Effect of Hub Motor Mass on Stability and Comfort ... - Protean Electric

Effect of Hub Motor Mass on Stability and Comfort ... - Protean Electric

Effect of Hub Motor Mass on Stability and Comfort ... - Protean Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

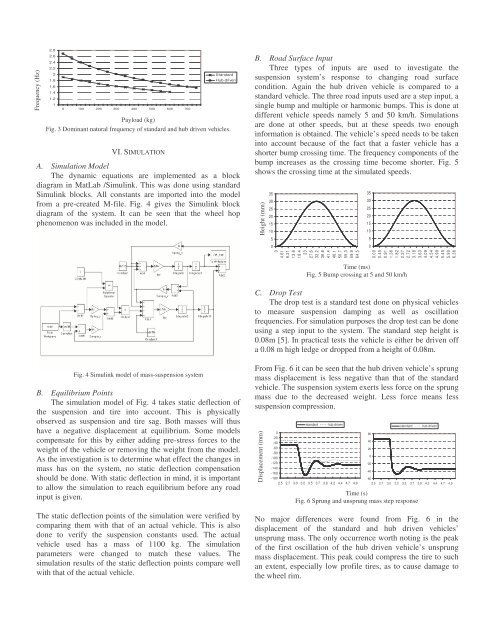

Frequency (Hz)<br />

2.8<br />

2.6<br />

2.4<br />

2.2<br />

2<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

1<br />

0 100 200 300 400 500 600 700<br />

St<strong>and</strong>ard<br />

<str<strong>on</strong>g>Hub</str<strong>on</strong>g>-driven<br />

Payload (kg)<br />

Fig. 3 Dominant natural frequency <str<strong>on</strong>g>of</str<strong>on</strong>g> st<strong>and</strong>ard <strong>and</strong> hub driven vehicles.<br />

VI. SIMULATION<br />

A. Simulati<strong>on</strong> Model<br />

The dynamic equati<strong>on</strong>s are implemented as a block<br />

diagram in MatLab /Simulink. This was d<strong>on</strong>e using st<strong>and</strong>ard<br />

Simulink blocks. All c<strong>on</strong>stants are imported into the model<br />

from a pre-created M-file. Fig. 4 gives the Simulink block<br />

diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> the system. It can be seen that the wheel hop<br />

phenomen<strong>on</strong> was included in the model.<br />

Fig. 4 Simulink model <str<strong>on</strong>g>of</str<strong>on</strong>g> mass-suspensi<strong>on</strong> system<br />

B. Equilibrium Points<br />

The simulati<strong>on</strong> model <str<strong>on</strong>g>of</str<strong>on</strong>g> Fig. 4 takes static deflecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the suspensi<strong>on</strong> <strong>and</strong> tire into account. This is physically<br />

observed as suspensi<strong>on</strong> <strong>and</strong> tire sag. Both masses will thus<br />

have a negative displacement at equilibrium. Some models<br />

compensate for this by either adding pre-stress forces to the<br />

weight <str<strong>on</strong>g>of</str<strong>on</strong>g> the vehicle or removing the weight from the model.<br />

As the investigati<strong>on</strong> is to determine what effect the changes in<br />

mass has <strong>on</strong> the system, no static deflecti<strong>on</strong> compensati<strong>on</strong><br />

should be d<strong>on</strong>e. With static deflecti<strong>on</strong> in mind, it is important<br />

to allow the simulati<strong>on</strong> to reach equilibrium before any road<br />

input is given.<br />

The static deflecti<strong>on</strong> points <str<strong>on</strong>g>of</str<strong>on</strong>g> the simulati<strong>on</strong> were verified by<br />

comparing them with that <str<strong>on</strong>g>of</str<strong>on</strong>g> an actual vehicle. This is also<br />

d<strong>on</strong>e to verify the suspensi<strong>on</strong> c<strong>on</strong>stants used. The actual<br />

vehicle used has a mass <str<strong>on</strong>g>of</str<strong>on</strong>g> 1100 kg. The simulati<strong>on</strong><br />

parameters were changed to match these values. The<br />

simulati<strong>on</strong> results <str<strong>on</strong>g>of</str<strong>on</strong>g> the static deflecti<strong>on</strong> points compare well<br />

with that <str<strong>on</strong>g>of</str<strong>on</strong>g> the actual vehicle.<br />

