Yacht

July/ August 2007 - Classic Yacht Magazine

July/ August 2007 - Classic Yacht Magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

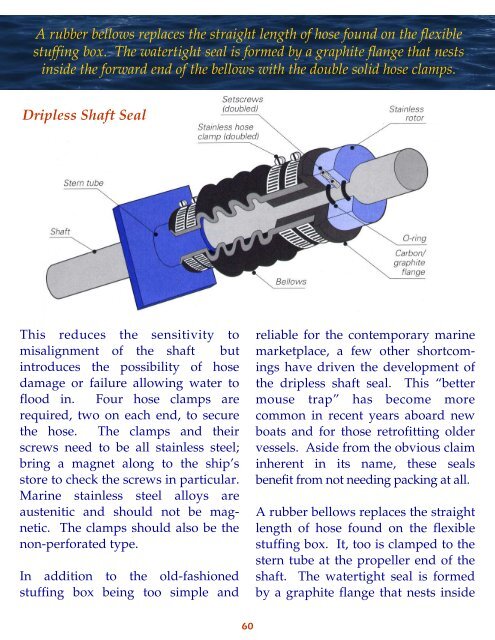

A rubber bellows replaces the straight length of hose found on the flexible<br />

stuffing box. The watertight seal is formed by a graphite flange that nests<br />

inside the forward end of the bellows with the double solid hose clamps.<br />

Dripless Shaft Seal<br />

This reduces the sensitivity to<br />

misalignment of the shaft but<br />

introduces the possibility of hose<br />

damage or failure allowing water to<br />

flood in. Four hose clamps are<br />

required, two on each end, to secure<br />

the hose. The clamps and their<br />

screws need to be all stainless steel;<br />

bring a magnet along to the ship’s<br />

store to check the screws in particular.<br />

Marine stainless steel alloys are<br />

austenitic and should not be magnetic.<br />

The clamps should also be the<br />

non-perforated type.<br />

In addition to the old-fashioned<br />

stuffing box being too simple and<br />

reliable for the contemporary marine<br />

marketplace, a few other shortcomings<br />

have driven the development of<br />

the dripless shaft seal. This “better<br />

mouse trap” has become more<br />

common in recent years aboard new<br />

boats and for those retrofitting older<br />

vessels. Aside from the obvious claim<br />

inherent in its name, these seals<br />

benefit from not needing packing at all.<br />

A rubber bellows replaces the straight<br />

length of hose found on the flexible<br />

stuffing box. It, too is clamped to the<br />

stern tube at the propeller end of the<br />

shaft. The watertight seal is formed<br />

by a graphite flange that nests inside<br />

60