VERDERAIR VA 25 Air-Operated Diaphragm Pump

Operations Manual - Double Diaphragm Pump

Operations Manual - Double Diaphragm Pump

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

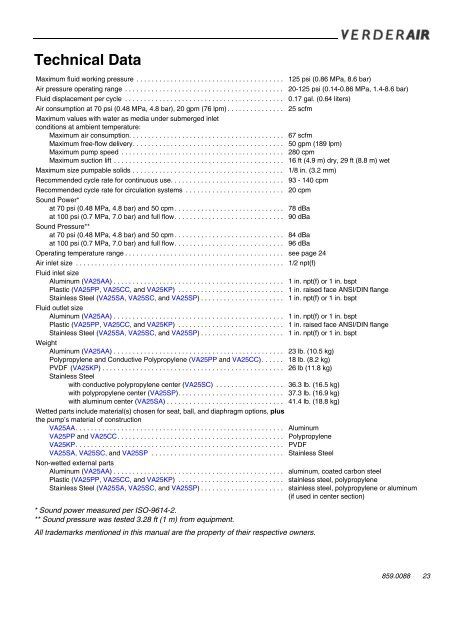

Technical Data<br />

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<strong>25</strong> psi (0.86 MPa, 8.6 bar)<br />

<strong>Air</strong> pressure operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1<strong>25</strong> psi (0.14-0.86 MPa, 1.4-8.6 bar)<br />

Fluid displacement per cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.17 gal. (0.64 liters)<br />

<strong>Air</strong> consumption at 70 psi (0.48 MPa, 4.8 bar), 20 gpm (76 lpm) . . . . . . . . . . . . . . . <strong>25</strong> scfm<br />

Maximum values with water as media under submerged inlet<br />

conditions at ambient temperature:<br />

Maximum air consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Maximum free-flow delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Maximum pump speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Maximum suction lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Maximum size pumpable solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8 in. (3.2 mm)<br />

Recommended cycle rate for continuous use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 - 140 cpm<br />

Recommended cycle rate for circulation systems . . . . . . . . . . . . . . . . . . . . . . . . . . 20 cpm<br />

Sound Power*<br />

at 70 psi (0.48 MPa, 4.8 bar) and 50 cpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

at 100 psi (0.7 MPa, 7.0 bar) and full flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Sound Pressure**<br />

at 70 psi (0.48 MPa, 4.8 bar) and 50 cpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

at 100 psi (0.7 MPa, 7.0 bar) and full flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

* Sound power measured per ISO-9614-2.<br />

** Sound pressure was tested 3.28 ft (1 m) from equipment.<br />

All trademarks mentioned in this manual are the property of their respective owners.<br />

67 scfm<br />

50 gpm (189 lpm)<br />

280 cpm<br />

16 ft (4.9 m) dry, 29 ft (8.8 m) wet<br />

78 dBa<br />

90 dBa<br />

84 dBa<br />

96 dBa<br />

Operating temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see page 24<br />

<strong>Air</strong> inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 npt(f)<br />

Fluid inlet size<br />

Aluminum (<strong>VA</strong><strong>25</strong>AA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Plastic (<strong>VA</strong><strong>25</strong>PP, <strong>VA</strong><strong>25</strong>CC, and <strong>VA</strong><strong>25</strong>KP) . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Stainless Steel (<strong>VA</strong><strong>25</strong>SA, <strong>VA</strong><strong>25</strong>SC, and <strong>VA</strong><strong>25</strong>SP) . . . . . . . . . . . . . . . . . . . . . .<br />

Fluid outlet size<br />

Aluminum (<strong>VA</strong><strong>25</strong>AA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Plastic (<strong>VA</strong><strong>25</strong>PP, <strong>VA</strong><strong>25</strong>CC, and <strong>VA</strong><strong>25</strong>KP) . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Stainless Steel (<strong>VA</strong><strong>25</strong>SA, <strong>VA</strong><strong>25</strong>SC, and <strong>VA</strong><strong>25</strong>SP) . . . . . . . . . . . . . . . . . . . . . .<br />

Weight<br />

Aluminum (<strong>VA</strong><strong>25</strong>AA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Polypropylene and Conductive Polypropylene (<strong>VA</strong><strong>25</strong>PP and <strong>VA</strong><strong>25</strong>CC). . . . . .<br />

PVDF (<strong>VA</strong><strong>25</strong>KP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Stainless Steel<br />

with conductive polypropylene center (<strong>VA</strong><strong>25</strong>SC) . . . . . . . . . . . . . . . . . .<br />

with polypropylene center (<strong>VA</strong><strong>25</strong>SP). . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

with aluminum center (<strong>VA</strong><strong>25</strong>SA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Wetted parts include material(s) chosen for seat, ball, and diaphragm options, plus<br />

the pump’s material of construction<br />

<strong>VA</strong><strong>25</strong>AA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

<strong>VA</strong><strong>25</strong>PP and <strong>VA</strong><strong>25</strong>CC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

<strong>VA</strong><strong>25</strong>KP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

<strong>VA</strong><strong>25</strong>SA, <strong>VA</strong><strong>25</strong>SC, and <strong>VA</strong><strong>25</strong>SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Non-wetted external parts<br />

Aluminum (<strong>VA</strong><strong>25</strong>AA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Plastic (<strong>VA</strong><strong>25</strong>PP, <strong>VA</strong><strong>25</strong>CC, and <strong>VA</strong><strong>25</strong>KP) . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Stainless Steel (<strong>VA</strong><strong>25</strong>SA, <strong>VA</strong><strong>25</strong>SC, and <strong>VA</strong><strong>25</strong>SP) . . . . . . . . . . . . . . . . . . . . . .<br />

1 in. npt(f) or 1 in. bspt<br />

1 in. raised face ANSI/DIN flange<br />

1 in. npt(f) or 1 in. bspt<br />

1 in. npt(f) or 1 in. bspt<br />

1 in. raised face ANSI/DIN flange<br />

1 in. npt(f) or 1 in. bspt<br />

23 lb. (10.5 kg)<br />

18 lb. (8.2 kg)<br />

26 lb (11.8 kg)<br />

36.3 lb. (16.5 kg)<br />

37.3 lb. (16.9 kg)<br />

41.4 lb. (18.8 kg)<br />

Aluminum<br />

Polypropylene<br />

PVDF<br />

Stainless Steel<br />

aluminum, coated carbon steel<br />

stainless steel, polypropylene<br />

stainless steel, polypropylene or aluminum<br />

(if used in center section)<br />

859.0088 23