B. Road Surface Input<br />

Three types <str<strong>on</strong>g>of</str<strong>on</strong>g> inputs are used to investigate the<br />

suspensi<strong>on</strong> system’s resp<strong>on</strong>se to changing road surface<br />

c<strong>on</strong>diti<strong>on</strong>. Again the hub driven vehicle is compared to a<br />

st<strong>and</strong>ard vehicle. The three road inputs used are a step input, a<br />

single bump <strong>and</strong> multiple or harm<strong>on</strong>ic bumps. This is d<strong>on</strong>e at<br />

different vehicle speeds namely 5 <strong>and</strong> 50 km/h. Simulati<strong>on</strong>s<br />

are d<strong>on</strong>e at other speeds, but at these speeds two enough<br />

informati<strong>on</strong> is obtained. The vehicle’s speed needs to be taken<br />

into account because <str<strong>on</strong>g>of</str<strong>on</strong>g> the fact that a faster vehicle has a<br />

shorter bump crossing time. The frequency comp<strong>on</strong>ents <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

bump increases as the crossing time become shorter. Fig. 5<br />

shows the crossing time at the simulated speeds.<br />

Height (mm)<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

4.61<br />

9.21<br />

13.8<br />

18.4<br />

23<br />

27.6<br />

32.2<br />

36.8<br />

41.4<br />

46.1<br />

50.7<br />

55.3<br />

59.9<br />

64.5<br />

Time (ms)<br />

Fig. 5 Bump crossing at 5 <strong>and</strong> 50 km/h<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0.00<br />

0.45<br />

0.91<br />

1.36<br />

1.82<br />

2.27<br />

2.72<br />

3.18<br />

3.63<br />

4.09<br />

4.54<br />

4.99<br />

5.45<br />

5.90<br />

6.36<br />

C. Drop Test<br />

The drop test is a st<strong>and</strong>ard test d<strong>on</strong>e <strong>on</strong> physical vehicles<br />

to measure suspensi<strong>on</strong> damping as well as oscillati<strong>on</strong><br />

frequencies. For simulati<strong>on</strong> purposes the drop test can be d<strong>on</strong>e<br />

using a step input to the system. The st<strong>and</strong>ard step height is<br />

0.08m [5]. In practical tests the vehicle is either be driven <str<strong>on</strong>g>of</str<strong>on</strong>g>f<br />

a 0.08 m high ledge or dropped from a height <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.08m.<br />

From Fig. 6 it can be seen that the hub driven vehicle’s sprung<br />

mass displacement is less negative than that <str<strong>on</strong>g>of</str<strong>on</strong>g> the st<strong>and</strong>ard<br />

vehicle. The suspensi<strong>on</strong> system exerts less force <strong>on</strong> the sprung<br />

mass due to the decreased weight. Less force means less<br />

suspensi<strong>on</strong> compressi<strong>on</strong>.<br />

Displacement (mm)<br />

st<strong>and</strong>ard hub driven<br />

0<br />

-20<br />

-40<br />

-60<br />

-80<br />

-100<br />

-120<br />

-140<br />

-160<br />

-180<br />

2.5 2.7 3.0 3.2 3.5 3.7 3.9 4.2 4.4 4.7 4.9<br />

60<br />

40<br />

20<br />

0<br />

-20<br />

-40<br />

st<strong>and</strong>ard hub driven<br />

-60<br />

2.5 2.7 3.0 3.2 3.5 3.7 3.9 4.2 4.4 4.7 4.9<br />

Time (s)<br />

Fig. 6 Sprung <strong>and</strong> unsprung mass step resp<strong>on</strong>se<br />

No major differences were found from Fig. 6 in the<br />

displacement <str<strong>on</strong>g>of</str<strong>on</strong>g> the st<strong>and</strong>ard <strong>and</strong> hub driven vehicles’<br />

unsprung mass. The <strong>on</strong>ly occurrence worth noting is the peak<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the first oscillati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the hub driven vehicle’s unsprung<br />

mass displacement. This peak could compress the tire to such<br />

an extent, especially low pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile tires, as to cause damage to<br />

the wheel rim.