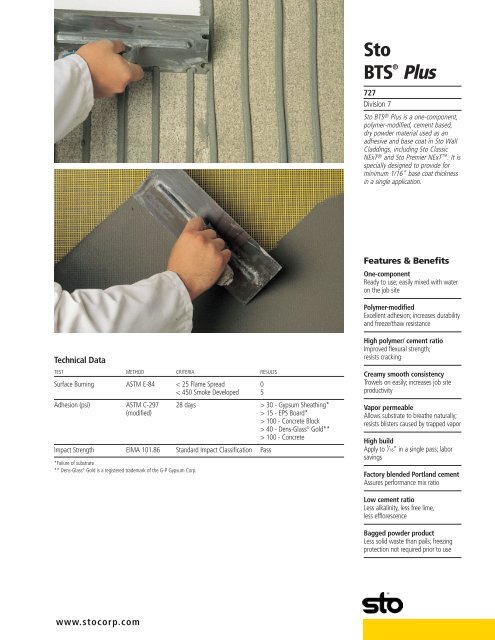

<strong>Sto</strong><strong>BTS</strong> ® <strong>Plus</strong>727Division 7<strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> is a one-component,polymer-modified, cement based,dry powder material used as anadhesive and base coat in <strong>Sto</strong> WallCladdings, including <strong>Sto</strong> ClassicNExT ® and <strong>Sto</strong> Premier NExT . It isspecially designed to provide forminimum 1/16" base coat thicknessin a single application.Features & BenefitsOne-componentReady to use; easily mixed with wateron the job sitePolymer-modifiedExcellent adhesion; increases durabilityand freeze/thaw resistanceTechnical DataTEST METHOD CRITERIA RESULTSSurface Burning ASTM E-84 < 25 Flame Spread 0< 450 Smoke Developed 5Adhesion (psi) ASTM C-297 28 days > 30 - Gypsum Sheathing*(modified)> 15 - EPS Board*> 100 - Concrete Block> 40 - Dens-Glass ® Gold**> 100 - ConcreteImpact Strength EIMA 101.86 Standard Impact Classification Pass*Failure of substrate** Dens-Glass ® Gold is a registered trademark of the G-P Gypsum Corp.High polymer/ cement ratioImproved flexural strength;resists crackingCreamy smooth consistencyTrowels on easily; increases job siteproductivityVapor permeableAllows substrate to breathe naturally;resists blisters caused by trapped vaporHigh buildApply to 1 ⁄ 16" in a single pass; laborsavingsFactory blended Portland cementAssures performance mix ratioLow cement ratioLess alkalinity, less free lime,less efflorescenceBagged powder productLess solid waste than pails; freezingprotection not required prior to usewww.stocorp.com

<strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong>727Coverage“Through the wall”: 65-90 ft 2 (6.0 - 8.4 m 2 ) perbag (when used for both adhesive and base coatapplications).As an adhesive over sheathing: 110-170 ft 2(10.2-15.8 m 2 ) per bag, applied with a 1/2" x 1/2"(13 mm x 13 mm) U-notched trowel.As an adhesive over masonry:100-130 ft 2(9.3-12.1 m 2 ) per bag, applied with a 5/8" x 5/8"(16 mm x 16 mm) square-notched trowel.As a base coat:100-160 ft 2 (9.3-14.9 m 2 ) per bagAs a skim coat:110-160 ft 2 (10.2-14.9 m 2 ) per bagCoverages may vary depending on applicationtechnique and surface conditions.Packaging60 lb. bag (27 kg)Shelf Life12 months, if properly stored and protected frommoisture.<strong>Sto</strong>rage<strong>Sto</strong>re off the ground in a dry area. Protect fromdirect sunlight, extreme heat [90º F (32º C)], andfreezing.Surface PreparationConcrete and masonry surfaces: Surfaces mustbe clean, dry, and free of frost, damage, and allbond-inhibiting materials, including dirt, efflorescence,form oil and other foreign matter. Loose ordamaged material must be removed by waterblasting,sandblasting or mechanical wire brushing andrepaired. Avoid application over irregular surfaces.Resurface, patch or level surfaces to required toleranceand smoothness with appropriate <strong>Sto</strong> levelingmaterials. Refer to ASTM D-4258 and ASTM D-4261 for complete details on methods of preparingcementitious substrates for coatings.<strong>Sto</strong> Exterior Insulation and Finish Systems(EIFS): Insulation board must be rasped and free ofall bond-inhibiting materials.Sheathing: (Gypsum sheathing in compliance withASTM C-79 or Glass Mat faced gypsum sheathingin compliance with ASTM C-1177 [such as Dens-Glass ® Gold]). Surface must be clean, dry and freeof all bond-inhibiting materials. Sheathing must beinstalled and protected in accordance with manufacturer’srequirements. Remove and replaceweather damaged sheathing. Avoid applicationover irregular, out of plane surfaces.MixingUse 6-8 quarts (5.7-7.6 L) of water per 60 lb.bag (27 kg). Mix automatically using <strong>Sto</strong>’s S-25Continuous Mixer, or mix 1/2 bag at a time byadding <strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> to 3-4 quarts (2.8-3.8 L) ofclean, potable water in a clean mixing pail. Mixwith a clean, rust-free electric drill and paddle.Allow to set