Endumax – an ultra-strong thin tape with a high modulus

1JX6ojQ

1JX6ojQ

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

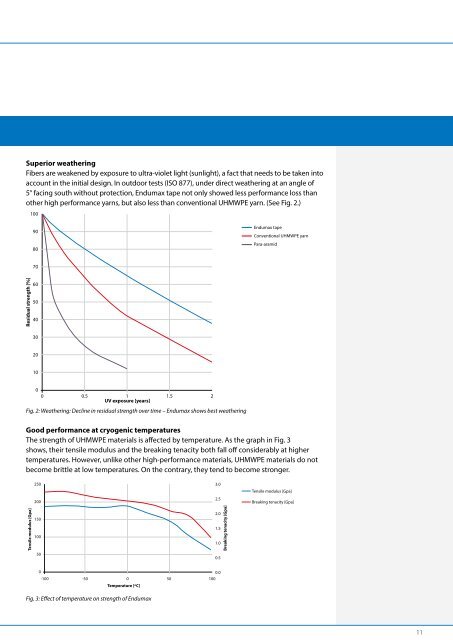

Superior weathering<br />

Fibers are weakened by exposure to <<strong>strong</strong>>ultra</<strong>strong</strong>>-violet light (sunlight), a fact that needs to be taken into<br />

account in the initial design. In outdoor tests (ISO 877), under direct weathering at <<strong>strong</strong>>an</<strong>strong</strong>> <<strong>strong</strong>>an</<strong>strong</strong>>gle of<br />

5° facing south <strong>with</strong>out protection, <<strong>strong</strong>>Endumax</<strong>strong</strong>> <strong>tape</strong> not only showed less perform<<strong>strong</strong>>an</<strong>strong</strong>>ce loss th<<strong>strong</strong>>an</<strong>strong</strong>><br />

other <strong>high</strong> perform<<strong>strong</strong>>an</<strong>strong</strong>>ce yarns, but also less th<<strong>strong</strong>>an</<strong>strong</strong>> conventional UHMWPE yarn. (See Fig. 2.)<br />

100<br />

90<br />

80<br />

<<strong>strong</strong>>Endumax</<strong>strong</strong>> <strong>tape</strong><br />

Conventional UHMWPE yarn<br />

Para-aramid<br />

70<br />

Residual strength [%]<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 0.5 1 1.5 2<br />

UV exposure [years]<br />

Fig. 2: Weathering: Decline in residual strength over time <<strong>strong</strong>>–</<strong>strong</strong>> <<strong>strong</strong>>Endumax</<strong>strong</strong>> shows best weathering<br />

Good perform<<strong>strong</strong>>an</<strong>strong</strong>>ce at cryogenic temperatures<br />

The strength of UHMWPE materials is affected by temperature. As the graph in Fig. 3<br />

shows, their tensile <strong>modulus</strong> <<strong>strong</strong>>an</<strong>strong</strong>>d the breaking tenacity both fall off considerably at <strong>high</strong>er<br />

temperatures. However, unlike other <strong>high</strong>-perform<<strong>strong</strong>>an</<strong>strong</strong>>ce materials, UHMWPE materials do not<br />

become brittle at low temperatures. On the contrary, they tend to become <strong>strong</strong>er.<br />

250 3.0<br />

Tensile <strong>modulus</strong> [Gpa]<br />

200<br />

2.5<br />

Breaking tenacity [Gpa]<br />

Tensile <strong>modulus</strong> [Gpa]<br />

150<br />

100<br />

2.0<br />

1.5<br />

1.0<br />

Breaking tenacity [Gpa]<br />

50<br />

0.5<br />

0<br />

0.0<br />

-100 -50<br />

0<br />

50 100<br />

Temperature [oC]<br />

Fig. 3: Effect of temperature on strength of <<strong>strong</strong>>Endumax</<strong>strong</strong>><br />

11