approximately five minutes, adjustmix if necessary by adding up to 1/2 pint (.24 L) ofwater per 1/2 bag, remix to a uniform consistency.Avoid retempering after mixing of product.ApplicationAs an adhesive: Apply to the back of <strong>Sto</strong>Insulation Board with the appropriate size notchedtrowel, or directly onto the substrate using <strong>Sto</strong>’sM-8 Spray Pump, then the appropriate sizednotched trowel. Form uniform ribbons of adhesiveparallel to the long* dimension of the board.Immediately install the board horizontally withstaggered joints and apply firm pressure over theentire board surface.*NOTE: For drainage of incidental moisture, formadhesive ribbons parallel to the short dimension ofthe insulation board.As a base coat: Apply with spray equipment suchas <strong>Sto</strong>’s M-8 Spray Pump or a stainless steel trowelto an approximate thickness of 1/8" (3 mm). Workhorizontally or vertically in strips of 40” (1016 mm)and immediately embed <strong>Sto</strong> Mesh in the wet <strong>Sto</strong><strong>BTS</strong> <strong>Plus</strong> by troweling from the center to the edgesof the mesh. Avoid wrinkles in the mesh andsmooth the base coat to eliminate trowel marks.Minimum recommended thickness of the reinforcedbase coat is 1/16" (1.6 mm) when dry. Reapplyadditional base coat if necessary to achieve minimumthickness as soon as the first application isdry.As a skim coat: Apply in one application toa maximum thickness of 1/16" (1.6 mm) to theprepared surface and smooth the surface.Protect from rain and freezing until completely dry.Curing/Drying<strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> dries within 3 hours, hardens within12 hours depending upon temperatures/humidityand surface conditions.Clean UpClean tools and equipment with water immediatelyafter use. Dried material can only be removedmechanically.LimitationsUse <strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> only when surface and ambienttemperatures are above 40° F (4° C) during applicationand drying period. <strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> should notbe used on weather-exposed horizontal or belowgrade surfaces or where immersion in water mayoccur.Sloped surfaces: Refer to <strong>Sto</strong> details.<strong>Sto</strong> <strong>BTS</strong> ® <strong>Plus</strong> should not be used as a finishcoating. It should not be used over woodsurfaces except for wood surfaces protectedby <strong>Sto</strong> Guard.Health & SafetyHealth PrecautionsContains Portland cement and crystalline-freesilica. Avoid breathing dust. As with any chemicalconstruction product, exercise care when handling.Safety PrecautionsUse adequate ventilation. Use of a NIOSH/MSAapproveddust respirator, safety goggles andprotective gloves is recommended.First AidSKIN CONTACT: Wash thoroughly with soap andwater.EYE CONTACT: Flush immediately with water for10-15 minutes and contact a physician.RESPIRATORY PROBLEMS: Remove affectedperson to fresh air immediately and contact aphysician.HYGIENE: Wash hands immediately after use. Washclothing before re-use.SpillsCollect in an appropriate container. Uncuredmaterial may be removed with water.DisposalDispose in accordance with local, state orfederal regulations.WarningKEEP CONTAINER CLOSED WHEN NOT IN USE.KEEP OUT OF REACH OF CHILDREN. NOT FORINTERNAL CONSUMPTION. FOR INDUSTRIAL USEONLY. Consult the Material Safety Data Sheet forfurther health and safety information.LIMITED WARRANTYTHIS PRODUCT IS SUBJECT TO A WRITTENLIMITED WARRANTY WHICH CAN BE OBTAINEDFREE OF CHARGE FROM: <strong>Sto</strong> Corp., 3800 CampCreek Parkway, Building 1400, Suite 120,Atlanta, GA 30331; Tel: 404-346-3666;Fax: 404-346-3119Refer to <strong>Sto</strong> Specifications for more complete informationon proper use and handling of this product.<strong>Sto</strong> Corp.3800 Camp Creek ParkwayBuilding 1400, Suite 120Atlanta, GA 30331Tel: 404-346-3666Toll Free: 1-800-221-2397Fax: 404-346-3119www.stocorp.comS155-727 06/03 VEN 5609